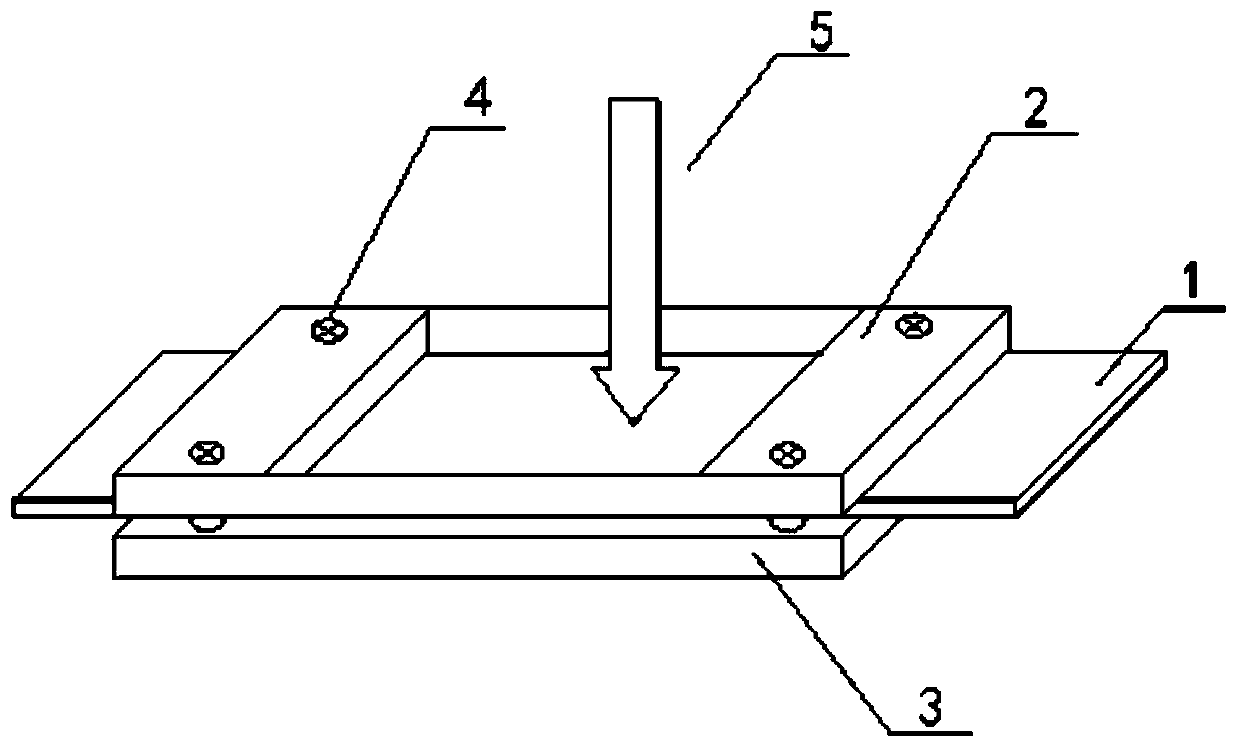

Laser hole making method for carbon fiber composite material and tooling fixture thereof

A technology of composite materials and fixtures, which is applied in the direction of manufacturing tools, laser welding equipment, metal processing equipment, etc., can solve problems such as thermal defects, and achieve the effects of improved precision, low processing cost, and neat edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

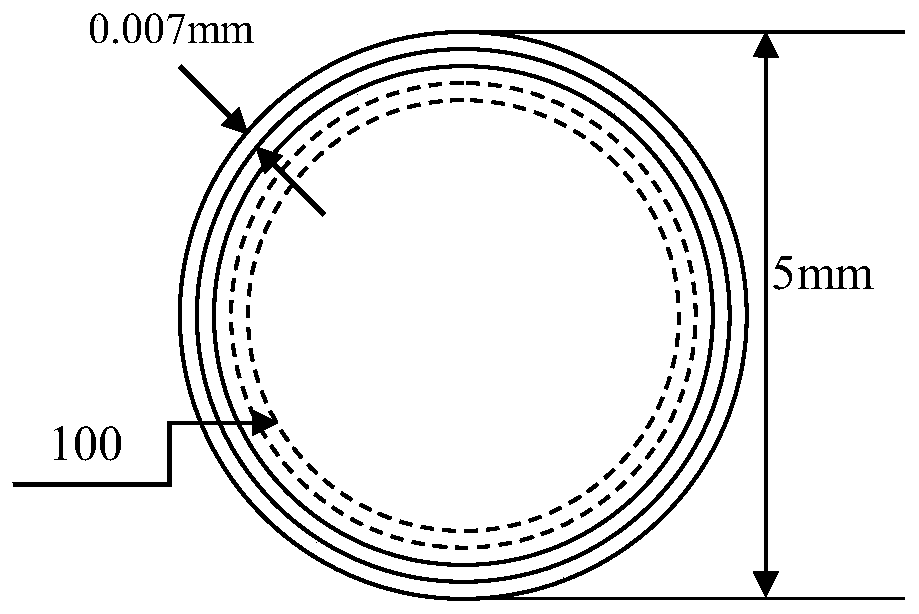

[0040] The circular ring adopts such as Figure 2a The concentric circles shown are scanned in circles from outside to inside, refer to Figure 3a , the edges of the concentric holes made in this way are relatively neat, the surface morphology is good, and there is a small amount of heat-affected zone. Refer to Figure 4a It can be seen that the concentric circular holes have a heat-affected zone of about 110 μm. Figure 5c The inner wall roughness Sa of the middle mechanical hole is 4.02μm, the reference Figure 5a , The roughness Sa of the inner wall of the concentric circle hole is only 3.01 μm, and the roughness is significantly reduced.

Embodiment 2

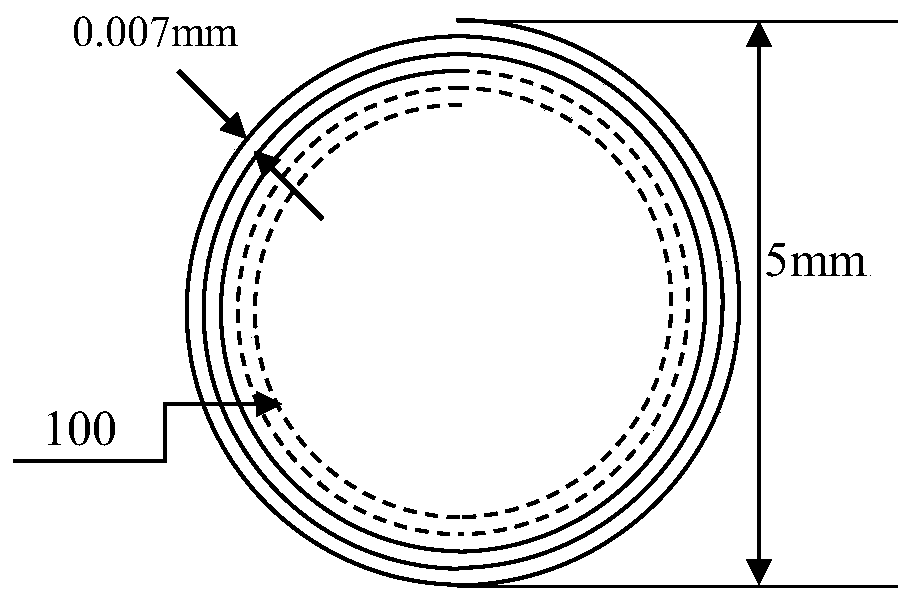

[0042] Different from Example 1, the circular ring adopts such as Figure 2b The spiral circle shown is scanned from the outside to the inside, refer to Figure 3b , the edge of the hole of the spiral circle hole made in this way is more tidy in Example 1, the surface morphology is good, and there is a small amount of heat-affected zone. Refer to Figure 4b It can be seen that the heat-affected zone of the spiral circular hole is further reduced compared with Example 1, and the heat-affected zone of the spiral circular hole is about 75 μm. Figure 5c The inner wall roughness Sa of the middle mechanical hole is 4.02μm, the reference Figure 5b , the roughness Sa of the inner wall of the spiral circle hole is only 2.61 μm, and the roughness is significantly reduced.

[0043] In the above two examples, KEYENCE optical microscopes were used to observe the surface morphology of the laser-made holes, the morphology of the inner wall of the hole, and measure the roughness of the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com