Method of recovering carbon fibers by low-temperature microwave efficient treatment of carbon fiber composite material

A technology for recycling carbon fiber and composite materials, applied in the field of fiber composite materials, can solve the problems of pyrolysis gasification, easy carbonization of carbon fibers, and low oxygen content, etc., and achieve the effects of fast heating, energy saving, and high recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

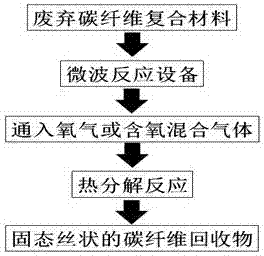

[0039] Such as figure 1 As shown, the method of low-temperature microwave efficient treatment of carbon fiber composite materials to recover carbon fibers, the specific steps are as follows: first put waste carbon fiber composite materials (carbon fiber form is short fiber, matrix resin is epoxy resin, size is 1.9×1.7×3cm) Enter the microwave heating device, feed oxygen (the amount of oxygen feed is 4LPM), and feed microwaves with a frequency of 2450±50MHz until the temperature rises to 450°C, and treat at low temperature for 0.1h to make the resin organic matter oxidize and decompose, and then naturally The temperature is lowered to below 200°C, and the solid product is taken out to be carbon fiber.

[0040] After the degradation is completed, the solid carbon fiber epoxy resin-based composite material is degraded into filamentous short carbon fibers with a smooth and complete surface and basically no resin residue.

Embodiment 2

[0042] Such as figure 1 As shown, the method of low-temperature microwave efficient treatment of carbon fiber composite materials to recover carbon fibers, the specific steps are as follows: first, the waste carbon fiber composite materials (the carbon fiber form is medium-long fiber, the matrix resin is epoxy resin, and the size is 5×5×2cm) Put it into the microwave heating device, feed oxygen (the amount of oxygen feed is 0.5LPM), and feed microwaves with a frequency of 2450±50MHz until the temperature rises to 450°C, and treat at low temperature for 1 / 6h to make the resin organic matter oxidize and decompose. , and then naturally lower the temperature to a temperature below 200°C, and the solid product is taken out to be carbon fiber.

[0043] After the degradation is completed, the solid carbon fiber epoxy resin-based composite material is degraded into filamentous filamentary medium-length carbon fibers with a smooth and complete surface, basically no resin residue, and u...

Embodiment 3

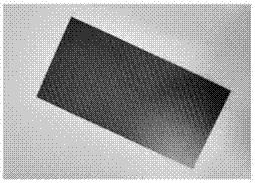

[0045] Such as figure 1 As shown, the method of low-temperature microwave efficient treatment of carbon fiber composite materials to recover carbon fibers, the specific steps are as follows: first, the waste carbon fiber composite materials (carbon fiber form is medium-long fiber, matrix resin is epoxy resin, the size is 15×10×2cm, Photos like figure 2 As shown) put into the microwave heating device, feed oxygen (the amount of oxygen feed is 1.5LPM), feed microwave with a frequency of 915±50MHz, until the temperature rises to 450°C, and treat at low temperature for 1 / 3h, so that the organic matter of the resin is generated Oxidative decomposition reaction, then naturally cool down to a temperature below 200°C, and the solid product is taken out as carbon fiber.

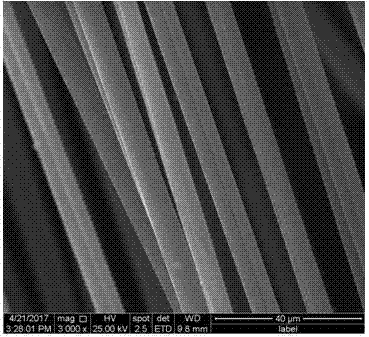

[0046] After the degradation is completed, the solid carbon fiber epoxy resin-based composite material is degraded into carbon fibers with filamentous lengths, as shown in the photo image 3 shown, from image 3 I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com