Composite microsphere prepn of lactic acid-hydroxyacetic acid copolymer and its prepn process

A technology of composite microspheres and copolymers, which is applied in the field of pharmacy, can solve the problems of large particle size and complicated preparation methods, and achieve the effect of simple preparation method, simple preparation and delayed release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

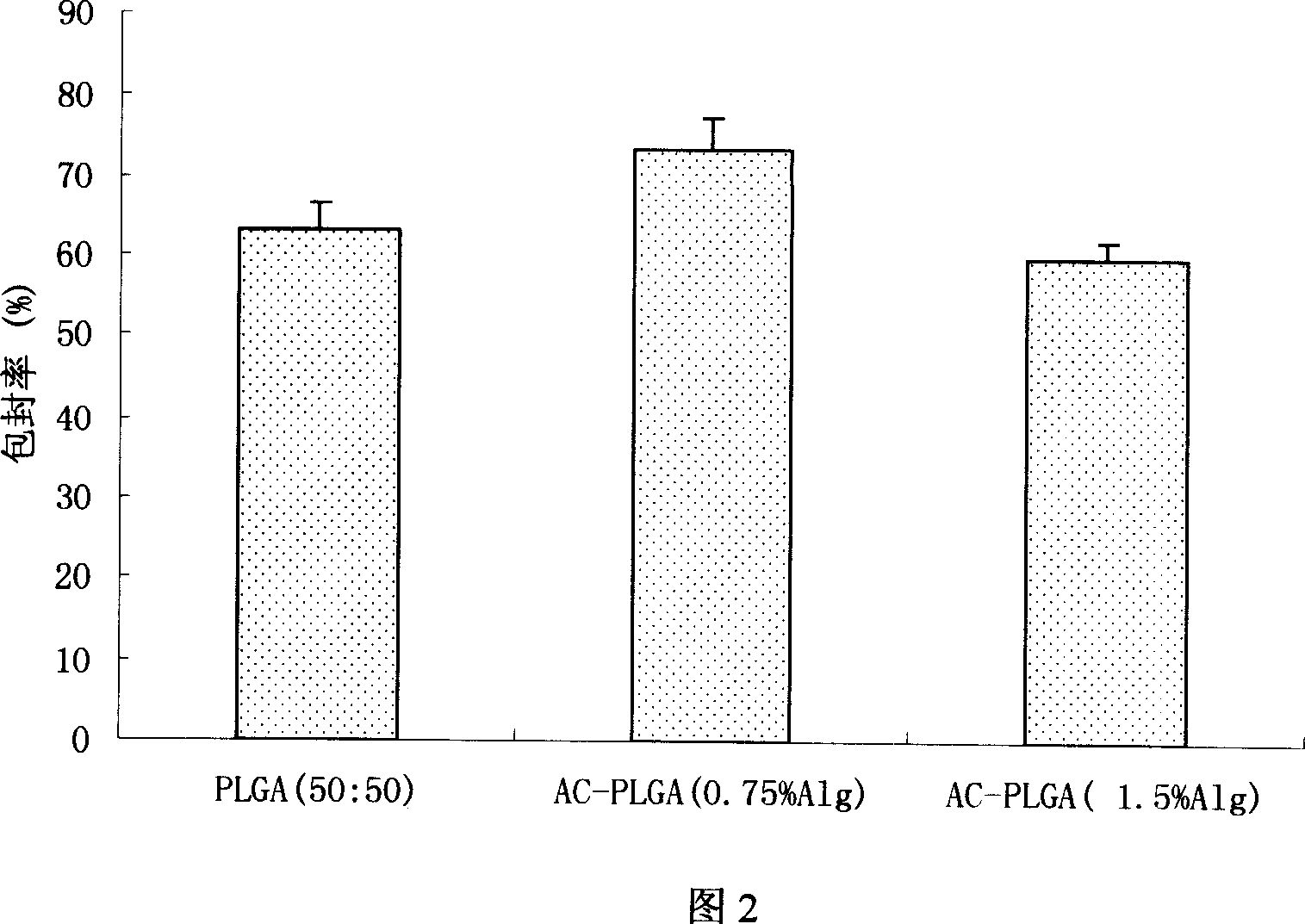

[0026] Embodiment 1 A kind of preparation method of the PLGA microsphere modified by alginic acid and chitosan of the present invention

[0027] Weigh about 0.33g PLGA (50:50), dissolve it in 4ml of dichloromethane as the organic phase; weigh another 30mg BSA model drug, dissolve it in 100μl distilled water and 100μl 1% sodium alginate as the inner water phase, and mix the two phases After the probe is ultrasonicated (50w, 1s×20 times), it is fully emulsified and injected into a 40ml mixed solution (50ml 2% PVA+50ml 2% chitosan solution+1g CaCl 2 The continuous filtrate of the mixed solution), 12000rpm high-speed stirring for 5min, vacuum rotary evaporation for 1h, centrifugation, washing with water 3 times, and freeze-drying. The alginic acid and chitosan modified PLGA microspheres with a size of 5 μm, a uniform particle size and a rounded shape were obtained.

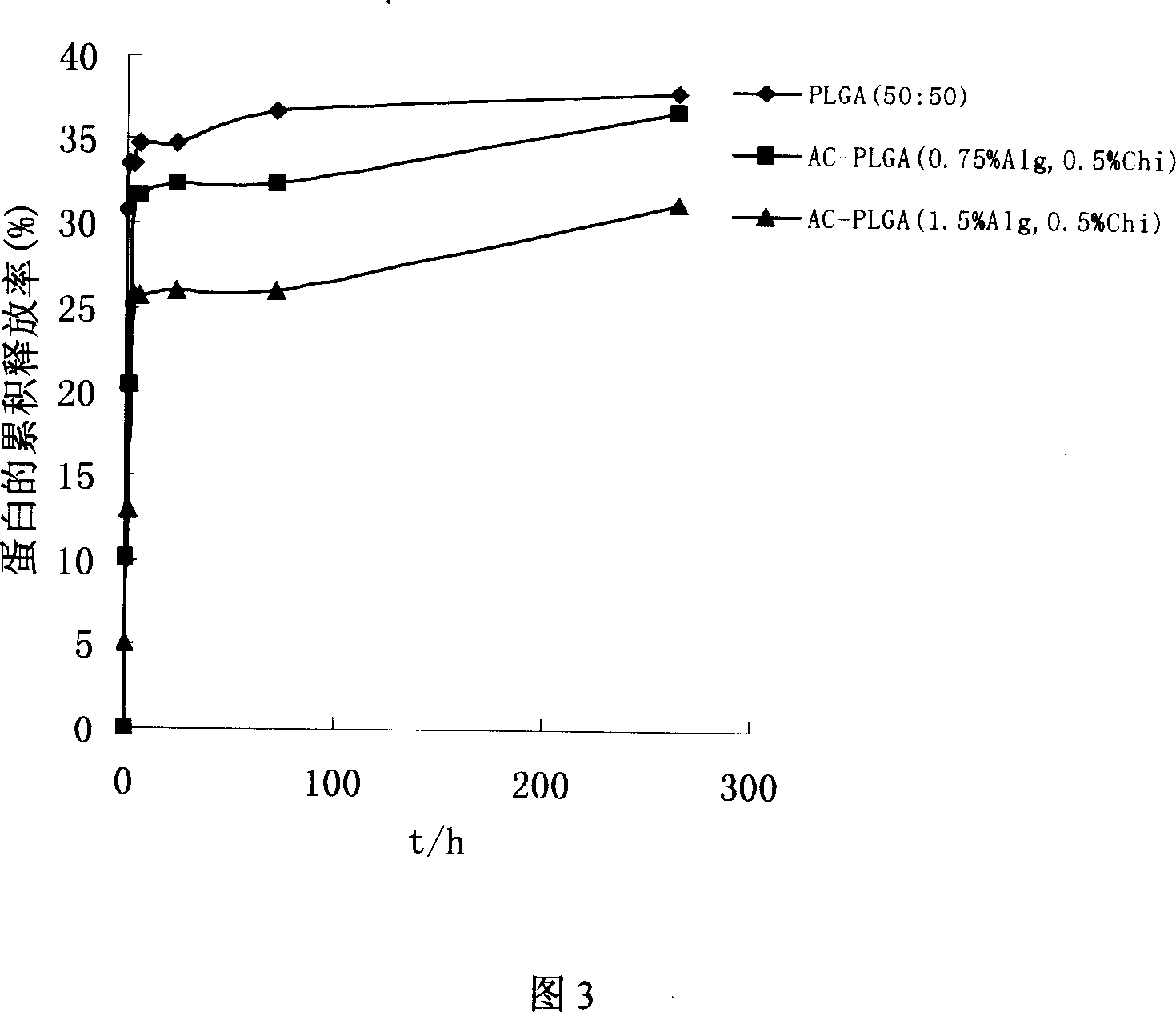

[0028] The composite microsphere prepared by the method of the invention can obviously reduce the burst release ph...

Embodiment 2

[0033] The same as Example 1, but the ratio of PLGA is 70:30, to obtain PLGA (70:30) microspheres modified by alginic acid and chitosan.

Embodiment 3

[0035] Same as Example 1, but the amount of PLGA weighed is 0.2g, dissolved in 2ml of dichloromethane as the organic phase, mixed with the water phase, then installed with a probe-type ultrasonic instrument, ultrasonicated at 200w, 40s, and injected with 20ml of the mixed solution after forming colostrum In the process, stirring at 800rpm for 3min, the encapsulation efficiency and particle size of PLGA microspheres modified by alginic acid and chitosan were not statistically different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com