A high-strength flexible epoxy resin modified cyanate resin/carbon fiber composite shape memory material and its preparation method

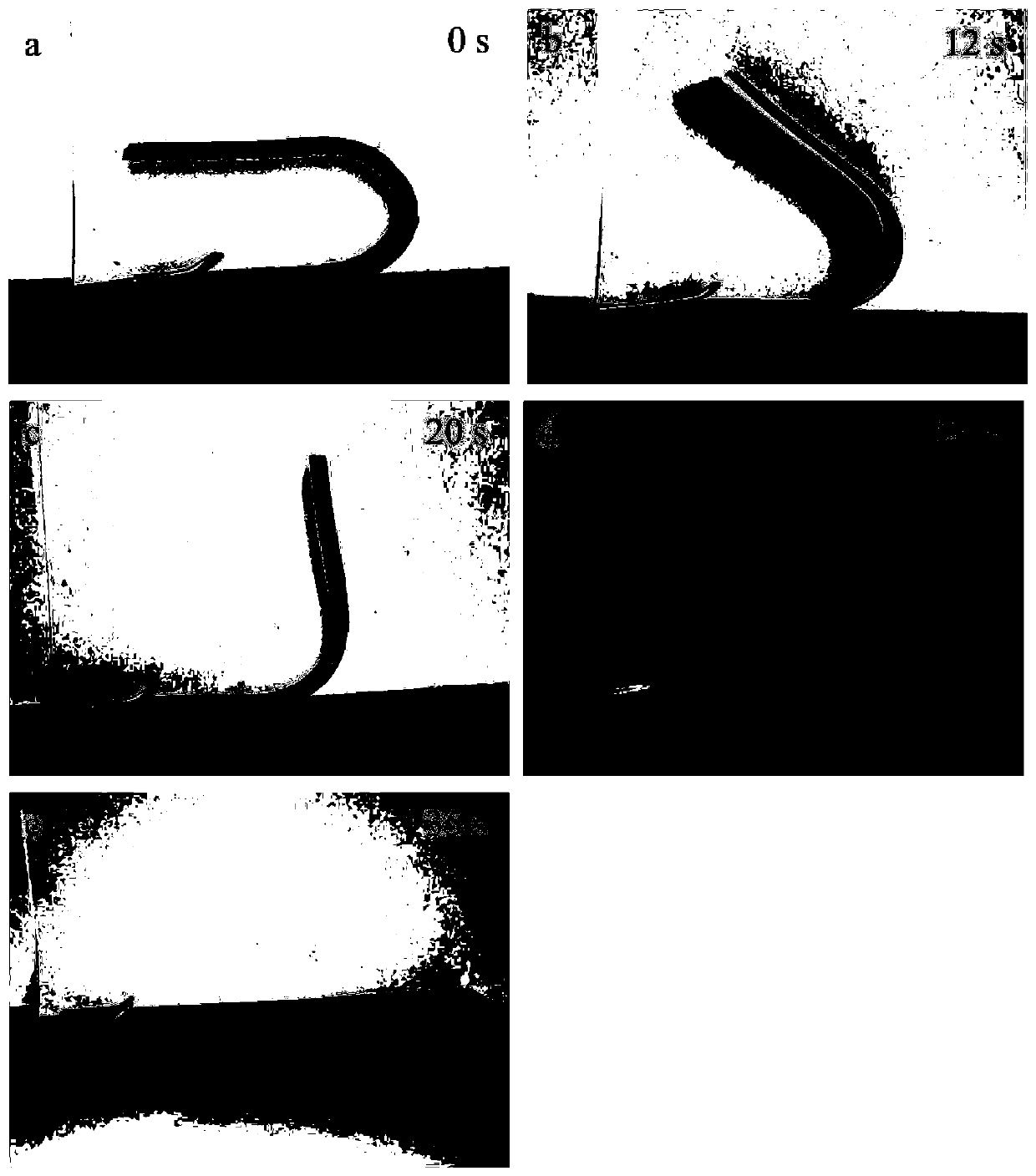

A flexible epoxy resin and cyanate resin technology, which is applied in the field of high-strength flexible epoxy resin modified cyanate resin/carbon fiber composite shape memory materials and its preparation, can solve the problem of poor mechanical properties and slow deformation recovery rate , low deformation density and other issues, to achieve the effect of high strength, smooth surface and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

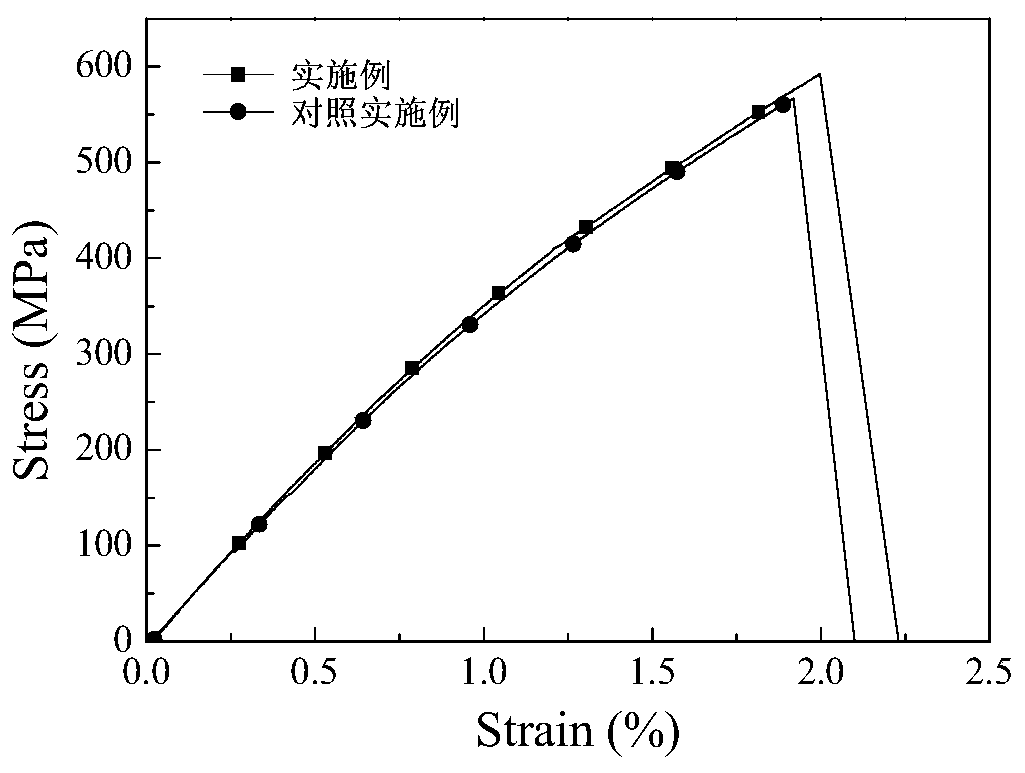

[0038] The preparation method of the high-strength flexible epoxy resin modified cyanate ester resin / carbon fiber composite shape memory material is: according to the above mass fractions, weigh 30 g of carboxyl-terminated liquid nitrile rubber, 30 g of Jef-0211 flexible epoxy resin, bisphenol E-type cyanate resin 100g, heated to 100°C and stirred for 2h. Then apply evenly at about 1m 2 On the T300 carbon fiber plain weave fabric, and then cut the carbon fiber plain weave fabric into the specified size according to [0 / 90°] and [+45° / -45°] directions. Then lay them in alignment layer by layer, 20 layers of carbon fiber cloth cut in the [0 / 90°] direction, and 10 layers of carbon fiber cloth cut in the [+45° / -45°] direction. The cyanate ester resin / carbon fiber shape memory composite material plate is obtained by vacuum bagging, vacuum heating and curing. The curing process is 120°C / 4h+150°C / 2h+170°C / 2h.

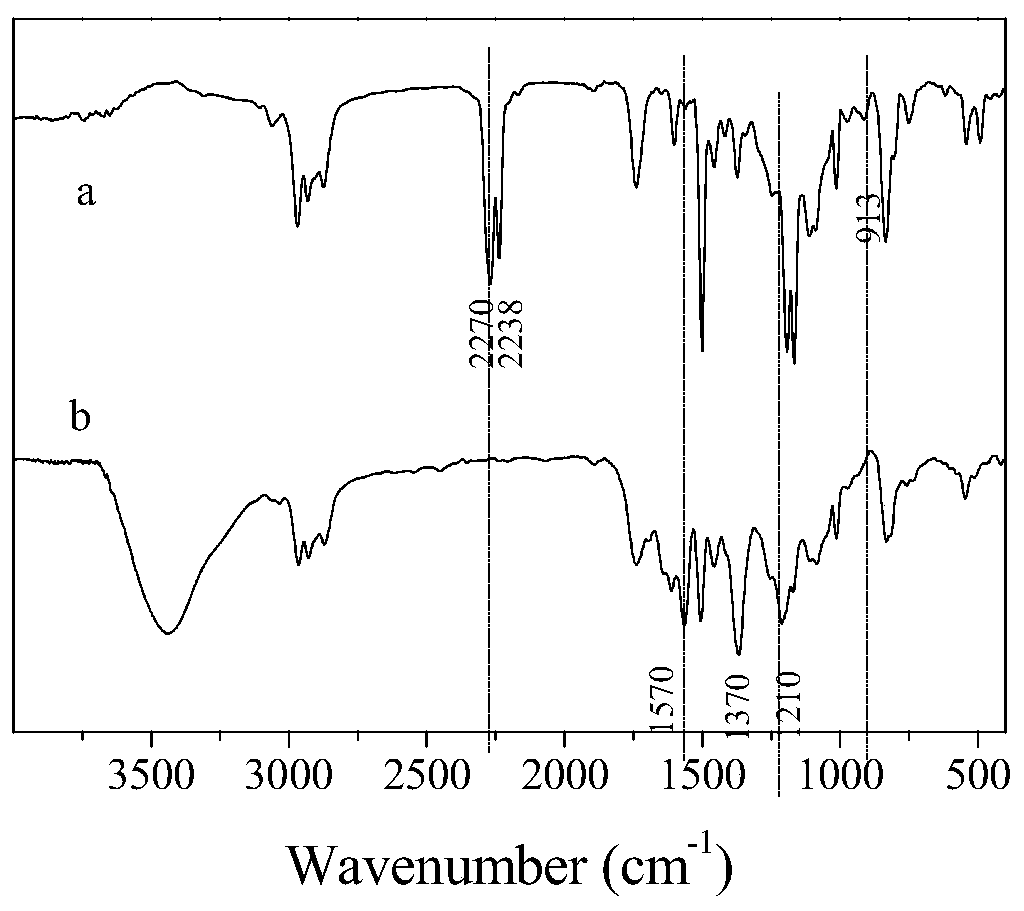

[0039] The carboxyl group in the carboxyl-terminated liquid nitrile rub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com