High-amylose corn starch inclusion antibacterial essential oil degradable antibacterial food packaging material and preparation method thereof

A corn starch and food packaging technology, applied in the direction of sustainable packaging, packaging, wrapping paper, etc., can solve the problems of food quality degradation, restrictions on the wide application of high-amylose corn starch, perishability, etc., and achieve the effect of delayed release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] S1. Preparation of dimethyl sulfoxide (DMSO) and H 2 The molar ratio of O is 1:1.5 DMSO solution.

[0036] S2. Preparation of 5% high amylose corn starch solution: Weigh 5g of high amylose corn starch (containing 64% of amylose) dissolved in 95g of the above S1 prepared DMSO solution, stirred until completely dispersed. Then continuously agitate at 125 °C to gelatinize for 2 h until the solution is transparent and cooled to 25 °C for later use.

[0037] S3. Preparation of membrane solution: Add 2 g of cinnamaldehyde and 1 g of glycerol (glycerol) to the 5% high amyl corn starch solution prepared by S2. Agitation at 25 °C for 24 h to give a highly amylose-cinnamaldehyde membrane solution.

[0038] S4. Using the solution casting method, take 50g of high-ryndolane corn starch-cinnamaldehyde film solution into a glass dish (16.5cm×11.5cm), dry at 50 °C, and obtain high amyl corn starch-coated cinnamaldehyde degradable antibacterial food packaging materials.

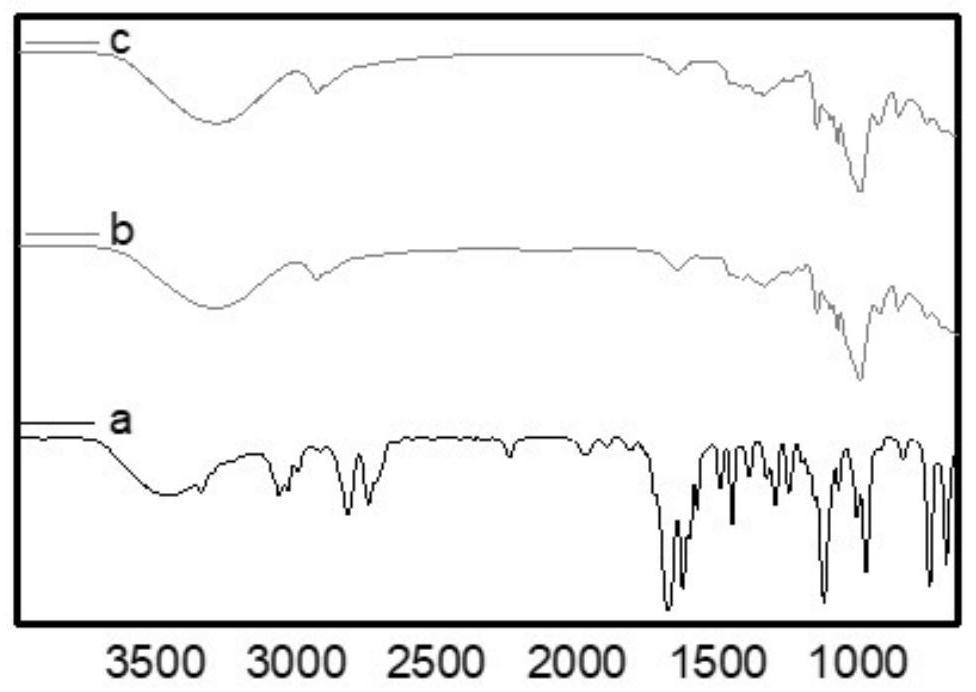

[0039] as Figure 1 A...

Embodiment 2

[0041] S1. Preparation of high amylose corn starch solution: Weigh 0.5 g of high amylose corn starch (64% of amylose containing amylose) dissolved in DMSO with a concentration of 4.5 g ≥ 99.5%.

[0042] S2. Preparation of cinnamaldehyde antibacterial solution: 0.2g of cinnamaldehyde was added to 0.5g of absolute ethanol solution at 25 °C, stirred to dissolve, and 40% cinnamaldehyde antibacterial solution was obtained.

[0043] S3. The high amylose corn starch solution prepared in the above S1, S2 steps and the cinnamaldehyde antibacterial solution were thoroughly stirred evenly, and then 4.5g of high amyl corn starch (containing 64% of amylose) and 0.75g of choline chloride were stirred, and placed under 100 °C conditions to be closed and heated for 15 hours to form a plastic high amyl corn starch- cinnamaldehyde-coated material.

[0044] S4. The plastic high amylose corn starch-cinnamaldehyde-coated material after treatment was repeatedly pressed roller, and 0.5g of glycerol was ...

Embodiment 3

[0047] S1. Preparation of high amylose corn starch solution: Weigh 0.5g of high amylose corn starch (containing 64% of amylose) dissolved in 4.5g concentration ≥ 99.5% DMSO.

[0048] S2. Add 0.2g polymethylsesquisiloxane to S1 high-amylosewax starch solution and stir well.

[0049]S3. Preparation of antibacterial solution of thyme essential oil: 0.2g of thyme essential oil was added to 0.5g of absolute ethanol solution at 25 °C, stirred to dissolve, and 40% thyme essential oil antibacterial solution was obtained.

[0050] S4. The high amylose corn starch solution prepared in the above S2, S3 steps and the antibacterial solution of thyme essential oil were thoroughly stirred, loaded into two layers of 4cm×5cm sealing film, and placed in a thermal reaction of 100 °C for 15h to form a plastic high lyxyl corn starch-thyme essential oil-coated material.

[0051] S5. The plastic high-lamina corn starch-thyme essential oil-coated material after treatment is repeatedly pressed and rolled,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com