Cold-rolled dual-phase steel with tensile strength being 780MPa and high hole reaming performance and preparation method thereof

A tensile strength, dual-phase steel technology, applied in the field of steel plate production, can solve problems such as poor hole expansion performance, achieve excellent welding performance, achieve lightweight, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

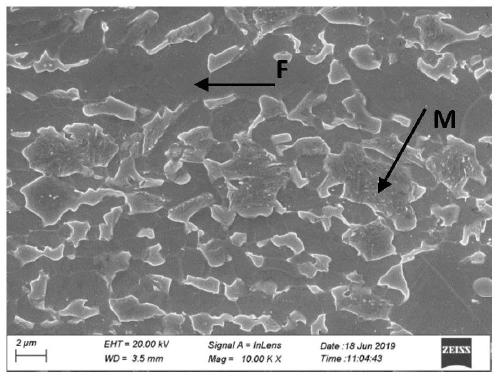

Image

Examples

Embodiment 1

[0028] The present invention has a tensile strength of 780MPa and a method for preparing cold-rolled dual-phase steel with high hole-expanding performance. The specific process is as follows:

[0029] A, smelting process: through the smelting process, a dual-phase steel slab with the chemical composition shown in Table 1 is prepared, wherein the original molten iron V content is controlled in the converter, instead of adding additional ferro-vanadium alloy;

[0030] Table 1 Example 1 Cold-rolled dual-phase steel chemical composition (wt.%)

[0031] Numbering C Si mn P S N als V 1 0.090 0.50 2.05 0.010 0.002 0.0030 0.045 0.050 2 0.085 0.55 2.10 0.008 0.004 0.0035 0.036 0.052

[0032] B, hot-rolling process: the hot-rolled coil is obtained after the slab is heated, dephosphorized, hot-rolled and laminar cooling, and the specific hot-rolling process parameters are as shown in Table 2;

[0033] Table 2 Example 1 Cold-rolled dual-phas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com