Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

100results about How to "Lower oxygen partial pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

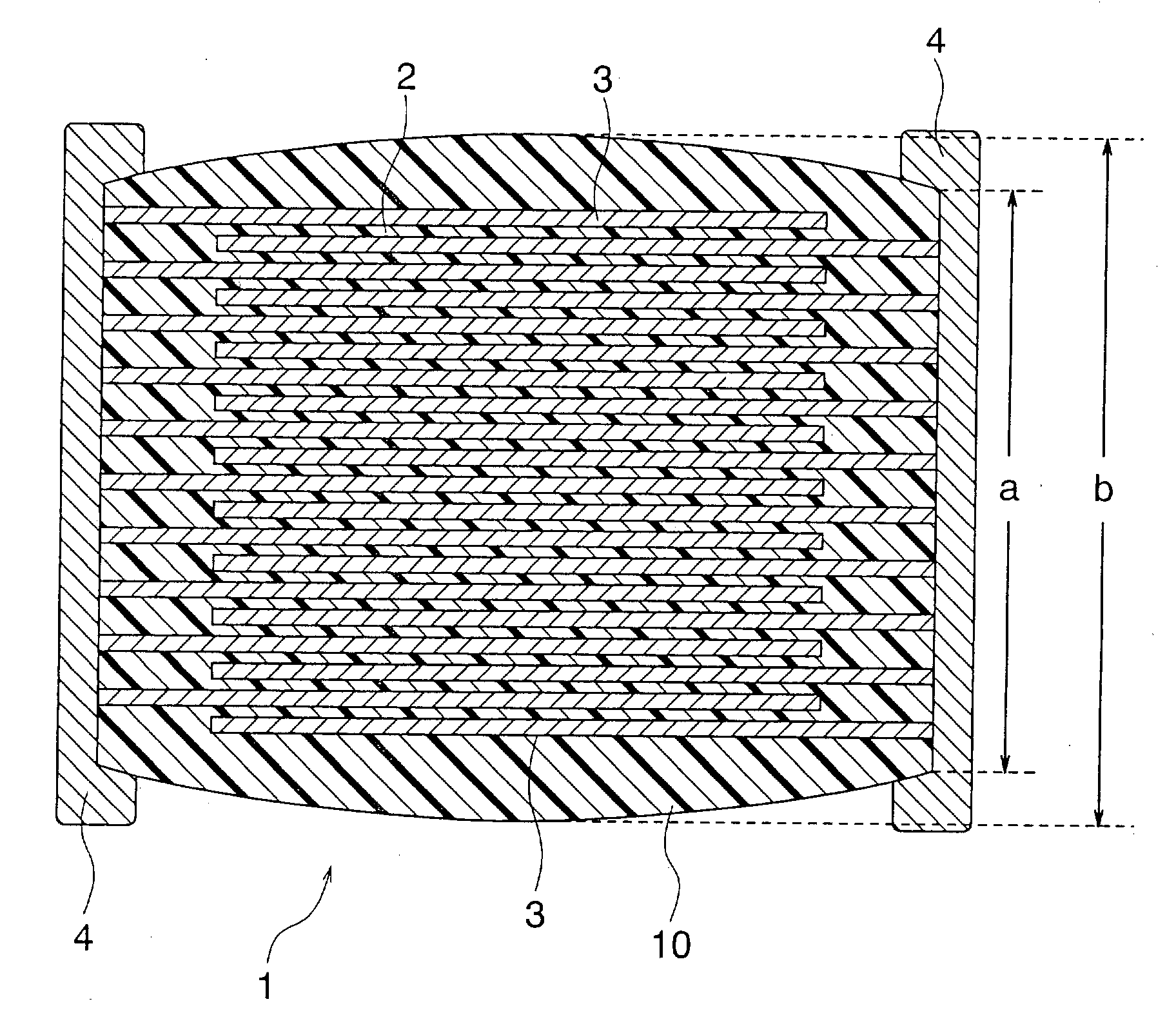

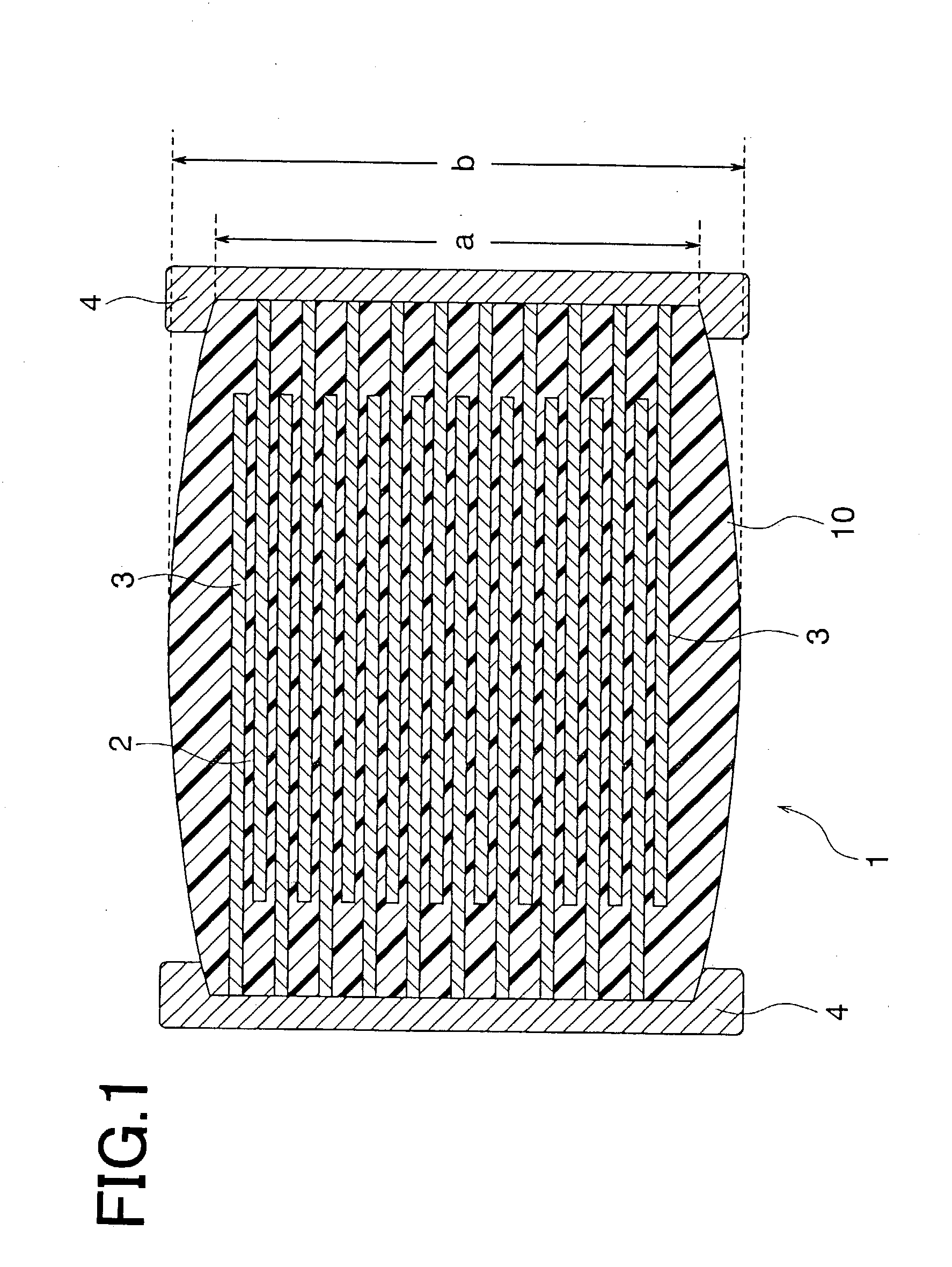

Production method of laminate ceramic electronic component

InactiveUS20030147194A1Easy to controlLower oxygen partial pressureFixed capacitor dielectricStacked capacitorsElectricityHydrogen

A method of producing a multilayer ceramic electronic device, having a firing step for firing a pre-firing element body wherein a plurality of dielectric layers and internal electrode layers containing a base metal are alternately arranged, characterized in that the firing step has a temperature raising step for raising a temperature to a firing temperature, and hydrogen is continued to be introduced from a point in time of the temperature raising step. According to the method, it is possible to provide a method of producing a multilayer ceramic electronic device, such as a multilayer ceramic capacitor, wherein shape anisotropy and other structural defaults are hard to occur and electric characteristics are improved while suppressing deterioration thereof even if dielectric layers becomes thinner and stacked more.

Owner:TDK CORPARATION

Microporous high chrome brick and preparation method thereof

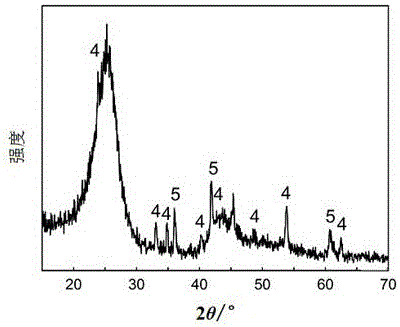

The invention relates to a microporous high chrome brick and a preparation method thereof. According to the technical scheme thereof, the microporous high chrome brick comprises the following compositions: 40-70 wt percent of fused chromium oxide particle, 10-20 wt percent of fused chromium oxide fine powder, 0.3-5 wt percent of SiC particle, 0.3-5 wt percent of SiC fine powder, 3-15 wt percent of monoclinic zirconia micropowder, 2-15 wt percent of alumina micropowder and 4-12 wt percent of chromium oxide green fine powder, and dextrin and aluminum dihydrogen phosphate which respectively occupy 0.5-3 wt percent and 2-7 wt percent of the mixture are added as binders. The preparation method comprises the following steps of dry mixing the fused chromium oxide particle with the SiC particle for 3-5min according to the compositions, adding the aluminum dihydrogen phosphate to be wet mixed for 5-7min, then adding a mixed powder prefabricated from the fused chromium oxide fine powder, the SiC fine powder, the monoclinic zirconia micropowder, the alumina micropowder, the chromium oxide green fine powder and the dextrin, mixing milling for 15-30min, ageing the mixture, pressing to form a green body, drying, and sintering in air at the temperature 1350-1650 DEG C. The invention has the advantages of simple process, high micropore formation rate of the prepared microporous high chrome brick and good cinder permeation resistance, and prolongs the service life of a high chrome brick.

Owner:WUHAN UNIV OF SCI & TECH

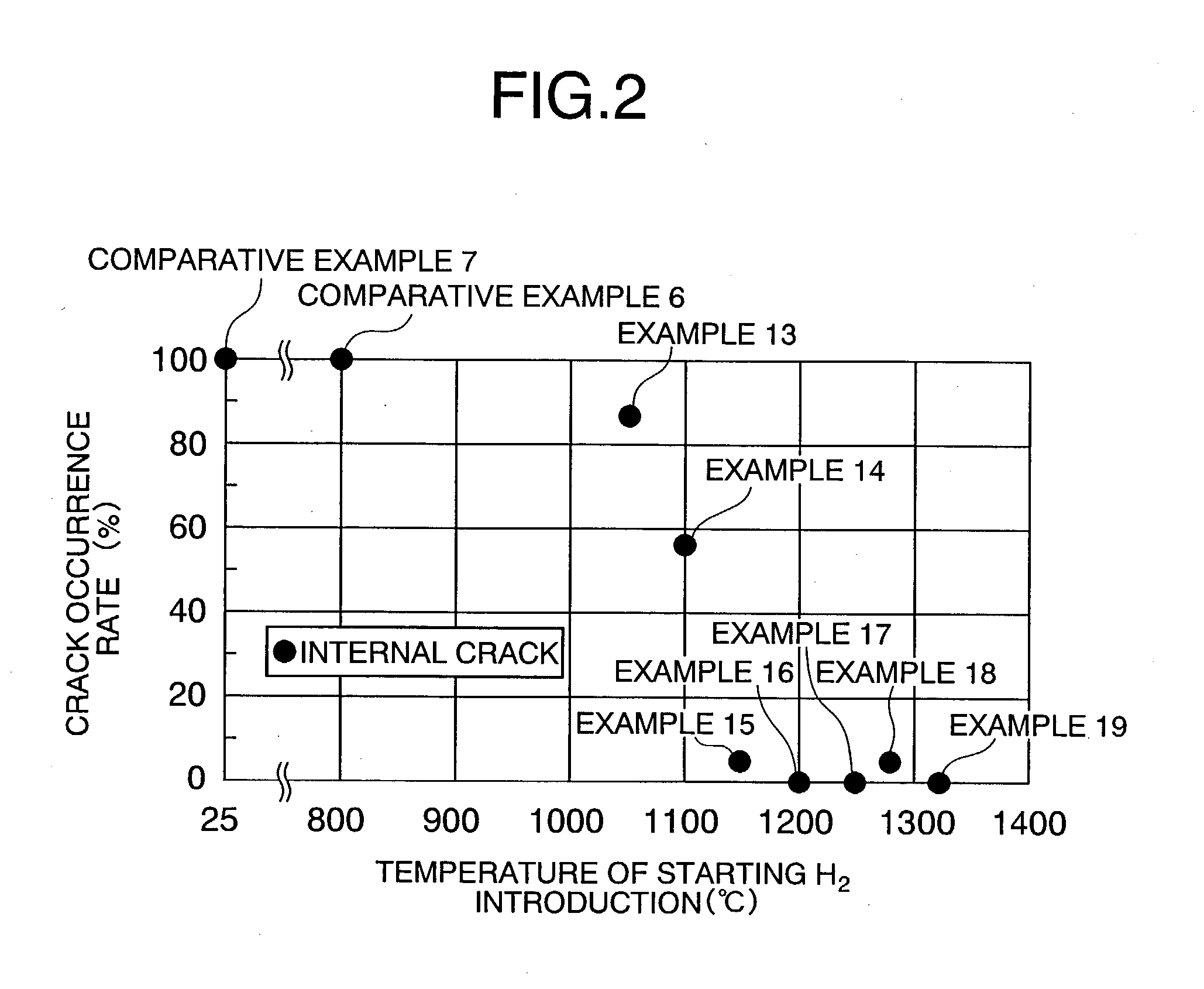

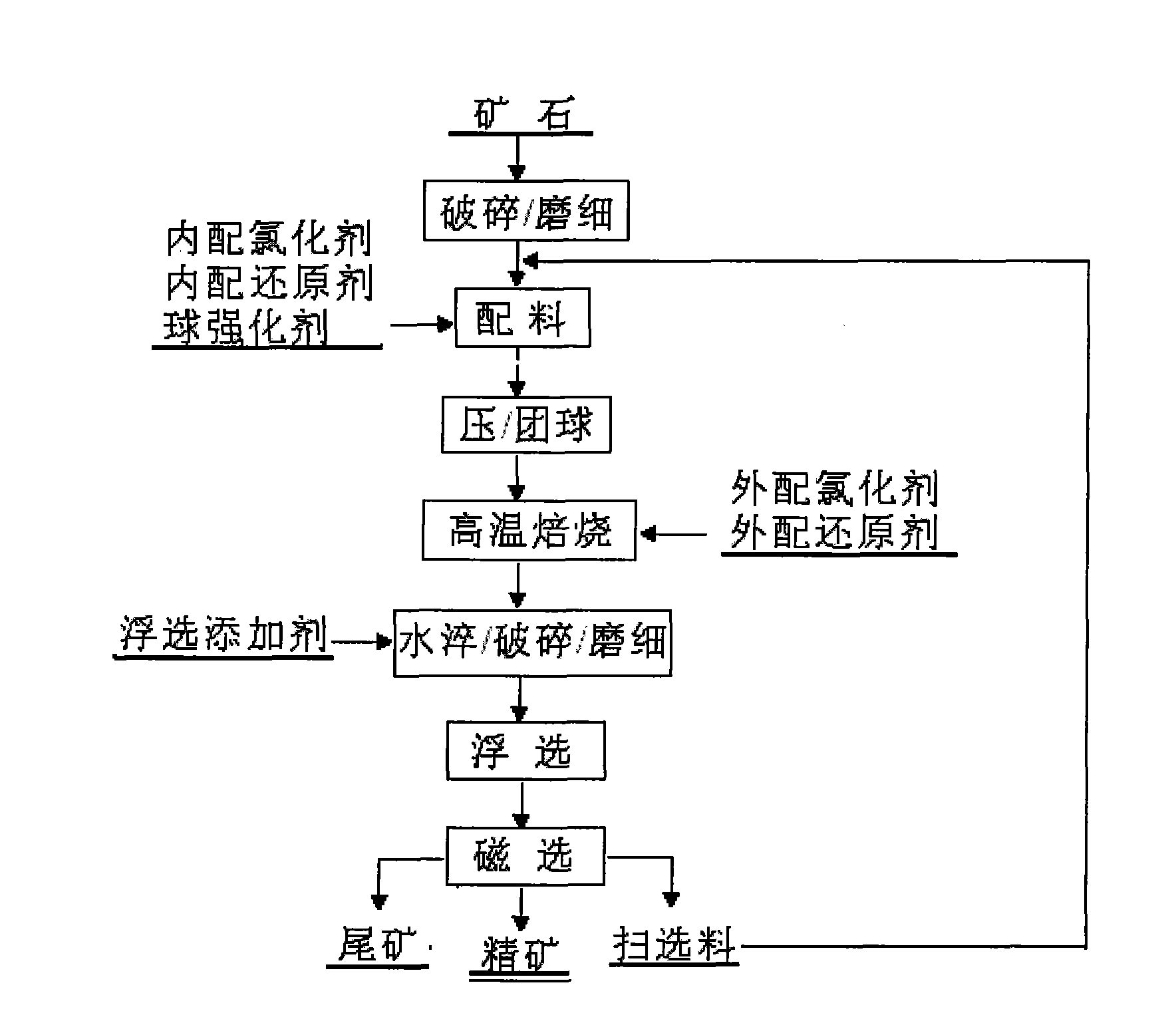

Method for efficiently concentrating cobalt and nickel from low-grade nickeliferous laterite ore

InactiveCN101514401ASimple processPractical processMagnetic separationWet separationLower gradeAlloy

The invention provides a method for efficiently concentrating cobalt and nickel from a low-grade nickeliferous laterite ore. The method is based on mine-phase reconstruction, and the ore is subject to physical treatment, high temperature chlorination and reduction roasting to convert the nickel and the cobalt in the ore from oxide or composite oxide (silicate and ferrite) mineral into magnetic metal or alloy, magnetic separation method or combined floatation-magnetic separation method is used for separation to concentrate the cobalt and the nickel. The method is used for treating the low-grade nickeliferous laterite ore (Ni is 0.2-2.0%), contents of the nickel ore concentrate is more than ten times of that of the crude nickel ore; and the nickel recovery is more than 80%.

Owner:CENT SOUTH UNIV

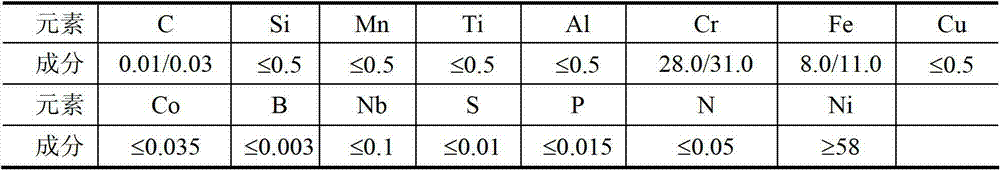

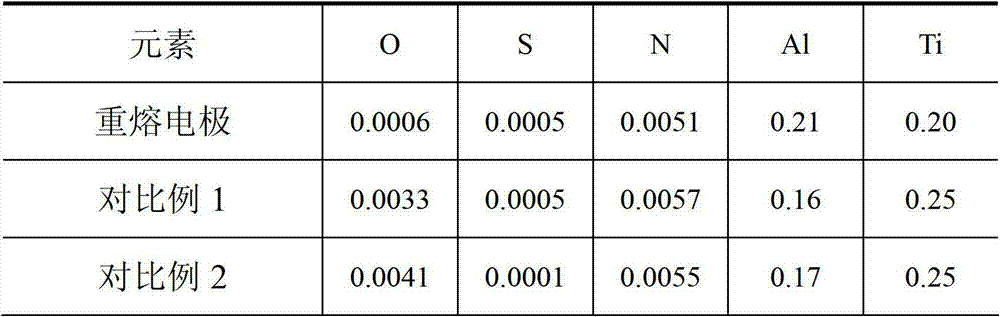

Process for industrially producing ultrapure Inconel 690 (I-690) alloy electroslag remelting ingot of 3 tons

ActiveCN103008621AReduce the chance of passingReasonable selection of cooling water temperatureIncreasing energy efficiencyMagnesiumSulfur content

The invention belongs to the technical field of electroslag remelting and relates to an improvement of a process for industrially producing Inconel 690 (I-690) alloy electroslag remelting ingots, in particular to a process for industrially producing an ultrapure low-segregation I-690 alloy electroslag remelting ingot of 3 tons. An electrode bar smelted by a vacuum induction furnace is phi430mm in dimension, and a crystallizer is phi503 / phi527mm*2400mm in dimension. Remelting process parameters are shown as follows: according to the requirements of I-690 alloy components, a five-component premelting slag system with a new proportion is adopted by the remelting, wherein the five-component premelting slag system comprises the five components: calcium fluoride, calcium oxide, aluminum oxide, magnesium oxide and titanium dioxide, and the total content of unstable oxide impurities, such as manganese oxide, ferrous oxide and silicon oxide, is less than 0.5 percent. Before the remelting is performed, an electrode is used after being baked at 700 DEG C for 8 hours, a slag charge is used after being baked at 680 DEG C for 8 hours, and argon shield is adopted during a remelting process. According to the process, the oxygen content of I-690 alloy after the remelting is performed can be reduced to 20 parts per million (ppm) or below, and thus, the goal of no oxygenation or less oxygenation is achieved after the remelting is performed. Moreover, sulfur content is reduced to 5ppm or below; the oxide inclusion grade is lower than 1, and the alloy after the remelting is performed is even in structure component, and therefore, the high-quality remelting alloy is obtained.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

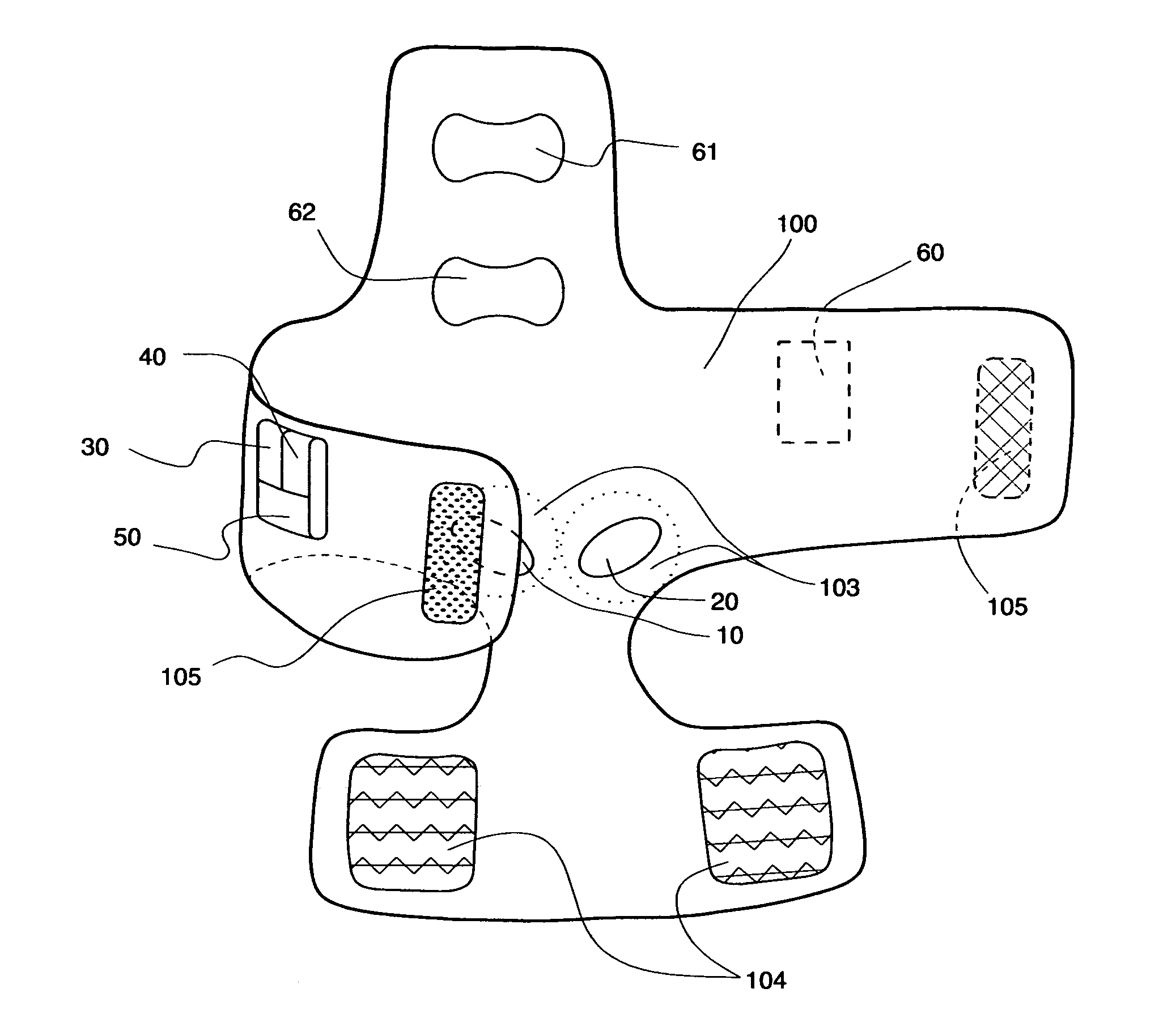

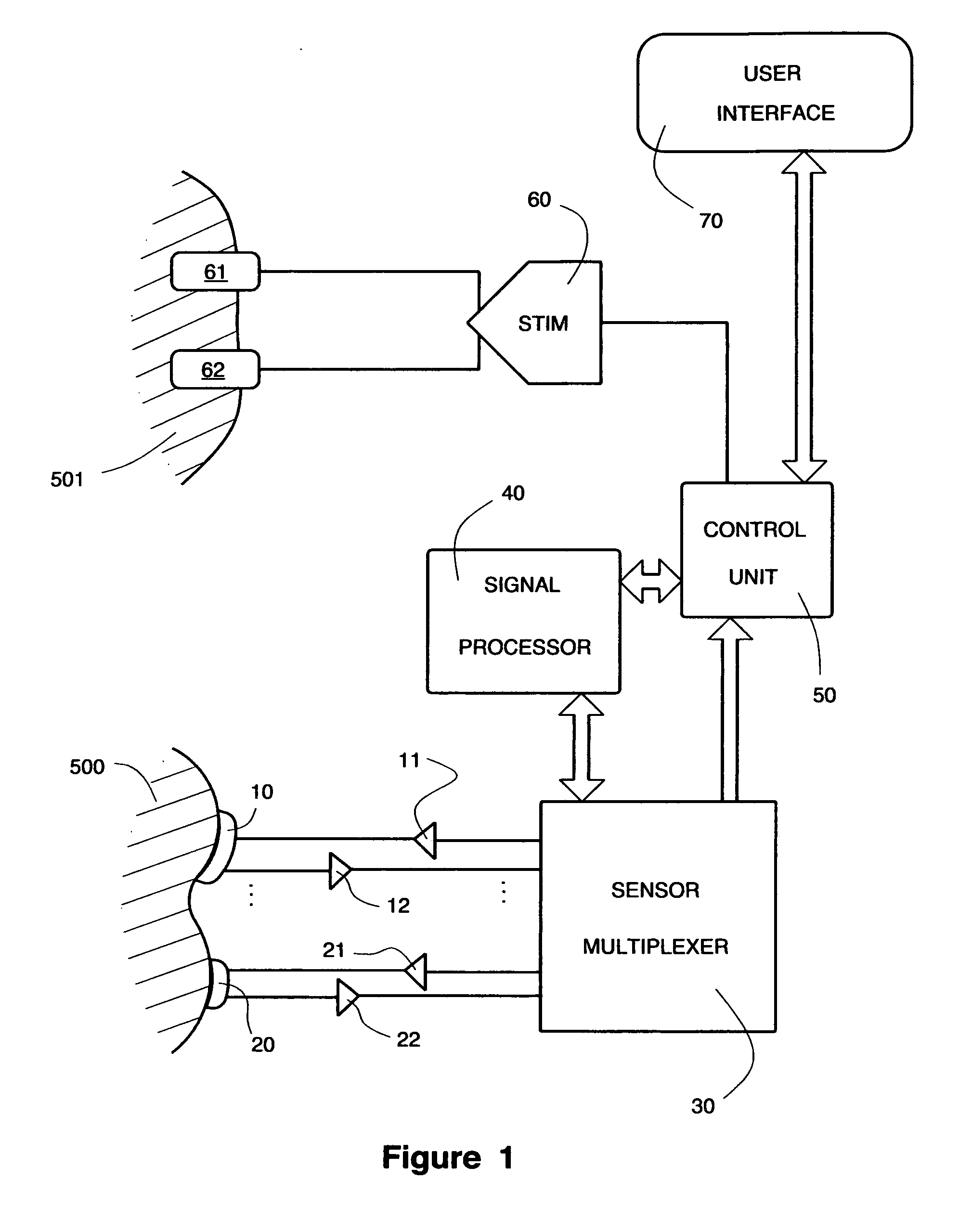

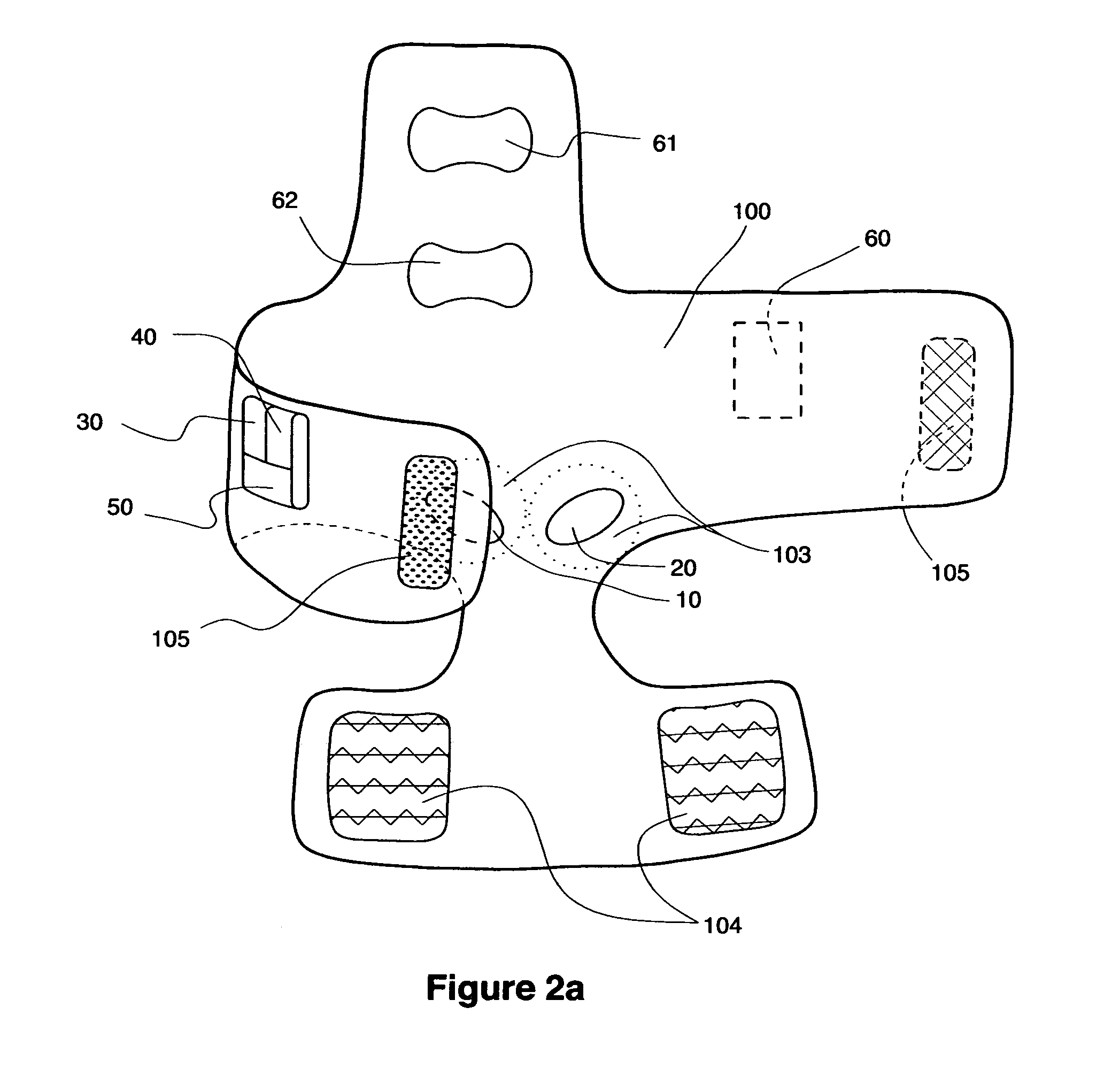

Apparatus and method for treating and preventing formation of pressure ulcers

ActiveUS20120277825A1Lower oxygen partial pressureDecreasing cellular metabolite removalElectrotherapyArtificial respirationWheelchairPhysical therapy

An apparatus and means of detecting tissue conditions conducive to pressure ulcer formation and reversing these conditions which includes the steps of: noninvasively detecting tissue parameters indicative of tissue health, calculating when these conditions fall outside normal healthy physiological ranges in such a manner that indicates future formation of a pressure ulcer, and in such a situation applying therapeutic stimulation to normalize tissue physiological condition. Said apparatus and method comprise a single, wearable unit. The device can be used in bed or in a wheelchair to treat and prevent the development of pressure ulcers.

Owner:CHALFONT LLC

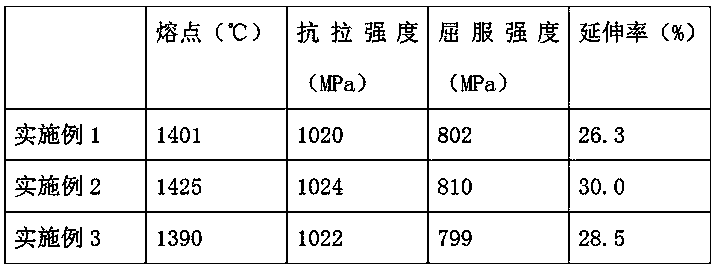

Cobalt-based high-temperature alloy wire and preparation method thereof

InactiveCN110983113ADecreased high temperature strengthImprove high temperature strengthDouble phaseOxidation resistant

The invention provides a cobalt-based high-temperature alloy wire which is prepared from the following chemical components in percent by mass: 0.06-0.12% of C, less than or equal to 0.3% of Si, 1-1.8%of Mn, less than or equal to 0.015% of P, less than or equal to 0.015% of S, 19.2-20% of Cr, 9.5-10.5% of Ni, 14.2-15.5% of W, less than or equal to 2.8% of Fe, less than or equal to 0.4% of other impurities and the balance Co. By adding 19.2-20% of Cr, the cobalt-based high-temperature alloy wire has excellent corrosion resistance, and a condition that high-temperature strength is decreased as aresult of a double phase area as the content of Cr is too high to promote generation of an epsilon-Co phase and a sigma phase is avoided. Elements such as massive Co, 14.2-15.5% of W and 19.2-20% ofCr and the like in the cobalt-based alloy can reduce stacking fault energy, so that the high-temperature strength of the alloy is improved. The content of W is controlled at 19.2-20%, so that it is ensured that a condition of prominent work hardening of the alloy, difficulty in cold processing and poor stability as the too high W content is avoided. As the cobalt-based high-temperature alloy wirecontains 9.5-10.5% of Ni, the tissue stability of the alloy is improved favorably, and precipitation of a Co7W6 phase is reduced. By adding 1.1-1.8% of Mn, the oxidation resistance of a Ni-Cr alloy isimproved effectively.

Owner:JIANGSU XINHUA ALLOY ELECTRIC

High thermal conductivity and high microporous electrically calcined coal based carbon brick and preparation method thereof

ActiveCN107244924AImprove the degree of graphitizationHigh reactivityCeramicwareBrickConstruction aggregate

The invention discloses a high thermal conductivity and high microporous electrically calcined coal based carbon brick and a preparation method thereof. The technical scheme includes: conducting presintering in reducing atmosphere in an atmosphere furnace successively to obtain activated electrically calcined anthracite particles and activated electrically calcined anthracite fine powder; mixing nickel nitrate hexahydrate with anhydrous ethanol to obtain a nickel nitrate solution; taking 10-20wt% of activated electrically calcined anthracite fine powder, 4-10wt% of alpha-Al2O3 micropowder, 4-10wt% of silicon powder, 2-6wt% of aluminum magnesium alloy powder, 1-2wt% of carbon black and 0.5-1wt% of boron carbide powder as the matrix, and using 60-70wt% of activated electrically calcined anthracite particles as the aggregate; firstly putting the aggregate and a nickel nitrate solution into a mixing mill, performing mixing, then adding thermosetting phenolic resin, and conducting mixing milling, then adding the matrix blended matrix fine powder, and carrying out mixing milling, molding and drying; and finally performing firing in nitrogen atmosphere and under a 1080-1280DEG C condition, thus obtaining the high thermal conductivity and high microporous electrically calcined coal based carbon brick. The product prepared by the method provided by the invention has the characteristics of high thermal conductivity, high micropore ratio and good resistance to molten iron erosion.

Owner:WUHAN UNIV OF SCI & TECH

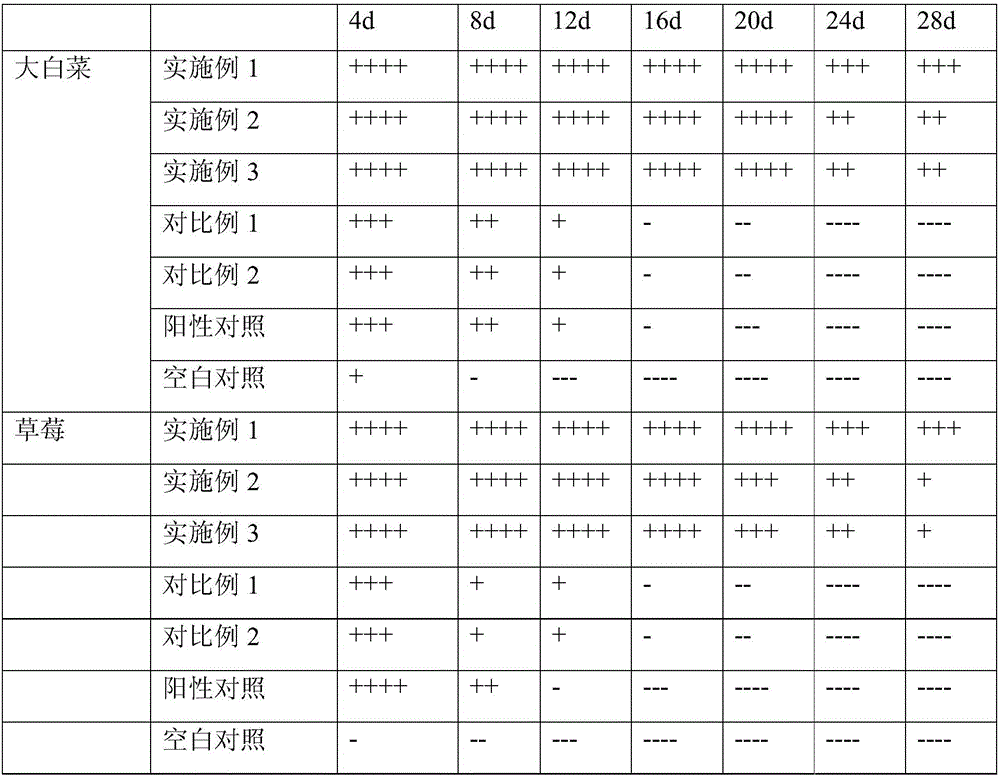

Three-stage pressure-reducing preservation method for long-term storage of perishable fruits and vegetable

InactiveCN1672529AImprove cold damage resistanceImprove storabilityFruit and vegetables preservationFlavorThree stage

The present invention is three-stage pressure-reducing preservation method for long term storage of perishable fruits and vegetable, and belongs to the field of fruits and vegetable preserving technology. The three-stage pressure-reducing preservation method includes: 1) the first fruits and vegetable storing stage of 5-10 days at high vacuum of 5-20 KPa pressure to control water losing rate of 2-3.5 %; 2) the middle stage of 10-30 days in intermediate vacuum of 20-60 KPa pressure to control water losing rate of 1-2 %; and 3) final stage of 10-30 days at low vacuum of 60-100 KPa under humidity of 93-98 % without further water loss, to maintain the fresh state, flavor and post-mature performance. The present invention has long storage term of perishable fruits and vegetable.

Owner:JIANGNAN UNIV

Process method for producing 1 ton of I-690 alloy electroslag remelted ingot in industrialized mode

The invention belongs to the technical field of electroslag remelting, relates to improvement on a process for producing Inconel 690 alloy electroslag remelted ingot in an industrialized mode, in particular to a process method for producing 1 ton of I-690 alloy electroslag remelting ingot in an industrialized mode. A vacuum induction furnace smelts an electrode bar of phi 240 mm; the size of a crystallizer is phi 340 / 380*1,500 mm; the remelting process parameters comprise: remelting voltage of 47 to 55 V, current of 7,500 to 8,500 A and slag quantity of 38 to 45 kg; according to the I-690 alloy component requirement, the remelting adopts a new proportioned pentabasic slag system; the components comprise calcium fluoride, calcium oxide, aluminum oxide, magnesium oxide and titanium dioxide; the purity of each component is required to be more than 98.5 percent; the total content of unstable oxide impurities such as manganese oxide, ferrous oxide and silica is less than 0.5 percent; the granularity is less than 50 meshes; before the remelting process, the electrode is roasted at the temperature of 700 DEG C for 8 to 12 hours and the slag is roasted at the temperature of 680 DEG C for 8 to 12 hours for use; and in the remelting process, argon and burning gas are adopted for protection. By the process, the content of the remelted I-690 alloy is reduced to be below 20 ppm, the sulfur content is reduced to be below 5 ppm, oxide inclusion is effectively removed, and high-quality remelted alloy is obtained.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

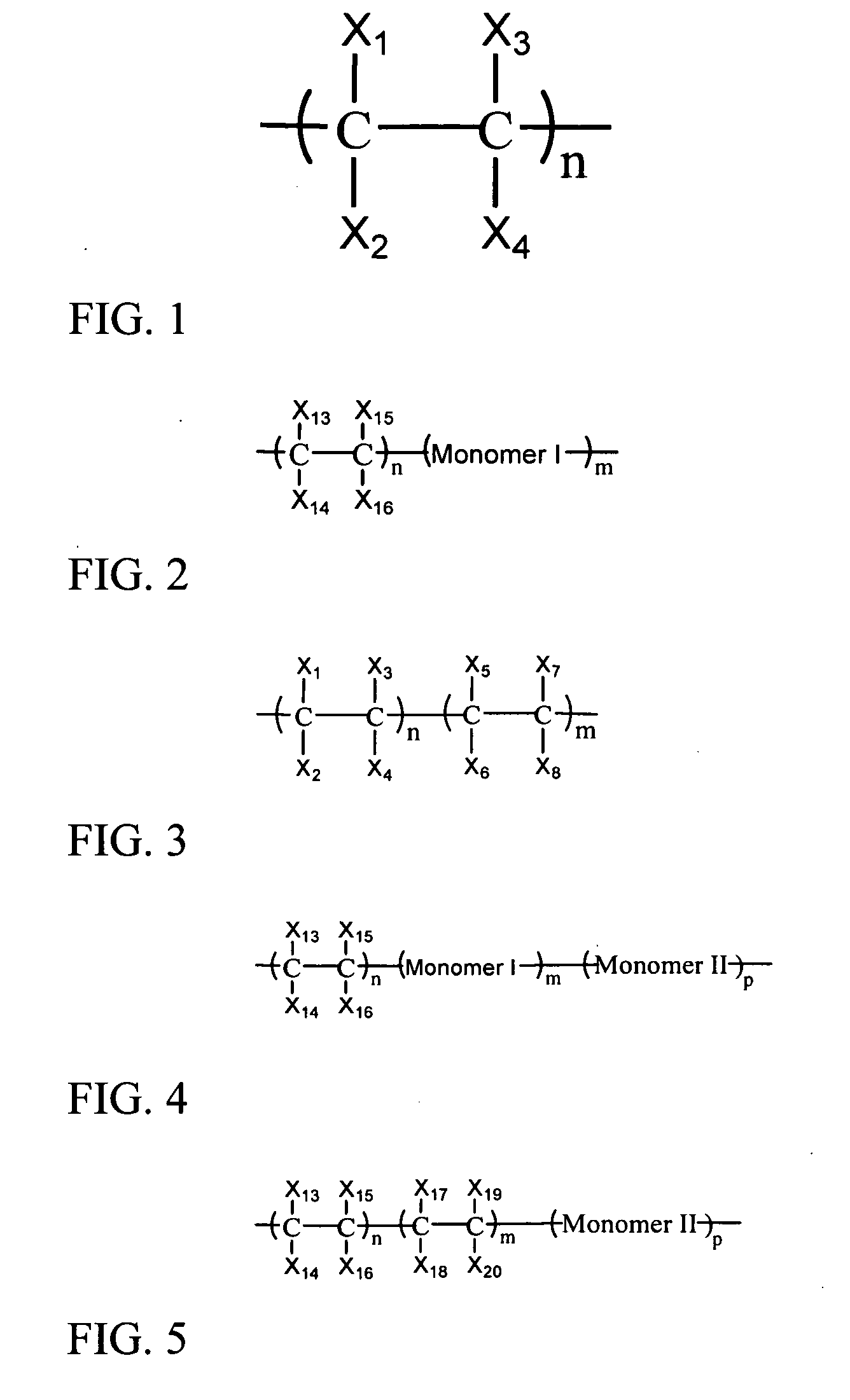

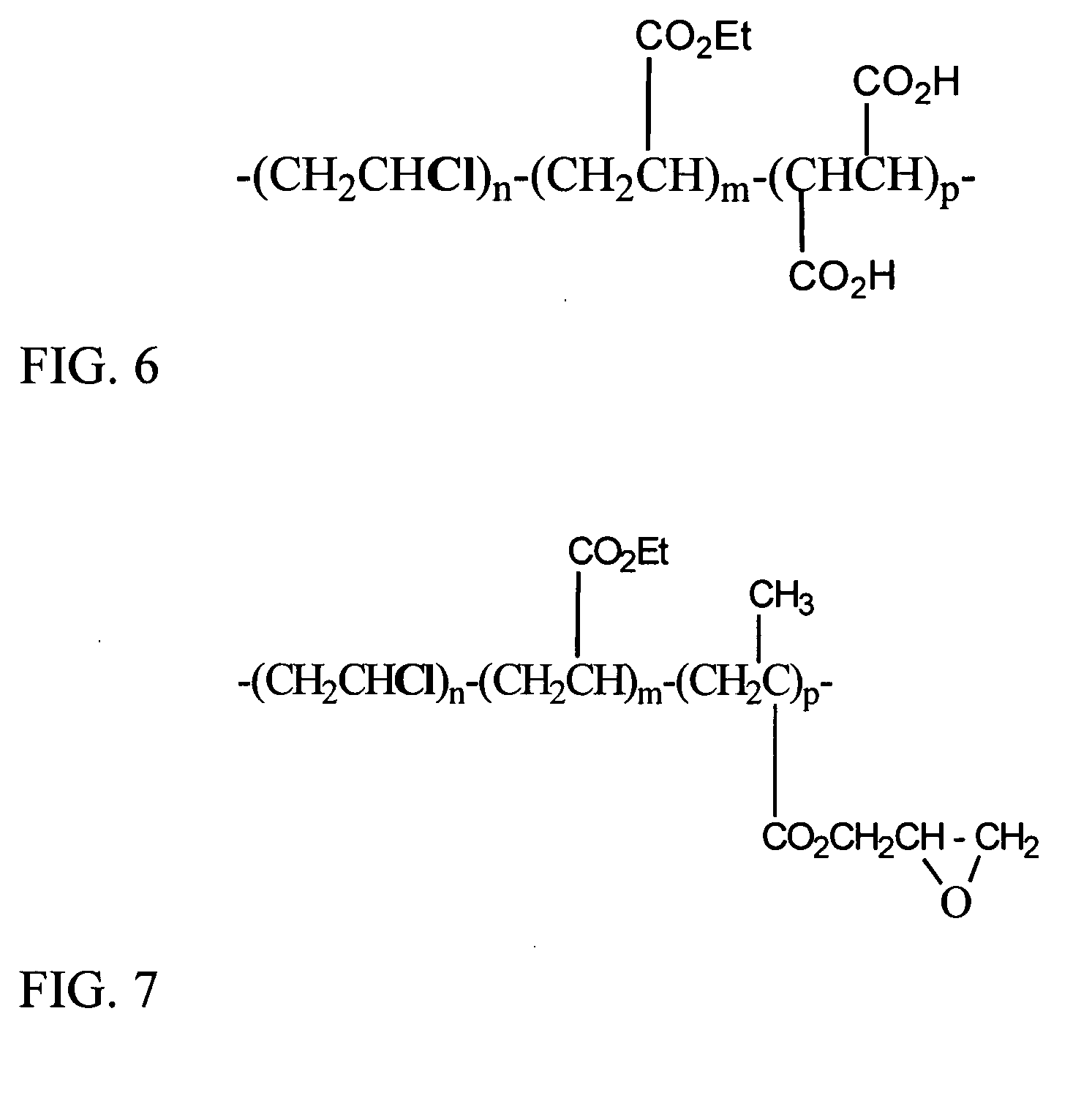

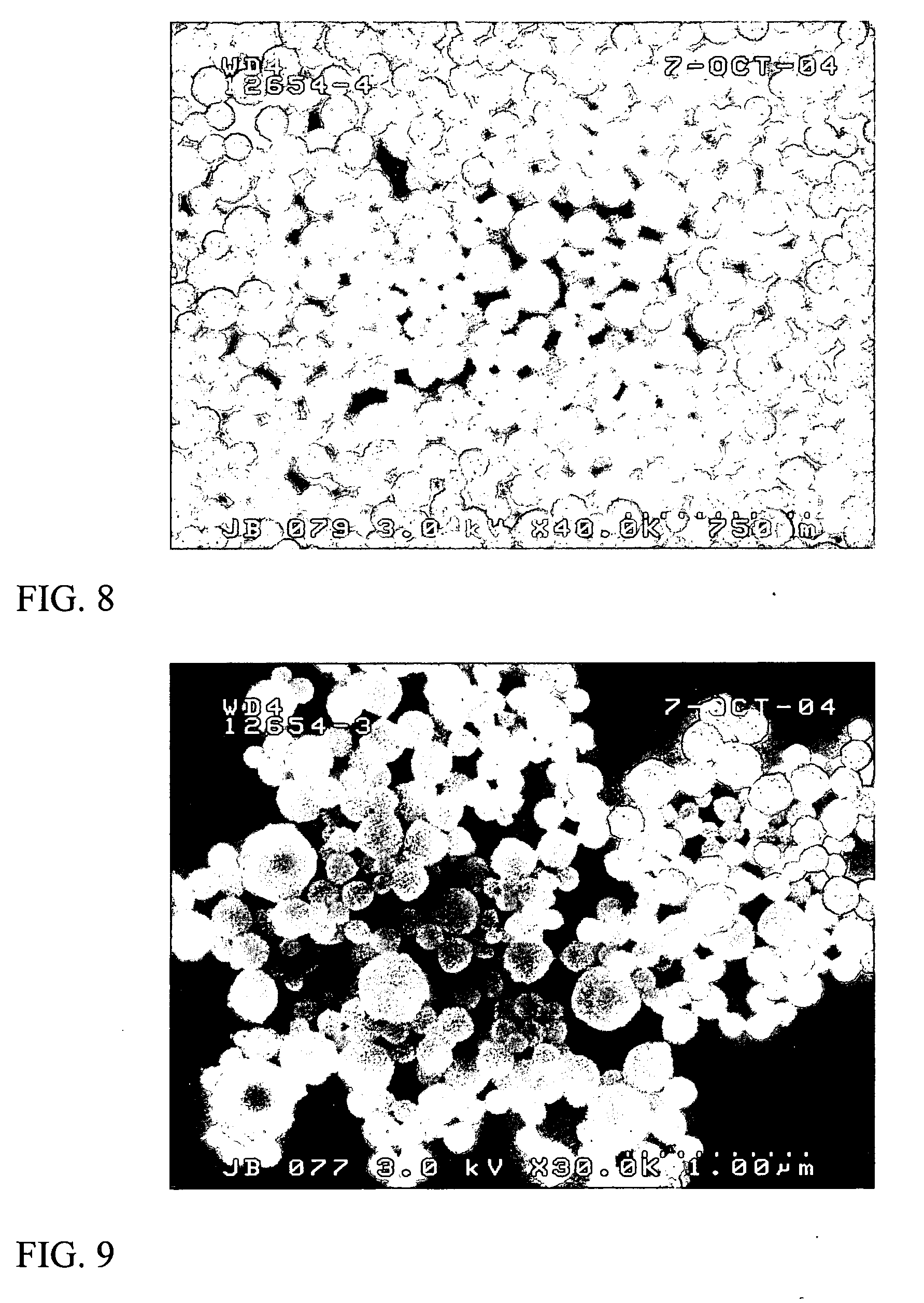

Photo-stable and surface-functionalizable colorant particles

InactiveUS20070065743A1Facilitate functionalizationEnhance attachmentSynthetic resin layered productsCellulosic plastic layered productsHalogenIon

A composition and method for encapsulating colorant molecules in polymeric particles are described. Colorant molecules, such as dye, are doped or embedded in a particle, at least in part, composed of a halogen-containing polymeric matrix that can effectively isolate the dye molecules from reaction with photo-oxidizing or reducing agents. The isolated colorant molecule is protected from photo-bleaching and other color degradation, and show superior photo-stability. The encapsulating polymer matrix can be cross-linked and can have a variety of surface functional groups, which may be adapted to help achieve either strong ionic or covalent binding to desired substrates. Also described are methods for producing protective particles, and ink mediums for applying the particles to substrates.

Owner:KIMBERLY-CLARK WORLDWIDE INC

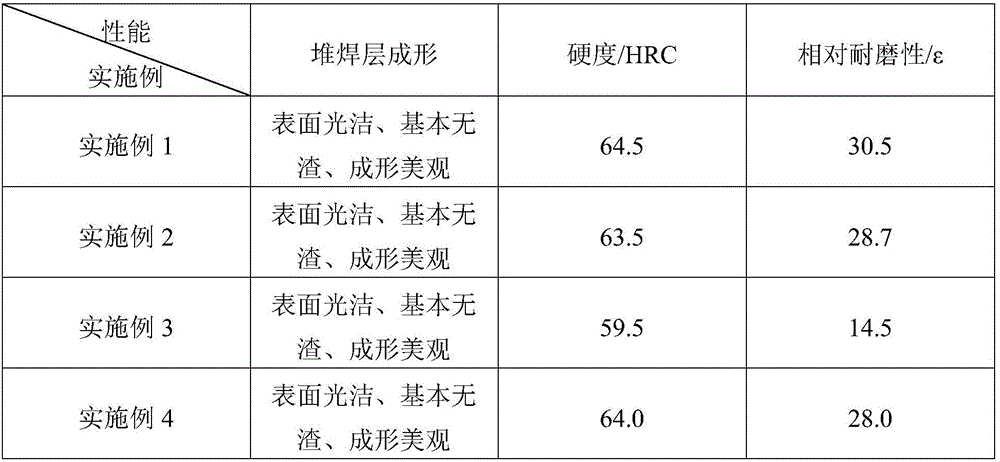

High-efficient energy-saving and surfacing layer well-forming self-shielded flux-cored welding wire and manufacture method thereof

ActiveCN106041356ALow melting pointReduce surface tensionWelding/cutting media/materialsSoldering mediaHigh carbonManganese

The invention discloses a high-efficient energy-saving and surfacing layer well-forming self-shielded flux-cored welding wire. A low-carbon steel belt is an outer skin; and a flux core comprises the following components in percentage by mass: 42-60% of high carbon ferro-chrome with the particle size of 80 meshes, 10-18% of ferrosilicon, 16-25% of ferroboron, 2-8% of rare earth silicon, 2-8% of graphene, 1-4% of aluminum magnesium alloy, 2-5% of manganese powder and the balance of iron powder, wherein the graphene, the aluminum magnesium alloy and the manganese powder are added with two kinds of particle sizes of 60 meshes and 200 meshes, and the weight of the flux core powder accounts for 49-53% of the total weight of the welding wire. According to the welding wire provided by the invention, by adding the flux core components with different particle sizes, good welding technological performance is ensured; and by adding B, Si and other self-fluxing alloy elements simultaneously in the flux core, the fusing point of the welding wire is effectively lowered; a welding process window is expanded; the surfacing efficiency is improved; a high-efficient and energy-saving effect is realized; and the surface tension of a surfacing welding bead is effectively lowered, and the forming of the surfacing welding bead is effectively improved.

Owner:JIANGSU UNIV OF SCI & TECH

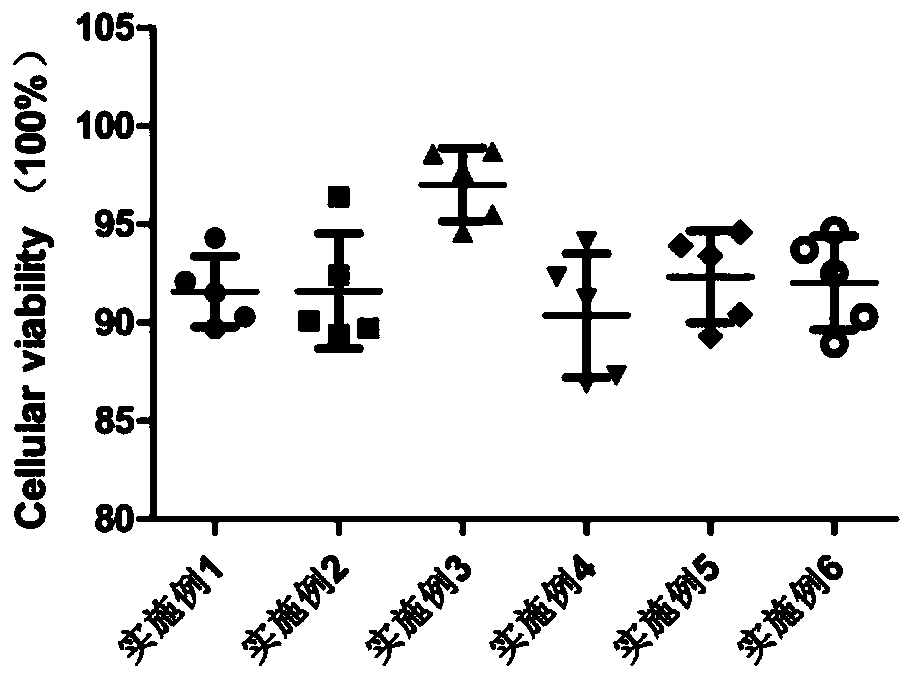

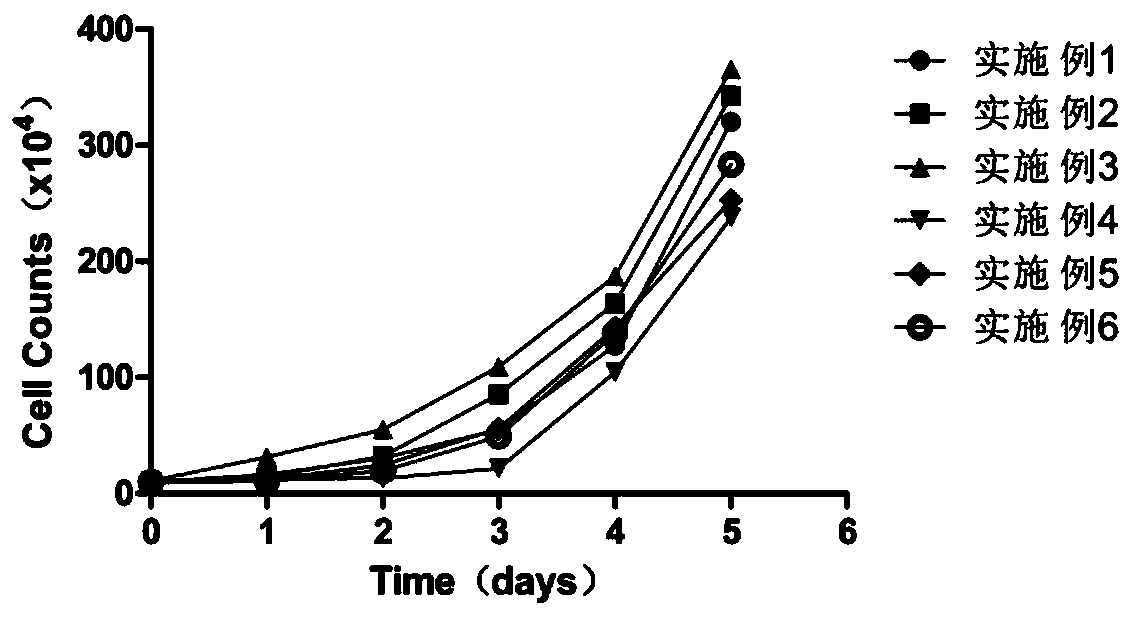

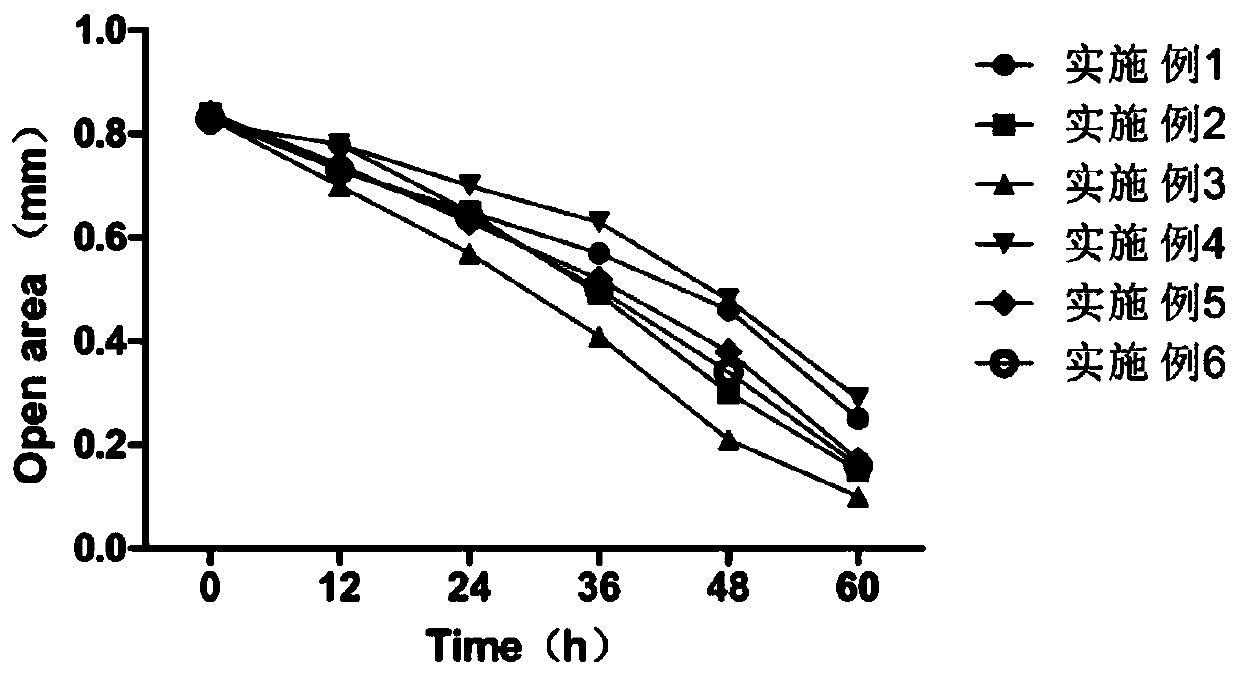

Culture medium for promoting growth of mesenchymal stem cells and preparation method thereof

ActiveCN109762782AAvoid reactionAvoid cytotoxicitySkeletal/connective tissue cellsCytokineCulture mediums

The invention discloses a culture medium capable of promoting the division growth of mesenchymal stem cells, which comprises a serum-free basic culture medium and an additive added on the basis of theserum-free basic culture medium, wherein the additive comprises a hibiscus mutabilis extract, seaweed polysaccharide, astragaloside IV, human serum albumin, transferrin, glutamine, platelet-derived factor, epidermal growth factor, fibroblast growth factor, human insulin growth factor and vitamin A; the hibiscus mutabilis extract has antioxidant and cell activating activity, and can effectively promote the growth of cell metabolic by compounding seaweed polysaccharide and astragaloside IV; human serum albumin, transferrin, glutamine and vitamin A provide essential nutrient substances for the growth of stem cells; platelet-derived factor, epidermal growth factor, fibroblast growth factor, human insulin growth factor and other cytokines together promote the rapid growth and proliferation ofstem cells; the culture medium not only can improve the growth activity of mesenchymal stem cells, shorten the culture time, promote the expression of cell growth factors, but also can maintain the stem cell activity of the differentiation potential of mesenchymal stem cells; stem cells are not differentiated in daily culture, thereby providing convenience for scientific research.

Owner:嘉文丽(福建)化妆品有限公司

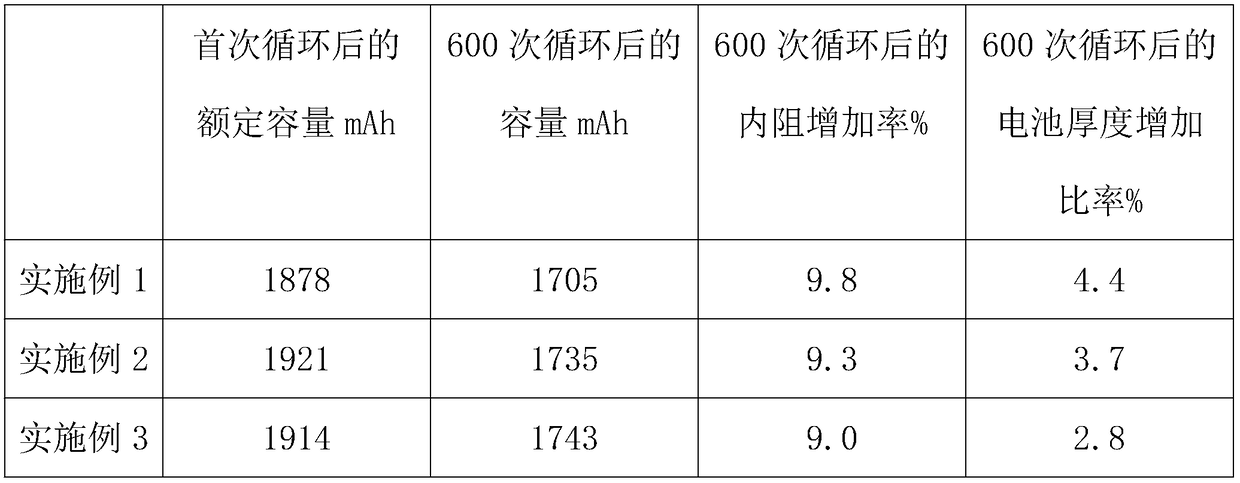

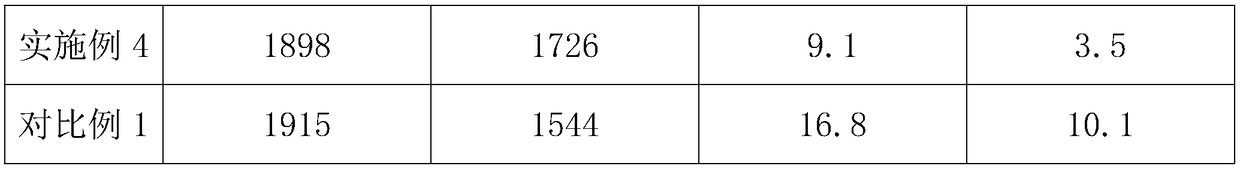

Wear-resistance medicine core composition, wear-resistance welding wire and preparation method and application thereof

ActiveCN110977248AReduce heat damageImprove brazing activityWelding/cutting media/materialsSoldering mediaLinear expansion coefficientNickel base

The invention relates to a wear-resistance medicine core composition, a wear-resistance welding wire and a preparation method and application thereof. The wear-resistance medicine core composition comprises a wear-resistance material and the balance of a filling material; the wear-resistance material is 0.6-10 wt.% of the wear-resistance medicine core composition; the wear-resistance material comprises diamond particles; the filling material comprises transition metal oxide powder and nickel base alloy powder; and the transition metal oxide powder is 12-65 wt.% of the filling material. The wear-resistance medicine core composition uses the diamond particles as wear-resistance filling materials to form wear-resistance coating layers during welding or braze coating; and transition metal oxides are used as the filling material, so that the heat loss of diamond is reduced, the brazing activity is improved, and meanwhile, the linear expansion coefficient of clad metal is reduced.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

A method for forming a long-life flexible packaging battery

ActiveCN109148991AExtend battery lifeImprove film qualityFinal product manufactureSecondary cells charging/dischargingEngineeringForming processes

Owner:江门市力源电子有限公司

Method for preparing TiCxOy and/or TiC through carbon-added hydrogen reduction

ActiveCN106744960AEfficient productionQuick responseTitanium carbideOxy/sulfo carbidesHydrogenWater vapor

The invention provides a method for preparing TiCxOy and / or TiC through carbon-added hydrogen reduction. According to the method, pure titanium dioxide or rutile is used as an initial material, hydrogen and carbon powder are used as a reducing agent and a carburizing agent, the other role of the carbon powder is to reduce oxygen partial pressure, the preparation temperature is only required to be as low as 1,200-1,350 DEG C, hydrogen and a titanium-containing raw material are subjected to a gas-solid reduction reaction in a TiCxOy and / or TiC preparation process, the reduction efficiency is high, the reduction speed is high, the carbon powder fully and uniformly mixed with the raw material and vapor produced after hydrogen reduction are subjected to a water-gas reaction, the oxygen partial pressure in a material layer is reduced, a titanium oxide reduction is promoted, the uniformly mixed carbon powder greatly improves the carbonization efficiency, the carbonization rate is high, the reduction of TiC oxide at the lower temperature is realized, energy consumption cost is saved, and the problems of high preparation temperature, low production efficiency, high cost and the like in existing TiCxOy and TiC production technologies are well solved.

Owner:CHONGQING UNIV

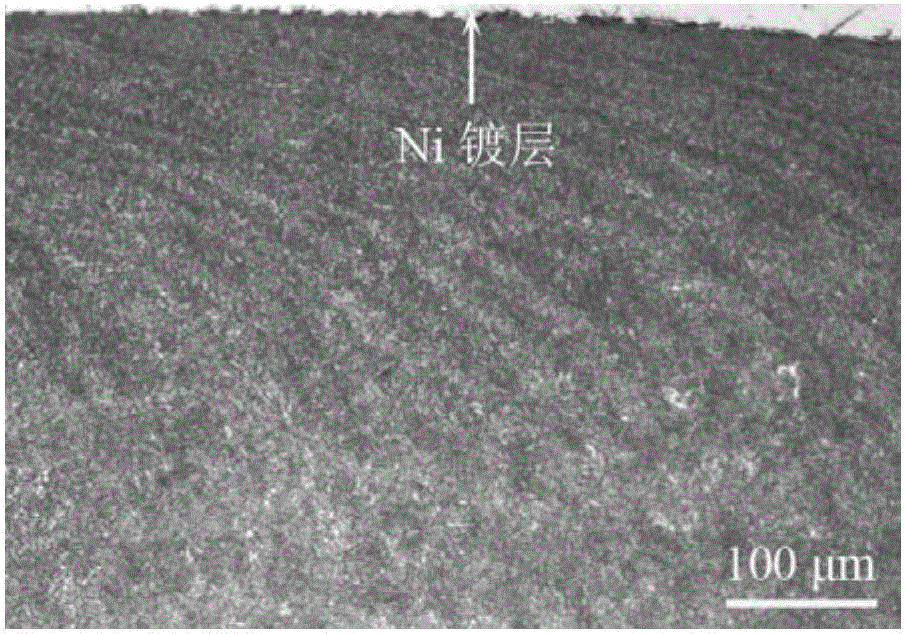

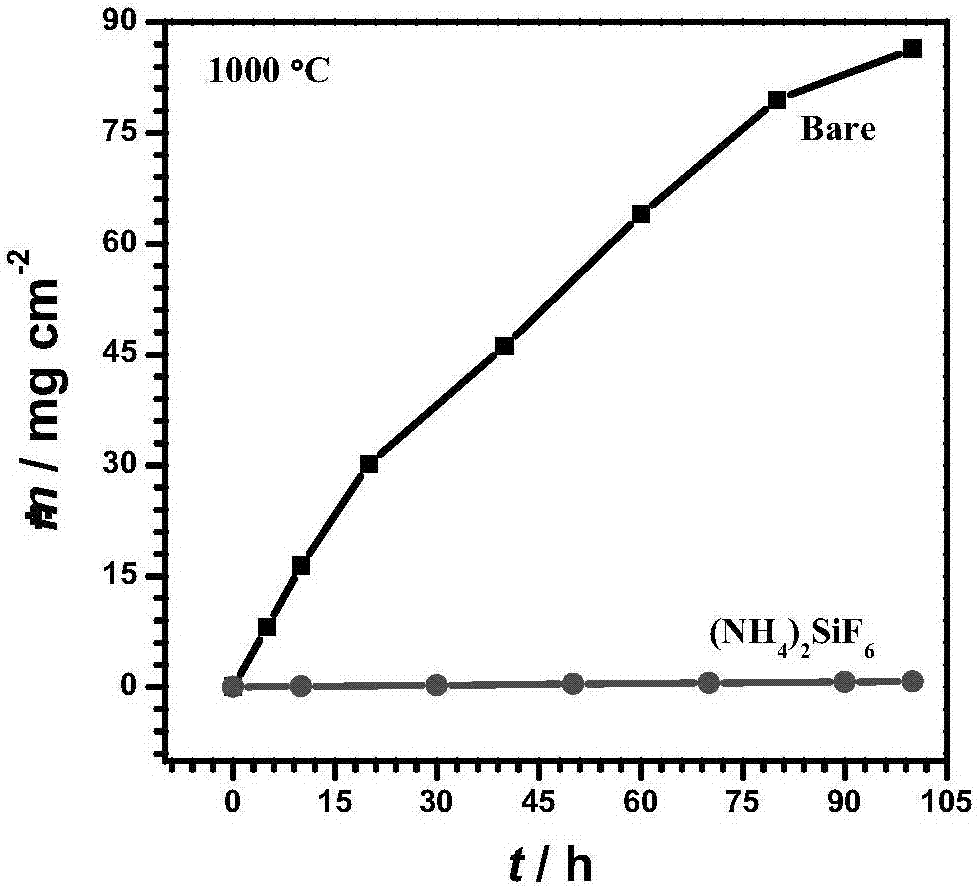

Method for improving lead bismuth alloy corrosion resistance of nuclear power structural material

The invention discloses a method for improving the lead bismuth alloy corrosion resistance of a nuclear power structural material. According to the method for improving the lead bismuth alloy corrosion resistance of the nuclear power structural material, surface treatment is conducted on the nuclear power structural material through the surface nanocrystallization technology, the surface of the nuclear power structural material is made to form a gradient nano-structure and a structure refined structural layer, the nuclear power structural material obtained after surface nanocrystallization generates a compact passivation coating with the thickness smaller than 5 [mu]m in liquid-state lead bismuth alloy, the passivation coating relieves the corrosion of the nuclear power structural material in the liquid-state lead bismuth alloy, and therefore the lead bismuth alloy corrosion resistance of the nuclear power structural material is improved. After surface treatment, the thickness of the surface gradient nanometer crystals and the structure refined structural layer of the nuclear power structural material reaches over 150[mu]m, the surface crystallite dimension is refined to be below 50 nm, and the surface roughness Ra is controlled to be below 0.3 [mu]m. After the nuclear power structural material is treated by the adoption of the method, compared with the nuclear power structural material which is not treated, the lead bismuth alloy corrosion resistance of the nuclear power structural material can be significantly improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

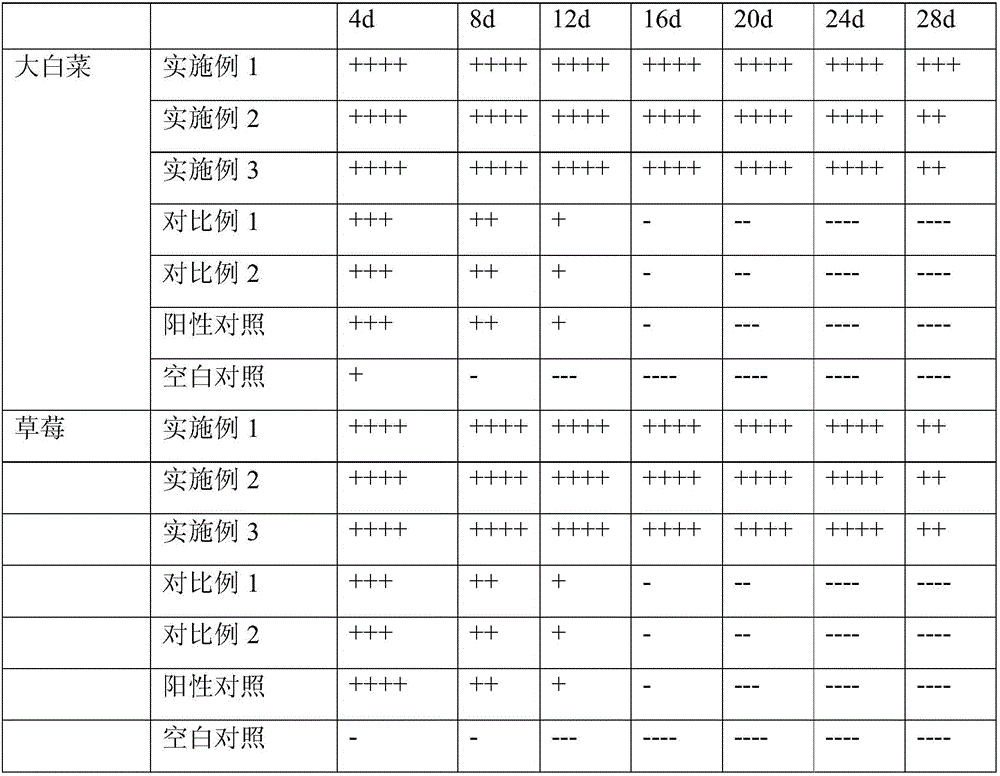

Biological fresh-keeping agent for probiotic-edible fungus mixed fermentation fruits and vegetables and preparation method of biological fresh-keeping agent

ActiveCN106509081AEasy to synthesizeGrowth inhibitionFungiFruit and vegetables preservationBiotechnologyDecomposition

The invention discloses a biological fresh-keeping agent for probiotic-edible fungus mixed fermentation fruits and vegetables. The main ingredient of the biological fresh-keeping agent is a mixed fermentation broth containing lactobacillus plantarum and cordyceps militaris, wherein the lactobacillus plantarum is CICC No.20242, and the cordyceps militaris is CICC No.14014. The invention further discloses a preparation method and application of the biological fresh-keeping agent for probiotic-edible fungus mixed fermentation fruits. The biological fresh-keeping agent has the characteristics of safety and high efficiency, is safe, nutritional and free from chemical pollution, has advantages of environmental friendliness, outstanding biocontrol efficacy and the like, is capable of obviously reducing fruit and vegetable decomposition, preventing oxidation stain, retarding softening and flavor reversion and reducing application of chemical fungicides, and has great significance in food safety, environmental protection, improvement of agricultural profits and agricultural efficiency, sustainable development and the like.

Owner:重庆市涪陵区洪丽食品有限责任公司

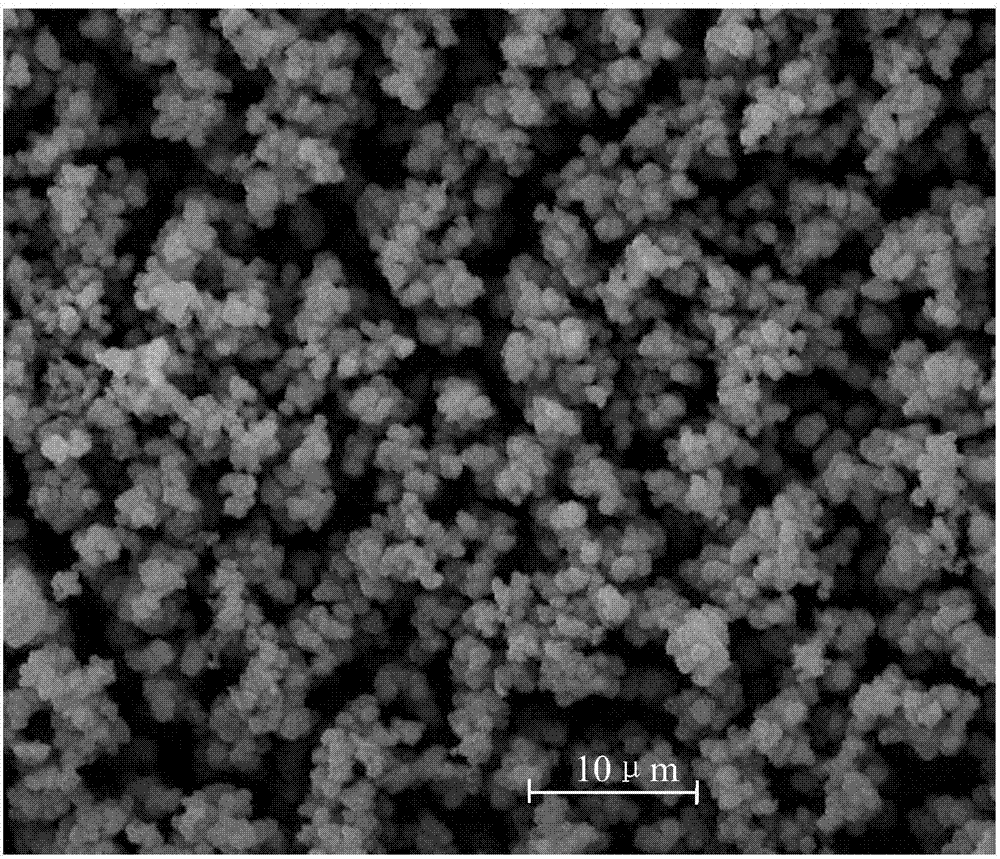

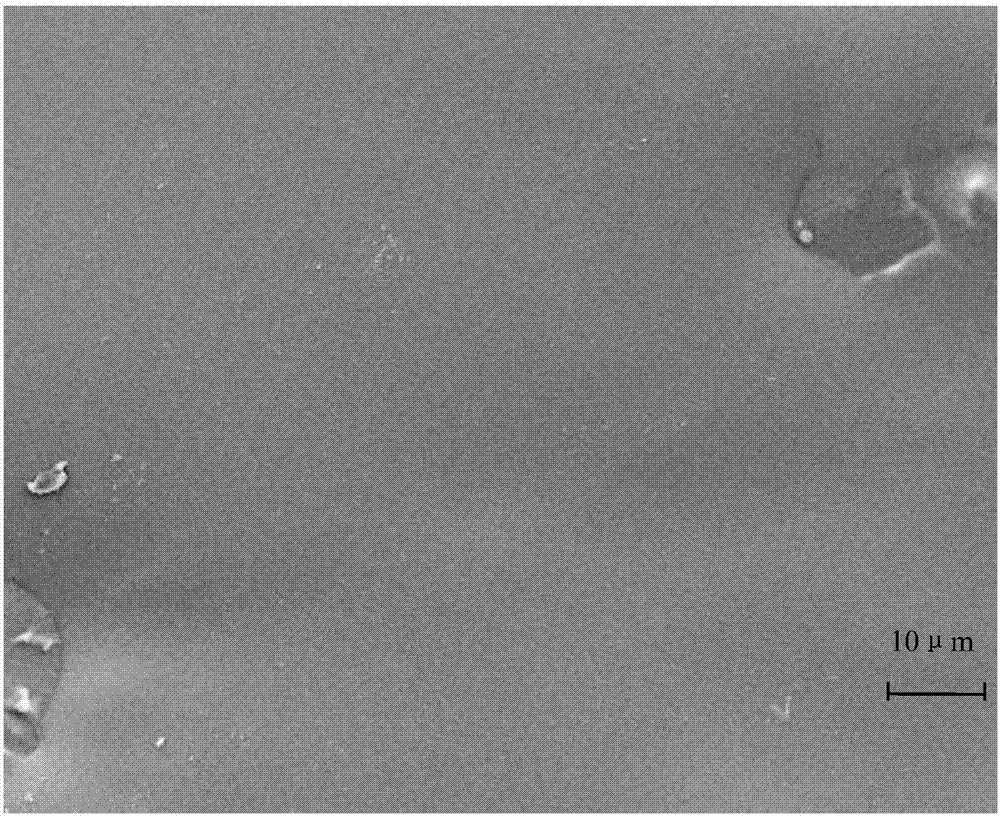

Method for improving high temperature oxidation resistance of titanium-based alloy on basis of halide effect and ceramic coating obtained through pretreatment

ActiveCN106906505ASimple preparation processEasy to operateElectrolytic inorganic material coatingMicro nanoOxidation resistant

A method for improving the high temperature oxidation resistance of titanium-based alloy on the basis of a halide effect and a ceramic coating obtained through pretreatment includes the following steps that (1) surface oxides of a titanium-based alloy substrate are removed at first, and then cleaning and drying are carried out; (2) ammonium acetate, ammonium chloride, fluosilicate and water are mixed and stirred at the room temperature for 2-48 h, and a precursor solution is obtained; (3) the prepared precursor solution is added into a three-electrode cell, electro-deposition is carried out by taking the titanium-based alloy substrate as a working electrode, taking a platinum sheet or graphite as a counter electrode and taking an Ag / AgCl electrode as a reference electrode, and a fluorine-containing micro-nano SiO2 coating is obtained; and (4) the titanium-based alloy with the surface provided with the fluorine-containing micro-nano SiO2 coating is subjected to heat treatment in a gas mixture of argon and oxygen, and the high temperature oxidation resistance composite coating of the titanium-based alloy is obtained. According to the method, the preparation process is simple, excellent binding force between the obtained coating and the substrate is achieved, and the high temperature oxidation resistance of the titanium-based alloy can be remarkably improved.

Owner:ZHEJIANG UNIV OF TECH

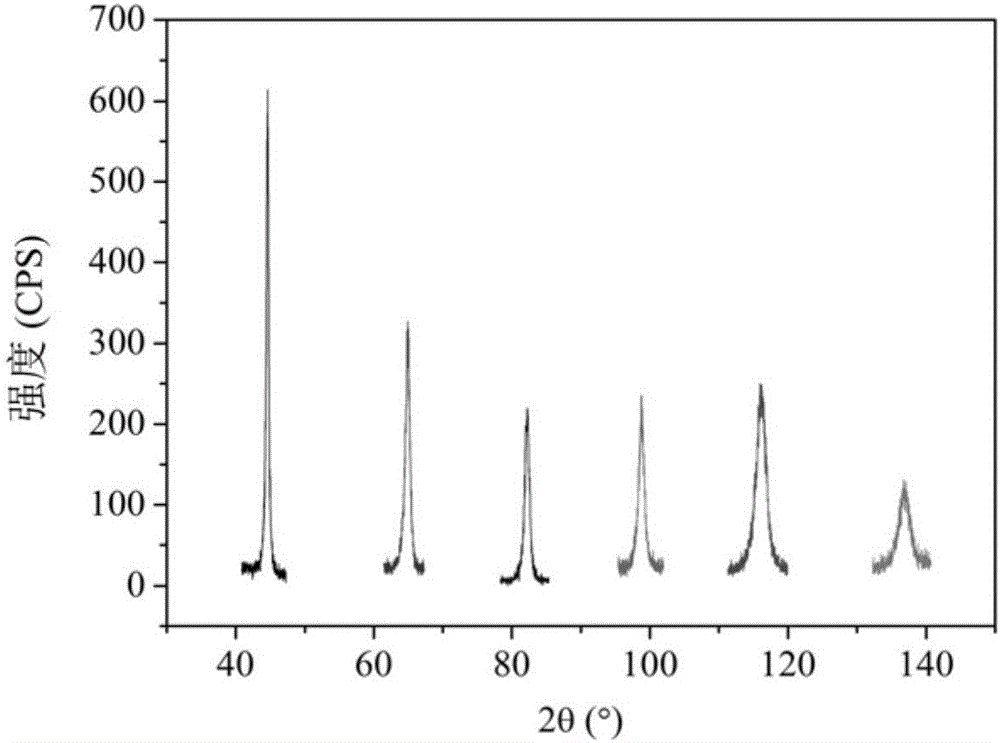

Manufacturing method of target material assembly

InactiveCN111041431AImprove bindingLower oxygen partial pressureMolten spray coatingSoldering apparatusWorking environmentSemiconductor

The invention provides a manufacturing method of a target material assembly. The method comprises the steps: providing a silicon dioxide target material and a metal back plate, wherein the silicon dioxide target material is provided with a target material welding face, and the metal back plate is provided with a back plate welding face; forming a nickel layer on the welding surface of the silicondioxide target material by adopting a plasma spraying process; and welding the nickel layer which locates on the welding surface of the silicon dioxide target material on the welding surface of the metal back plate to form the target material assembly. The method achieves welding between the silicon dioxide target material and the metal back plate, is suitable for the working environment with thehigh temperature, helps to improve the welding bonding rate and bonding strength between the silicon dioxide target material and the metal back plate, and meanwhile, meets the using requirement of thesemiconductor sputtering target material at the high temperature.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

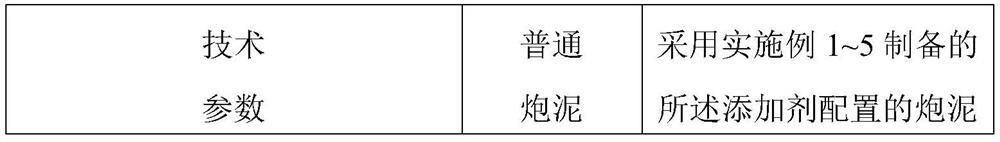

Additive for anhydrous stemming and preparation method thereof

ActiveCN111704472ACause potential harmAvoid the problem of high carcinogen benzopyreneProcess efficiency improvementPhysical chemistryCarbide

The invention relates to an additive for anhydrous stemming and a preparation method thereof. The preparation method comprises the following steps: preparing following raw materials in percentage by weight at first: 35 to 55 wt% of andalusite fine powder; 10-30 wt% of kyanite fine powder, 6-16 wt% of titanium oxide fine powder, 5-15 wt% of silicon oxynitride fine powder, 3-7 wt% of titanium aluminum carbide fine powder, 3-7 wt% of earthy graphite fine powder, 1-3 wt% of simple substance silicon fine powder, 2-5 wt% of bentonite fine powder and 2-5 wt% of nickel oxide fine powder; adding 0.5-2.5 wt% of polypropylene fibers and 7-15 wt% of cobalt modified phenolic resin fine powder into the raw materials, and mixing in a mixer for 20-30 minutes to obtain the additive for anhydrous stemming,wherein the Al2O3 content of the andalusite fine powder is more than 52 wt%, the particle size of the andalusite fine powder is less than 75 [mu]m; the Al2O3 content of the kyanite fine powder is larger than 54 wt%, and the particle size of the kyanite fine powder is smaller than 45 [mu]m. The prepared additive for the anhydrous stemming does not pollute the environment, and can obviously improvethe strength, the volume stability, the oxidation resistance and the erosion resistance of the anhydrous stemming.

Owner:湖南立达高新材料有限公司 +1

Electrically calcined coal-based carbon brick with high thermal conductivity and high corrosion resistance and preparation method thereof

ActiveCN108002854AImprove the degree of graphitizationReduce manufacturing costCeramicwareAir atmosphereBrick

The invention relates to an electrically calcined coal-based carbon brick with high thermal conductivity and high corrosion resistance and a preparation method thereof. According to the technical scheme, 8 to 16wt% of microwave treated electrically calcined coal fine powder, 10 to 25wt% of alpha-Al2O3 micro powder, 4 to 8wt% of silicon powder, 1 to 4wt% of aluminum titanium alloy powder and 2 to 4wt% of high temperature pitch are used as substrates, 50 to 65wt% of microwave treated electrically calcined coal particles are used as aggregate, and thermoset phenolic resin accounting for 10-20wt%of the sum of the substrates and the aggregate is additionally added. The preparation method comprises the following steps: mixing the substrates to obtain substrate fine powder; then putting the aggregate into a mixing mill and performing mixed milling, then adding the thermoset phenolic resin and performing mixed milling; finally adding the substrate fine powder and performing mixed milling; andperforming moulding and drying to obtain green bodies of carbon bricks. The surfaces of the green bodies of the carbon bricks are uniformly sprayed or brushed with a layer of slurry and dried, and the green bodies of the carbon bricks are subjected to thermal insulation in an air atmosphere at 1,150 to 1,250 DEG C for 12 to 24h, thereby obtaining the electrically calcined coal-based carbon brickwith high thermal conductivity and high corrosion resistance. The electrically calcined coal-based carbon brick has the advantage of low cost and is easy to industrially produce, and the prepared products have high strength, high thermal conductivity and excellent property of resisting corrosion of liquid iron.

Owner:WUHAN UNIV OF SCI & TECH

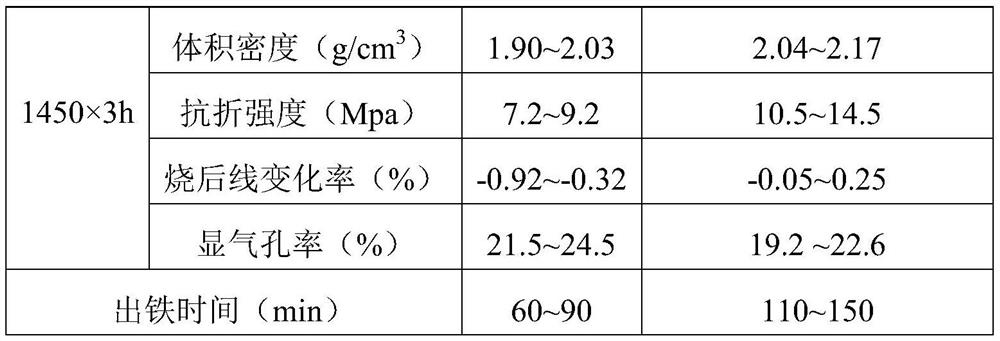

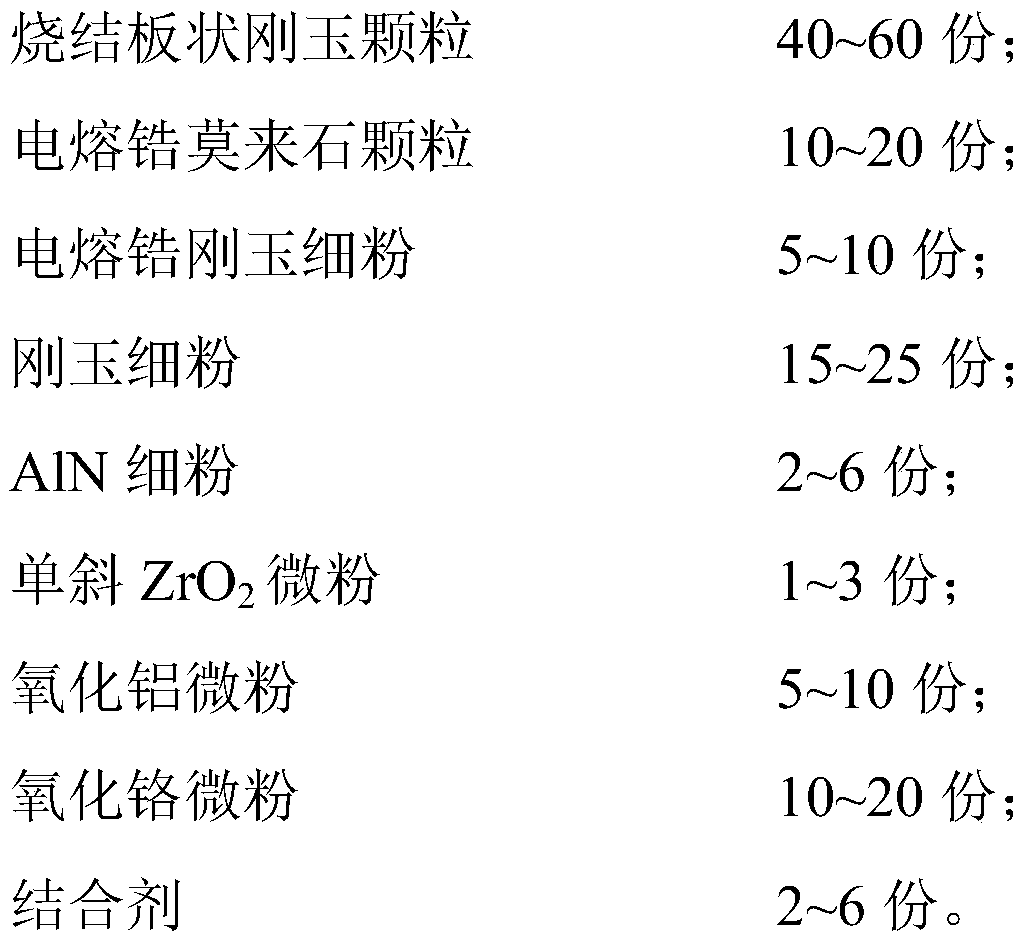

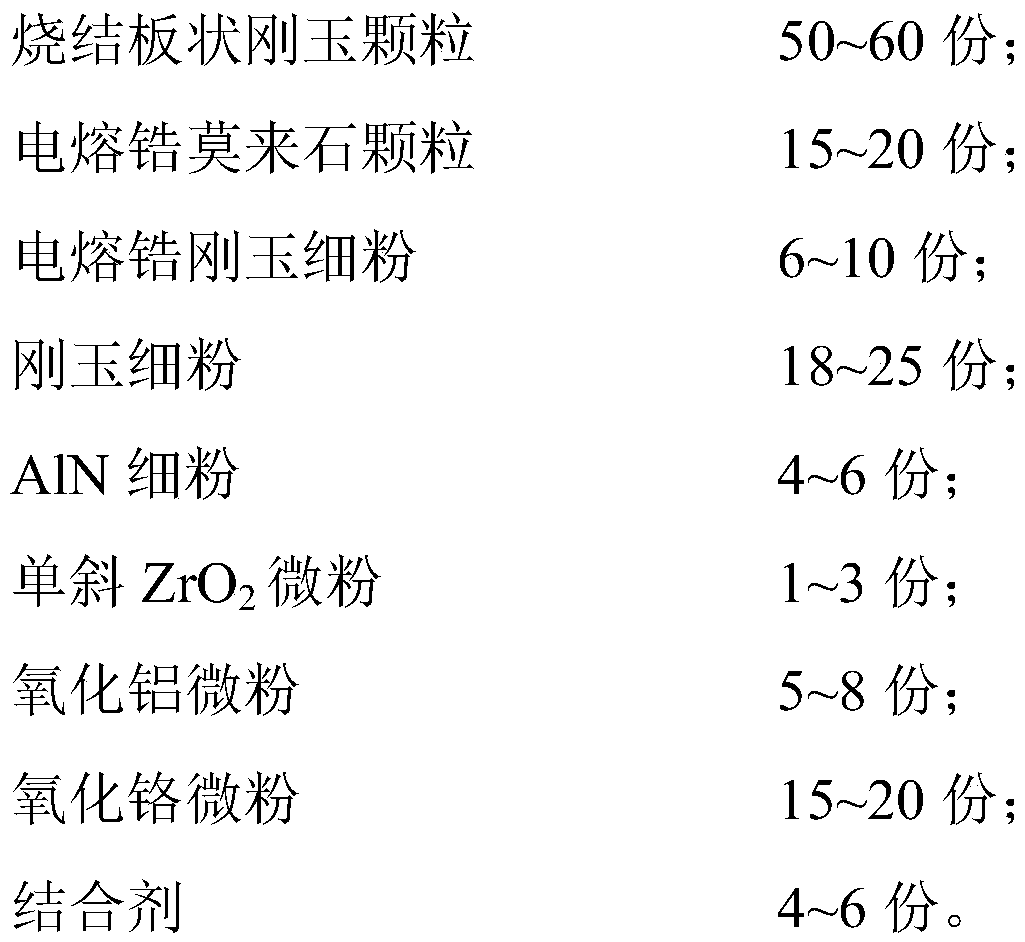

Sintered aluminum-chromium-zirconium sliding plate brick for copper smelting anode furnace and preparation method of sintered aluminum-chromium-zirconium sliding plate brick

The invention provides a sintered aluminum-chromium-zirconium sliding plate brick for a copper smelting anode furnace and a preparation method of the sintered aluminum-chromium-zirconium sliding platebrick. The sintered aluminum-chromium-zirconium sliding plate brick comprises the raw materials in parts by mass: 40 to 60 parts of sintered tabular corundum particles, 10 to 20 parts of fused zirconium mullite particles, 5 to 10 parts of fused zirconia corundum fine powder, 15 to 25 parts of corundum fine powder, 2 to 6 parts of AlN fine powder, 1 to 3 parts of monoclinic ZrO2 micro powder, 5 to10 parts of alumina micro powder, 10 to 20 parts of chromium oxide micro powder, and 2 to 6 parts of a binding agent. A raw material composition system of the sliding plate brick does not contain carbon, and the problem of oxidation or galling of the plate surface of the sliding plate brick in the using process is solved; meanwhile, the AlN fine powder is introduced into the material matrix, andNO, NO2 and other gas phases are formed through oxidation in the high-temperature firing process; sintering of Cr2O3 in the material matrix is promoted; and an Al2O3 phase with quite high activity isformed in the material matrix in the oxidation process and reacts with ZrO2, Cr2O3 and the like in the raw materials to form Al2O3-ZrO2 and Al2O3-Cr2O3 solid solutions, so that the sliding plate brickhas excellent corrosion resistance and permeability of copper liquid and molten slag (FeO, SiO2 and the like).

Owner:ZHEJIANG ZILI HIGH TEMPERATURE TECH CO LTD

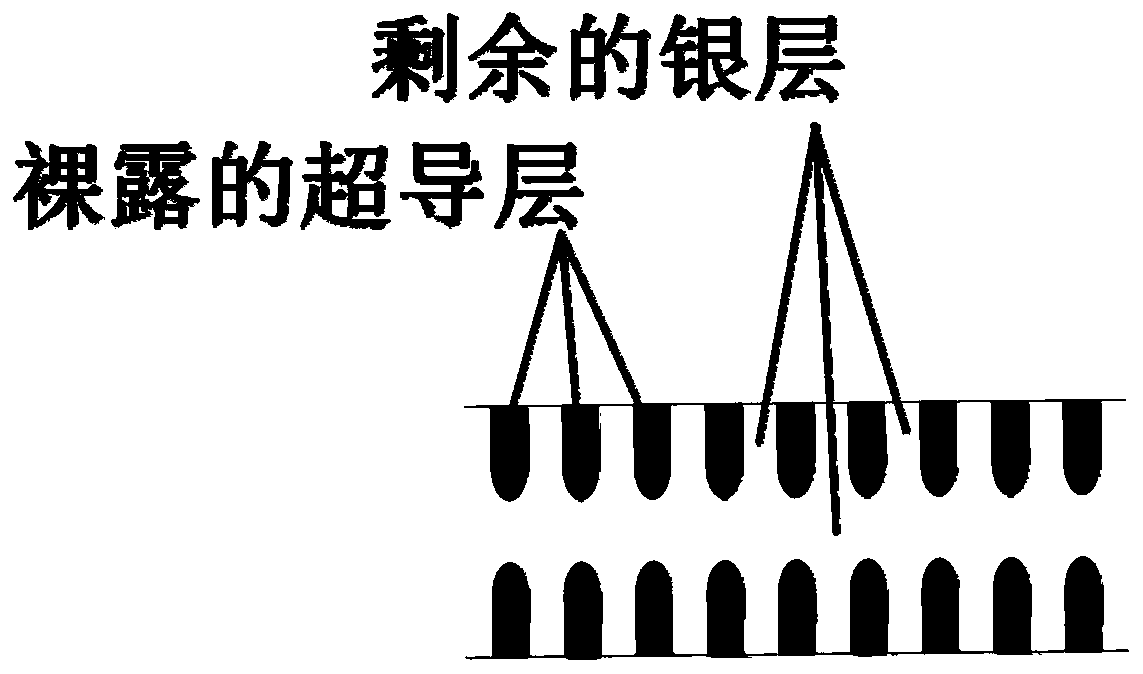

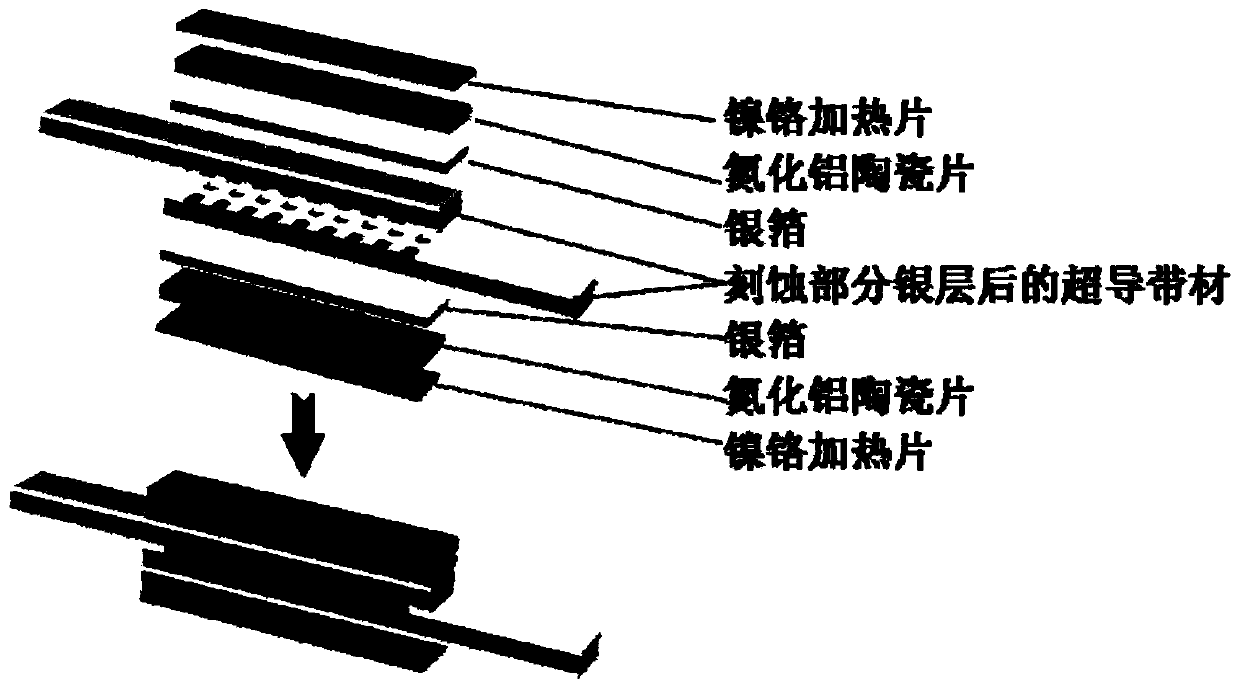

Connecting method of second-generation high-temperature superconducting tape and superconducting wire

ActiveCN111106453AHigh mechanical strengthAchieve connectionSuperconductors/hyperconductorsSoldered/welded conductive connectionsOvercurrentLap joint

The invention relates to a connecting method of a second-generation high-temperature superconducting tape and a superconducting wire. The connecting method comprises the following steps: removing a protection layer: removing a silver layer of a part of a to-be-connected region of the second-generation high-temperature superconducting tape, and enabling the remaining silver layer and the exposed superconducting layer to be distributed at intervals; carrying out silver layer diffusion welding: making every two to-be-connected regions of at least two second-generation high-temperature superconducting tapes processed through the protection layer removing step in lap joint to form a lap joint area, making the remaining silver layers make contact in an overlapped mode, then, clamping the lap joint areas, and carrying out diffusion welding on the silver layers; performing fusion diffusion welding on the superconducting layer; and carrying out superconductivity recovery. According to the method, the structure of the superconducting layer is not damaged, meanwhile, an oxygen diffusion channel can be provided; the prepared superconducting joint has the superconducting characteristic in a liquid nitrogen temperature zone and also has high mechanical strength, and meanwhile, current can pass through the residual silver layer, so that the superconducting joint further has certain quench protection capacity.

Owner:EASTERN SUPERCONDUCTOR SCI & TECH SUZHOU CO LTD +1

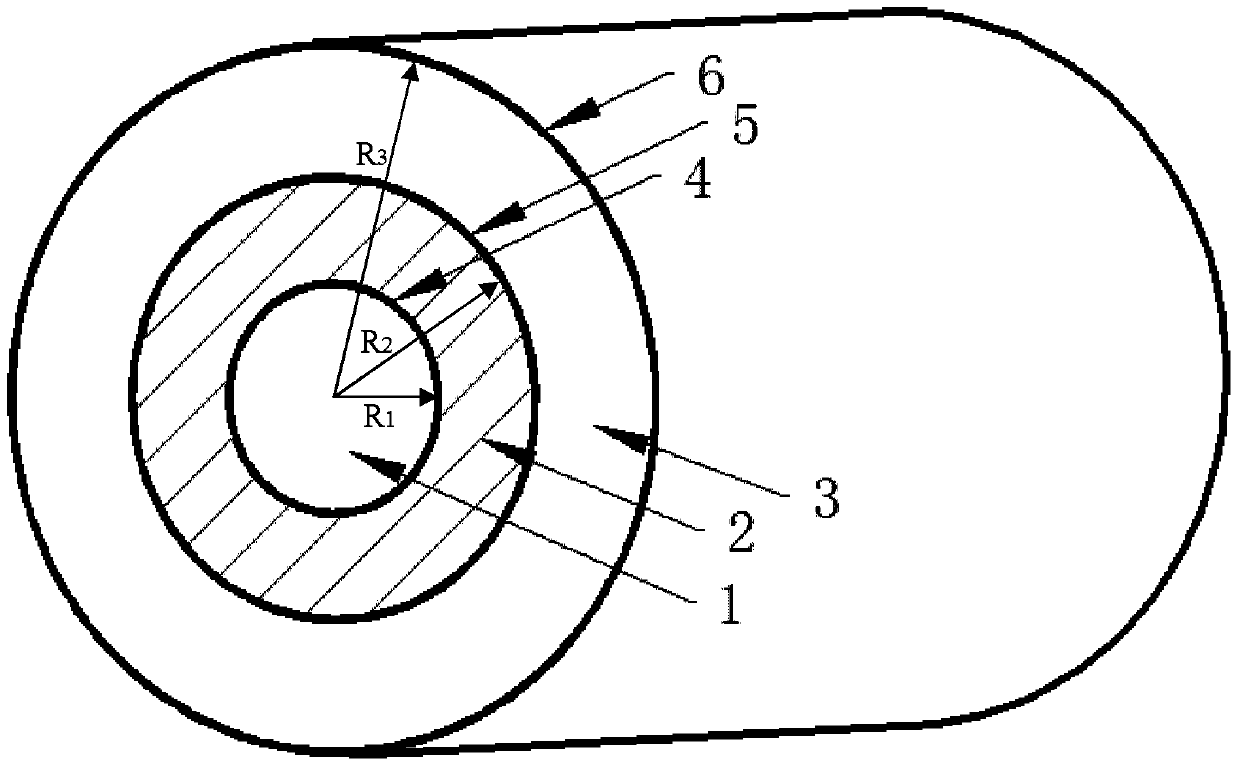

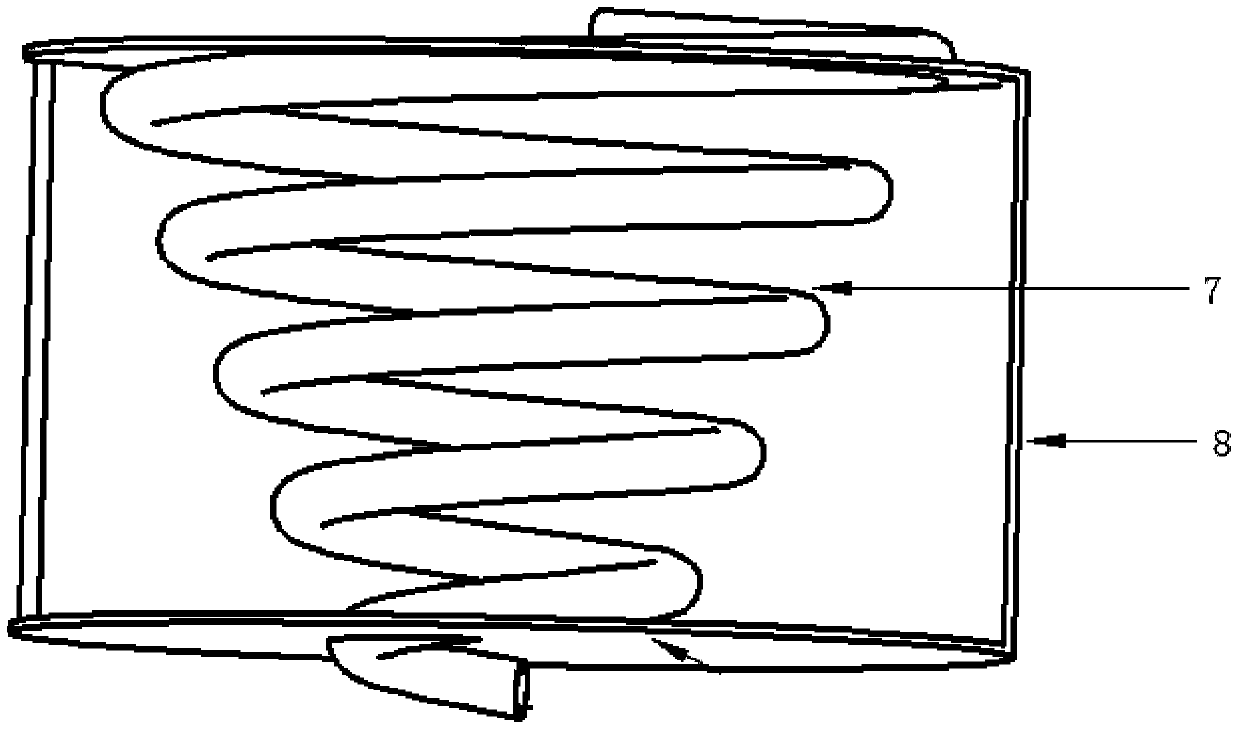

Device for preparing hydrogen gas by decomposing water through synergic action of oxygen-permeable membrane and hydrogen-permeable membrane

InactiveCN104192795AShorten the lengthImprove hydrogen production efficiencyHydrogen productionWater vaporDecomposition

The invention provides a device for preparing hydrogen gas by decomposing water through synergic action of an oxygen-permeable membrane and a hydrogen-permeable membrane, which comprises a reaction chamber a vapor chamber, a hydrogen-permeable chamber and an oxygen-permeable chamber, wherein the reaction chamber is used for providing working temperature required for reaction; the vapor chamber is positioned in the reaction chamber and used for introducing water vapor; the hydrogen-permeable chamber and the oxygen-permeable chamber are positioned in the reaction chamber at both sides of the vapor chamber; the hydrogen-permeable chamber is separated from the vapor chamber by a casing made of a hydrogen-permeable membrane material; the oxygen-permeable chamber is separated from the vapor chamber by a casing made of an oxygen-permeable membrane material; a first chemical potential difference exists between the hydrogen-permeable chamber and the vapor chamber; a second chemical potential difference exists between the oxygen-permeable chamber and the vapor chamber; and oxygen gas / hydrogen gas produced by decomposition of the water vapor in the vapor chamber permeates through the corresponding casing under the action of the chemical potential difference and enters the corresponding chamber. According to the invention, under the synergetic action of the oxygen-permeable membrane and the hydrogen-permeable membrane, hydrogen permeation and oxygen permeation are mutually promoted, and the hydrogen production efficiency is greatly improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

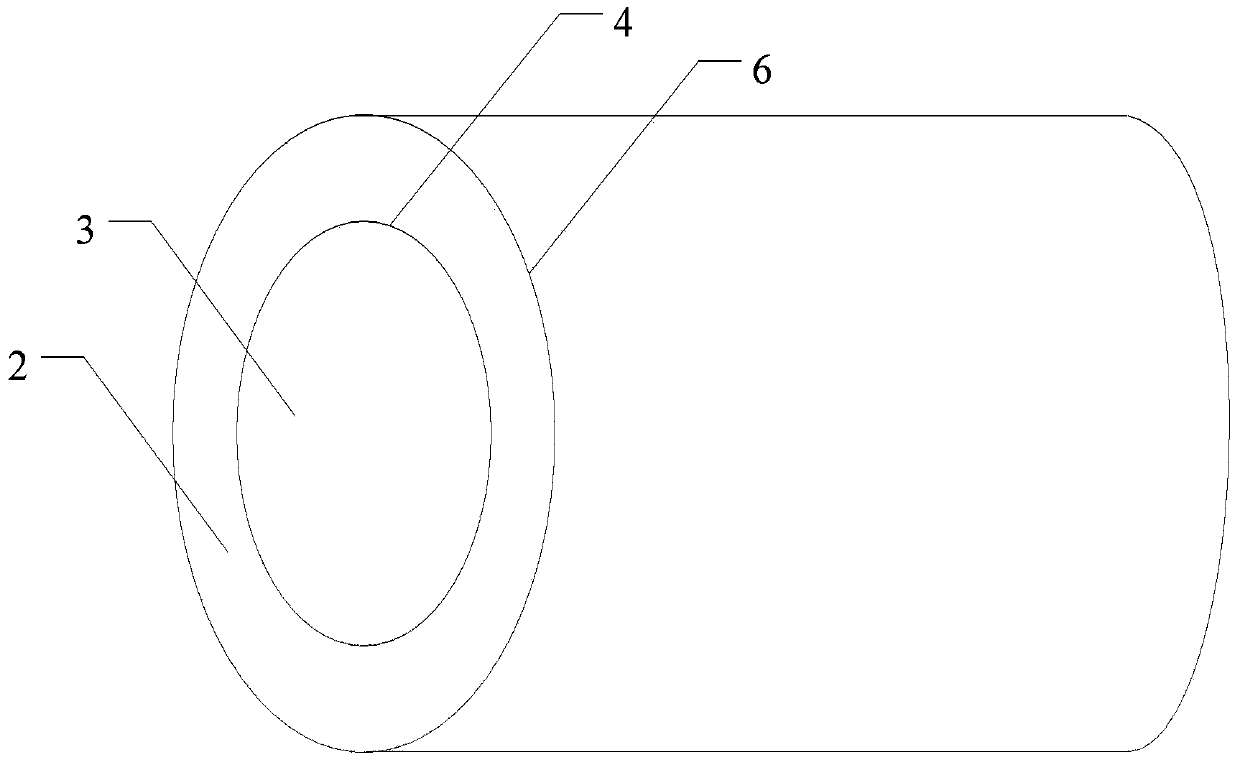

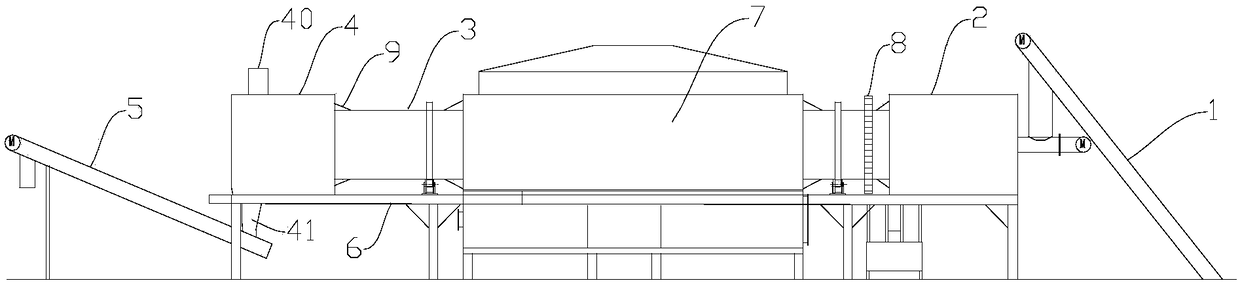

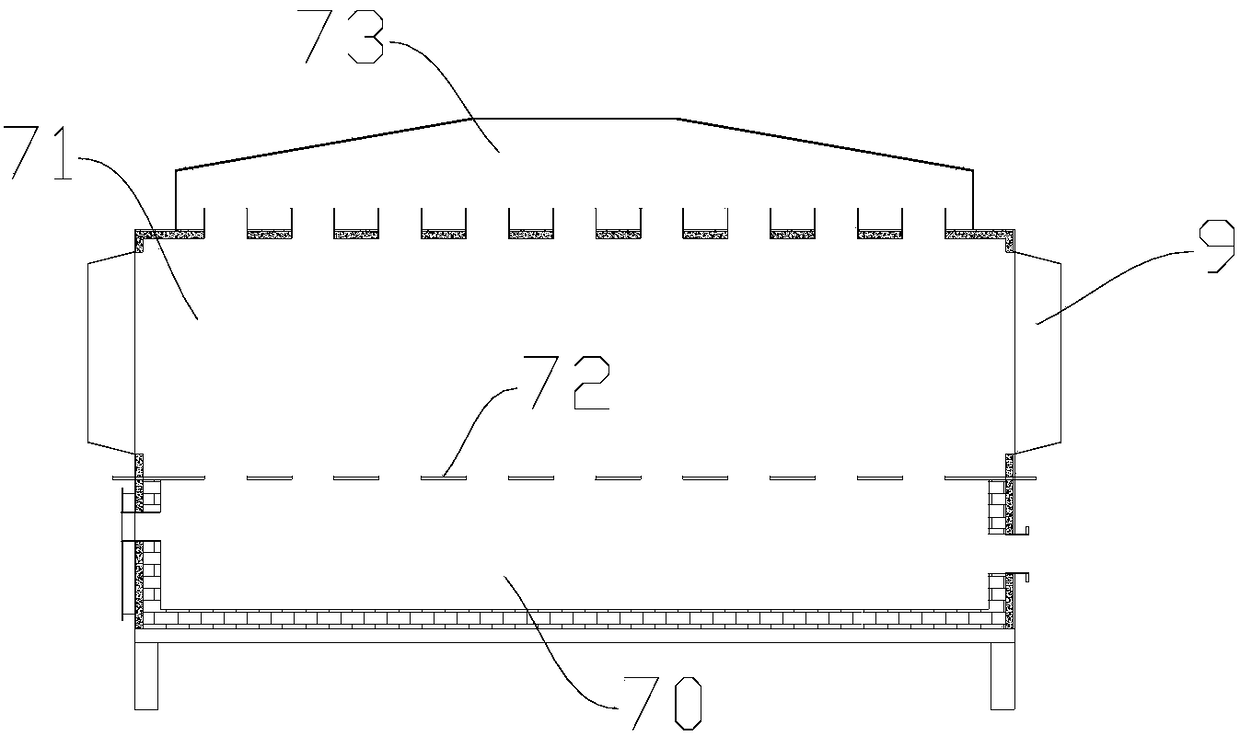

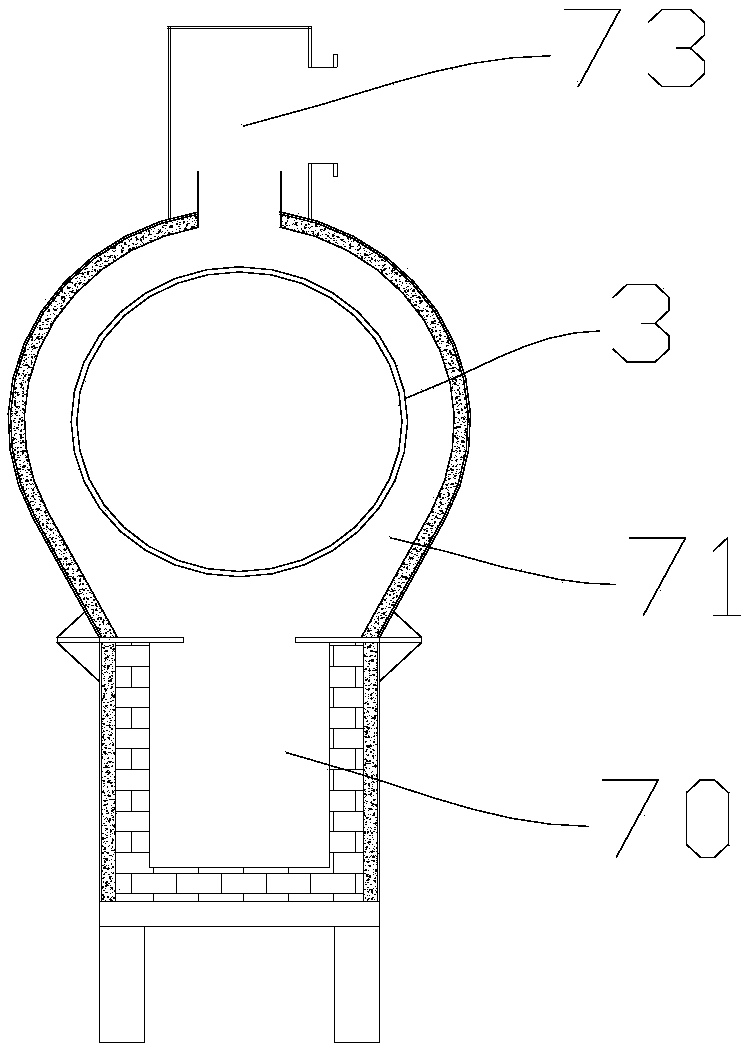

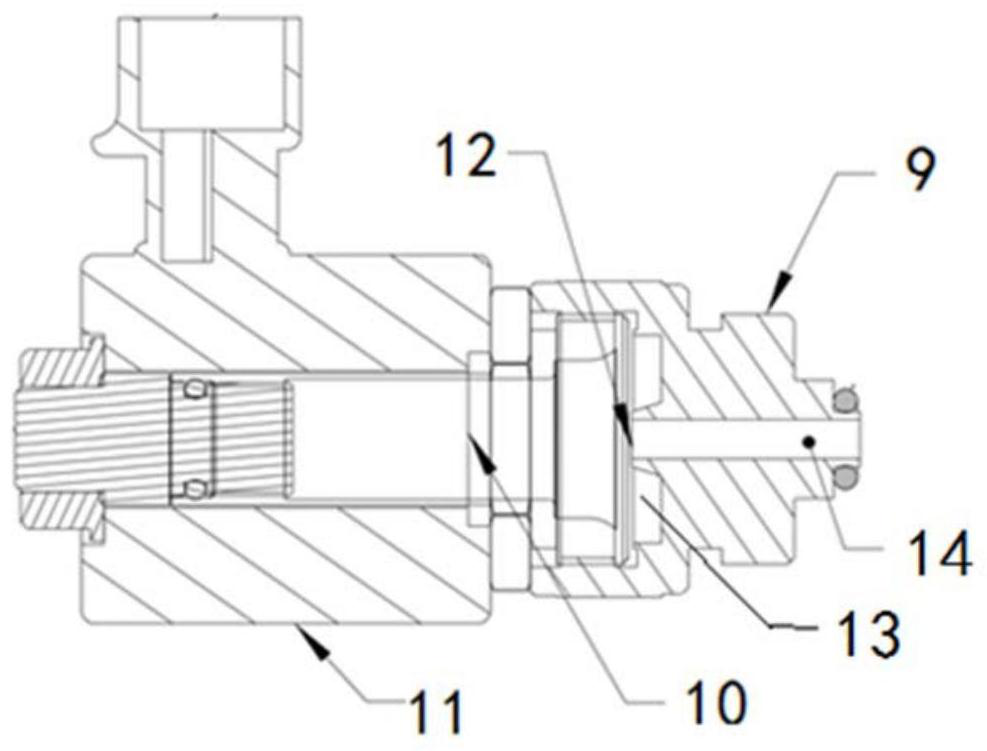

Sealing pyrolyzing furnace achieving continuous feeding and discharging

PendingCN108441241ALower oxygen partial pressureSmooth pyrolysisProductsReagentsCombustion chamberContinuous feeding

The invention relates to a sealing pyrolyzing furnace achieving continuous feeding and discharging. The furnace comprises a screw feeder, a feeding bin, a pyrolyzing furnace cylinder, a discharging bin and a screw discharge bin which are sequentially connected in the material conveying direction, the feeding bin and the discharge bin are fixedly arranged on a rack, the pyrolyzing furnace cylinderis supported on the upper portion of the rack through multiple rollers, the outer wall of the pyrolyzing furnace cylinder is sleeved with a gear ring, the rack is provided with a driving mechanism driving the pyrolyzing furnace cylinder to rotate along the central axis through the gear ring, one end of the pyrolyzing furnace is communicated with the feeding bin, the other end of the pyrolyzing furnace is communicated with the discharge bin, a heating pyrolyzing mechanism is arranged in the middle of the pyrolyzing furnace and comprises a combustion chamber located on the lower portion and a pyrolyzing chamber located on the upper portion, openings allowing the pyrolyzing furnace to penetrate through are formed in the left side and the right side of the pyrolyzing chamber, and elastic sealing structures preventing air leakage are arranged on the joints of the pyrolyzing furnace cylinder and the feeding bin, the discharge bin and the pyrolyzing chamber. The sealing pyrolyzing furnace hasthe advantages that the structure is reasonable, continuous feeding and discharging can be achieved, the sealing effect is good, the safety is good, and the pyrolyzing efficiency is high.

Owner:湖北春阳环保装备有限公司

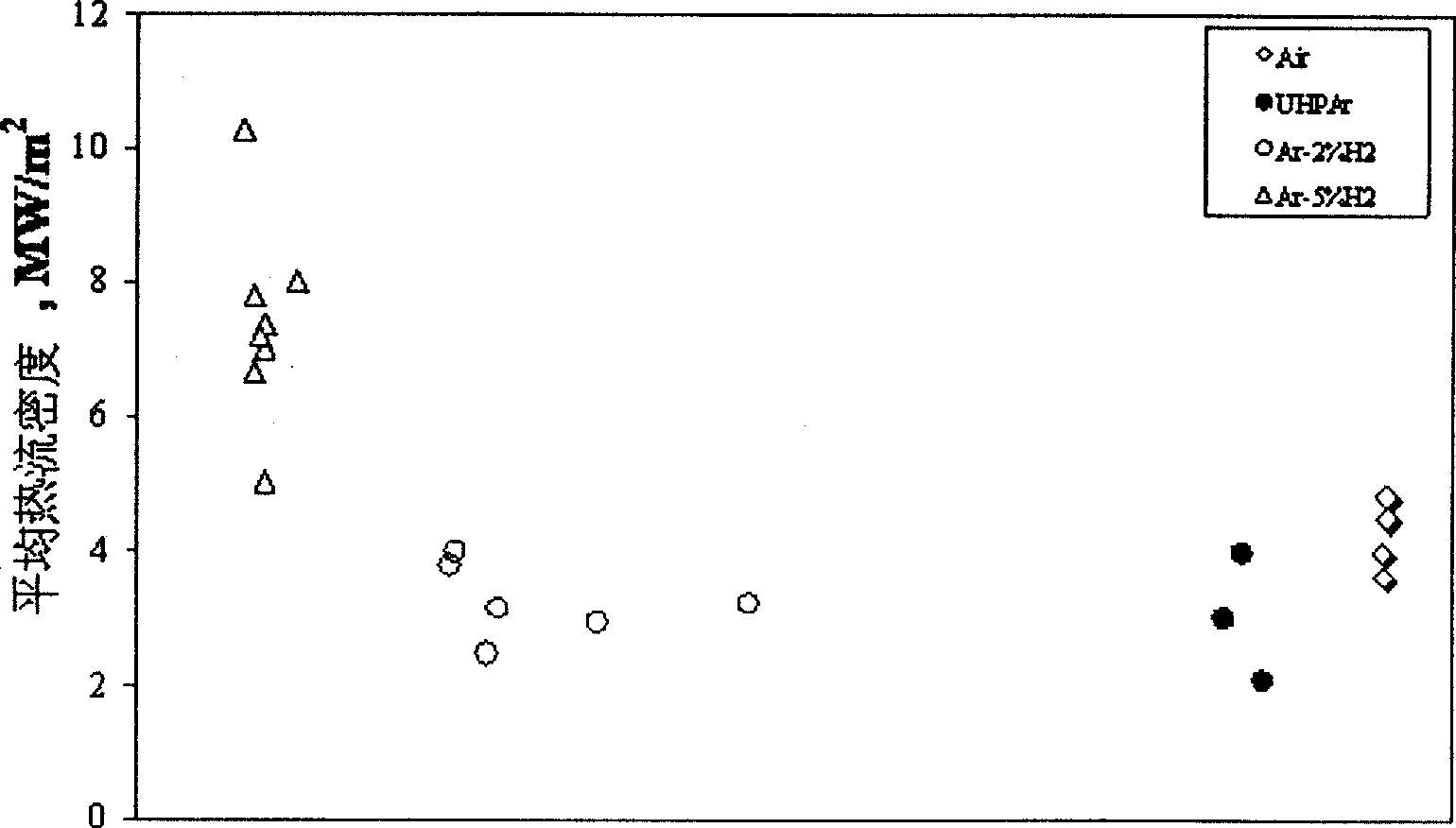

Method for continuously casting sheet band by dual roller

ActiveCN100493745CReduce subcoolingChange the solidification conditionsMetal rolling arrangementsHydrogenContact time

The invention discloses a double- roller sheet band continuous casting method. It induces mixture gas of argon gas and hydrogen into molten steel, reasonably controls the ratio of mixture gas to decrease oxygen partial pressure. Thus, the condensate depression of molten steel is decreased, and molten steel curing condition is altered, molten steel and crystal roller contacting time are increased. It improves producing efficiency. It also decreases the surface roughness of casting band and improves equal-axial crystal ratio, refines crystal grain.

Owner:BAOSHAN IRON & STEEL CO LTD

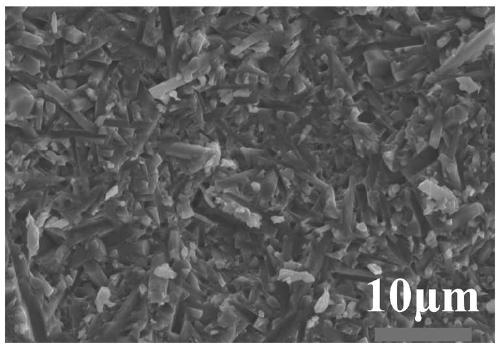

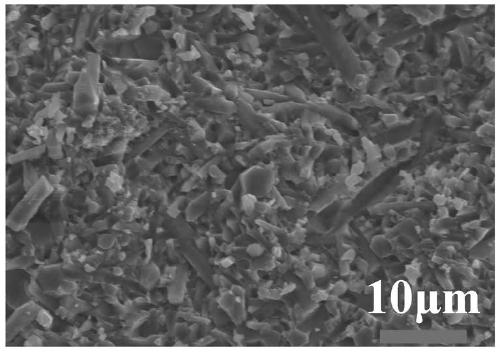

High-thermal-conductivity silicon nitride ceramic material and preparation method thereof

ActiveCN111196727APromote densificationHigh thermal conductivityMetallic hydrogenAlkaline earth oxides

The invention relates to a high-thermal-conductivity silicon nitride ceramic material and a preparation method thereof. The silicon nitride ceramic material is prepared from the following raw materials: alpha-Si3N4 and a sintering aid, wherein the sintering aid is metal hydride and alkaline earth metal oxide, and the total content of the sintering aid is 5-20wt%; the metal hydride is TiH2; and thealkaline earth metal oxide is preferably MgO.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

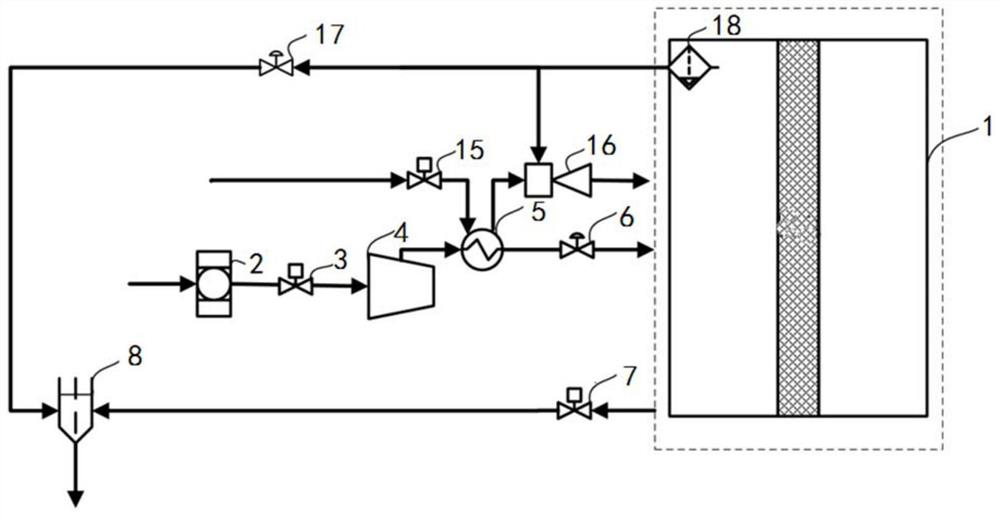

Quick cold start system and quick cold start method for fuel cell

PendingCN111682243ALower oxygen partial pressureIncrease concentration overpotentialFuel cell heat exchangeAutomotive engineeringIntercooler

The invention relates to a rapid cold start system and a rapid cold start method for a fuel cell. The system comprises a controller, and an air subsystem and a hydrogen subsystem which are respectively connected with an electric pile; the air subsystem comprises a back pressure valve, an air filter, an air compressor, an intercooler and an air inlet stop valve, wherein the air filter, the air compressor, the intercooler and the air inlet stop valve are sequentially connected. The air subsystem further comprises an air inlet adjusting valve, the air inlet adjusting valve is connected with the air filter and the air compressor, and the controller controls the air inlet adjusting valve. The method comprises the steps that the controller controls the opening degree of the air inlet adjusting valve, so the excess air coefficient is controlled to reduce the external output efficiency of the fuel cell; meanwhile, the compression ratio of the air compressor is adjusted, and the power consumption of the air compressor is increased to increase the air inlet temperature. Compared with the prior art, the method can achieve the rapid cold starting without auxiliary preheating and the success rate of cold starting.

Owner:TONGJI UNIV

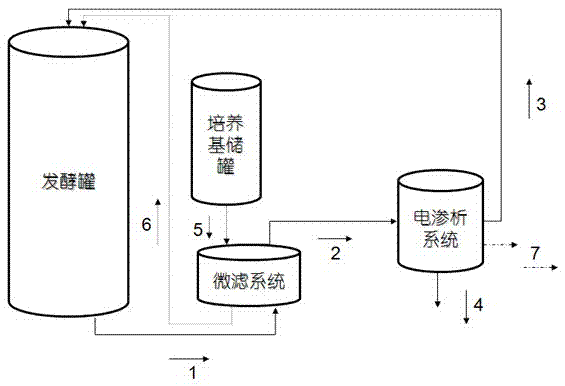

Method and device for producing 1,3-propylene glycol by utilizing microbial conversion

ActiveCN106957877AMaintain osmotic pressureSuitable osmotic pressureBioreactor/fermenter combinationsBiological substance pretreatmentsFiltration membraneMicrobial transformation

The invention relates to a method for producing 1,3-propylene glycol by utilizing microbial conversion. The method comprises the following steps: (1) performing micro-aerobic culture, thereby acquiring a fermented culture solution; (2) performing anaerobic fermentation, discharging 10%-20% of fermentation liquor into a microfiltration system when the conductivity is above 14mS / cm, guiding the microfiltration liquid into an electrodialysis system, and flowing back to a fermentation tank when the conductivity is 2-9mS / cm; (3) ending the microfiltration, backwashing a micro-filtration membrane with a culture medium of which the volume is 1%-3% of the volume of the fermentation liquor and then injecting into the fermentation tank; and (4) discharging the fermentation liquor of which the volume is 60%-80% of the volume of the fermenting tank into the microfiltration system when the concentration of 1,3-propylene glycol in the fermentation liquor is above 90g / L, guiding the microfiltration liquid into the electrodialysis system, reducing the conductivity to 0.1mS / cm, recovering the clear liquid, adding the culture medium of which the volume is 50%-80% of the volume of the original fermentation liquor and fermenting for the next time. The continuous fermentation system according to the invention can prolong the fermentation stable period and maintain higher production strength by reducing the inhibiting effect of the byproduct of the system.

Owner:CHINA PETROLEUM & CHEM CORP +1

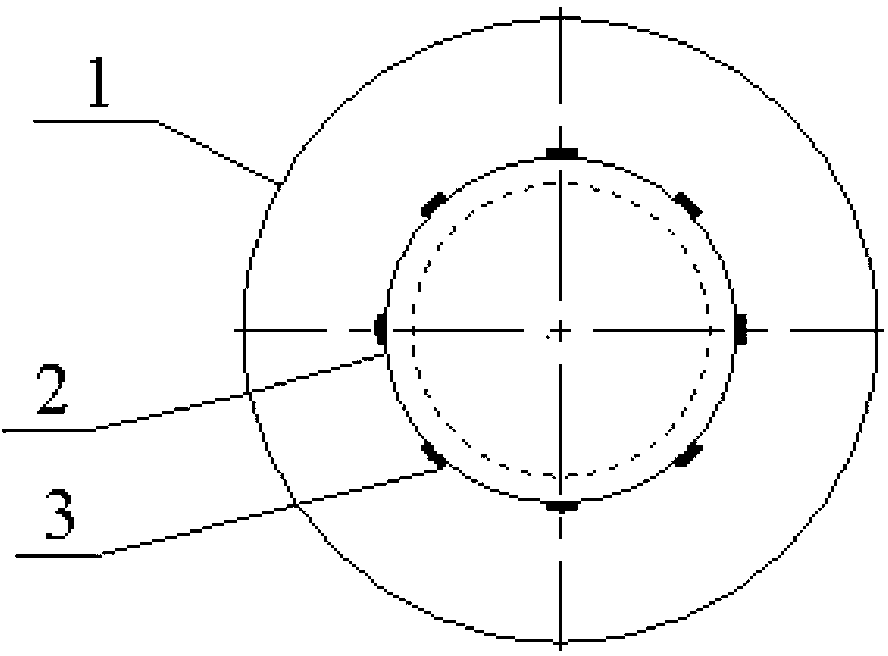

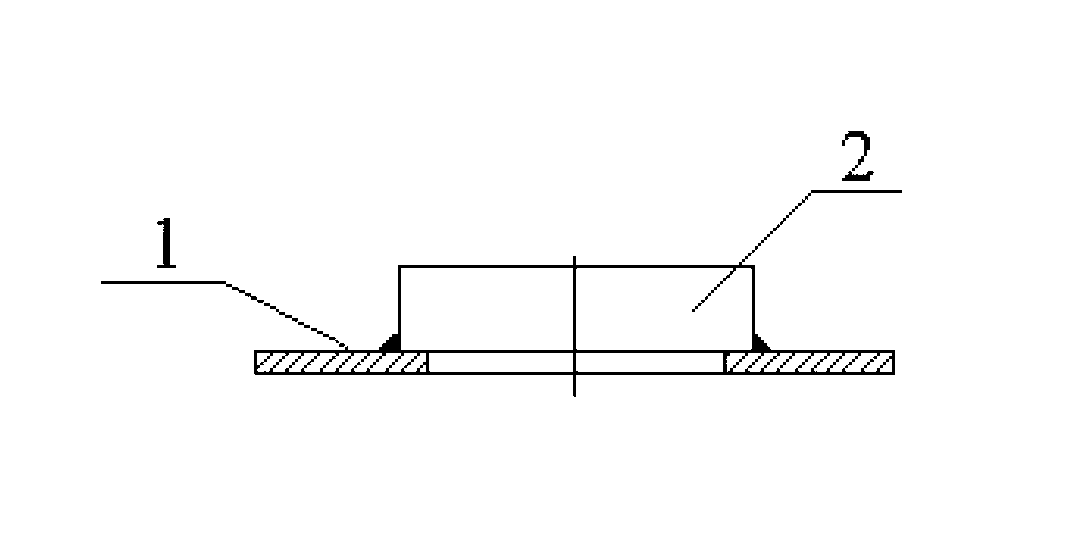

Burning type oxidation-proof guard circle for pouring molten steel and preparation method thereof

InactiveCN101347832AAvoid secondary oxidationLow priceMolten metal conveying equipmentsWaxCombustion

The invention discloses a combustion type anti-oxidation protective ring used for casting liquid steel as well as a preparation method thereof. The protective ring is a ring made of combustible material, and the ring is infiltrated with combustible organics. The ring is braided by dry rice straw. The best combustible organics is paraffin. The preparation method of the protective ring comprises two main steps: the preparation of the ring and waxing. When in use, the protective ring is positioned above a central casting pipe and aligned with a ladle nozzle. The ring is combusted under the high temperature of the liquid steel when steel stream flows through the ring. Oxygen near the steel stream is consumed by combustion, therefore, oxygen partial pressure can be lowed effectively, and the infiltration and dissolution of oxygen in the air into the liquid steel to the utmost extent is reduced.

Owner:宜兴市瑞华新型炉料厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com