In-situ synthetic method for zeolite molecular sieve membrane

A technology for synthesizing zeolite and molecular sieve, applied in the field of membrane technology separation, can solve the problems of poor uniformity and low repetition rate, and achieve the effects of good stability and permeability, uniform distribution and thin membrane layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

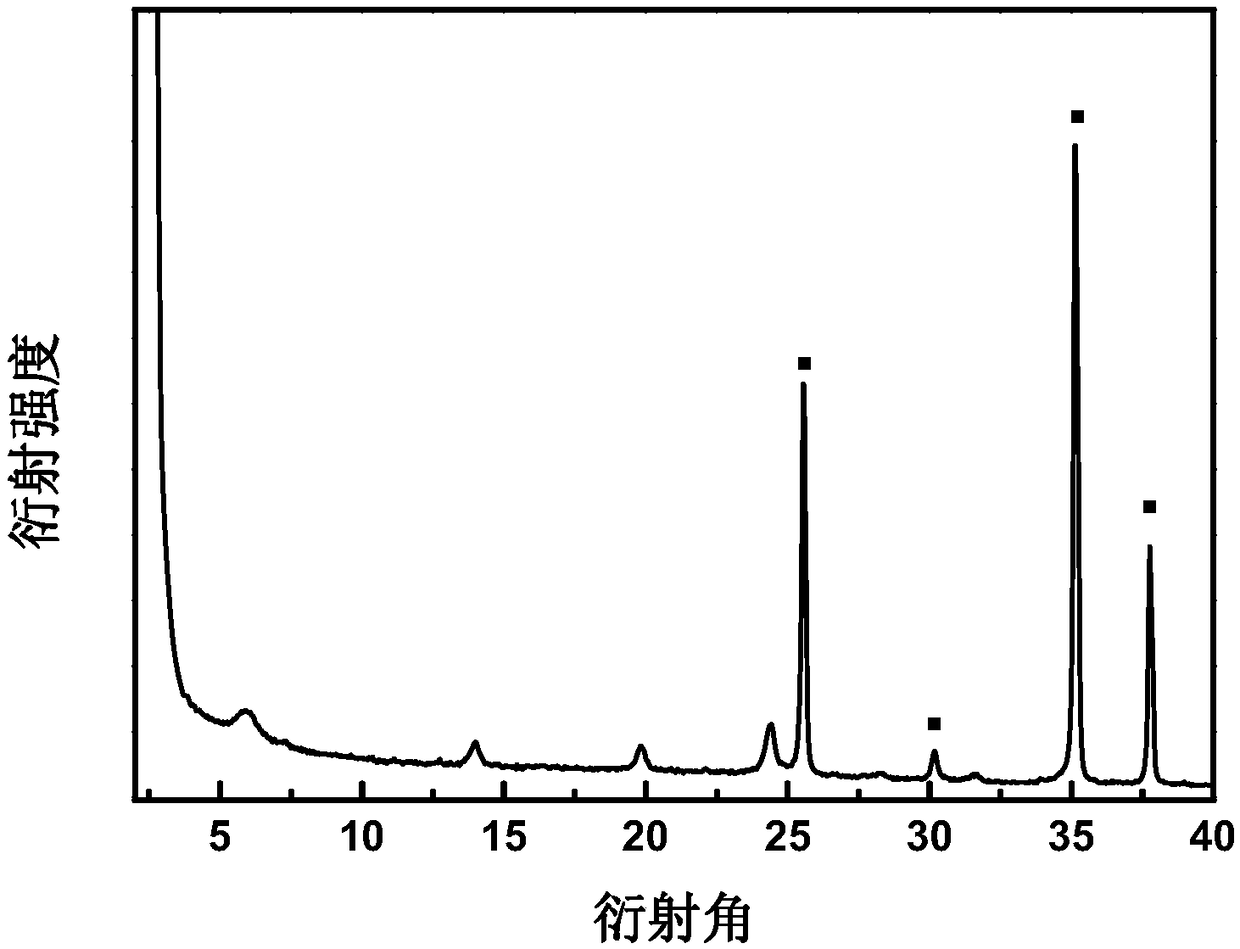

Embodiment 1

[0042] Dissolve 0.515g of aluminum sec-butoxide in 3.668g of 35wt.% tetraethylammonium hydroxide aqueous solution to form a colorless homogeneous solution 1, and dissolve 2.585g of 40wt.% silica sol in 3.668g of 35wt.% tetraethylammonium hydroxide Ammonium aqueous solution forms milky white solution 2, pour solution 2 into solution 1, stir for 3 hours until it is evenly mixed, put the light milky white sol in an oven at 95°C for aging for 18 hours, and obtain a colorless homogeneous charge density mismatch solution; weigh Dissolve 0.400g of tetramethylammonium chloride in 0.766g of deionized water, add it to the charge density mismatch solution and stir for 30min to obtain a synthetic solution; 2 o 3 Put it horizontally in the synthesis liquid, screw the reactor tightly; put the closed reactor in an oven at 150°C for 96 hours. After the reaction was completed, 10 mL of deionized water was used to ultrasonically wash and dry at 65°C. A zeolite molecular sieve membrane synthes...

Embodiment 2

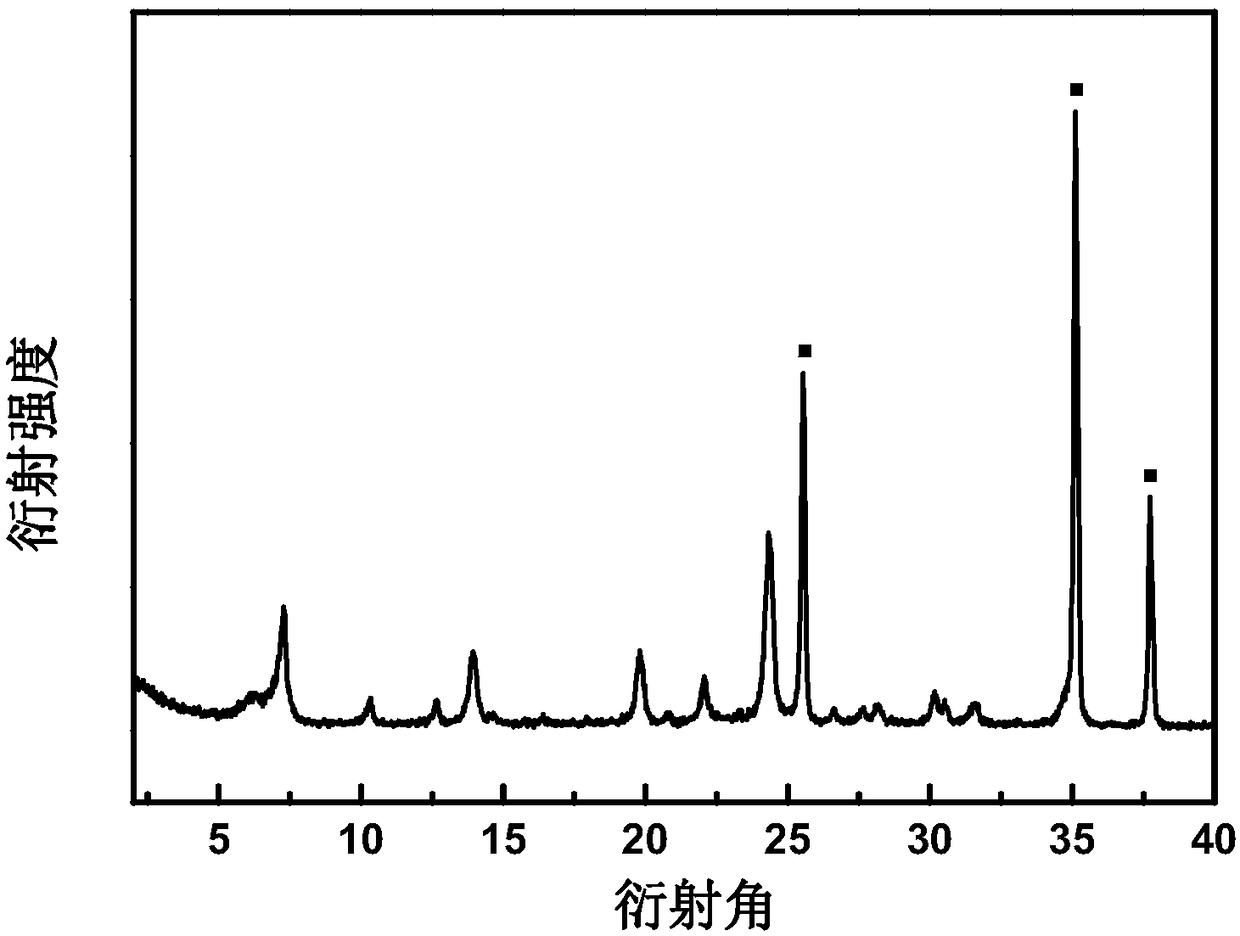

[0049] 0.570g of aluminum sec-butoxide was dissolved in 7.794g of 35wt.% tetraethylammonium hydroxide aqueous solution to form a colorless homogeneous solution 1, and 3.858g of 40wt.% tetraethoxysilane was added to solution 1 under stirring conditions, Stir well until the mixture is complete to form a light milky white solution 2, which is aged in a water bath at 80°C for 24 hours to obtain a colorless homogeneous charge density mismatch solution; weigh 0.254g of tetramethylammonium chloride and dissolve it in 4.934g of deionized In water, after ultrasonication, it was added to the charge density mismatch solution, and stirred for 30 minutes to obtain a synthetic solution; the synthetic solution was transferred to a high-pressure reactor; the closed reactor was placed in an oven at 150°C for 96 hours. After the reaction was completed, the product was centrifuged to obtain a white solid product, which was ultrasonically washed with deionized water and centrifuged three times, an...

Embodiment 3

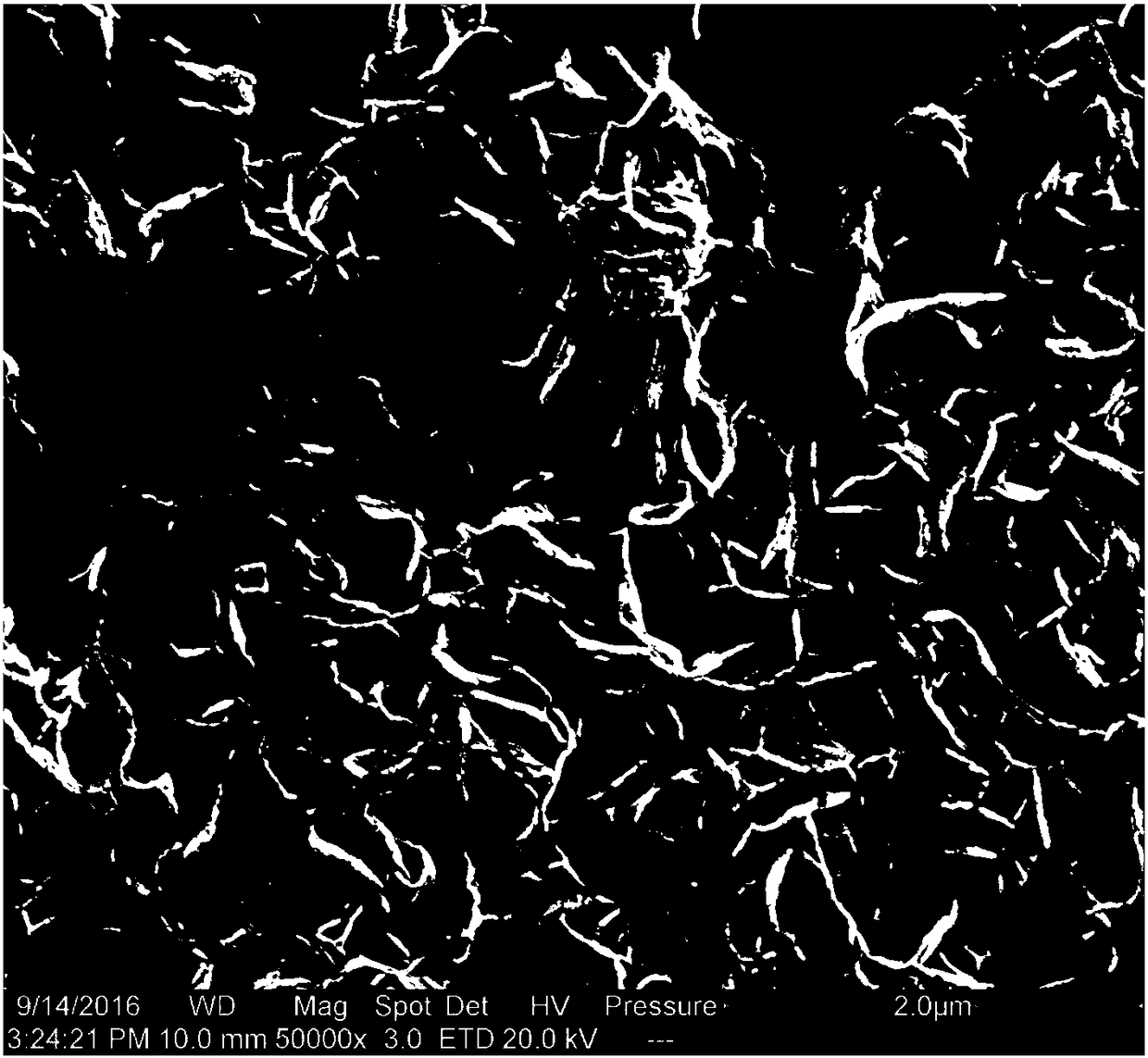

[0051] Dissolve 0.515g of aluminum sec-butoxide in 3.668g of 35wt.% tetraethylammonium hydroxide aqueous solution to form a colorless homogeneous solution 1, and dissolve 2.585g of 40wt.% silica sol in 3.668g of 35wt.% tetraethylammonium hydroxide Ammonium aqueous solution forms milky white solution 2, pour solution 2 into solution 1, stir for 3 hours until it is evenly mixed, put the light milky white sol in an oven at 95°C for aging for 18 hours, and obtain a colorless homogeneous charge density mismatch solution; weigh Dissolve 0.400g of tetramethylammonium chloride in 0.766g of deionized water, add it to the charge density mismatch solution and stir for 30min to obtain a synthetic solution; transfer the synthetic solution to a microwave reaction with a polytetrafluoroethylene liner In the kettle, at the same time, the α-Al 2 o 3 Put it horizontally in the synthesis solution, and tighten the reactor; put the closed reactor in an oven at 150°C for 10 hours. After the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com