Method for improving lead bismuth alloy corrosion resistance of nuclear power structural material

A technology for structural materials and corrosion performance, applied in the field of improving the anti-corrosion performance of lead-bismuth alloys for nuclear power structural materials, can solve the problems of oxygen partial pressure and oxygen content, high cost of new material development, weakened material properties, etc., to achieve improved lead resistance Corrosion properties of bismuth alloys, easy control of the process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

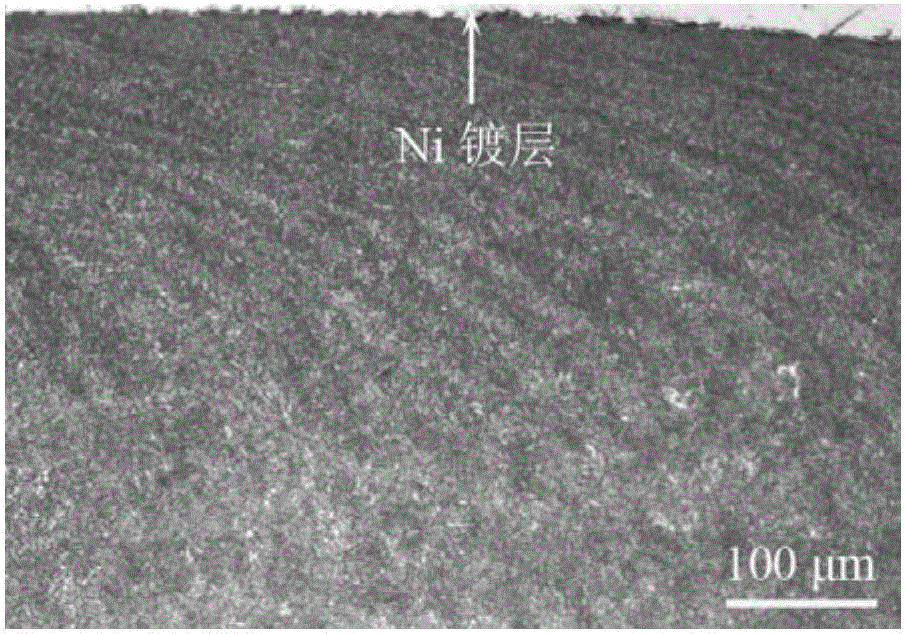

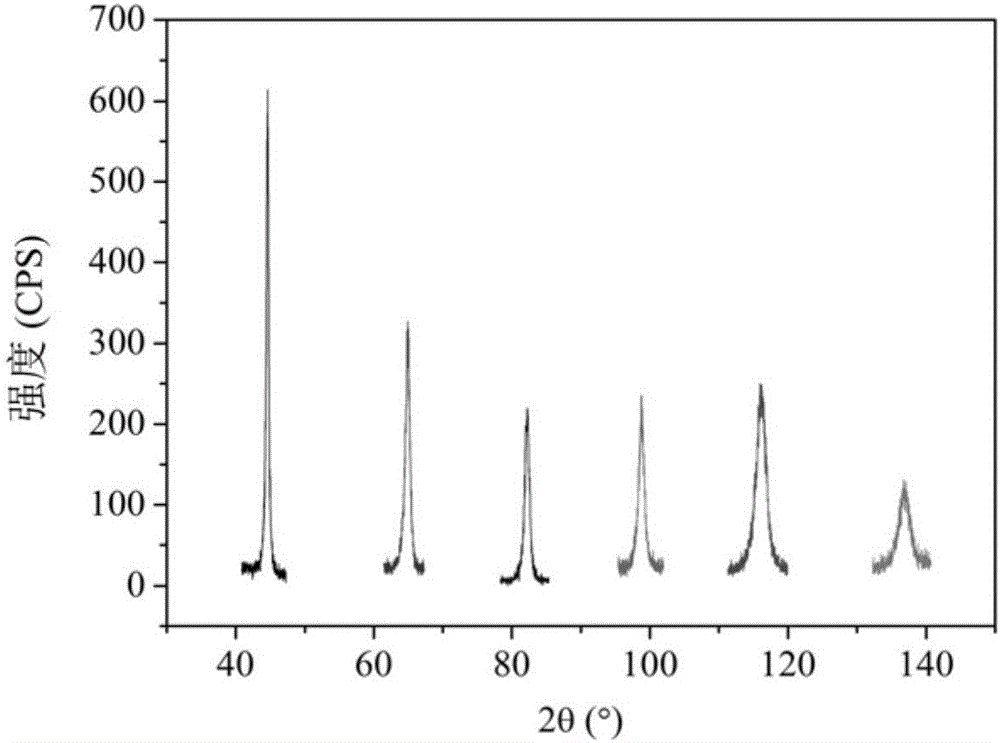

[0040] This embodiment selects low-activation ferrite / martensitic steel (11Cr-WVTaSi) as the object, and its chemical composition is (wt.%): C 0.23%, Si 1.15%, Mn 0.40%, S 0.01%, P 0.01 %, Cr 10.7%, Ni 0.2%, W1.7%, Ta 0.05%, V 0.35%, Nb 0.05%, B 0.005%, Fe balance. The low-activation ferrite / martensitic steel is supplied in tempered state, the diameter of the rotary test piece is 10mm, and the surface of the test piece is in the turned state. The corrosion medium is liquid lead-bismuth alloy (eutectic, LBE), the corrosion temperature is 550°C, and the corrosion time is 3500 hours.

[0041] The surface nano-processing method of the present invention is used to perform surface nano-processing on low-activation ferrite / martensitic steel. The material of the hard ball of the surface nano-processing head is WC / Co, and the diameter of the hard ball is 8mm. Rotation speed v of low activation ferritic / martensitic steel rotary specimen 1 =3×10 4 mm / min; the axial feed speed v of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com