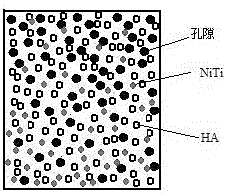

Preparation method of double-gradient porous NiTi / hydroxyapatite composite

A technology of hydroxyapatite and composite materials, which is applied in the field of preparation of double gradient porous NiTi/hydroxyapatite composite materials, can solve the problems of reducing NiTi alloys and unfavorable Ni ions for human health, and achieves the protection of biocompatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] 1. Preparation of NiTi / hydroxyapatite slurry

[0023] a. According to the number of parts by mass, put 20 parts of sodium stearate into 80 parts of absolute ethanol, then place the mixed solution in a constant temperature water bath at 60°C and stir to completely dissolve the sodium stearate, and prepare stearin with a concentration of 20%. Sodium bicarbonate-ethanol premix solution, and then keep warm in a constant temperature water bath at 60°C for later use.

[0024] b. In parts by mass, weigh 35.55 parts of hydroxyapatite with a particle size of 100 nm, 2.7 parts of NiTi with a particle size of 60 nm, 6.75 parts of polystyrene as a pore-forming agent with a particle size of 20 μm; 1.35 parts of polyethylene glycol as a dispersant, stearin 53.65 parts of sodium bicarbonate-ethanol premix, which was weighed and immediately placed in a constant temperature water bath at 60°C for future use.

[0025] c. Add 1.35 parts of dispersant polyethylene glycol to the 53.65 p...

example 2

[0030] 1. Preparation of NiTi / hydroxyapatite slurry

[0031] a. According to the number of parts by mass, put 20 parts of sodium stearate into 80 parts of absolute ethanol, then place the mixed solution in a constant temperature water bath at 70°C and stir to completely dissolve the sodium stearate, and prepare stearin with a concentration of 20%. Sodium acid-ethanol premixed solution, and then kept in a constant temperature water bath at 70°C for later use.

[0032] b. In parts by mass, weigh 47.4 parts of hydroxyapatite with a particle size of 100 nm, 3.6 parts of NiTi with a particle size of 60 nm, 9 parts of polystyrene as a pore-forming agent with a particle size of 20 μm; 3 parts of polyethylene glycol as a dispersant, stearin 37 parts of sodium bicarbonate-ethanol premixed solution, which was weighed and immediately placed in a constant temperature water bath at 70°C for future use.

[0033]c. Add 3 parts of dispersant polyethylene glycol to the 37 parts of sodium s...

example 3

[0038] 1. Preparation of NiTi / hydroxyapatite slurry

[0039] a. According to the number of parts by mass, put 20 parts of sodium stearate into 80 parts of absolute ethanol, then place the mixed solution in a constant temperature water bath at 65°C and stir to completely dissolve the sodium stearate, and prepare stearin with a concentration of 20%. Sodium acid-ethanol premixed solution, and then kept in a constant temperature water bath at 65°C for later use.

[0040] b. In parts by mass, weigh 39.5 parts of hydroxyapatite with a particle size of 100nm, 3 parts of NiTi with a particle size of 60nm, 7.5 parts of polystyrene as a pore-forming agent with a particle size of 20 μm; 2 parts of dispersant polyethylene glycol, stearic acid 48 parts of sodium-ethanol premixed solution, which was weighed and immediately placed in a constant temperature water bath at 65°C for future use.

[0041] c. Add 2 parts of dispersant polyethylene glycol to the 48 parts of sodium stearate-ethan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com