Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "No obvious defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

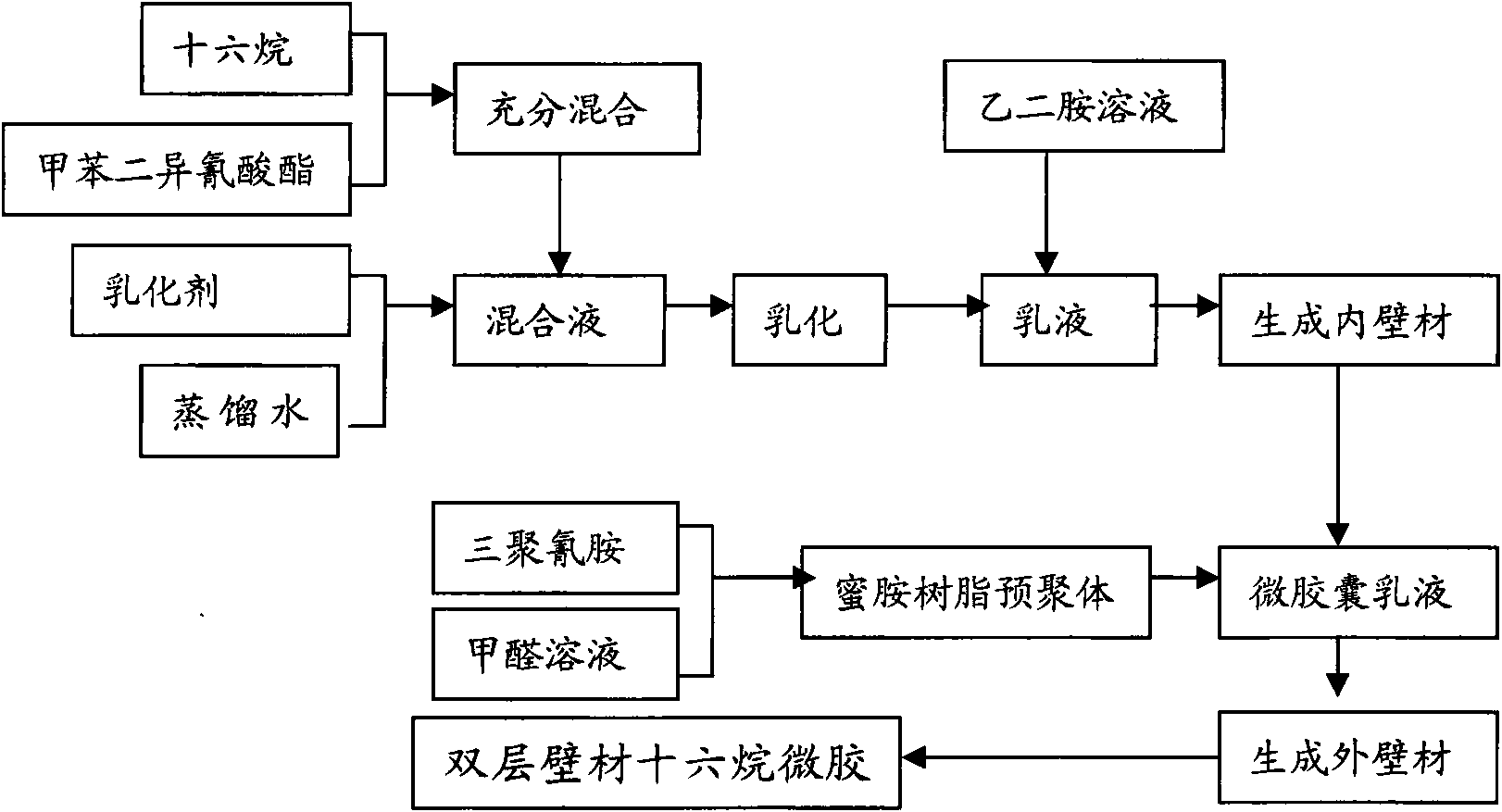

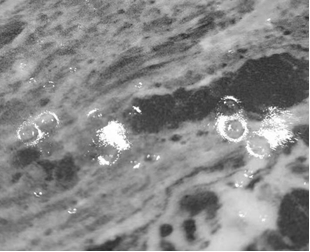

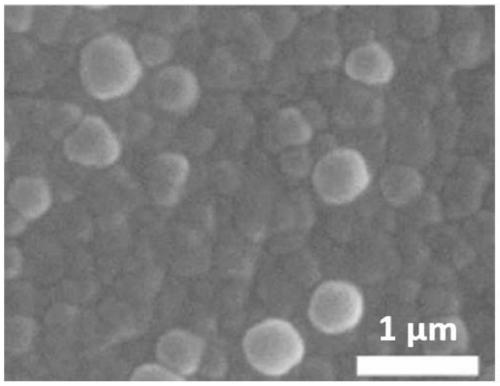

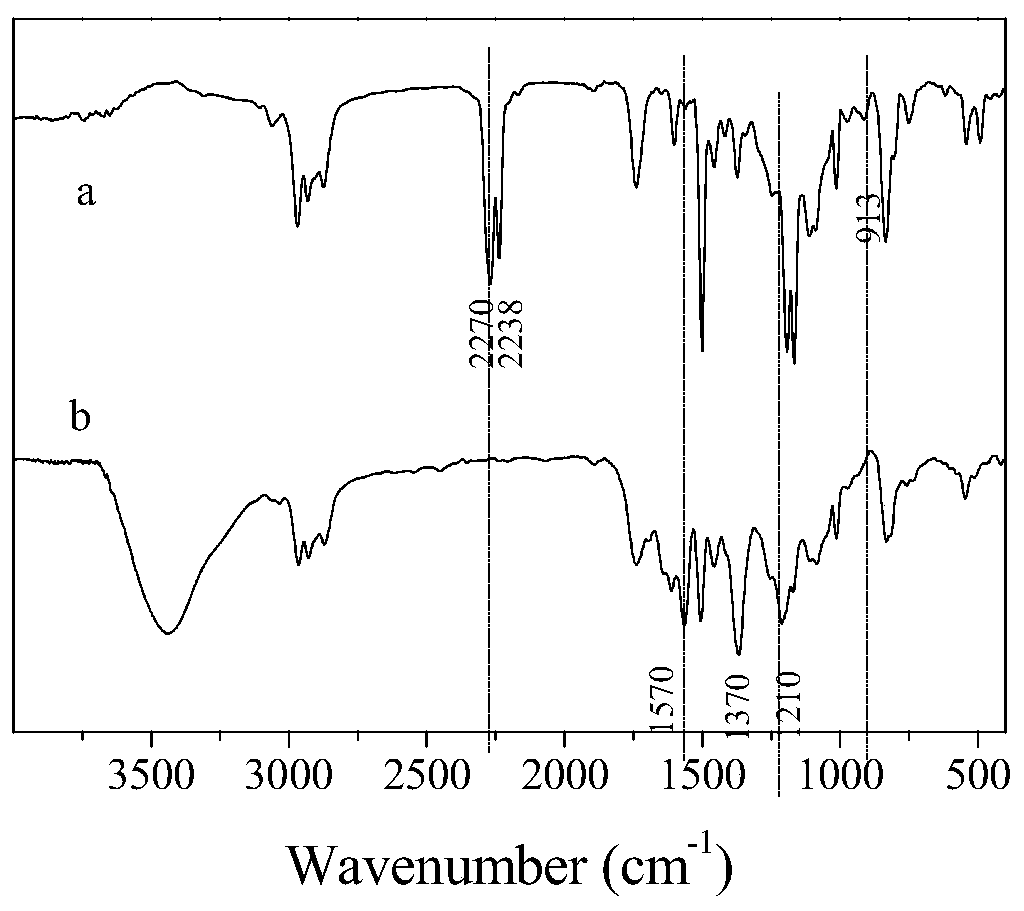

Polyurea-melamin resin double-wall material cetane microcapsule and preparation method thereof

ActiveCN101554573ANo obvious defectsNo adhesion phenomenonMicroballoon preparationMicrocapsule preparationEthylenediamineHexadecane

The invention provides a method for preparing polyurea-melamin resin double-wall material cetane microcapsule, which comprises: first, toluene-2, 4- vulcabond and quadrol are adopted to synthesize inner layer shell material of the cetane microcapsule by an interfacial polymerization method, and then melamin resin performed polymer is adopted to synthesize outer layer shell material of the cetane microcapsule by an in-situ polymerization method, so that the polyurea-melamin resin double-wall material cetane microcapsule can be prepared. More particularly, the method comprises: hexadecane and the toluene-2, 4- vulcabond are fully mixed together and then added into the mixture of de-ionized water, sodium dodecyl sulfate and polyethylene glycol nonylphenyl ether to be emulsified to obtain cetane emulsified liquid; then, the mixed quadrol solution is dripped into the cetane emulsified liquid to react to obtain polyurea monolayer shell material microcapsule; finally, the polyurea monolayer shell material microcapsule reacts with the melamin resin performed polymer to obtain the polyurea-melamin resin double-wall material cetane microcapsule. The prepared microcapsule has good compactness, high strength and core content and excellent particle size distribution.

Owner:SOUTHEAST UNIV

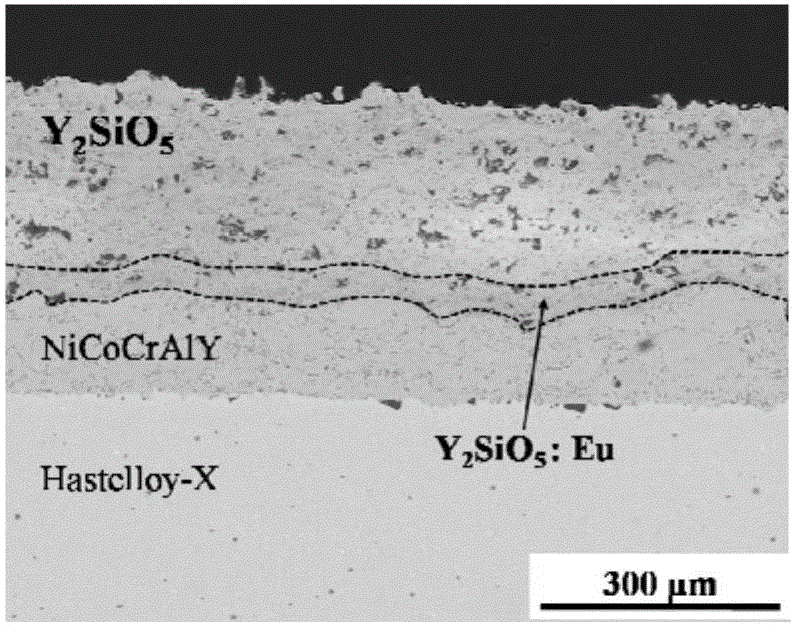

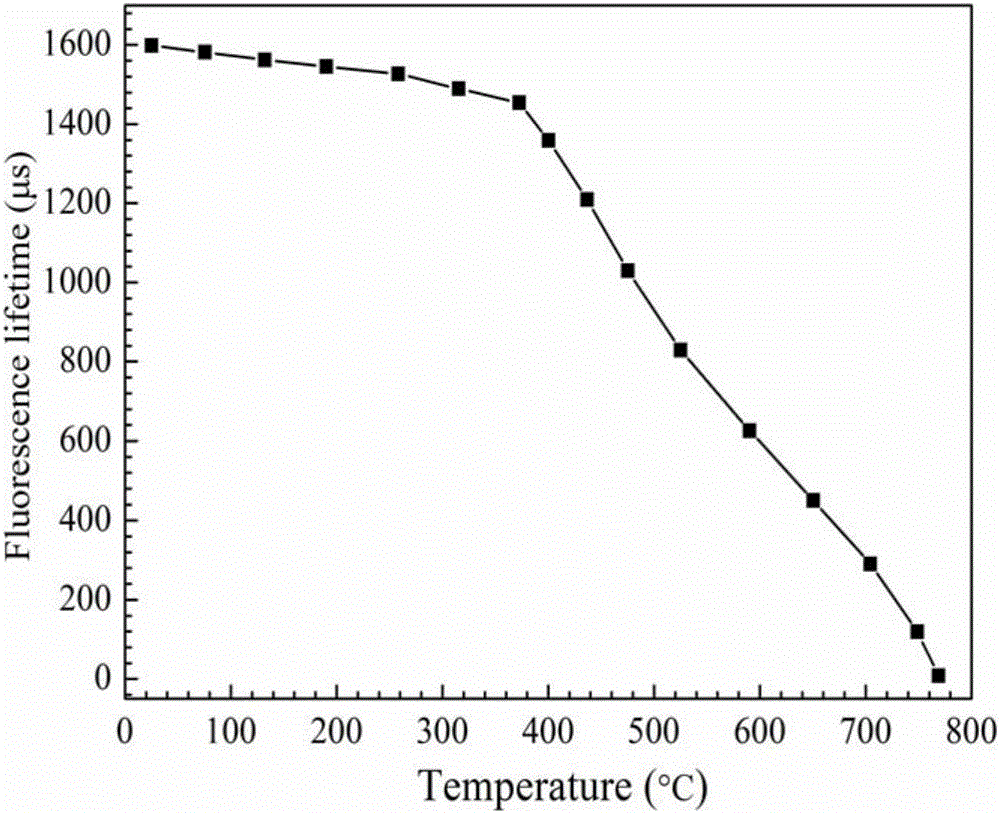

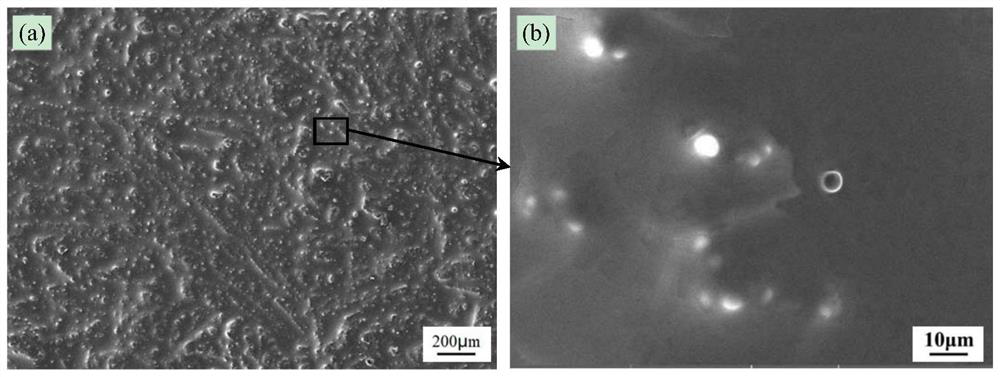

Preparation method and application of temperature sensitive type Y2SiO5:Eu intelligent thermal barrier coating

ActiveCN106119765ADoes not affect luminous propertiesFlexible combinationMolten spray coatingThermometers using electric/magnetic elementsFluorescenceMicrosphere

The invention relates to a preparation method and application of a temperature sensitive type Y2SiO5:Eu intelligent thermal barrier coating. The preparation method comprises the steps that nanometer yttrium oxide powder, micrometer silicon dioxide powder, nanometer europium oxide powder and LiYO2 powder are subjected to ball-milling and high-temperature sintering to obtain ceramic aggregate powder Y2SiO5:Eu powder which is then dispersed into 1-methyl pyrrolidone; polyving alcohol is added to enable the ceramic aggregate powder Y2SiO5:Eu powder to be dispersed completely and then ultrasonic oscillation is conducted; then a mixed binder is added to conduct L-S phase conversion preparation, and obtained coated Y2SiO5:Eu microballons are sprayed on the surface of a high-temperature alloy sample with a metal bonding layer to form a fluorescent layer with the thickness being 3-50 [mu]m; and then a Y2SiO5 coating is sprayed on the surface of the fluorescent layer according to the same spraying process, so that the temperature sensitive type Y2SiO5:Eu intelligent thermal barrier coating is obtained and can be used in coating temperature measurement. The prepared thermal barrier coating has the advantages that the surface is even, no microcrack occurs, the thickness is uniform, no penetrating hole exists, and the bonding force is good. In addition, excellent fluorescent emitting performance and a temperature fluorescent effect are achieved, and the temperature sensitive type Y2SiO5:Eu intelligent thermal barrier coating can be applied to the field of fluorescent temperature measurement of coatings.

Owner:SHANGHAI JIAO TONG UNIV

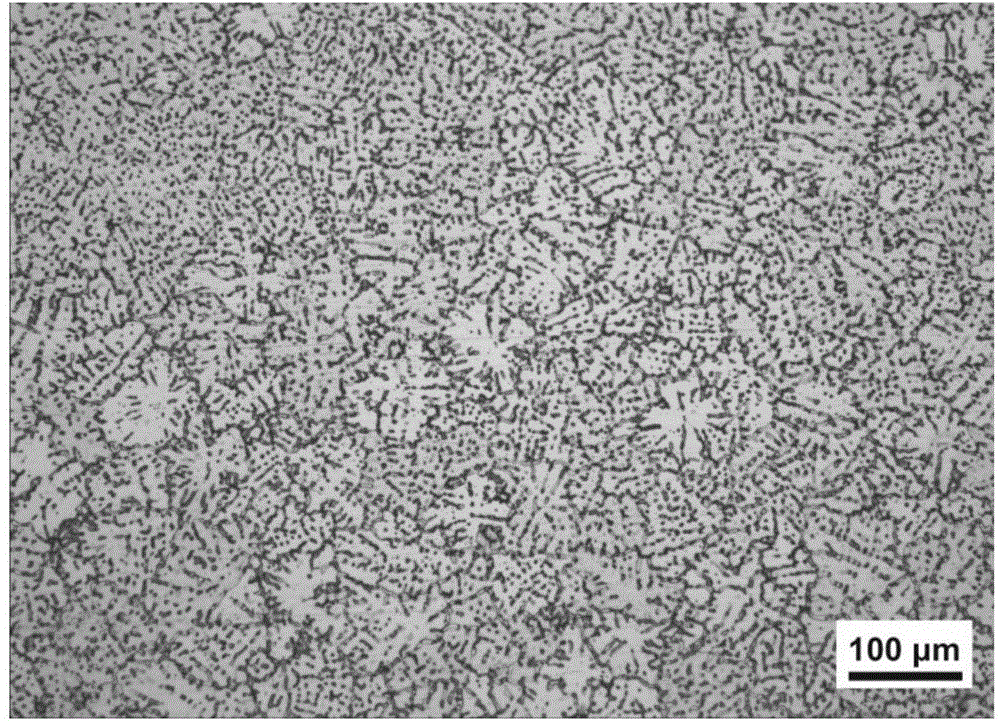

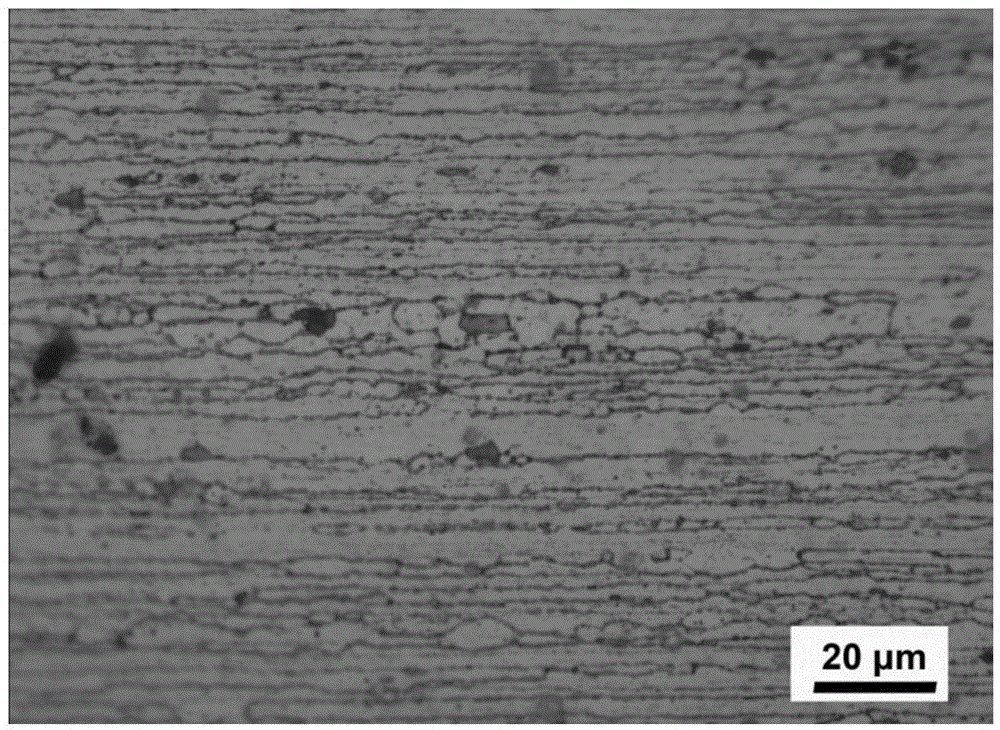

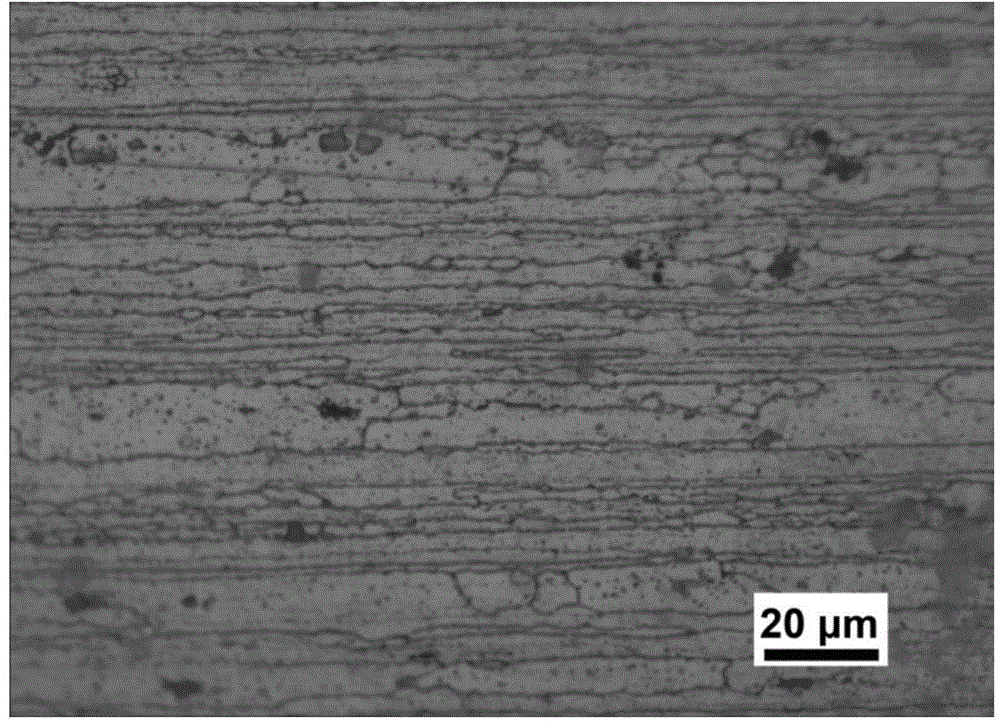

Preparation method and application of heat-resistant titanium alloy wires

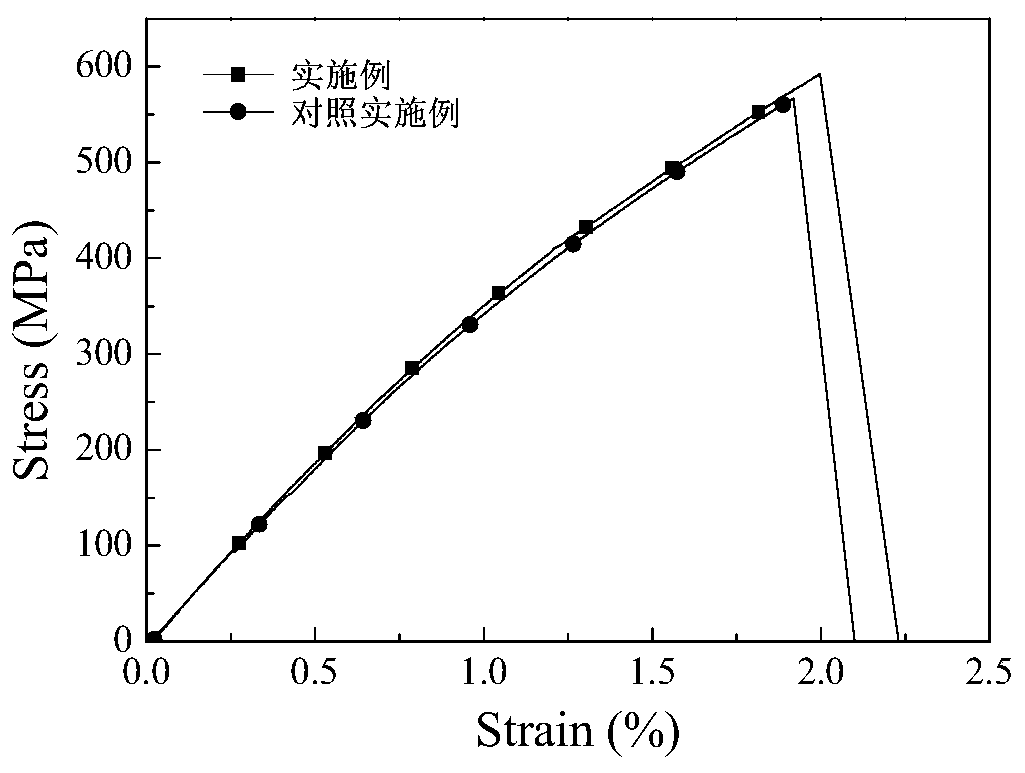

ActiveCN109355530ADifferent tensile strength matchingPlastic different matchingTitanium alloyHeat treated

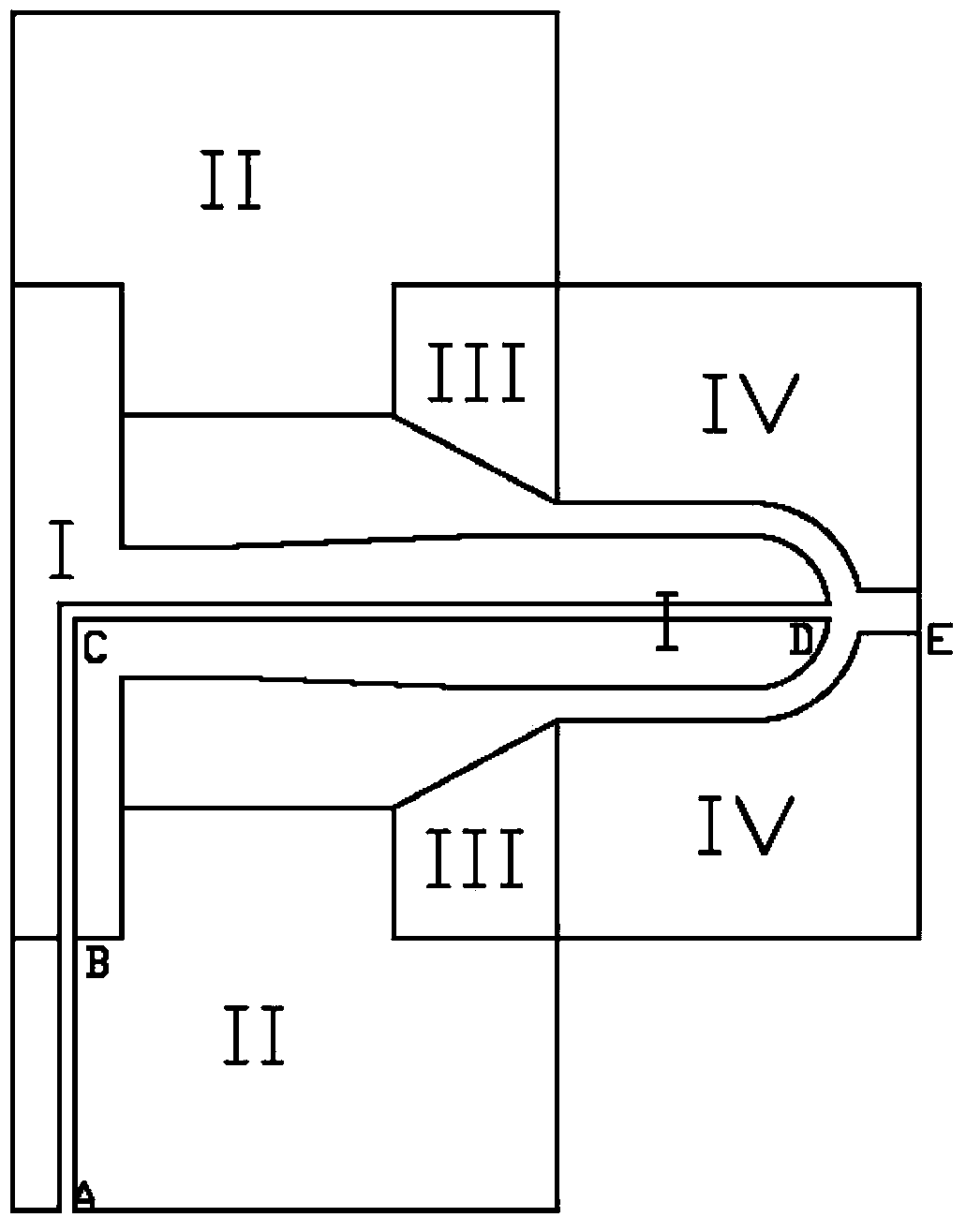

The invention provides a machining and manufacturing method and application of heat-resistant titanium alloy Ti60 wires. The method comprises the steps that Ti60 titanium alloy ingot castings are smelted by adopting a vacuum consumable smelting technology; the smelted Ti60 titanium alloy ingot castings are forged into rods by adopting a free forging technology; the Ti60 titanium alloy rods are finish-forged into thick rod blanks by adopting a finish forging technology; the Ti60 titanium alloy thick rod blanks are rolled into straight strip wire blanks by adopting a hot rolling technology; surface treatment is conducted on Ti60 titanium alloy annealing wire blanks, and pre-oxidation oxidation film hanging treatment is conducted after defects on the surfaces of the wire blanks are removed; continuous high-temperature drawing deformation is conducted on the Ti60 titanium alloy wire blanks obtained after surface treatment by adopting a straight wire drawing machine; the drawn wires are straightened by adopting electric heating tension; and annealing heat treatment is conducted on the straightened wires, and finally centerless grinding is conducted. According to the machining and manufacturing method and application of the heat-resistant titanium alloy Ti60 wires, through combination of different heat machining and heat treating technologies, different matching combinations of the tensile strength, the plasticity and the shearing strength can be obtained, and the heat-resistant titanium alloy Ti60 wires can be used for manufacturing advanced aerospace fasteners such as rivets, bolts and nuts and are used in the temperature range of 600-650 DEG C.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

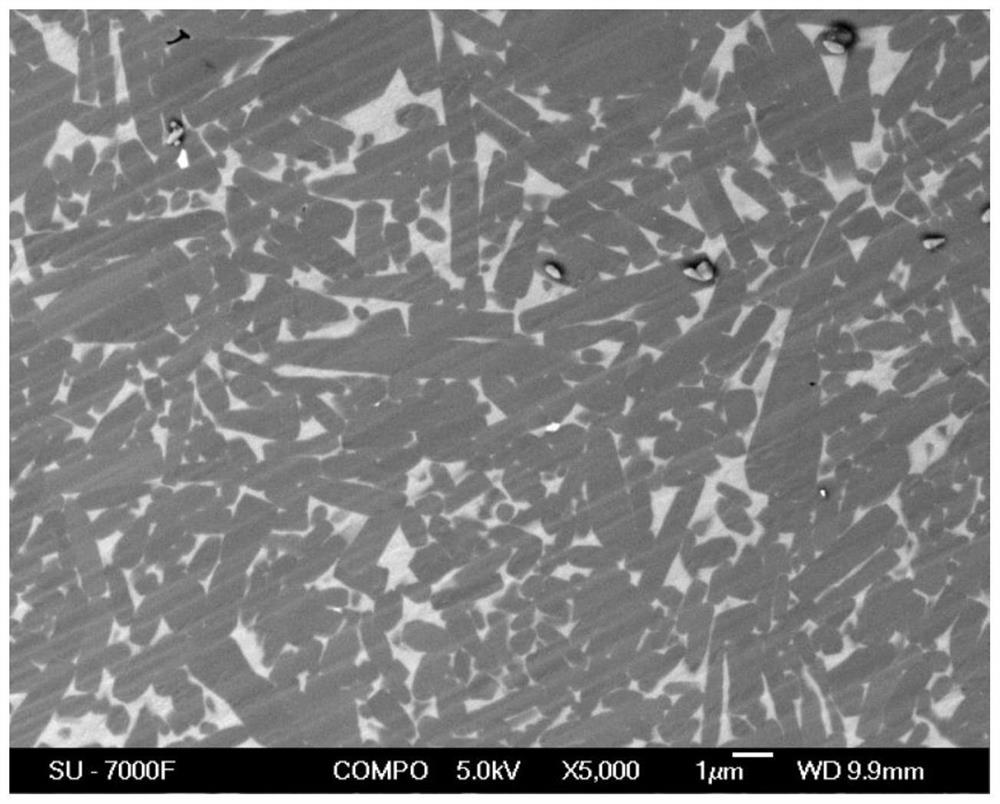

Silicon carbide ceramic thermocouple protection tube and preparation method thereof

The invention provides a silicon carbide ceramic thermocouple protection tube. The material of the silicon carbide ceramic thermocouple protection tube is prepared from the following raw materials by extrusion moulding and high-temperature sintering: submicron-order silicon carbide powder, the second-phase powder accounting for 0-15% of the weight of the submicron-order silicon carbide powder and a proper amount of sintering aid, wherein the second-phase powder is MoSi2, BN, TiB2, ZrB2 or composite powder thereof; and the sintering aid adopts a solid-phase sintering aid system selected from B4C-C system and C-B system.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

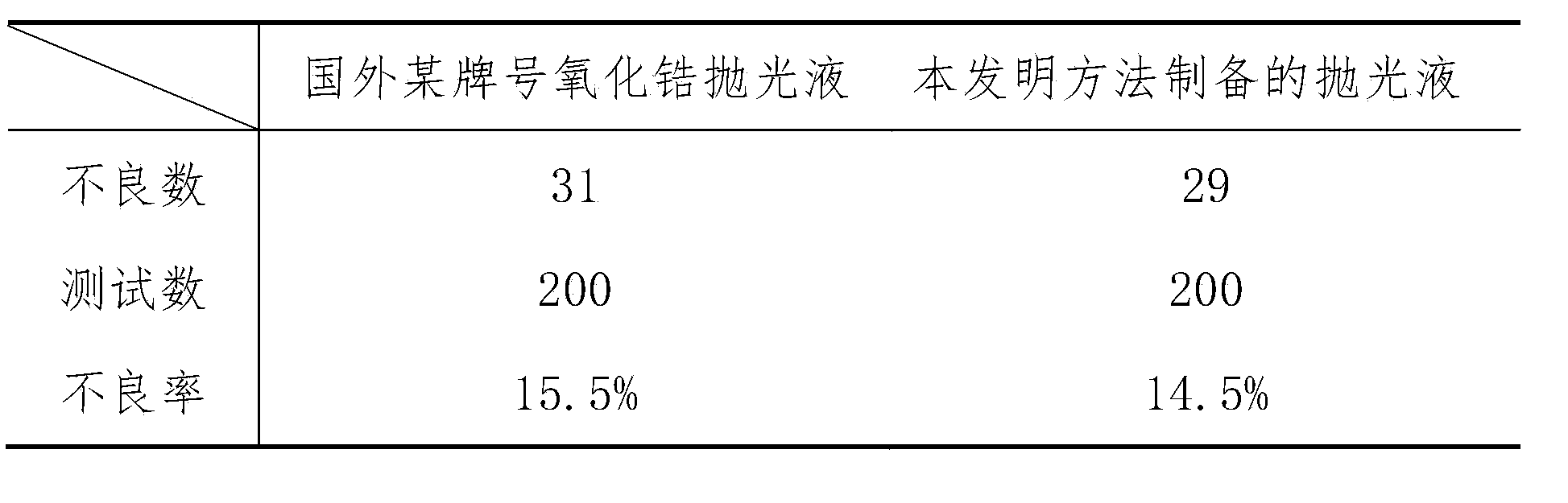

Preparation method of iron-doped zirconium oxide polishing solution

ActiveCN103450813AGood cutting rateAdjust hardnessPolishing compositions with abrasivesMaterials preparationWater soluble

The invention discloses an iron-doped zirconium oxide polishing solution, and relates to the technical field of preparation of polishing materials. The iron-doped zirconium oxide polishing solution is prepared from water-soluble inorganic zirconium salt, soluble trivalent ferric salt, alkali, zirconium carbonate, additives and a pH value modifier. The method comprises the preparation steps of material preparation, symbiotic solution preparation, symbiotic precipitate preparation, washing, drying, roasting, grinding and stirring dispersion; the method has the characteristics that the cutting rate is good and no obvious defects are generated on the surface of a polished material; the iron-doped zirconium oxide polishing solution prepared by using the method is suitable for the processing field of high-grade optical instruments, and particularly can be applied to polishing flexible glass.

Owner:HUNAN HAOZHI TECH

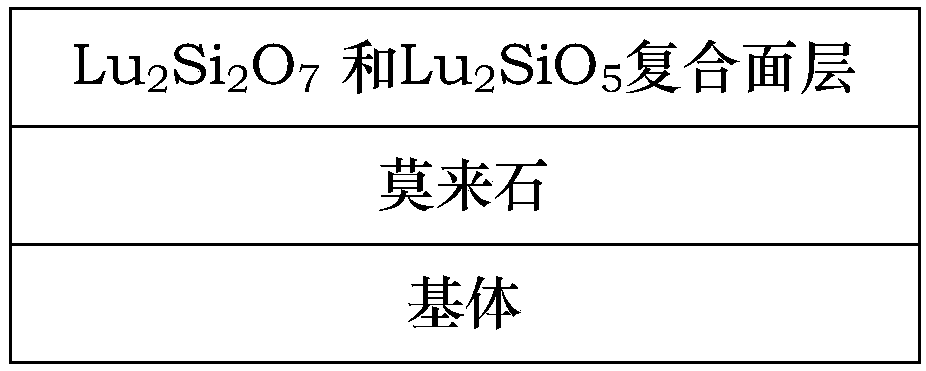

A rear earth lutetium silicate composite environmental barrier coating and a preparing method thereof

A rear earth lutetium silicate composite environmental barrier coating and a preparing method thereof are disclosed. The composite environmental barrier coating includes a SiC / SiC matrix, a mullite layer and a composite surface layer consisting of Lu2Si2O7 and Lu2SiO5 in a mass ratio of 6:4. The preparing method combining plasma spraying and physical vapor deposition is adopted, and mullite powderhaving a particle size of 18-58 [mu]m and Lu2Si2O7-Lu2SiO5 composite powder having a particle size of 62-105 [mu]m are adopted as raw materials to prepare the mullite layer on the SiC / SiC matrix andthe composite surface layer on the mullite layer in order. The coating prepared by the method has good resistance to water oxygen corrosion at 1723 K, effectively retards generation of cracks and effectively avoids oxidation and performance degradation of the SiC / SiC matrix at high temperatures.

Owner:BEIHANG UNIV

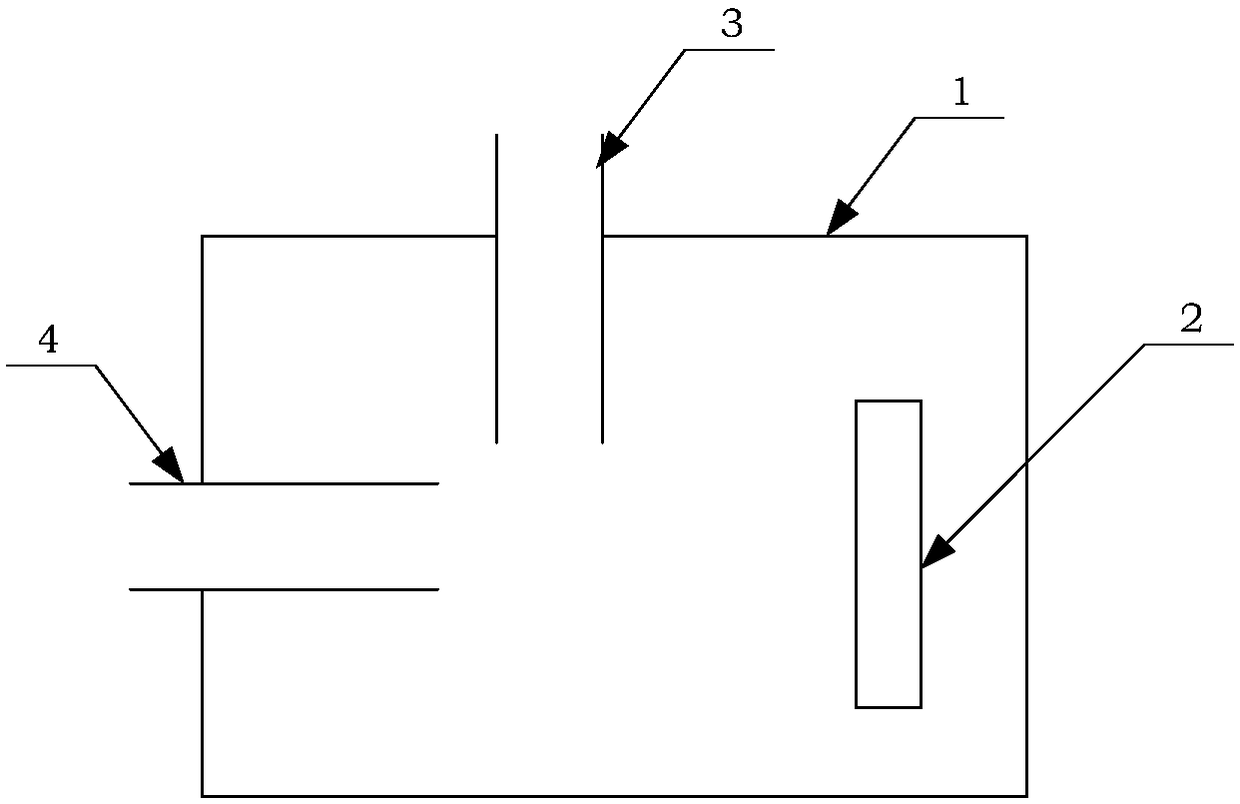

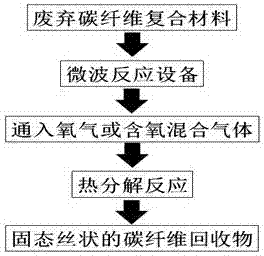

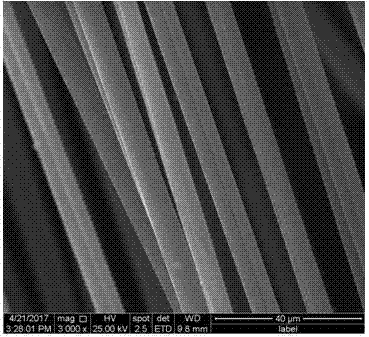

Method of recovering carbon fibers by low-temperature microwave efficient treatment of carbon fiber composite material

InactiveCN107216480AImprove the efficiency and effectiveness of recyclingHeating fastSolid productEnergy source

The invention relates to a method of recovering carbon fibers by low-temperature microwave efficient treatment of a carbon fiber composite material and belongs to the technical field of fiber composite materials. The method comprises the following steps: firstly, putting a waste carbon fiber composite material in a microwave heating device; introducing oxygen or oxygen-containing mixed gas; feeding microwaves, the frequencies of which are 2450+ / -50MHz or 915+ / -50MHz till the temperature is raised to 350-500 DEG C; performing low-temperature treatment for 0.1-1.0h; then naturally reducing the temperature to below 200 DEG C; and taking out the solid product to obtain the carbon fibers. The method is a method of uniformly and efficiently recovering high value carbon fibers from the waste carbon fiber composite material at a low temperature at a normal pressure. According to the method, organic matters of resin are oxidized to combust at the low temperature, and the integrity of the carbon fibers is ensured. The carbon fibers are regenerated and recycled while the mechanical property and recovery rate of the carbon fibers are increased, the reaction time is shortened, the reaction flow is simplified, the energy source is saved and the environment is protected.

Owner:KUNMING UNIV OF SCI & TECH

Manufacturing method of high-strength aluminum alloy welding connector

ActiveCN104084768AWell formed weldHigh strengthArc welding apparatusFurnace typesMelting tankHeat-affected zone

The invention discloses a manufacturing method of a high-strength aluminum alloy welding connector, and belongs to the technical field of high-strength aluminum alloy machining. The manufacturing method adopts Al-7.83Zn-2.87Mg-0.67Cu-0.50Mn-0.23Zr-0.14Er base metal and an Al-4.70Mg-0.70Mn-0.10Zr-0.30Er welding wire, after full-automatic TIG filler rod welding and proper post-welding heat processing, a nanoscale secondary precipitated phase formed by micro alloy elements Er and Zr serves as an effective nucleation core in a molten pool, the welding joint grain is fined, dislocation and sub-grain boundaries are pinned in a heat affected area, re-crystallization of the heat affected area is effectively inhibited, and softening of the heat affected area is reduced. The manufactured welding connector has the advantages that tensile strength is high, welding joints are well formed, and no obvious defect exists, and has the potential for industrial application.

Owner:BEIJING UNIV OF TECH

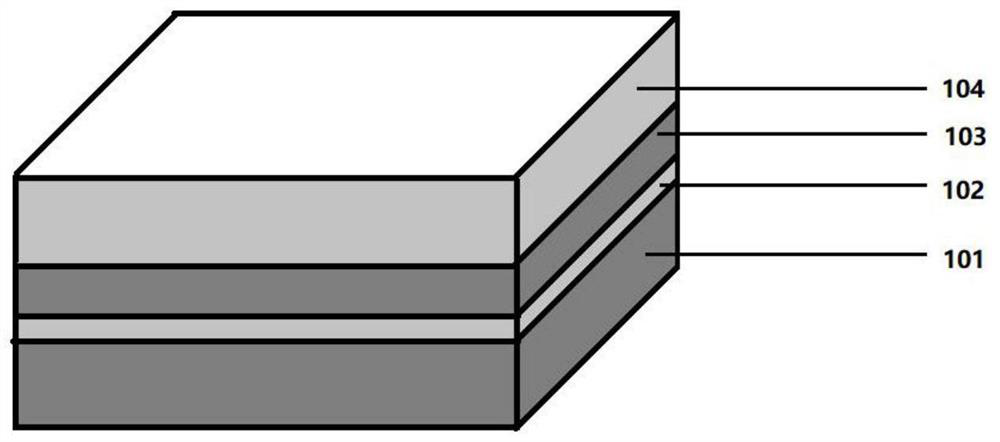

5G ceramic filter film material and preparation method thereof

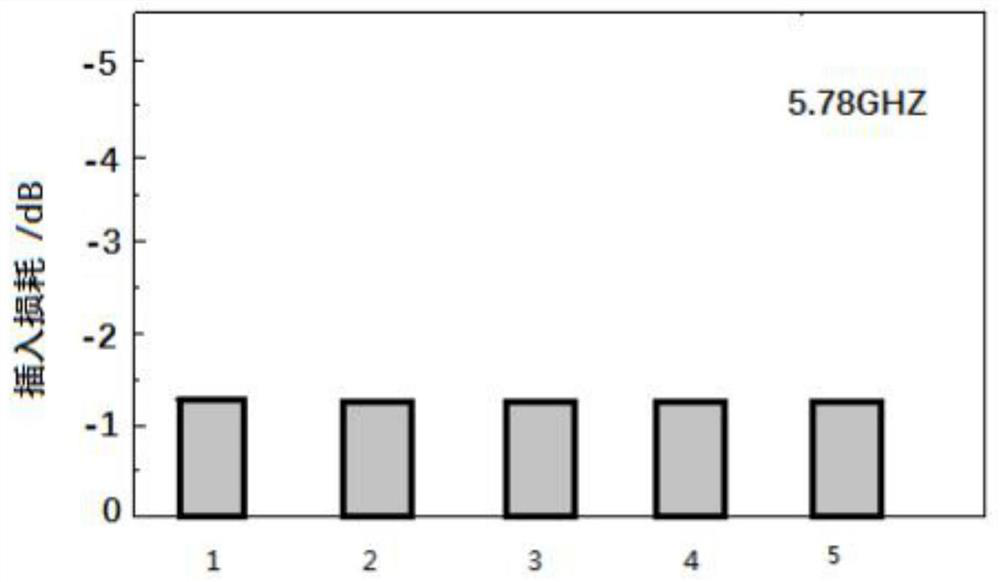

InactiveCN111607772AQuality improvementGood to achieve good quality for both methodsImpedence networksVacuum evaporation coatingChemical platingAlloy

The invention discloses a 5G ceramic filter film material and a preparation method thereof, and belongs to the technical field of ceramic material preparation. The film layer material is of a four-layer composite structure, a matrix is ceramic, a middle transition layer sequentially comprises an alloy layer and a connecting layer, a surface layer is a silver layer, wherein the alloy layer is obtained by taking alloy metal as a cathode and carrying out magnetron sputtering deposition on the ceramic matrix by utilizing a multi-arc target, the connecting layer is obtained by taking Mo, Cu or Cr as a cathode and depositing on the alloy layer by utilizing the cylindrical multi-arc target, and the surface silver layer is obtained by taking silver as a cathode and carrying out silver metal deposition on the connecting layer by utilizing the multi-arc target and a cylindrical target. According to the 5G ceramic filter film material and the preparation method thereof, magnetron sputtering and multi-arc ion plating are combined to prepare the film layer material, so that the problems of low bonding strength of metal and ceramic, high treatment cost and pollution to chemical plating / electroplating environment are solved, the preparation technology is simple and convenient, and the prepared 5G ceramic filter film layer material has the advantages of compact structure, no obvious defects and low insertion loss.

Owner:BEIJING NORMAL UNIVERSITY

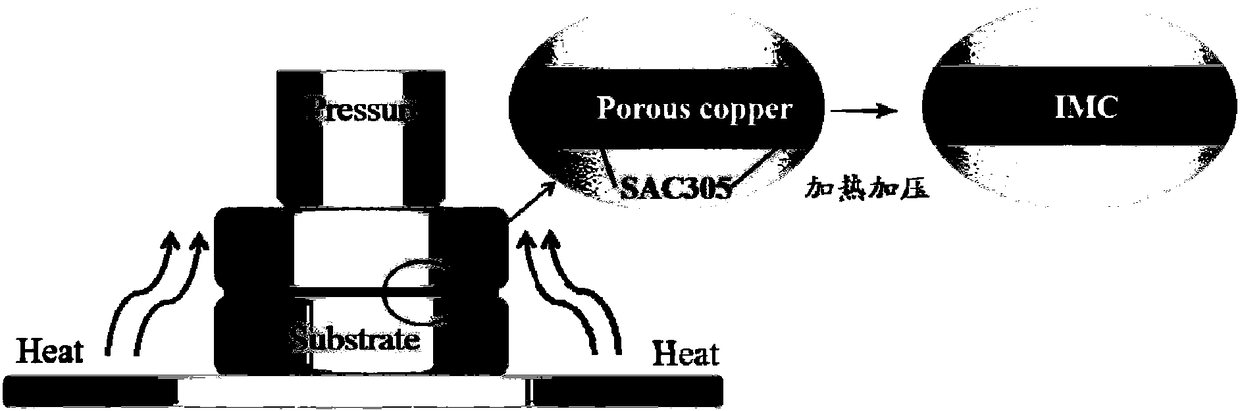

Preparation method of high-temperature serving welding point based on tin-filled foamy copper

InactiveCN108581109AEasy to getLow costSoldering apparatusWelding/soldering/cutting articlesAlloyCopper

The invention provides a preparation method of a high-temperature serving welding point based on tin-filled foamy copper, wherein the foamy copper has a three-dimensional porous structure and is prepared by adopting a dealloying corrosion method; brazing filler metal is bought; and the overall process is a heating and pressurizing welding process. Each welding point can be obtained in a welding way within a short time (5 min) under a low-temperature (230 DEG C) and low-pressure (3-5 MPa) condition; moreover the obtained mutually-connected welding points serve under a high temperature and can keep relatively good reliability; and each welding point is good in mechanical properties, good in electric conductivity and heat conductivity and widely applied to various high-temperature welding fields.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Crucible coating used for preparation of solar grade polysilicon, preparation method thereof and crucible

InactiveCN102453954AHigh strengthPrevent peelingPolycrystalline material growthBy pulling from meltChemical reactionSilicon dioxide

The invention discloses a crucible coating used for the preparation of solar grade polysilicon, a preparation method thereof and a crucible. The crucible coating is mainly prepared from silicon dioxide, barium hydroxide and water as raw materials. The preparation method of the coating comprises the followings steps of: mixing silicon dioxide and barium hydroxide powder, adding deionized water, homogenizing the mixture, spraying the mixture to the inner wall of a crucible main body, and drying and sintering the crucible main body to obtain the coating. The crucible comprises a crucible main body made of a quartz material, wherein one crucible coating is coated to the inner wall of the crucible main body. The invention relates to an effective quartz crucible coating. The crucible with the coating can be successfully used for smelting, purifying and ingoting solar grade polysilicon, the reaction between molten silicon and the crucible material can be effectively prevented, and the pollution of the molten silicon by the crucible material and the adhesion between ingots and the crucible is avoided. Meanwhile, certain contribution is made to remove impurities by using chemical reactions between coating compositions and the molten silicon and the impurities therein.

Owner:PROPOWER RENEWABLE ENERGY SHANGHAI

Repair welding method of austenite stainless steel casted nuclear pump shell

InactiveCN106808058APrevention of stomataInhibition of segregationArc welding apparatusEngineeringWelding defect

The invention provides a repair welding method of an austenite stainless steel casted nuclear pump shell. The repair welding method comprises the specific steps of defect detection and treatment; welding slot treatment; welding rod treatment: baking a welding rod at the temperature of 150 DEG C, and keeping the temperature for standby application; preheating of a to-be-welded zone; repair welding of the to-be-welded zone: carrying out repair welding layer by layer and pass by pass; confirmation of the repair welding effect: carrying out flaw detection on a repair welding zone of a pump body through rays, confirming the repair welding effect, and guaranteeing that the repair welding zone does not have weld defects; and solution treatment: carrying out solution treatment on workpieces subjected to repair welding. According to the repair welding method, samples do not have relatively large welding deformation through adoption of symmetrical arc-shaped welding slots, pre-welding preheating and postwelding thermal treatment; stress after repair welding is reasonably distributed through requirements on shape and radian of the welding slots and pre-welding thermal treatment; the content of impurity elements can be controlled and weld joints do not have obvious defects through surface roughness control and cleaning for the welding slots, and baking treatment for the welding rod; and intergranular corrosion resistance of austenite of the repair welding zone of a nuclear pump can be improved through postwelding solution treatment for a corresponding zone of the nuclear pump body.

Owner:DALIAN UNIV OF TECH

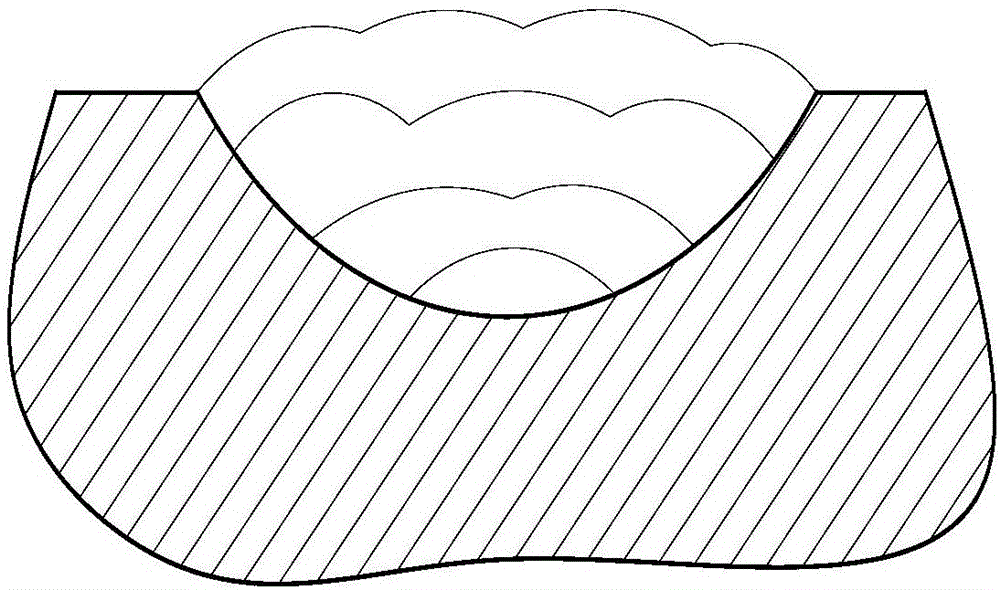

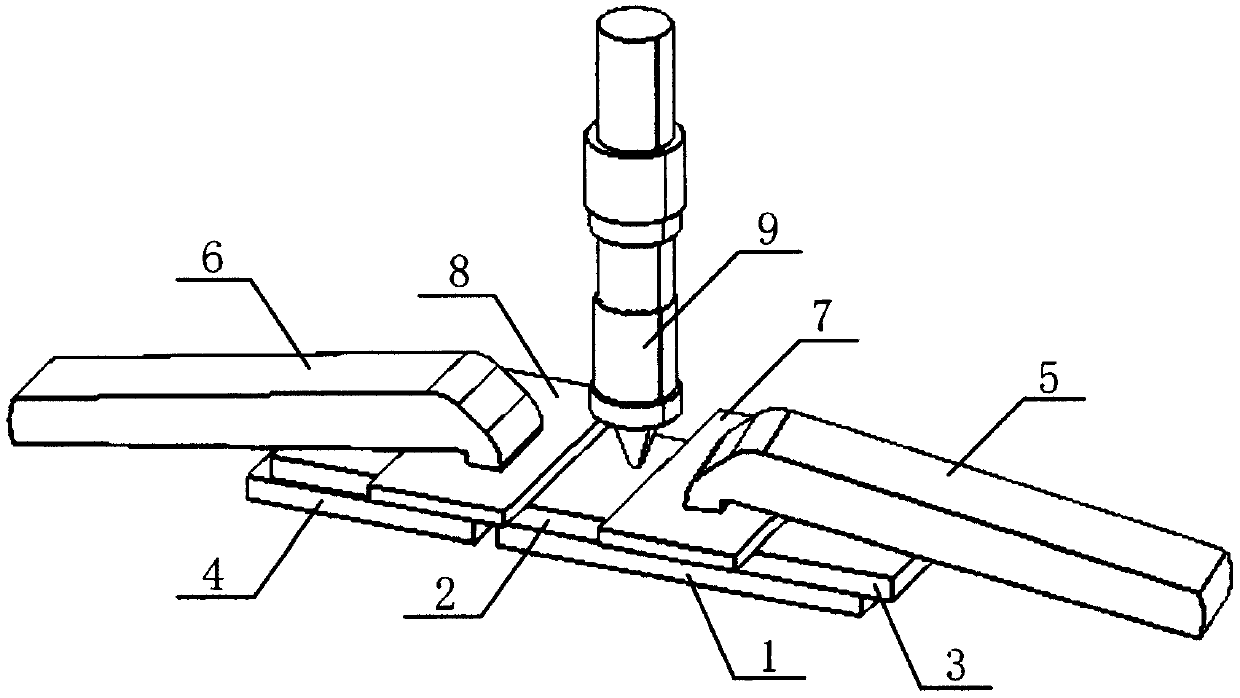

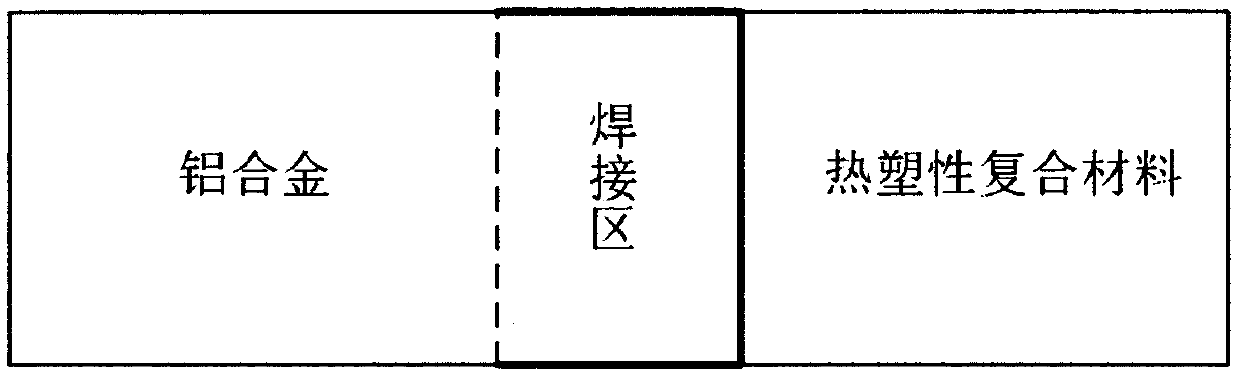

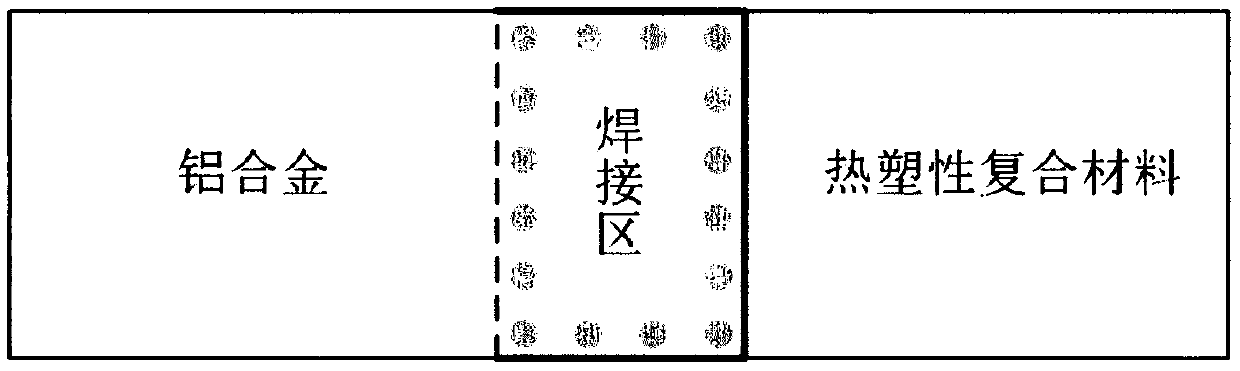

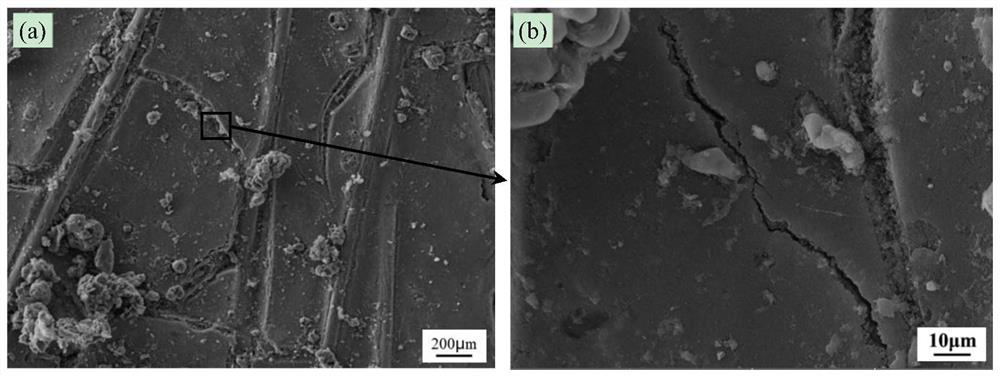

Laser swing welding method for lap joint structure of thermoplastic composite material and aluminum alloy

The invention relates to the technical field of dissimilar material connection, and discloses a laser swing welding method for a lap joint structure of a thermoplastic composite material and an aluminum alloy. The method comprises the steps that S1, sand blasting treatment is conducted on the laser welding surface of the aluminum alloy, and a nail hook structure is machined on the connecting surface through laser; S2, the interface of a lap joint between the thermoplastic composite material and the aluminum alloy is filled with a certain thickness of resin material; S3, a linear or dot-matrixclamping mode is selected according to the thickness of a to-be-welded part, and a stable lap joint is obtained; S4, the size, shape and defocusing amount of a light spot are determined according to the size and requirement of the to-be-welded part, and a laser swing track and a scanning path are designed; and S5, a laser device is started to weld the lap joint, a cooling device is used for cooling weld joints after the welding of each weld joint is completed, and then subsequent welding is conducted. The method can effectively improve the mechanical property of the connecting joint between the thermoplastic composite material and the aluminum alloy, is good in weld joint forming and high in quality, and has a wide application prospect in the aerospace field.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

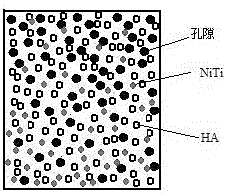

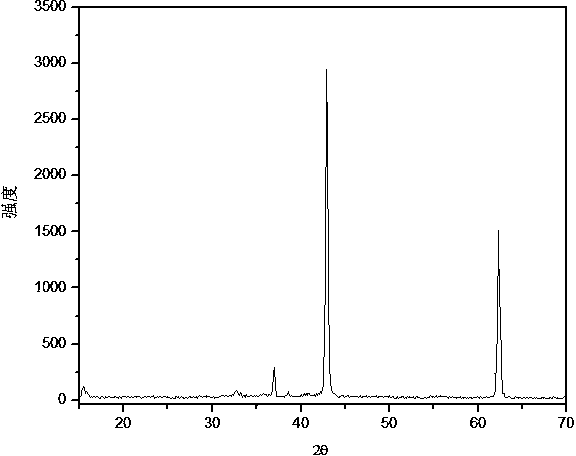

Preparation method of double-gradient porous NiTi / hydroxyapatite composite

InactiveCN106270516AAvoid stress concentrationNo obvious layered interfaceTransportation and packagingMetal-working apparatusWater basedMartensite transformation

The invention provides a preparation method of a double-gradient porous NiTi / hydroxyapatite composite. According to the preparation method, polystyrene, as a pore former, nanometer NiTi and hydroxyapatite are prepared into non-water-based complex-phase slurry; and then, the porous NiTi / hydroxyapatite composite with porosity and the NiTi content both in continuous gradient distribution is prepared through the centrifuging-gel casting technology. The end, having a high porosity and a high hydroxyapatite content, of the porous NiTi / hydroxyapatite composite has good biocompatibility and facilitates ingrowth of new bone tissue and conveyance of body fluids. The end, having a low porosity and a high NiTi content, of the porous NiTi / hydroxyapatite composite can significantly improve the strength and the tenacity of a hydroxyapatite base material because of the low porosity and the martensite phase transformation toughening of the nanometer NiTi particles.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

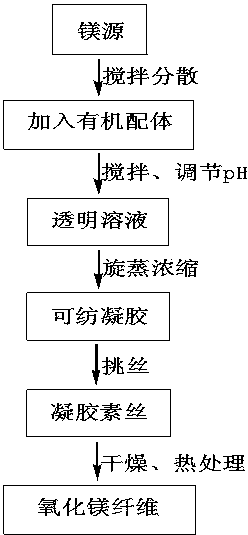

Method for preparing magnesium oxide fiber via sol-gel method

InactiveCN103556305AImprove spinnabilityRaw materials are easy to getInorganic material artificial filamentsFiberThermal insulation

The invention discloses a method for preparing a magnesium oxide fiber via a sol-gel method. The method comprises the following steps: forming a stable sol-gel system under the complexing action between a magnesium ion and an organic ligand; and spinning and calcining the sol-gel system, thereby obtaining the magnesium oxide fiber. The method is simple to operate and low in cost. The obtained magnesium oxide fiber is smooth in surface and long in length diameter and has no significant defect, thereby having good application prospects and commercial values for fire-proof thermal insulation materials.

Owner:EAST CHINA NORMAL UNIV

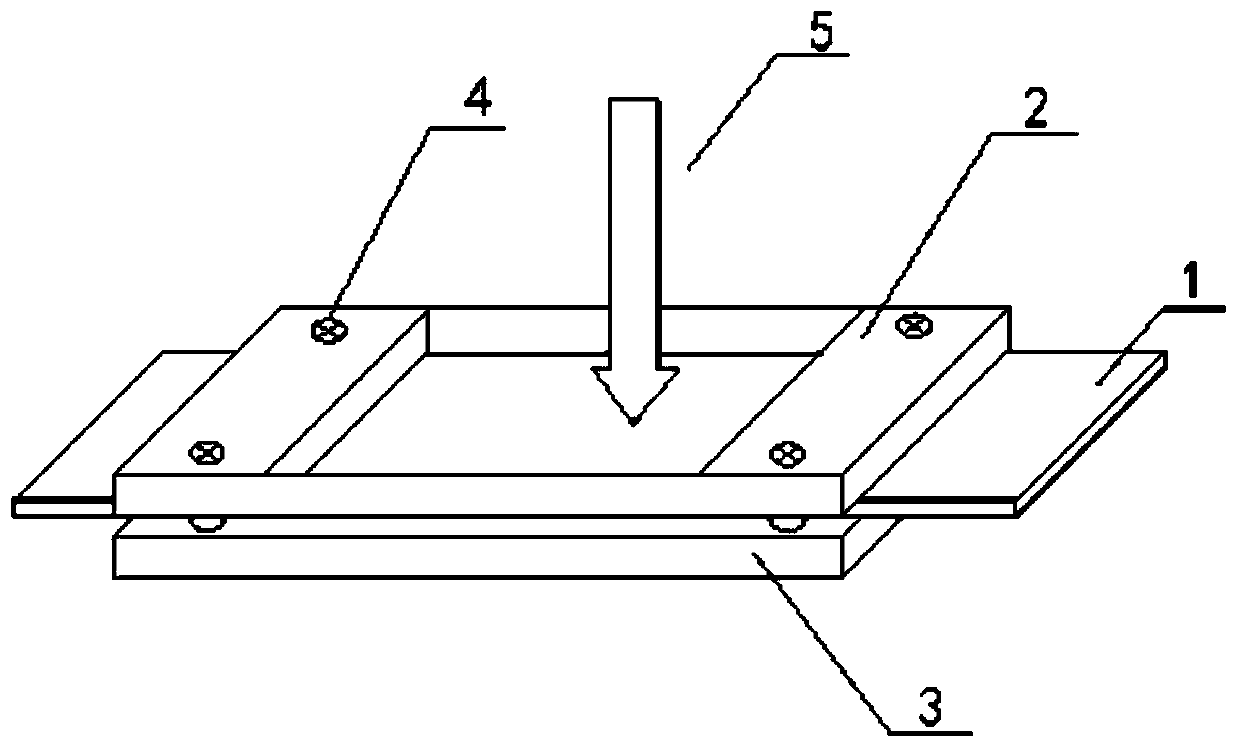

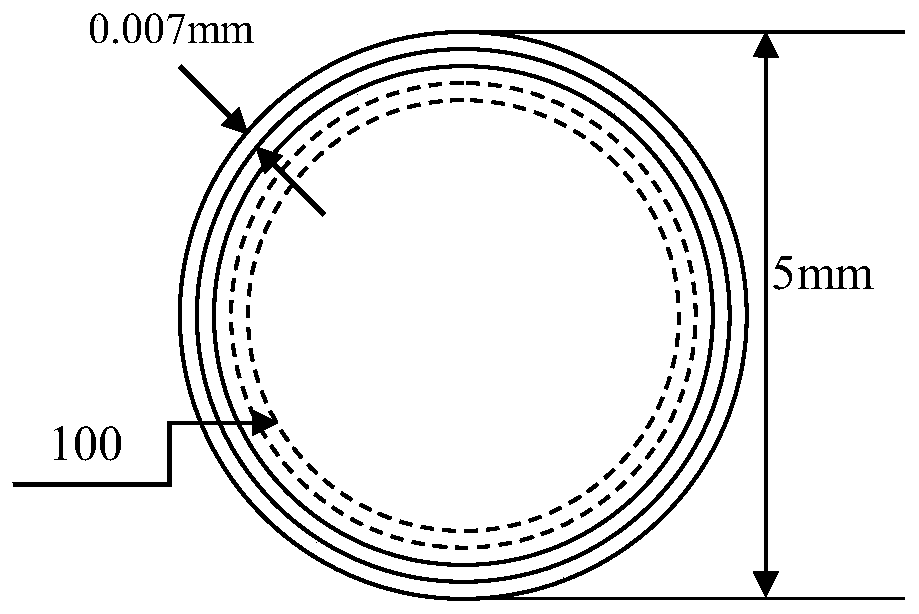

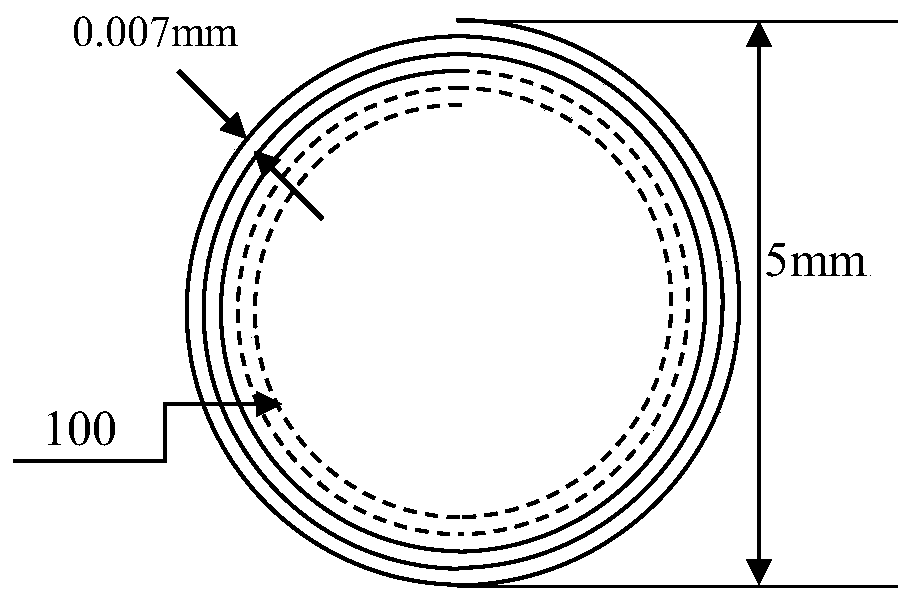

Nickel-coated graphite sealing coating on surface of cast-iron workpiece, and preparation method of nickel-coated graphite sealing coating

The invention relates to a nickel-coated graphite sealing coating on the surface of a cast-iron workpiece, and a preparation method of the nickel-coated graphite sealing coating, and belongs to the technical fields of composite materials and thermal spraying. The bonding strength of the coating and a matrix is increased by taking a NiAl metal coating as a bonding layer, a nickel-coated graphite coating is sprayed on the surface as a self-lubricating coating, a stable abradable coating system based on the thermal spraying on the cast-iron surface is formed through combination, a gap between anair compressor and a cartridge receiver can be effectively filled, good impact resistance and thermal shock resistance are achieved, and therefore the working efficiency of the air compressor is increased; and the NiAl bonding layer is prepared through electric arc spraying for wires, and the large-particle-size nickel-coated graphite sealing coating is prepared through flame spraying. The double-layer coating system prepared by the preparation method is compact in microstructure; high bonding performance between the coatings and between the coating and the cast-iron matrix is achieved; and graphite phases are uniformly distributed in the coating. Meanwhile, the nickel-coated graphite sealing coating on the surface of the cast-iron workpiece has the advantages of being low in graphite oxidation loss rate, simple in process, low in cost, high in efficiency, high in repeatability, suitable for large-scale production, and the like.

Owner:宁波思朴锐机械再制造有限公司

Laser hole making method for carbon fiber composite material and tooling fixture thereof

PendingCN111069798ATypical ultra-short pulse widthTypical Ultra High Peak Power CharacteristicsLaser beam welding apparatusPicosecond laserErbium lasers

The invention discloses a laser hole making method for a carbon fiber composite material. The method comprises the following steps that 1, surface wiping is performed on the carbon fiber composite material to be treated with alcohol cotton, surface pollutants are removed, the carbon fiber composite material is aired and then the carbon fiber composite material is used for later use; and 2, the carbon fiber composite material obtained in the step 1 is subjected to laser scanning machining treatment according to a designed scanning track by adopting an ultrashort pulse laser machining system, and machining holes with different apertures are prepared; and an ultrashort pulse laser adopts a picosecond laser, so that the defects such as thermal effect caused by long pulse laser machining can beavoided. The hole surfaces prepared by the laser hole making method is good in morphology, neat in edge and free of obvious defects, and compared with a mechanical hole making mode, the heat radiation area can be remarkably reduced, the roughness of the inner walls of the round holes is reduced, and the hole making precision is improved. The invention further discloses a tooling fixture suitablefor the laser hole making method of the carbon fiber composite material, the tooling fixture suitable for the laser hole making method of the carbon fiber composite material can effectively reduce thetemperature of the machining area and can reduce the heat radiation area.

Owner:SHANGHAI INST OF LASER TECH

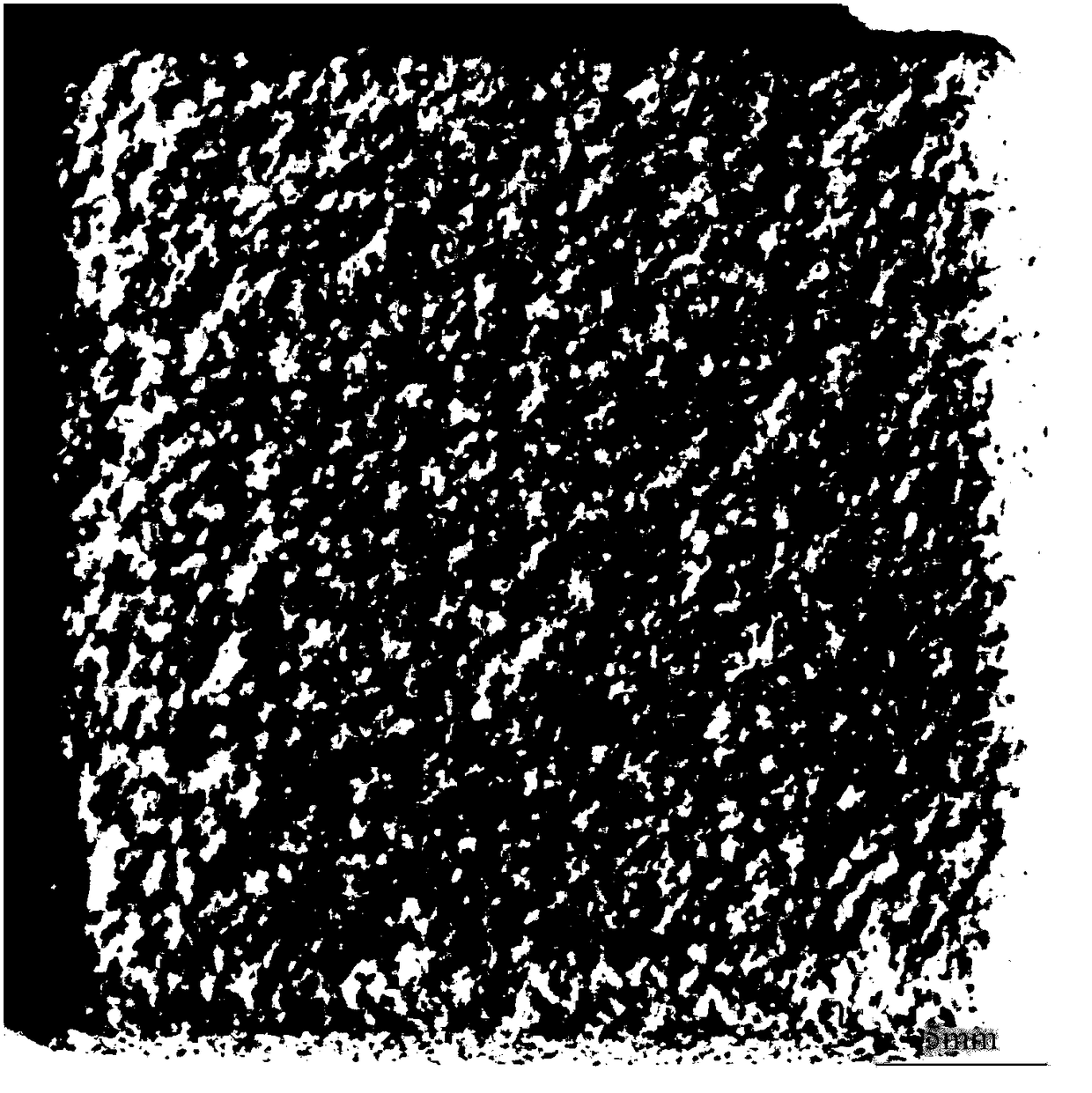

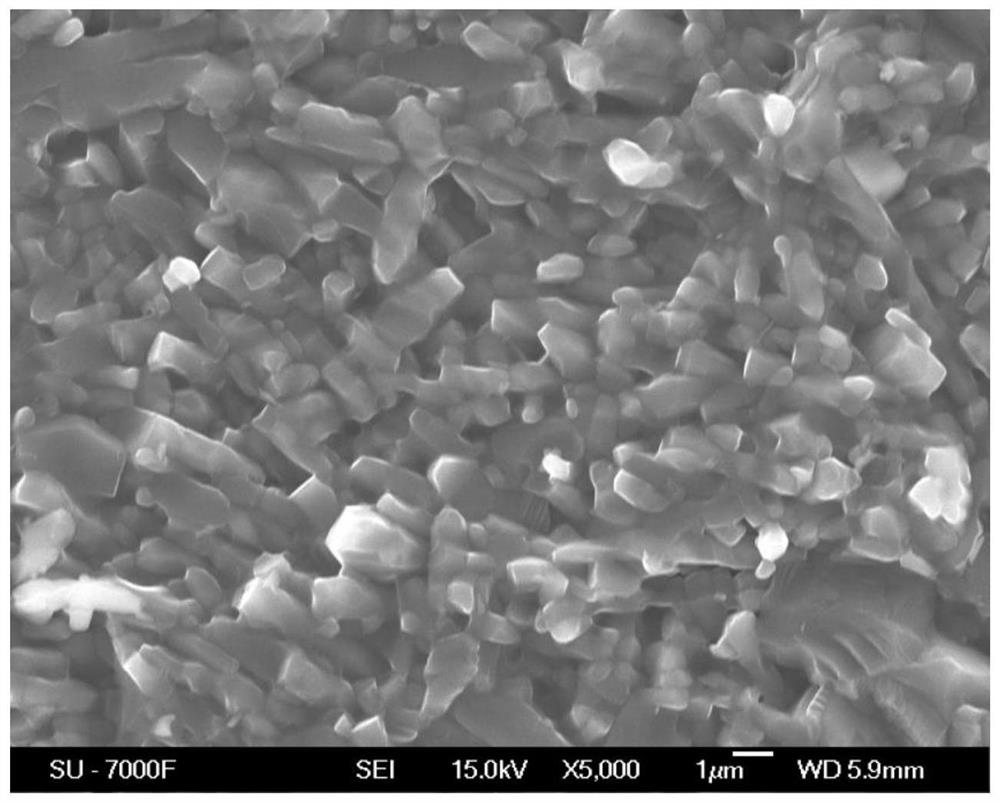

Silicon carbide whisker ceramic with typical long particle morphology and rich in lamination faults and twin crystals and preparation method thereof

The invention provides a silicon carbide whisker ceramic with typical long particle morphology and rich in lamination faults and twin crystals and a preparation method thereof. The preparation method comprises the steps that by taking beta-silicon carbide whiskers as a raw material, a high-temperature liquid-phase sintering aid Y2O3-Al2O3-SiO2 is added into the silicon carbide whiskers; in the high-temperature sintering process, gaps among silicon carbide whisker frameworks are filled through flowing of the liquid-phase sintering aid under pressure, so that abnormal growth and secondary recrystallization of the whiskers in the high-temperature sintering process are avoided while densification of the silicon carbide whiskers is realized, and the silicon carbide whisker long particle morphology and abundant twin crystals, dislocation and other microstructures are retained in the sintered silicon carbide ceramic. The silicon carbide ceramic obtained through the method has the advantages of being uniform in structure, high in whisker morphology retention degree, high in compactness, good in mechanical property and the like.

Owner:WUHAN UNIV OF TECH

Dry -particle decorative ceramic tile and preparation method thereof

ActiveCN113248285ASolve precipitationSolve segregationCeramic shaping apparatusBrickSuspending Agents

The invention discloses a dry-particle decorative ceramic tile and a preparation method thereof. The preparation method specifically comprises the following steps: pre-treating a green brick; and sequentially applying dry granules, a water-retaining wetting agent and glaze slip on the surface of the green brick subjected to pretreatment, and then performing aftertreatment, wherein the water retention wetting agent comprises transparent protective glaze, a suspending agent and water. The dry- particle decorative ceramic tile can be prepared by using the preparation method. The preparation method provided by the invention solves the problems that surface pits are easy to appear in a dry process and the like, also solves the problems of precipitation and segregation of the dry particles with large specific gravity in the liquid glaze slip, ensures the surface effect of the product decorated by the dry particles, improves the superior rate of the product, and is suitable for industrial large-scale production. And the dry- particle decorative ceramic tile prepared by the preparation method is excellent in product performance, stable in surface decorative effect and free of obvious defects.

Owner:FOSHAN OCEANO CERAMICS

Novel Ni-Cr corrosion-resistance alloy heat exchange tube plate and welding process thereof

InactiveCN108406058AImprove distributionGood welding effectArc welding apparatusHeat exchanger casingsHeat-affected zoneAlloy

The invention discloses a novel Ni-Cr corrosion-resistance alloy heat exchange tube plate and a welding process thereof. A heat exchange tube adopts ferrite stainless steel XDS-I with a chromium massfraction of 25-30%; the tube plate and a welding wire both adopt austenite stainless steel XDS-II with a chromium mass fraction of 24-26% and a nickel mass fraction of 19-22%; the total content of C+Nelements in the ferrite stainless steel XDS-I material adopted by the heat exchange tube is not higher than 0.025%; a special welding process is cooperated to achieve excellent welding effect, smoothand uniform welding lines and excellent metallographic structure distribution; macroscopic and microscopic structures of welding lines of the tube and the tube plate are free of obvious defects, excellent in morphology and free of such defects as cracks, incomplete fusion and incomplete penetration; and the welding lines are qualified. Heat affected zones and melting areas of microscopic metallographic structures of the sections of the welding lines are excellently transited, and are free of burnt structures, hardened martensitic structures, netty precipitates and netty structures.

Owner:ZHEJIANG YIDA SPECIAL ALLOY PROCESS EQUIP CO LTD

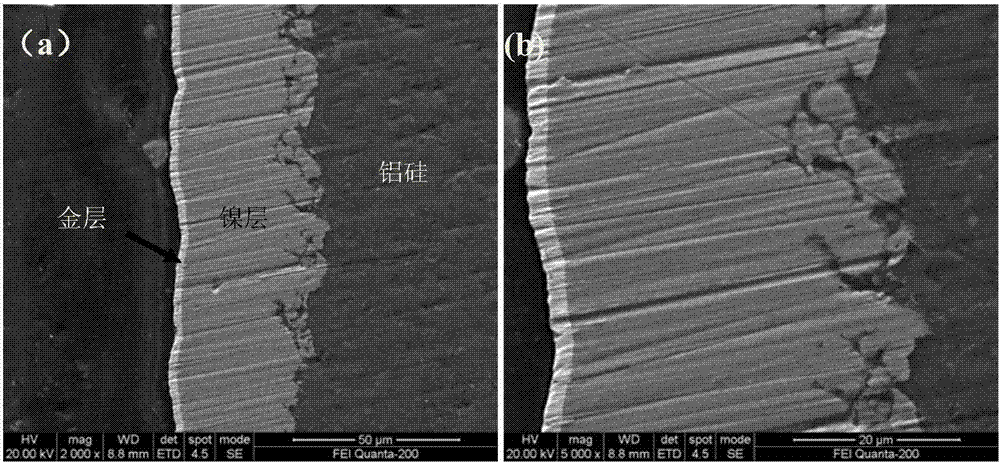

Plating method of high silicon aluminum alloy

ActiveCN107304479ATightly boundEasy to package and solderLiquid/solution decomposition chemical coatingColor changesAir tightness

The invention relates to a plating method of a high silicon aluminum alloy, is suitable for the high silicon aluminum alloy, the silicon content of which is 27-60%, and belongs to the field of metal surface modification. The plating method comprises the following basic steps: deoiling; coursing; primary activating; chemical nickel preplating; primary nickel plating; thermal treatment; secondary activating; secondary nickel plating; and gold-plating. The high silicon aluminum alloy obtained by the plating method is uniform in plating layer and good to combine, bubbling, falling or color-changing phenomena after a high-temperature roasting experiment are avoided, and the air tightness after welding packaging achieves operating requirements.

Owner:长沙博朗思达新材料科技有限公司

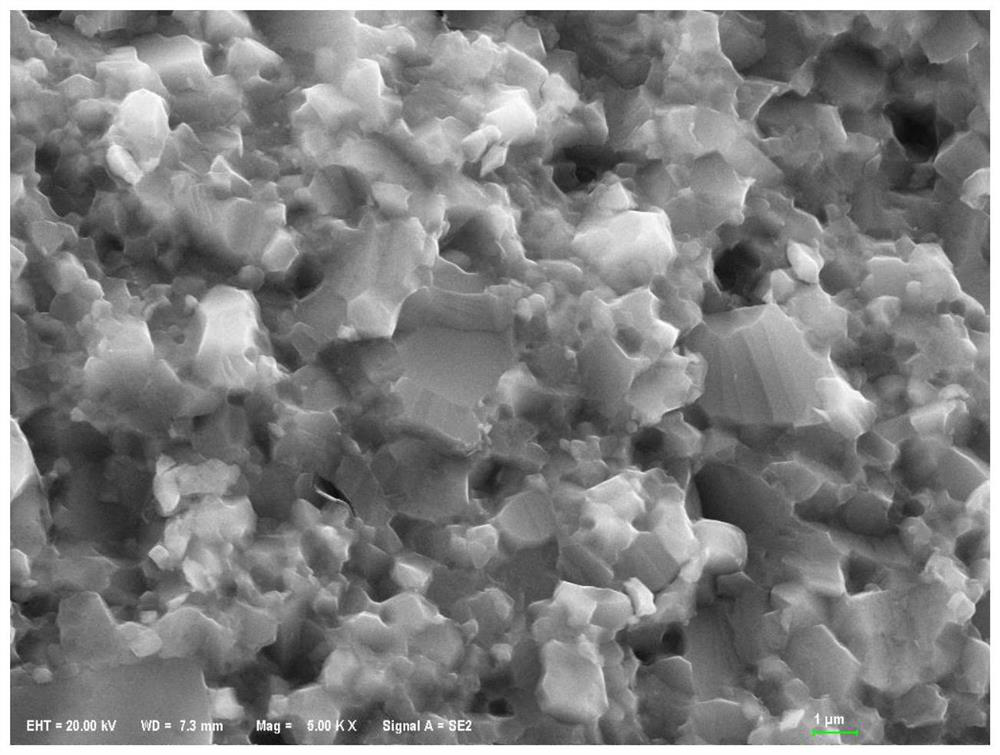

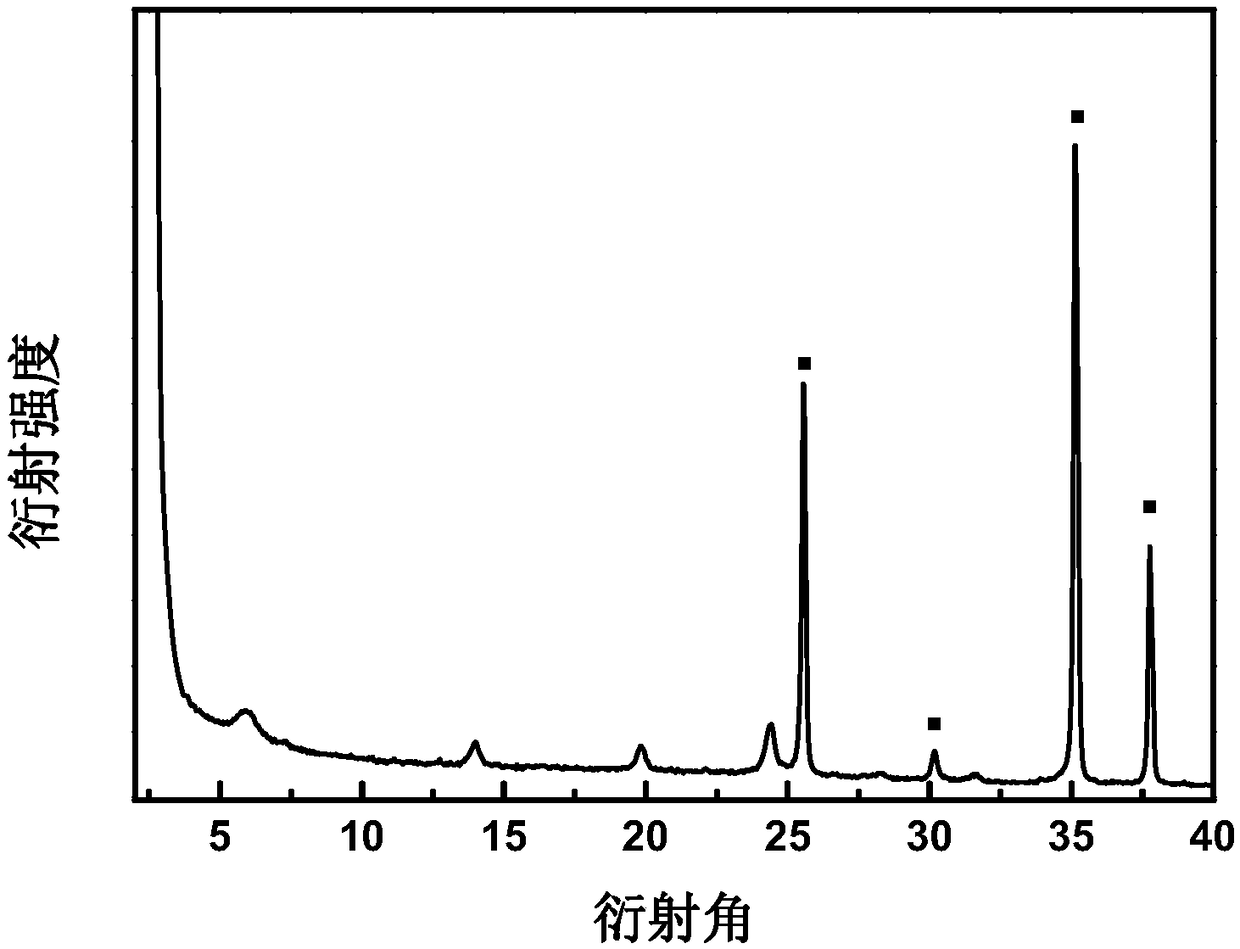

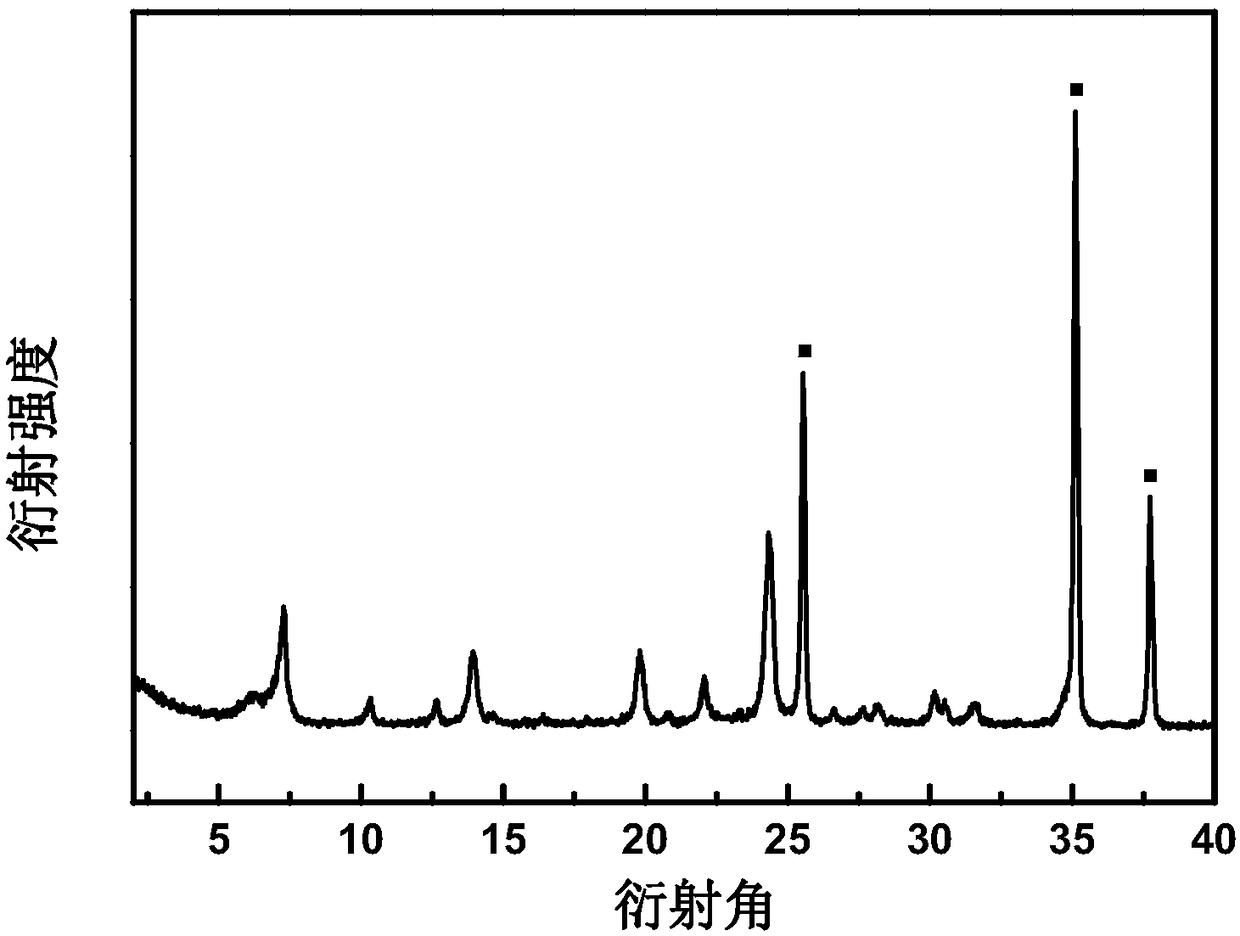

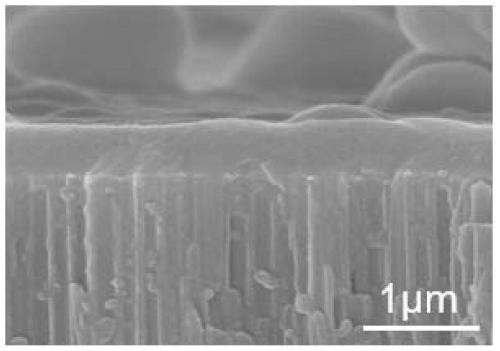

In-situ synthetic method for zeolite molecular sieve membrane

InactiveCN108117088AEvenly distributedSmall apertureDistillationCrystalline aluminosilicate zeolitesMolecular sieveOrganic acid

An in-situ synthetic method for a zeolite molecular sieve membrane comprises the steps of: preparing a synthetic solution from a silicon source, an aluminum source and an organic template agent, placing a porous carrier in the synthetic solution, and synthesizing an acid-resistant zeolite molecular sieve membrane under hydrothermal conditions. The zeolite molecular sieve membrane prepared by the synthetic method of the invention has thin, continuous, dense and uniform distribution without obvious defects. The average thickness of the membrane is 100 nm-50 [mu]m, the silicon-aluminum ratio is relatively high (5-12), and the pore diameter is relatively small (0.36*0.44 nm). The zeolite molecular sieve membrane shows extremely good stability and permeation performance in organic acid solutions with various acidity, is applicable to a pervaporation process under acidic conditions, and exhibits excellent selective permeability on water molecules in organic / water mixtures, especially in acidic systems.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

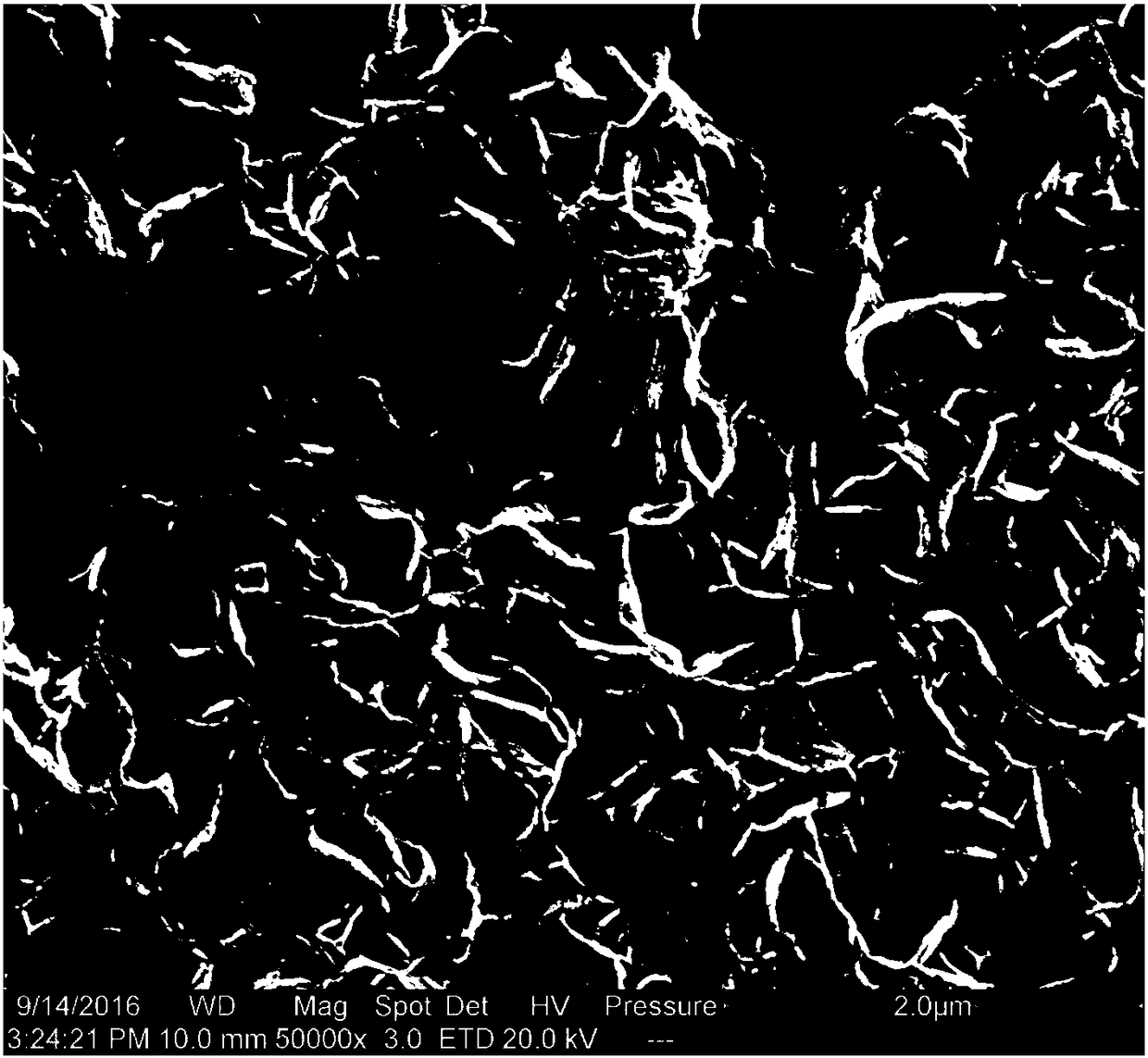

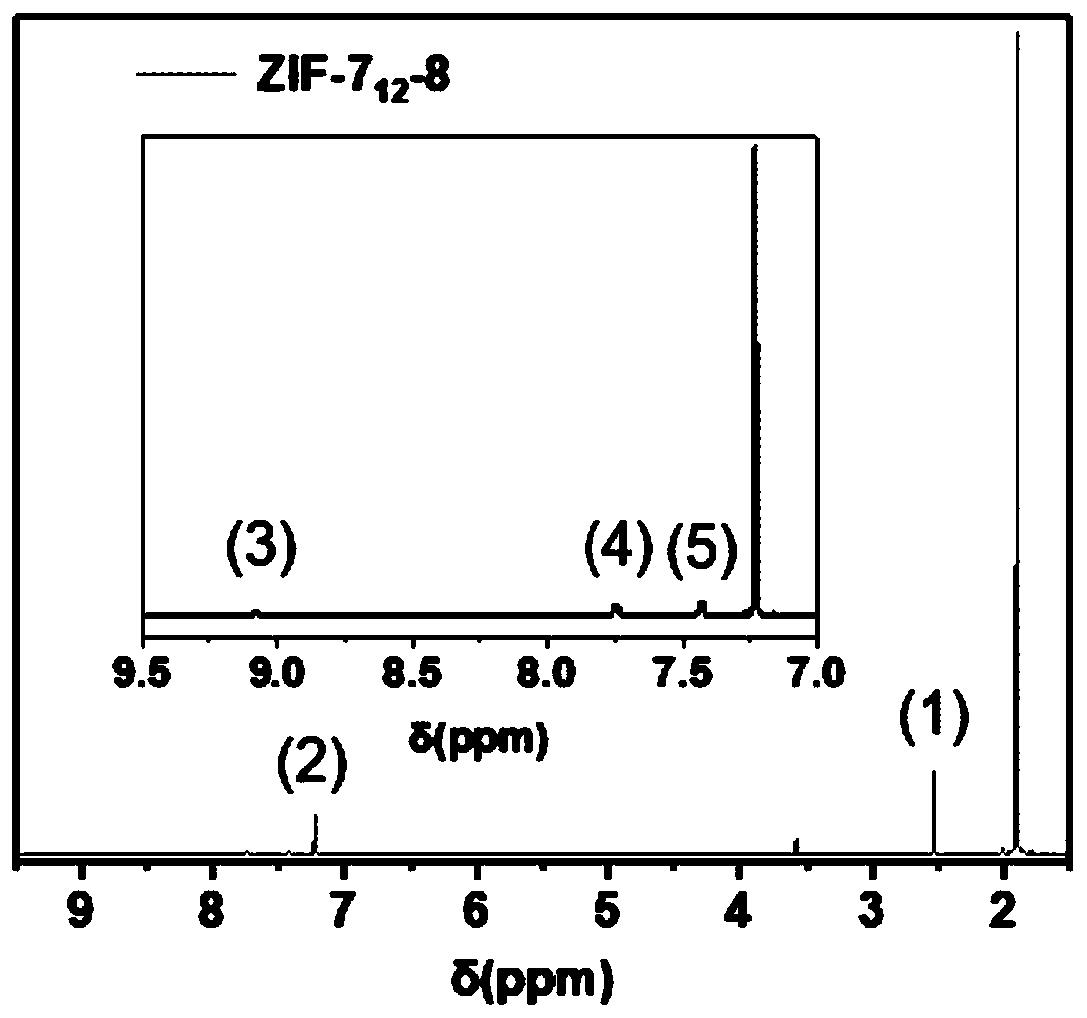

Method for preparing biligand film by utilizing in-situ electric field and biligand film prepared by method

InactiveCN109865435AEliminate post-processingFlawlessSemi-permeable membranesPower flowMixed materials

The invention discloses a method for preparing a biligand film by utilizing an in-situ electric field and the biligand film prepared by the method. The method comprises the following steps: (1) mixingzinc acetate dihydrate and dimethylimidazole, dissolving the mixed material into a solvent to obtain a solution A, and dissolving benzimidazole into a solvent to obtain a solution B; (2) adding the solution A obtained in the step (1) into the solution B, performing mixing, and allowing the mixed material to stand, wherein an appropriate amount of mixed solution is used as a precursor liquid; and(3) immersing a substrate into the precursor liquid obtained in the step (2), applying an electric current for a reaction to obtain the biligand film. The method provided by the invention prepares thebiligand film by the in-situ electric field method, the method is simple and rapid, greatly improves the production efficiency, and has good universality; the biligand film prepared by the in-situ electric field method has no obvious defects on the surface, and has good contact with the substrate without obvious cracks; and the simple high-efficiency in-situ electric field method used in the invention can be completed at normal temperature and pressure, and has no special requirements on the substrate, thereby providing a possibility for mass production.

Owner:SOUTH CHINA UNIV OF TECH

Antioxidant ZrB2-SiC-Y2O3-SiC coating on surface of C-C composite material, and preparation method thereof

ActiveCN113045339AThe embedding reaction process is simpleHigh bonding strengthOxidation resistantCrazing

The invention discloses an antioxidant ZrB2-SiC-Y2O3-SiC coating on the surface of a C-C composite material, and a preparation method thereof. The preparation method comprises the following steps: firstly, preparing a SiC transition layer on the surface of a C-C composite material matrix by virtue of an embedding infiltration technology, and continuously preparing a ZrB2-SiC-Y2O3 outer coating on the SiC transition layer by virtue of embedding infiltration. The SiC transition layer is introduced between the ZrB2-SiC-Y2O3 coating and the matrix, so that the effects of relieving mismatching of thermal expansion coefficients and releasing thermal stress can be achieved, and the oxidation resistance of the coating is further improved. The ZrB2-SiC-Y2O3-SiC composite coating is prepared by adopting a two-step embedding infiltration technology, so that the thermal damage to a C-C matrix is small, the binding force of the coating is strong, and the coating is compact. The SiC transition layer effectively relieves mismatching of thermal expansion coefficients of the outer coating and the base body, reduces cracks, caused by thermal stress, of the outer coating, improves the binding force of the coating, and effectively improves the oxidation resistance of the coating.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

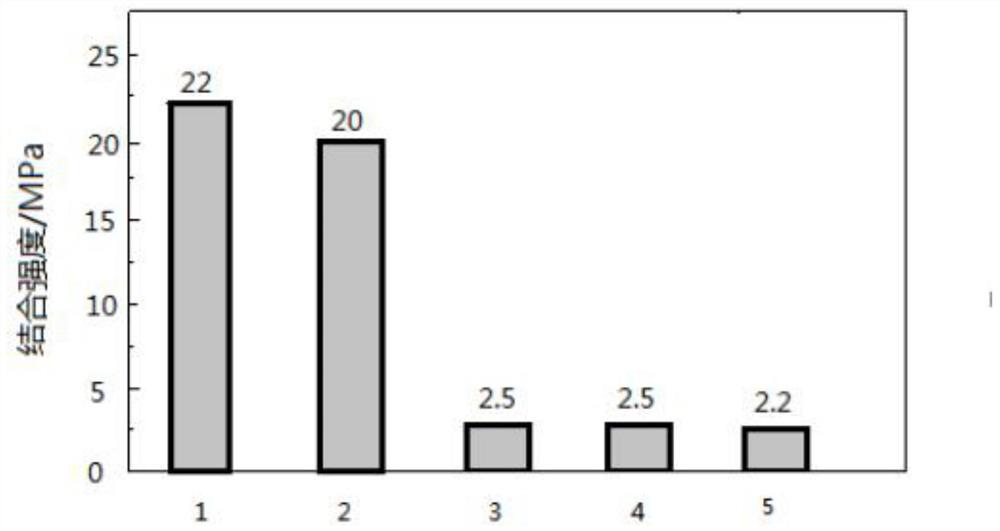

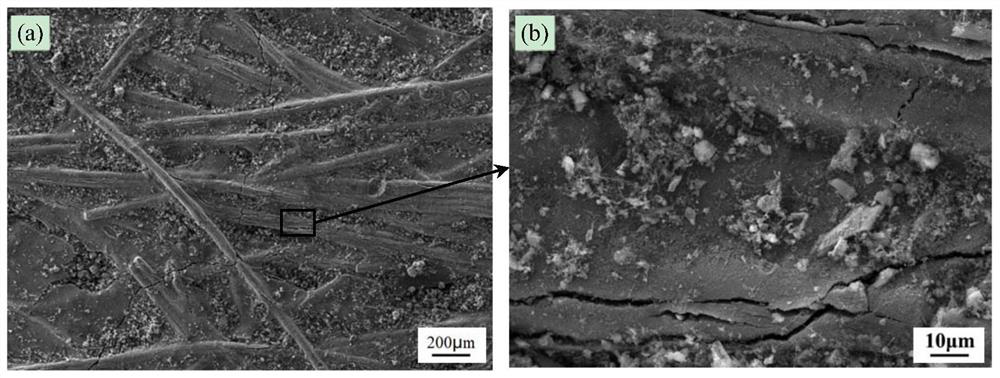

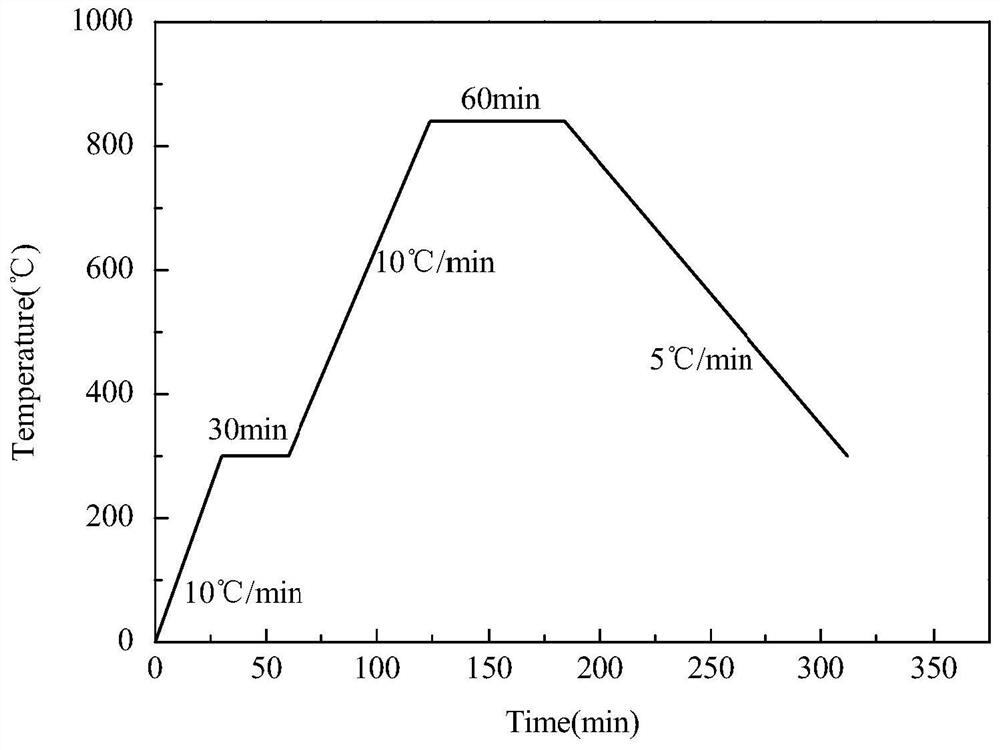

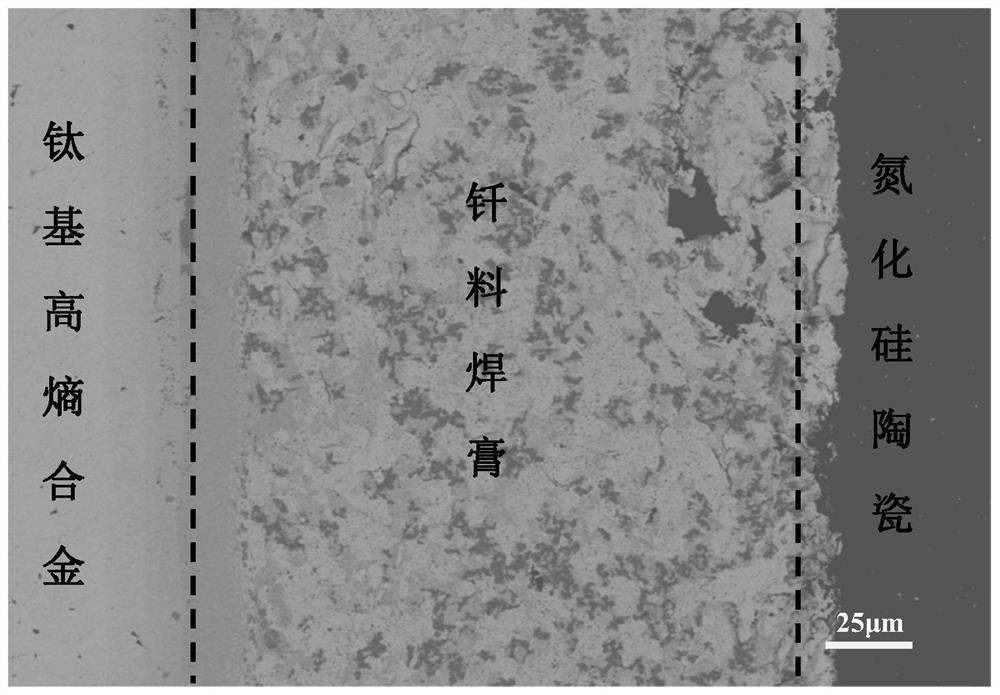

Brazing method for welding titanium-based high-entropy alloy and silicon nitride ceramic

PendingCN112872523AIncreased shear strengthExcellent brazing strengthSolder feeding devicesSoldering auxillary devicesHigh entropy alloysTitanium

The invention discloses a brazing method for welding a titanium-based high-entropy alloy and silicon nitride ceramic. The brazing method comprises the following steps that 1, silver-based brazing filler metal powder and brazing flux are prepared into brazing filler metal soldering paste according to the mass ratio of 9: 1; 2, the pretreated titanium-based high-entropy alloy and the pretreated silicon nitride ceramic are stacked layer by layer according to the sequence of the titanium-based high-entropy alloy, the filler metal soldering paste and the silicon nitride ceramic to obtain a brazing assembly block; 3, the brazing assembly block is placed in a mold, a pressing block is placed on the uppermost layer of the brazing assembly block, and then the brazing assembly block is placed in a brazing furnace; 4, after the brazing block is heated to 800 DEG C-900 DEG C in a stepped manner through the brazing furnace, heat preservation is conducted, and cooling and nature cooling are performed to the room temperature along with the furnace; and 5, the brazing process of the titanium-based high-entropy alloy and the silicon nitride ceramic is completed. According to the method, the titanium-based high-entropy alloy and the silicon nitride ceramic are brazed through the silver-based brazing filler metal soldering paste through the brazing process, the strength of a connector between the titanium-based high-entropy alloy and the silicon nitride ceramic after brazing is 21-86 MPa, reliable connection of the titanium-based high-entropy alloy and the silicon nitride ceramic is achieved, and meanwhile a technical scheme is provided for welding of the titanium-based high-entropy alloy.

Owner:QUZHOU UNIV

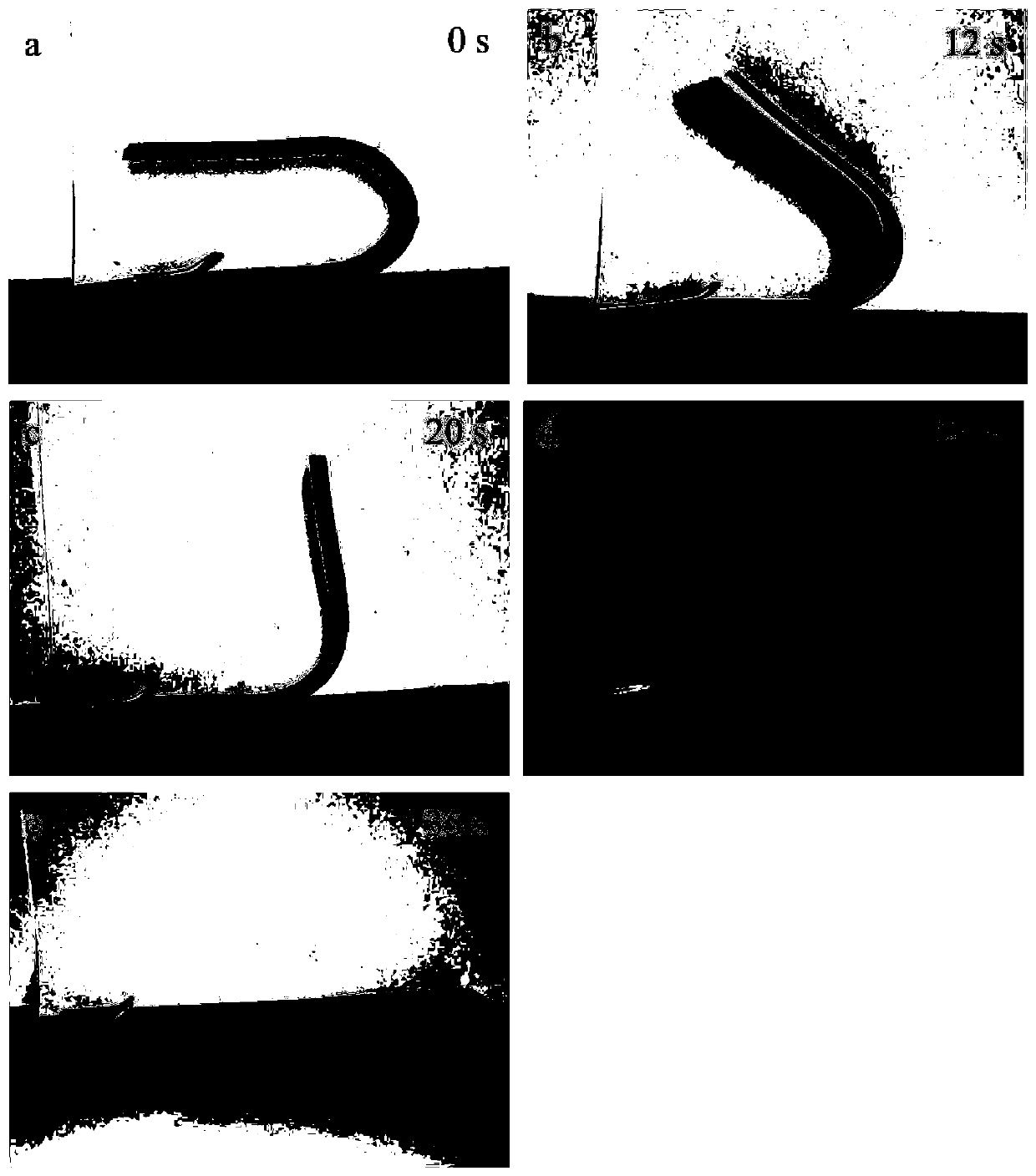

A high-strength flexible epoxy resin modified cyanate resin/carbon fiber composite shape memory material and its preparation method

The invention discloses a high-strength flexible epoxy resin modified cyanate resin / carbon fiber composite shape memory material and a preparation method thereof. According to the composite shape memory material, cyanate resin serves as matrix resin, carboxyl-terminated liquid nitrile rubber and flexible epoxy resin serve as flexibilizers, and carbon fiber materials are reinforced phases and formed by vacuum heating curing. A toughening cyanate resin pouring body is long in pot life and good in fiber overlay and compounded with a carbon fiber by an existing forming process to obtain the flexible epoxy resin modified cyanate resin / carbon fiber composite shape memory material which has flat surfaces, is free from obvious defects and has the advantages of high tensile strength, tensile modulus, shearing strength, bending strength and the like.

Owner:CENT SOUTH UNIV

Weld bonding method for car body cover

InactiveCN104985399AEliminate the need for orthopedic proceduresNo obvious defectsVehicle componentsLaser heatingPre treatment

The invention discloses a weld bonding method for a car body cover. The weld bonding method for the car body cover includes the steps of pretreatment, gluing, cover connecting, laser heating and secondary laser heating. In the application process of the weld bonding method for the car body cover, weld bonding of a car body framework and the car body cover can be achieved without any additional clamping tool, a weld joint has no obvious defects, the welding quality is high, the welded cover does not deform, and the production quality is improved. Meanwhile, the treatment process that shape righting is manually conducted on a deformed cover after welding in the prior art is omitted, and therefore the production efficiency is improved, and the cost is saved.

Owner:SUZHOU HUARI JINLING MACHINERY

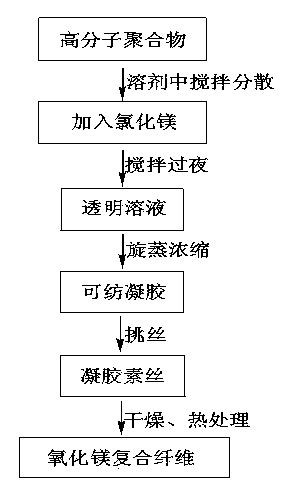

Method for preparing magnesium oxide composite fiber

The invention discloses a method for preparing a magnesium oxide composite fiber. The method is implemented by using a characteristic that a high-molecular polymer is easily formed into filaments and comprises the following steps: loading magnesium chloride on the high-molecular polymer so as to form a gel, and carrying out filament picking and calcining on the gel so as to obtain the magnesium oxide composite fiber. The obtained fiber is smooth in surface, has no significant defect, and has a relatively long length diameter, so that the fiber has good application prospect and good commercial value in the aspect of refractory and insulating materials.

Owner:EAST CHINA NORMAL UNIV

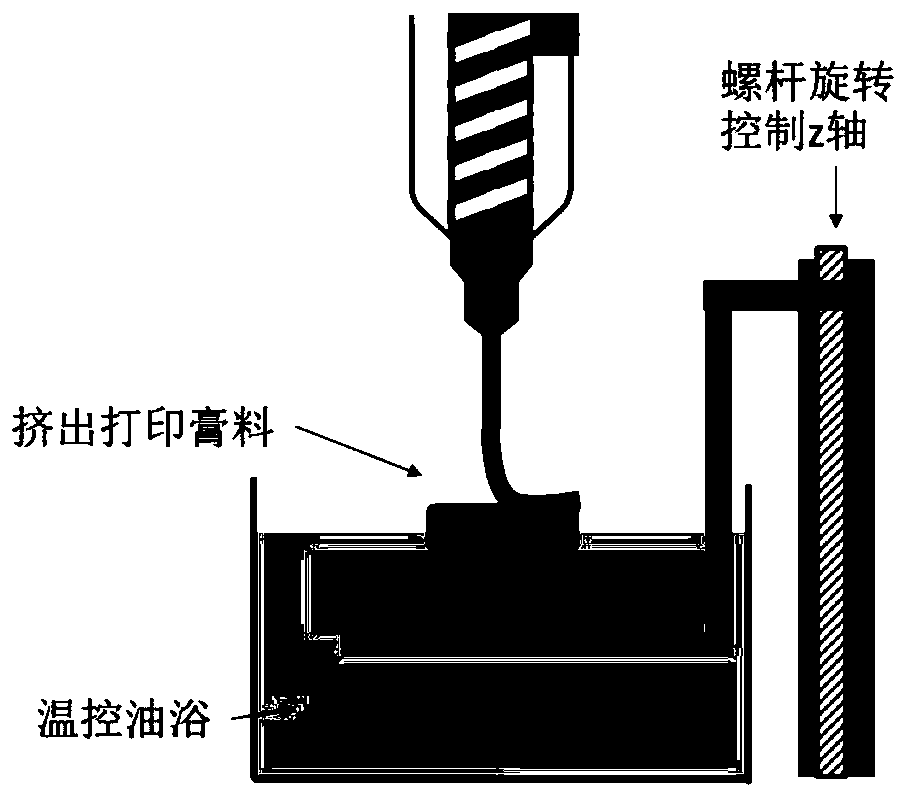

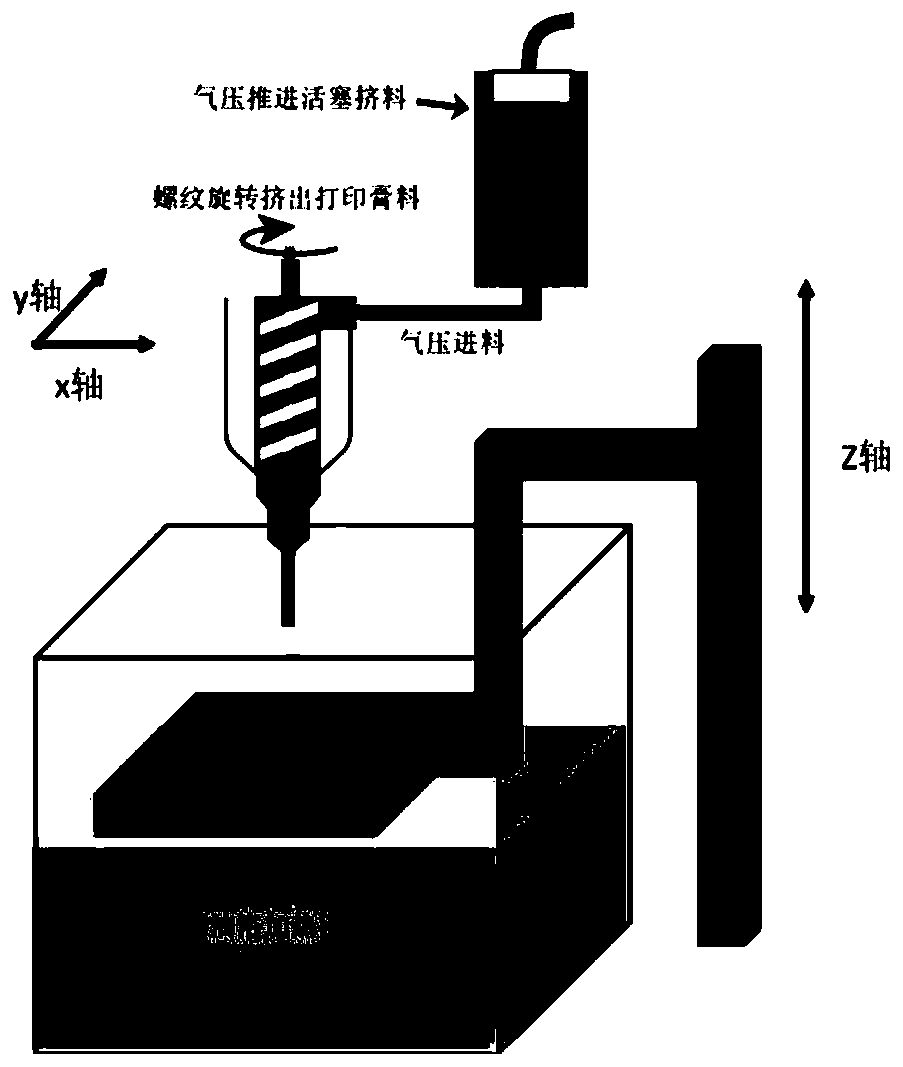

Method of ceramic 3D printing forming through temperature induced curing and application of method

InactiveCN109928765AGuaranteed continuityNo obvious defectsAdditive manufacturing apparatusTemperature induced3D printing

The invention relates to the field of ceramic manufacturing, in particular to a method of ceramic 3D printing forming through temperature induced curing and application of the method. The method comprises the steps of paste preparation, 3D printing and induced curing, wherein during paste preparation, on the basis of the weight of ceramic powder, 1-4% of carrageenin powder is mixed; and during induced curing, printed paste is placed in an environment at 60-70 DEG C. The purpose of rapid curing can be achieved under the situation of ensuring the continuity and precise forming capability of thepaste, and a printed body is free of obvious defects and obvious deformation. The method is simple, efficient and easy to implement, and application and popularization of the 3D printing technology inthe ceramic field are facilitated.

Owner:BEIHANG UNIV

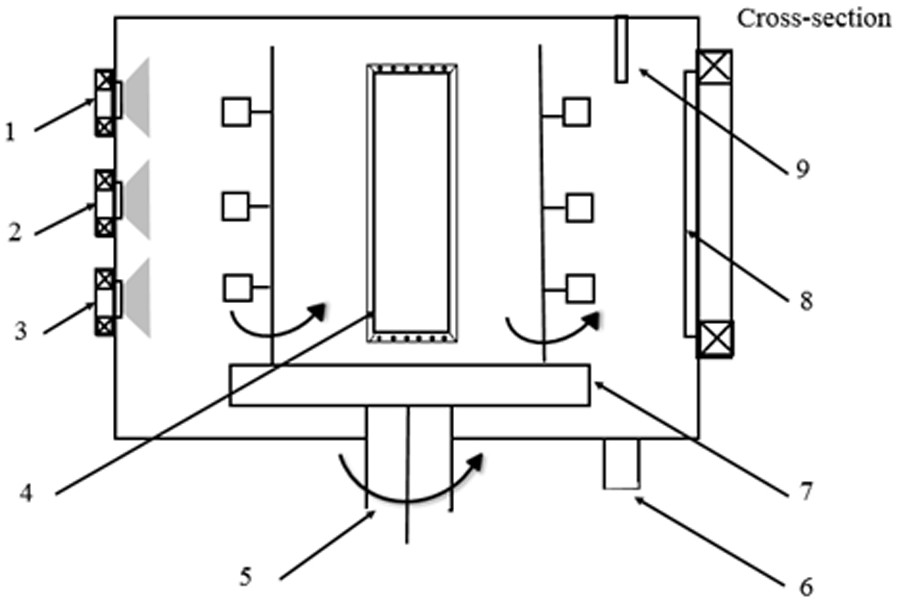

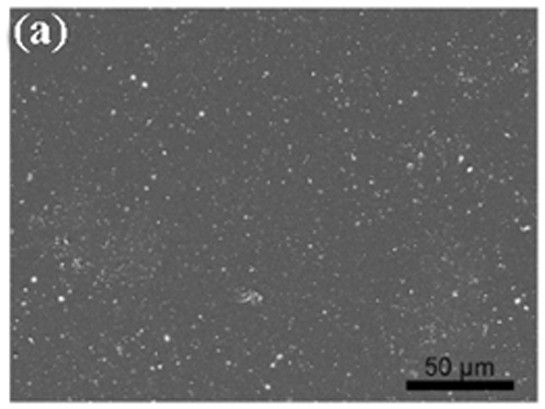

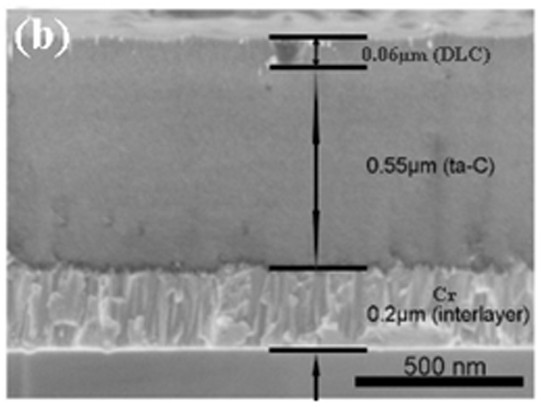

Ta-c-based multilayer wear-resistant cutter coating and preparation method thereof

ActiveCN112647040AReduce the stress concentration of the film baseSpalling failure suppressionVacuum evaporation coatingSputtering coatingThin membraneBonding strength

The invention relates to a magnetron sputtering multi-arc ion plating coupling process deposition cutter coating and particularly discloses a coating which is composed of a metal bonding layer, a ta-c functional wear-resistant layer and a surface diamond-like layer. According to the coating, a metal Cr target and a graphite target material serve as raw materials, and the system structure of a film layer is as follows: (1) a metal Cr layer serves as the bonding layer with a matrix, and provides relatively high bonding strength for the ta-c functional layer at the same time; (2) periodic continuous plating of the ta-c functional layer provides good lubricity in the cutting process; and (3) plating of a surface diamond-like carbon (DLC) film mainly reduces the surface roughness and the pinning effect, and the wear resistance of a film layer system is improved. The ta-c-based multilayer wear-resistant coating prepared through the coupling coating process can remarkably improve the wear resistance and reduce adhesion behaviors in the cutting process, and is particularly suitable for high-precision cutting working conditions.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com