Crucible coating used for preparation of solar grade polysilicon, preparation method thereof and crucible

A polysilicon preparation and crucible coating technology, which is applied in glass manufacturing equipment, crystal growth, single crystal growth, etc., can solve the problem of no help in impurity removal, achieve easy demoulding, reduce production costs, and improve strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

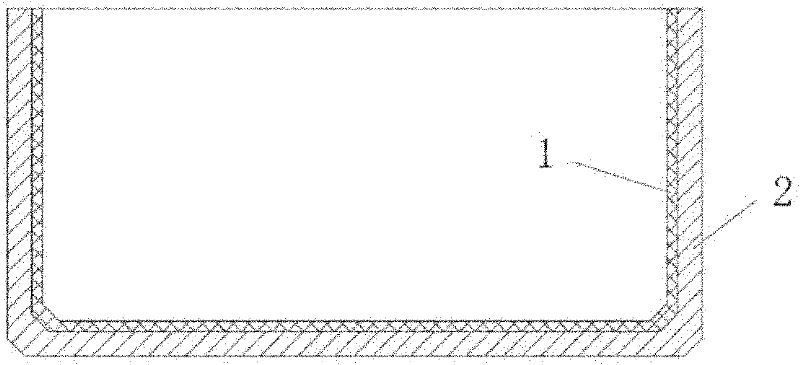

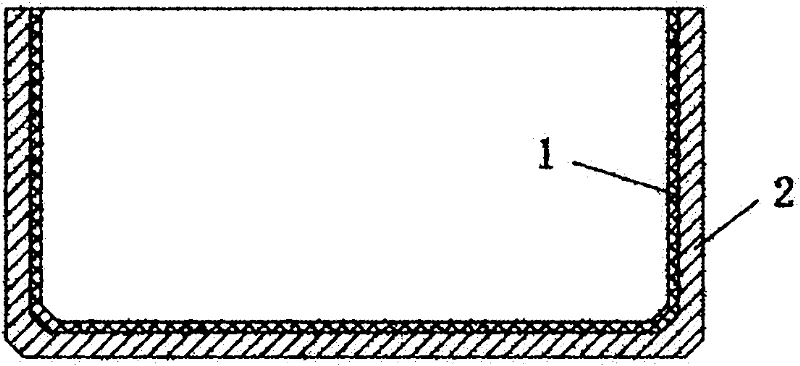

[0026] The coated crucible used in the preparation of solar-grade polysilicon has a structural schematic diagram as shown in the accompanying drawings, including a crucible body 2 made of quartz, wherein the inner wall of the crucible body 2 is coated with a layer of silicon dioxide, hydrogen Crucible coating 1 made from barium oxide and water. The thickness of the crucible coating 1 is 30-300 microns.

[0027] The above-mentioned crucible coating 1 is a crucible coating 1 used in the preparation of solar-grade polysilicon, and the preparation method of the crucible coating 1 is as follows:

[0028] (1) Mix silicon dioxide and barium hydroxide powder at a mass ratio of 20:1, wherein the particle size of silicon dioxide and barium hydroxide powder is 1500-2000 mesh.

[0029] (2) Add the mixed powder to deionized water and mix thoroughly, wherein the weight ratio of the mixed powder to deionized water is 1:2, and the resistivity of the deionized water is 10 megohms.

[0030] (...

Embodiment 2

[0034] The crucible with coating used in the preparation of solar-grade polysilicon in this embodiment is like embodiment 1, but wherein, the preparation method of crucible coating 1 is as follows:

[0035] (1) Mix silicon dioxide and barium hydroxide powder at a mass ratio of 20:1, wherein the particle size of silicon dioxide and barium hydroxide powder is 1000-1500 mesh.

[0036] (2) Add the mixed powder to deionized water and mix thoroughly, wherein the weight ratio of the mixed powder to deionized water is 1:2.5, and the resistivity of the deionized water is 15 megohms.

[0037] (3) Spray the mixed compound powder suspension on the inner wall of the quartz crucible body 2, and dry it at 80° C. for 6 hours.

[0038] (4) The dried crucible body 2 enters a heating furnace, and is sintered at 950° C. for 6 hours, and finally a layer of dense and uniform coating is obtained on the inner wall of the crucible body 2 .

[0039] Under the same method of purifying the ingot, the bo...

Embodiment 3

[0041] The crucible with coating used in the preparation of solar-grade polysilicon in this embodiment is like embodiment 1, but wherein, the preparation method of crucible coating 1 is as follows:

[0042] (1) Mix silicon dioxide and barium hydroxide powder at a mass ratio of 30:1, wherein the particle size of silicon dioxide and barium hydroxide powder is 1000-2000 mesh.

[0043] (2) Add the mixed powder into deionized water and mix thoroughly, wherein the weight ratio of the mixed powder to deionized water is 1:2.5, and the resistivity of the deionized water is 20 megohms.

[0044] (3) Spray the mixed compound powder suspension on the inner wall of the quartz crucible body 2, and dry it at 80° C. for 6 hours.

[0045] (4) The dried crucible body 2 enters a heating furnace, and is sintered at 950° C. for 6 hours, and finally a layer of dense and uniform coating is obtained on the inner wall of the crucible body 2 .

[0046]Under the same method of purifying the ingot, the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com