Method of ceramic 3D printing forming through temperature induced curing and application of method

A 3D printing, temperature-induced technology, applied in additive processing and other directions, can solve the problems of difficult control of gelation rate, low efficiency, and unfavorable rapid solidification of ceramic slurry, and achieves the effect that is beneficial to promotion and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for temperature-induced solidification of ceramic 3D printing, comprising the following steps:

[0038] (1) Configuration paste: 0.19 parts of the carrageenan powder, 0.4 parts of the dispersant and 18 parts of the deionized water are mixed in a planetary vacuum high-speed (1000r / min) mixer according to the proportioning ratio. After 3 minutes, the premix was obtained, and the premix was mixed with 82 parts of alumina ceramic powder with a particle size of 0.5 micron in a planetary vacuum high-speed (1500r / min) mixer for 5 minutes to obtain a uniform ceramic with good dispersibility. Paste;

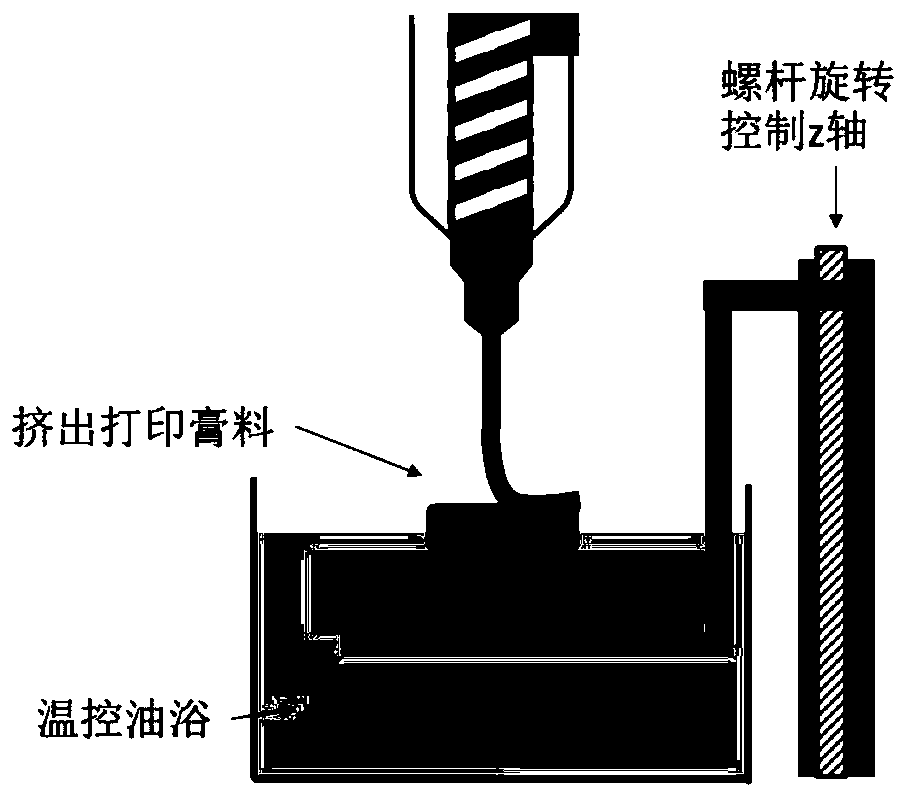

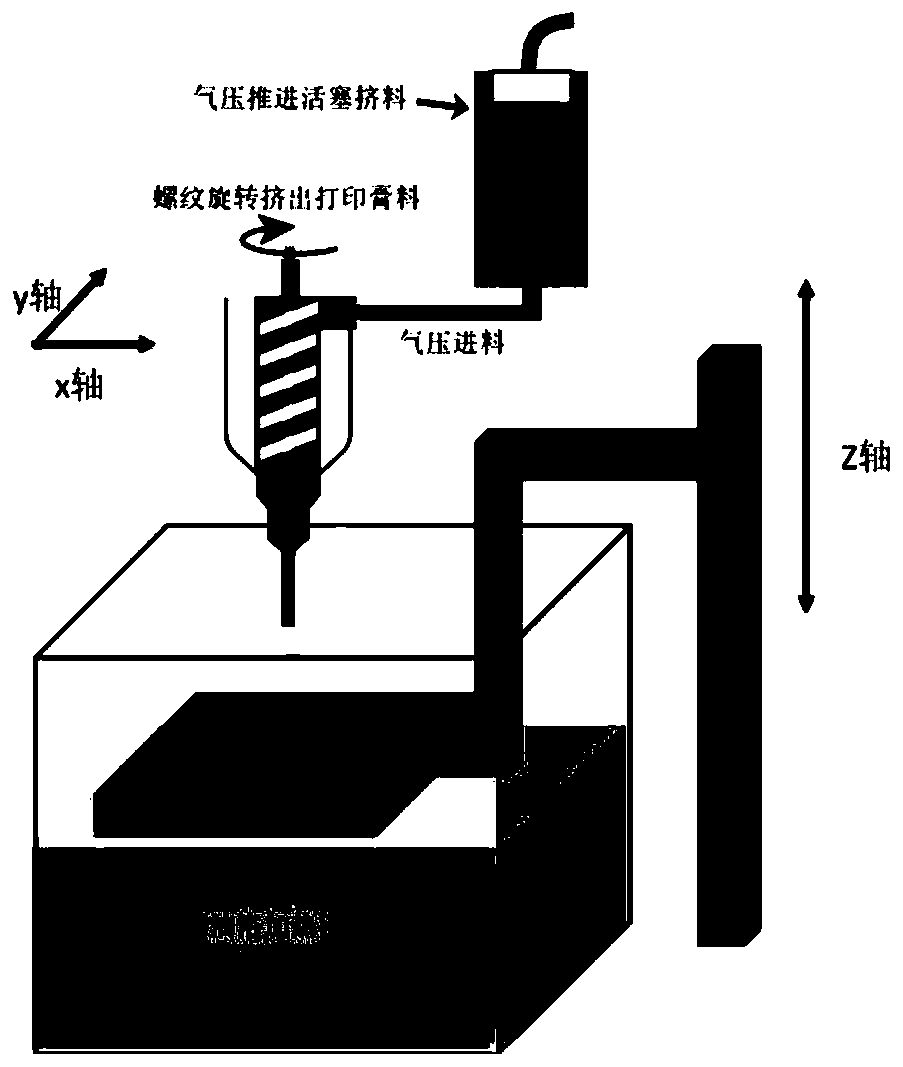

[0039] (2) 3D printing: Use the computer solidworks to model the ceramic parts three-dimensionally, and then slice them with Cura software to prepare for extruding 3D printing of the ceramic parts. Inject the ceramic paste into a 55 ml barrel, and adjust the gas pressure to make It is controlled at 0.2MPa, and the paste is squeezed into the rotating thread cavity by air p...

Embodiment 2

[0044] A method for temperature-induced solidification of ceramic 3D printing, comprising the following steps:

[0045](1) Configuration paste: 0.12 parts of the carrageenan powder, 0.5 parts of the dispersant and 20 parts of the deionized water are mixed in a planetary vacuum high-speed (900r / min) mixer according to the proportioning ratio. After 3 minutes, the premixed solution was obtained, and 82 parts of the zirconia ceramic powder with a particle size of 0.4 microns were mixed for 5 minutes in a planetary vacuum high-speed (1500r / min) mixer to obtain a uniform ceramic with good dispersibility. Paste;

[0046] (2) 3D printing: Use the computer solidworks to model the ceramic parts three-dimensionally, and then slice them with Cura software to prepare for extruding 3D printing of the ceramic parts. Inject the ceramic paste into a 55 ml barrel, and adjust the gas pressure to make It is controlled at 0.25MPa, and the paste is squeezed into the rotating thread cavity by air ...

Embodiment 3

[0051] A method for temperature-induced solidification of ceramic 3D printing, comprising the following steps:

[0052] (1) Configuration paste: 0.25 parts of the carrageenan powder, 0.4 parts of the dispersant and 20 parts of the deionized water are mixed in a planetary vacuum high-speed (1100r / min) mixer according to the proportioning ratio. 3 minutes, obtain the premixed liquid, 82 parts of silicon nitride ceramic powders of described premixed liquid and particle diameter 0.6 micron are mixed in planetary vacuum high-speed (1600r / min) mixer for 5 minutes, obtain the good uniformity of dispersibility ceramic paste;

[0053] (2) 3D printing: Use the computer solidworks to model the ceramic parts three-dimensionally, and then slice them with Cura software to prepare for extruding 3D printing of the ceramic parts. Inject the ceramic paste into a 55 ml barrel, and adjust the gas pressure to make It is controlled at 0.2MPa, and the paste is squeezed into the rotating thread cavi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com