Process for industrially producing ultrapure Inconel 690 (I-690) alloy electroslag remelting ingot of 3 tons

A process method, electroslag remelting technology, applied in the field of electroslag remelting, can solve the problems of difficult control of O content and tissue control, etc., achieve uniform structure, ensure efficiency and economy, and choose reasonable cooling water temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A process for industrialized production of 3 tons of I-690 alloy electroslag remelting ingots, the specific steps are as follows:

[0037] 1) Electrode preparation: The electrode size adopts the specification of φ430mm×2980mm. Before remelting, the electrode is cut and polished to ensure that the two ends are parallel and flat, and the cylindrical surface is polished clean. The surface must not have serious cracks, heavy skin, fins, Defects such as scars and slag inclusions, no scale or rust, and grease and refractory fragments adhering to the surface are cleaned; and baked at 700 ° C for 8 hours.

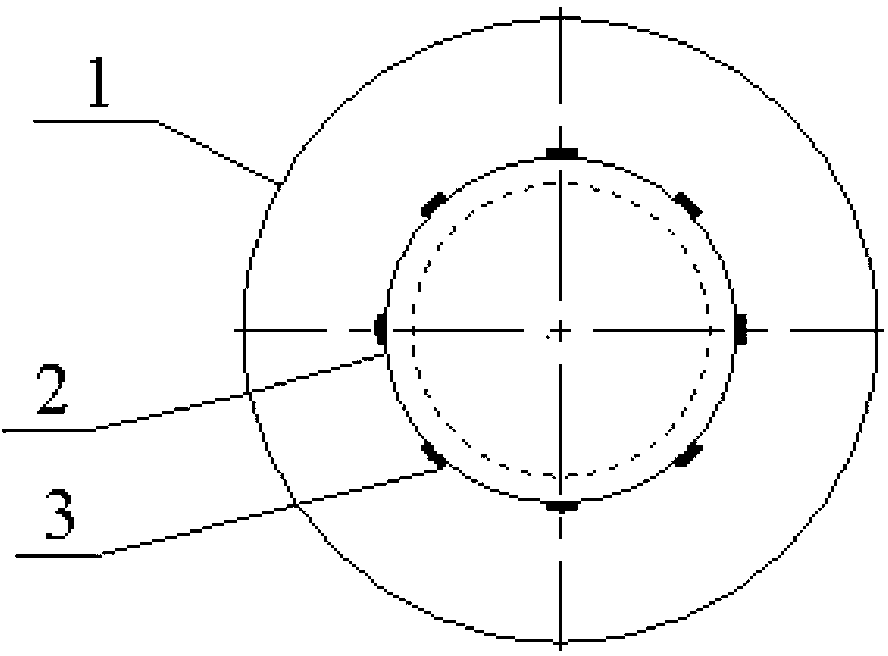

[0038] 2) Prepare the crystallizer: The crystallizer specifications are the diameter of the upper inner opening is 503mm, the diameter of the lower inner opening is 527mm, and the length is 2400mm; before remelting, clean the dirt on the inner surface of the crystallizer to ensure that the surface is dry and free of dirt.

[0039] 3) Use polishing equipment to polish the sur...

Embodiment 2

[0053] The difference with Example 1 is:

[0054] The proportion of slag used is (mass fraction): calcium fluoride 64%, calcium oxide 16%, aluminum oxide 15%, titanium dioxide 1.5%, and the rest is magnesium oxide.

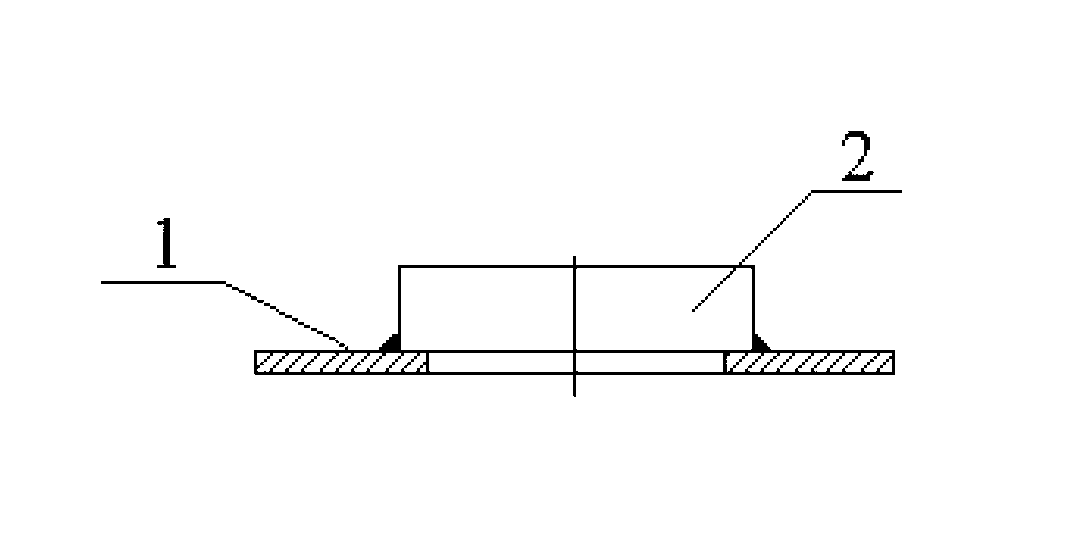

[0055] The thickness of the first starting plate is 7mm, the diameter of its outer circle is 40mm larger than the diameter of the inner hole at the lower end of the crystallizer, and the diameter of the inner circle is 17mm smaller than the diameter of the second starting plate; the thickness of the second starting plate is 40mm.

[0056] When argon is introduced into the crystallizer, the gas flow rate is 180L / min, and it is maintained for 35 minutes until the residual oxygen content in the gas hood is lower than 0.5% capacity, and the argon flow rate is adjusted to 55L / min. The steady state melting rate during the steady state melting period was 7.8 kg / min. The chemical composition analysis data of the alloy after remelting are shown in Table 4.

Embodiment 3

[0058] The difference with Example 1 is:

[0059] The proportion of slag used is (mass fraction): calcium fluoride 63%, calcium oxide 14%, aluminum oxide 16%, titanium dioxide 2%, and the rest is magnesium oxide.

[0060] The thickness of the first starting plate is 6mm, the diameter of its outer circle is 30mm larger than the diameter of the inner hole at the lower end of the crystallizer, and the diameter of the inner circle is 20mm smaller than the diameter of the second starting plate; the thickness of the second starting plate is 30mm.

[0061] When feeding argon gas into the crystallizer, the gas flow rate is 150L / min, keep it for 40min until the residual oxygen content in the gas hood is lower than 0.5% capacity, and adjust the argon flow rate to 50L / min. The steady state melting rate during the steady state melting period was 7.2 kg / min. The chemical composition analysis data of the alloy after remelting are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com