Process method for producing 1 ton of I-690 alloy electroslag remelted ingot in industrialized mode

A technology of electroslag remelting and process method, applied in the direction of improving process efficiency, improving energy efficiency, etc., can solve the problems of reducing the oxygen content to less than 20ppm, difficult to alloy oxygen content, the effect is not very ideal, etc., to achieve stable remelting process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

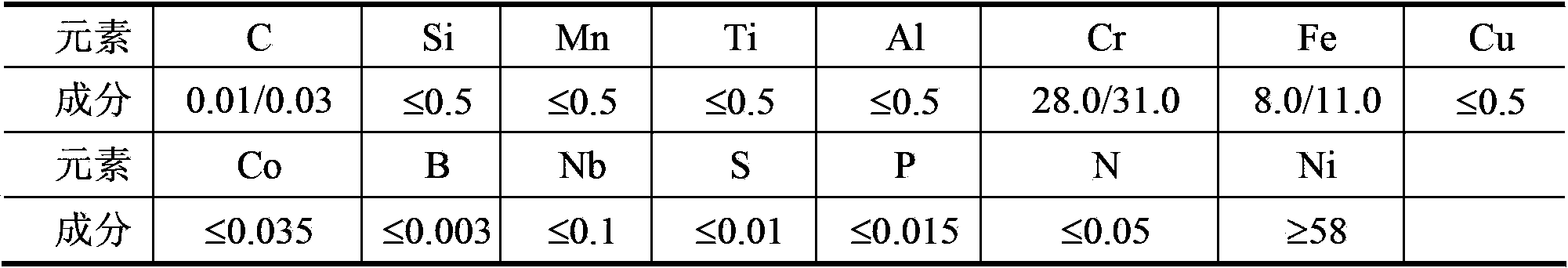

[0030] A process method for industrially producing 1 ton of I-690 alloy electroslag remelting ingots. The remelting electrode is smelted in a vacuum induction furnace. The specific operation steps are as follows:

[0031] 1) Before remelting, clean the bottom end of the mold and the inside of the mold. The electrode rod size is Φ240mm, and its surface must not have serious cracks, heavy skin, fins, scars, slag inclusions, etc., and no oxide scale or Rust, grease, and refractory fragments on the surface have been removed; the specification of the crystallizer is Φ340 / 380×1500mm, and the electrode rod is used after baking at 700°C for 10 hours;

[0032] 2) First use a polishing wheel to polish the surface of the copper plate above the bottom tank to remove the adherents;

[0033] 3) Put the starter plate on the center of the copper plate above the bottom water tank, take the starter plate on the center of the starter plate, put the solid conductive slag on the starter plate, hoist the ...

Embodiment 2

[0042] The difference from Example 1 is:

[0043] 1) The slag material ratio used is (mass percentage): 52% calcium fluoride, 22% calcium oxide, 20% alumina, 3% titanium dioxide, and the rest is MgO. The purity of each component of the slag is more than 98.5%, the unstable oxide impurity manganese oxide (MnO), ferrous oxide (FeO), silicon dioxide (SiO) 2 ) The total content is less than 0.5%, and the particle size is less than 50 mesh. After the slag is baked at 680°C for 10 hours, add the evenly mixed slag into the crystallizer at one time. After the slag is added, ignite the gas flame ring;

[0044] 2) The starter plate used is made of pure iron, the diameter is 15mm smaller than the inner hole diameter at the lower end of the mold, and the thickness is 12mm; the starter plate is an I-690 electrode slice, the diameter is the same as the electrode diameter, and the thickness is 30mm;

[0045] 3) The flow rate of argon at the bottom of the crystallizer is 80L / min, and the flow rate ...

Embodiment 3

[0048] The difference from Example 1 is:

[0049] 1) The slag material ratio used is (mass percentage): 55% calcium fluoride, 18% calcium oxide, 20% alumina, 3% titanium dioxide, and the rest is MgO. The purity of each component of the slag is more than 98.5%, the unstable oxide impurity manganese oxide (MnO), ferrous oxide (FeO), silicon dioxide (SiO) 2 ) The total content is less than 0.5%, and the particle size is less than 50 mesh. After the slag is baked at 680°C for 10 hours, add the evenly mixed slag into the crystallizer at one time. After the slag is added, ignite the gas flame ring;

[0050] 2) The starting board is an I-690 electrode slice, the diameter is the same as the electrode diameter, and the thickness is 30mm;

[0051] 3) The argon flow rate at the bottom of the crystallizer is 90L / min, and the argon flow rate at the top is 50L / min.

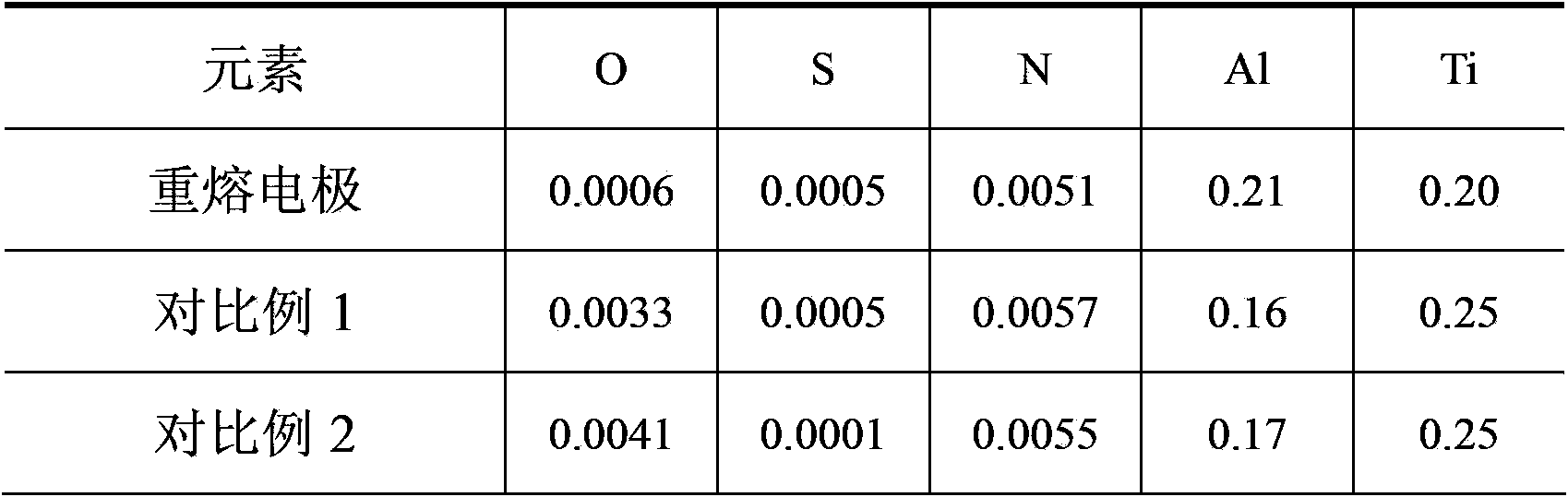

[0052] The chemical composition analysis data of I-690 alloy after remelting is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com