Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Good phase change performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for vanadium dioxide and doped powder thereof

The invention discloses a preparation method for vanadium dioxide and doped powder thereof. The method comprises the following steps: 1, weighing vanadium pentoxide, hydrogen peroxide and distilled water, preparing the materials into a V<5+>-containing complex aqueous solution; 2, adding a reducing agent, a surfactant and a dopant to the complex aqueous solution, and stirring to form a clear solution; 3, transferring the resulting solution from the step 2 to a hydrothermal reaction kettle, and carrying out a reaction for 1-168 hours at a temperature of 140-220 DEG C to obtain the doped powderof the VO2(B); 4, placing the resulting doped powder of the VO2(B) from the step 3 in high pure argon atmosphere or nitrogen atmosphere, and annealing for 10-720 minutes at the temperature of 400-700DEG C to obtain the doped powder of the VO2(M). The method of the present invention has characteristics of low cost, simple process and easy control, and is suitable for the large-scale industrial production. With the method of the present invention, the doping of the VO2 powder material can be realized, and the doped atoms can be uniformly dispersed in the VO2.

Owner:张家港楚人新材料科技有限公司

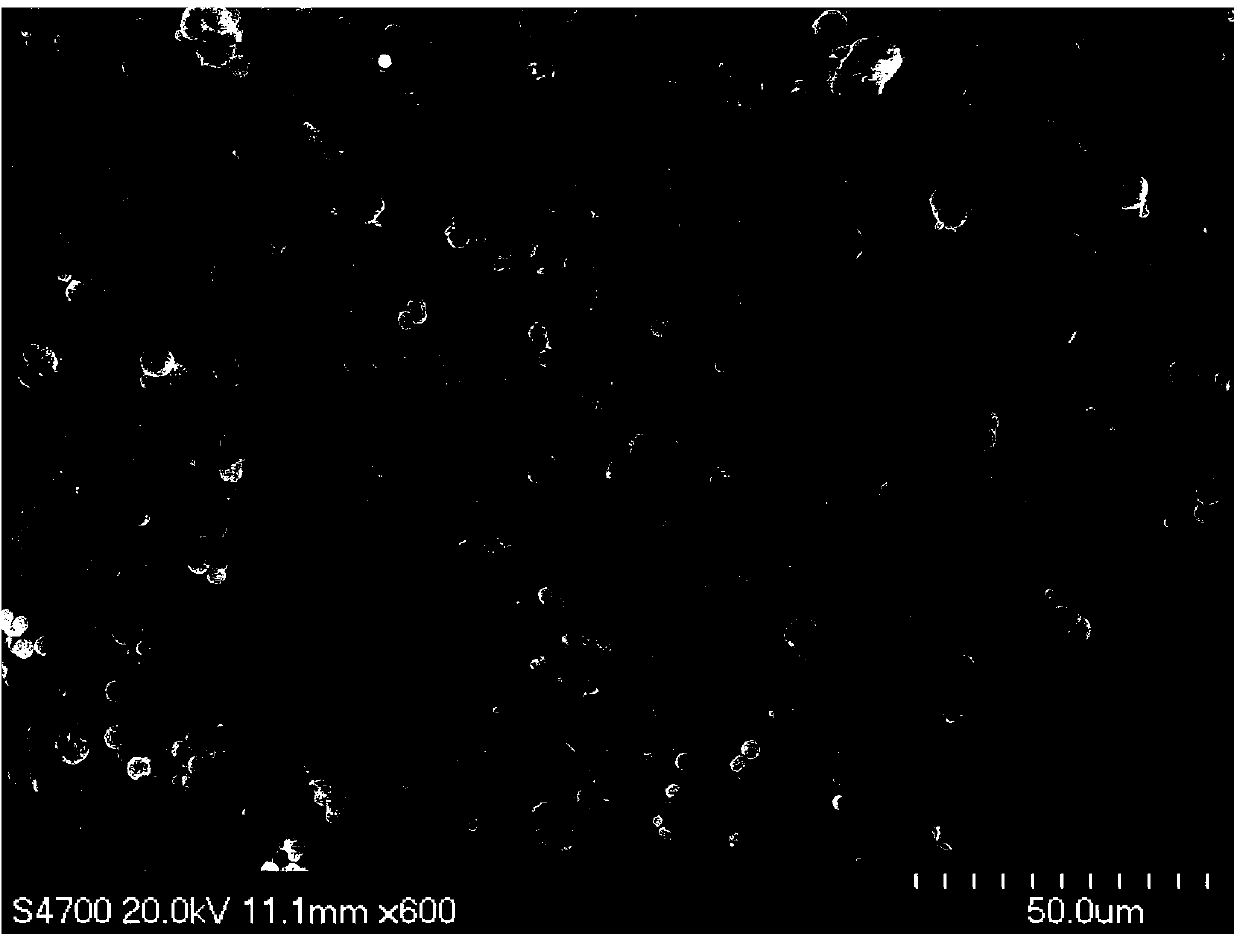

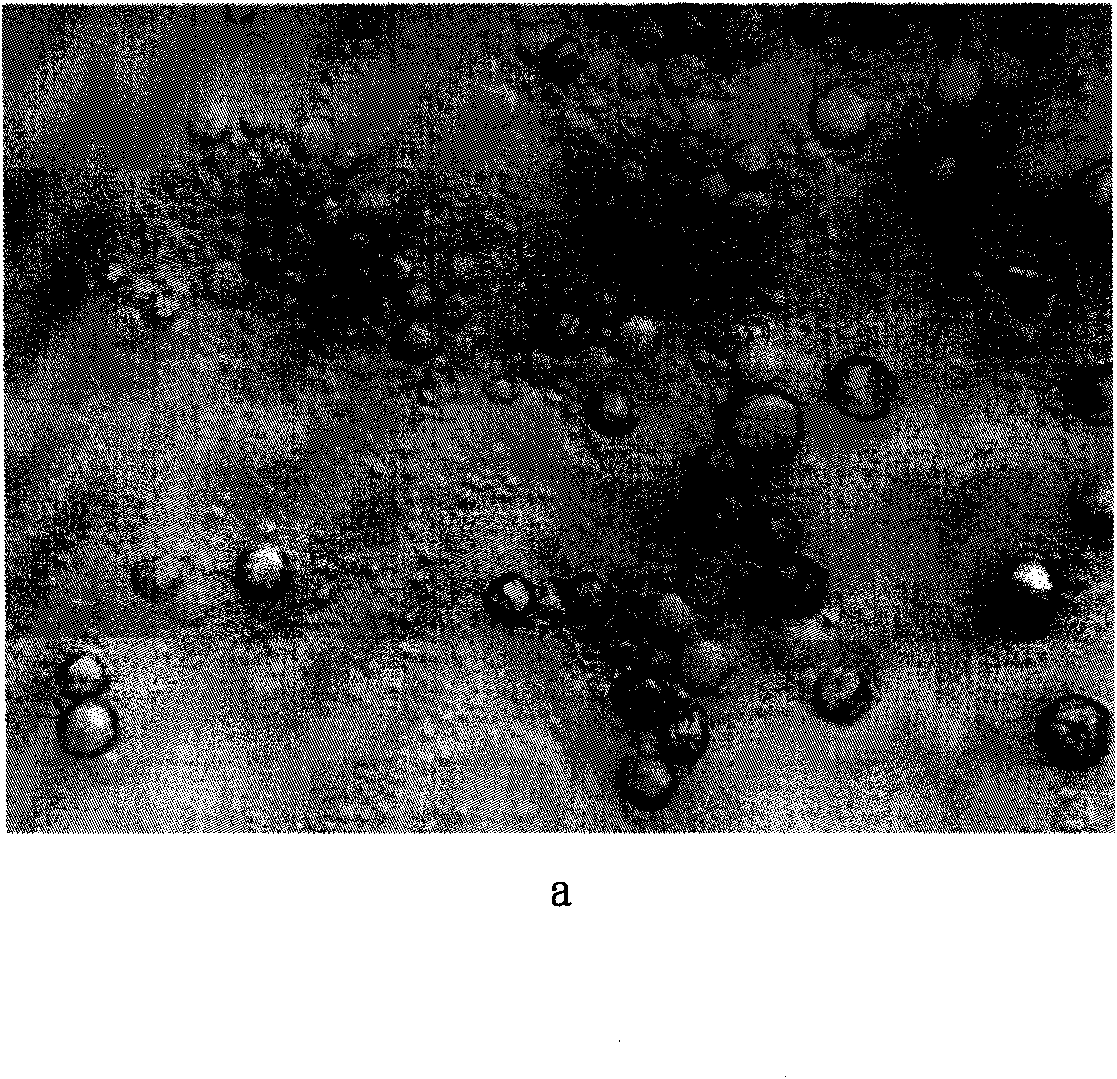

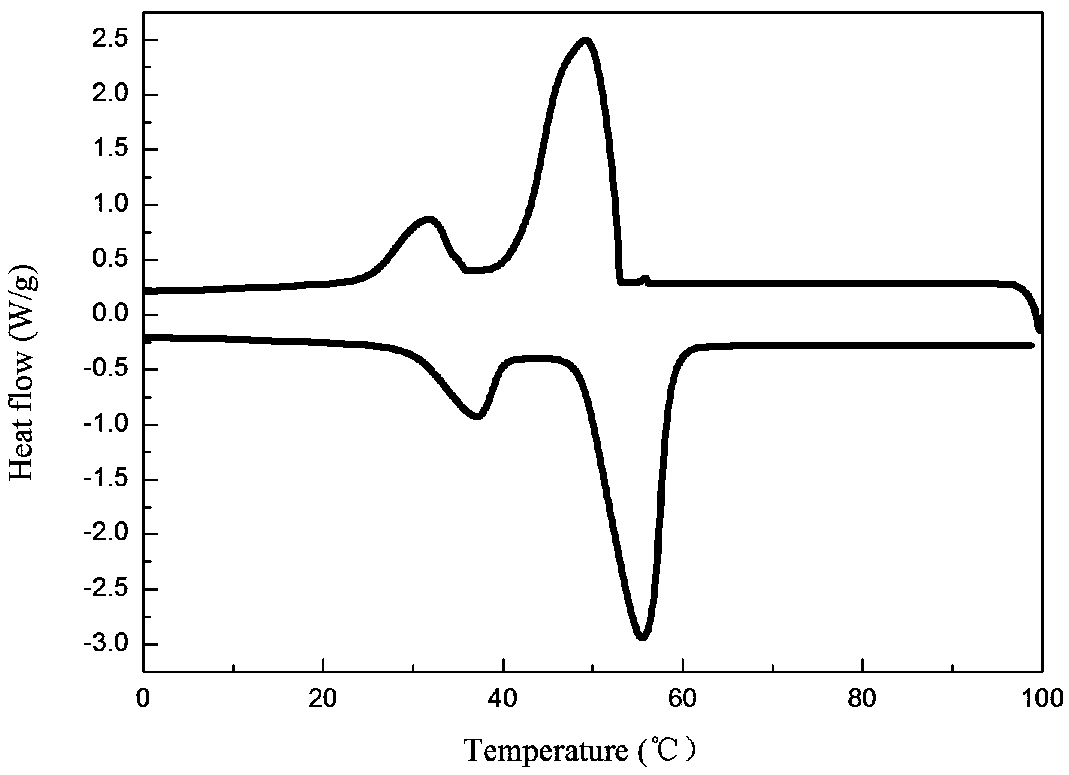

Magnetic microencapsulated phase change energy storage material and preparation method thereof

ActiveCN103992774AUniform particle size distributionAchieve dual functionHeat-exchange elementsMicroballoon preparationThermal energyThermal energy storage

The invention discloses a magnetic microencapsulated phase change energy storage material with magnetic and thermal energy storage functions and a preparation method thereof. A wall material of microcapsules is a magnetic ferrite / silica inorganic hybrid material with the magnetic function and a core material can be paraffin and a higher fatty alcohol, acid and ester type organic phase change energy storage material. The preparation method of the magnetic microencapsulated phase change energy storage material disclosed by the invention comprises the steps of firstly synthesizing magnetic ferrite nanoparticles and further assembling the magnetic ferrite nanoparticles in a solvent to the surfaces of suspended oil droplets of the organic phase change energy storage material through a Pickering emulsion technology; finally forming silica gel on the surface of the phase change energy storage material through an interfacial polymerization technology to fix the magnetic ferrite nanoparticles on the surfaces of the oil droplets of the organic phase change energy storage material so as to form the microcapsules using the magnetic ferrite / silica hybrid wall material to coat the phase change energy storage material.

Owner:上海弈峋科技有限公司

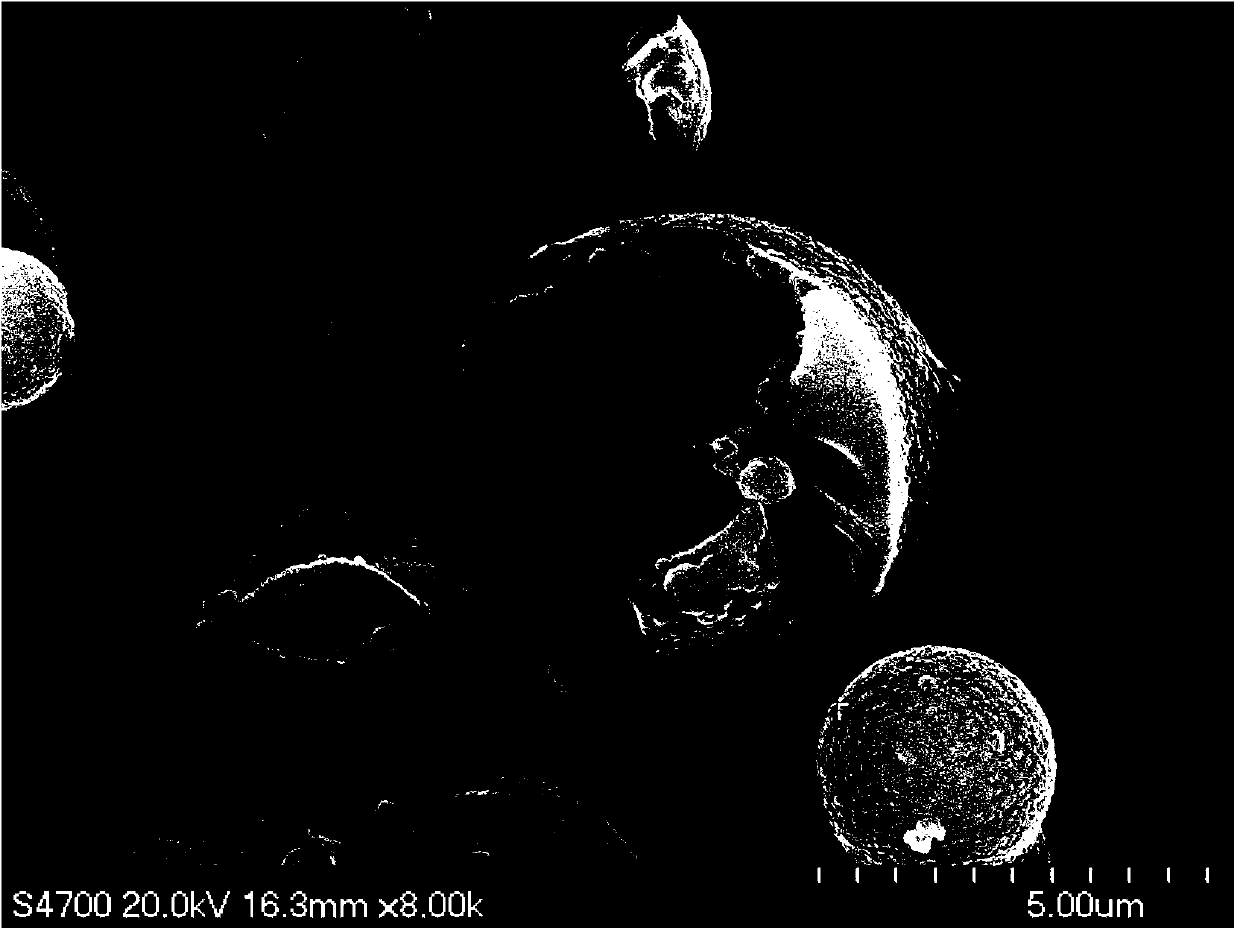

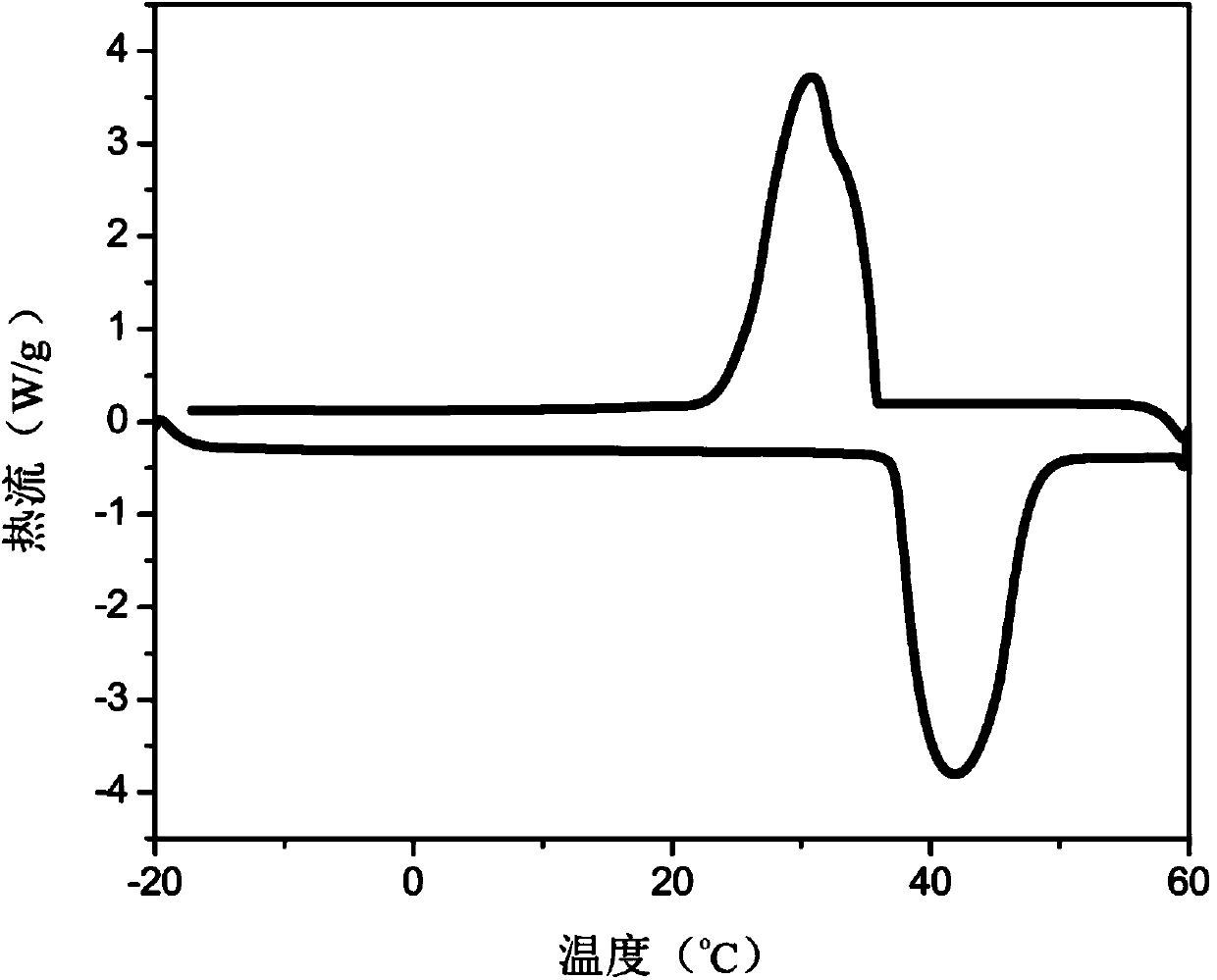

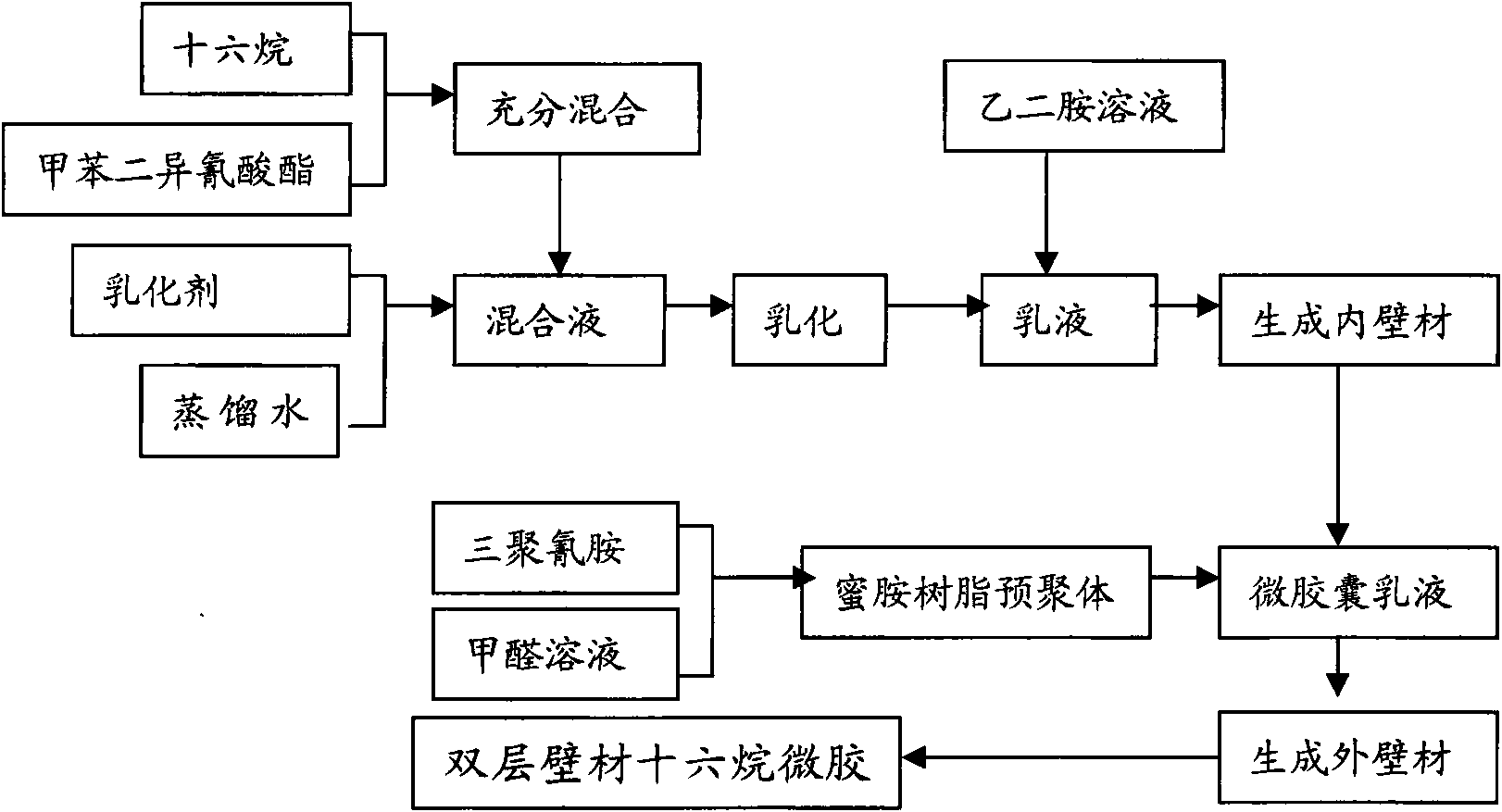

Polyurea-melamin resin double-wall material cetane microcapsule and preparation method thereof

ActiveCN101554573ANo obvious defectsNo adhesion phenomenonMicroballoon preparationMicrocapsule preparationEthylenediamineHexadecane

The invention provides a method for preparing polyurea-melamin resin double-wall material cetane microcapsule, which comprises: first, toluene-2, 4- vulcabond and quadrol are adopted to synthesize inner layer shell material of the cetane microcapsule by an interfacial polymerization method, and then melamin resin performed polymer is adopted to synthesize outer layer shell material of the cetane microcapsule by an in-situ polymerization method, so that the polyurea-melamin resin double-wall material cetane microcapsule can be prepared. More particularly, the method comprises: hexadecane and the toluene-2, 4- vulcabond are fully mixed together and then added into the mixture of de-ionized water, sodium dodecyl sulfate and polyethylene glycol nonylphenyl ether to be emulsified to obtain cetane emulsified liquid; then, the mixed quadrol solution is dripped into the cetane emulsified liquid to react to obtain polyurea monolayer shell material microcapsule; finally, the polyurea monolayer shell material microcapsule reacts with the melamin resin performed polymer to obtain the polyurea-melamin resin double-wall material cetane microcapsule. The prepared microcapsule has good compactness, high strength and core content and excellent particle size distribution.

Owner:SOUTHEAST UNIV

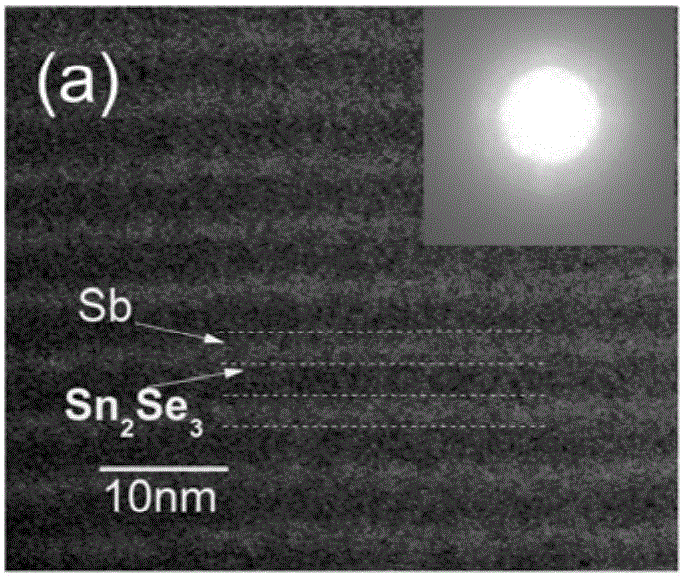

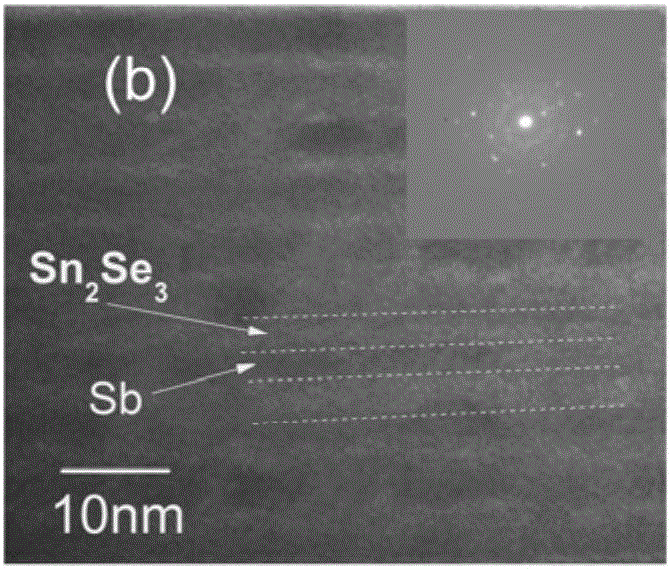

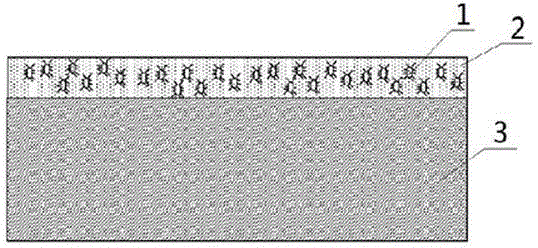

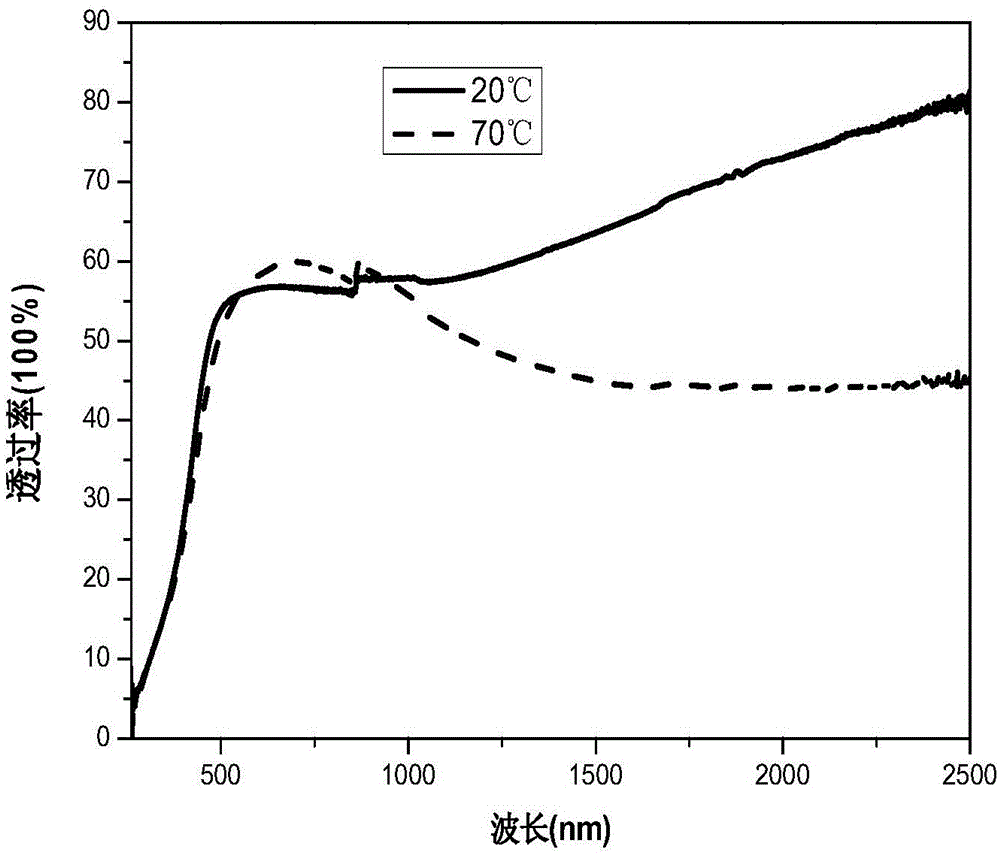

Multilayer nanometer composite phase-transition thin film material and preparation method and application thereof

ActiveCN105679934ALow thermal conductivityReduce lossElectrical apparatusVacuum evaporation coatingThermal stabilityPhase-change material

The invention discloses a multilayer nanometer composite phase-transition thin film material and a preparation method and application thereof. The material is formed by arranging Sn2Se3 film layers and Sb film layers alternatively, one Sn2Se3 film layer and one Sb film layer serve as an alternative period, and the Sn2Se3 layer in the latter alternative period is deposited on the Sb layer in the former alternative period. A general formula of the film structure of the film material is [Sn2Se3(a) / Sb(b)]x, a represents the thickness of the single Sn2Se3 film layer, b represents the thickness of the single Sb film layer, a is greater than or equivalent to 1nm and lower than or equivalent to 50nm, b is greater than or equivalent to 1nm and lower than or equivalent to 50nm, x represents the number of alternative periods or layers of the Sn2Se3 film layers and Sb film layers, and x is a positive integer. The phase-transition thin film material uses Sb as a crystallization induction layer to accelerate phase transition of the phase-transition material, and advantages of low melting point and high thermal stability of Sn2Se3 are used; and the clamping effect of multiple interfaces in the multilayer nanometer composite structure is used to reduce the size of crystal grains, and further to shorten the crystallization time, inhibit crystallization, improve the thermal stability and accelerate phase transition.

Owner:昆山模之特电子材料有限公司

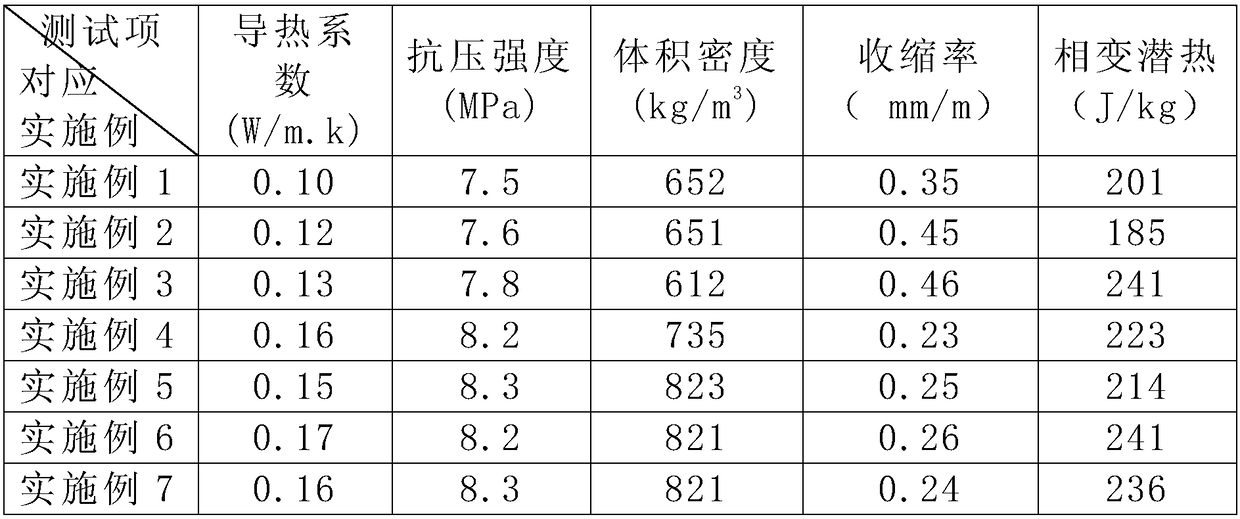

Phase change microcapsule temperature self-adjusting GRC dry-mixed mortar surface layer material

The invention discloses a phase change microcapsule temperature self-adjusting GRC dry-mixed mortar surface layer material. The surface of a phase change microcapsule is coated with a layer of a cement material to make the phase change microcapsule have a hard shell in order to guarantee the integrity of the phase change microcapsule in the stirring processing process, and carbon fibers are added in order to improve the heat conduction performance of the outer wall of the phase change microcapsule. The phase change microcapsule dry-mixed mortar material produced in the invention can be applied to make the surface layer of glass fiber concrete (GRC), and the GRC produced in the invention has an excellent temperature self-adjusting function.

Owner:江苏倍立达新材料科技有限公司

Low-temperature deposition method for vanadium dioxide thin film

ActiveCN105132877AGood phase change performanceReduce manufacturing costVacuum evaporation coatingSputtering coatingVanadium dioxideLow temperature deposition

The invention discloses a low-temperature deposition method for a vanadium dioxide thin film. A magnetron sputtering technique is adopted; vanadium metal or vanadium alloy is taken as a target; oxygen is taken as a reactant gas; argon is taken as a sputtering gas. A vacuum chamber is vacuumized until the air pressure is below the background vacuum of 1*10<-3> Pa before the thin film is prepared; then a mixed gas of the oxygen and the argon is pumped in, and oxygen partial pressure is held to be 0.01-0.06 Pa; in the process of deposition of the thin film, the deposition temperature is controlled to be 240-260 DEG C and negative bias is added to a base, the sputtering power density of the target surface is 2-3 W / cm<2> and the high-property VO2 thin film is obtained on the surface of the base. According to the low-temperature deposition method for the vanadium dioxide thin film, the deposition temperature of the VO2 thin film is low and is matched with appropriate negative bias and other technological parameters to prepare the high-property VO2 thin film which is even and compact, low in phase transition temperature of the vanadium dioxide and good in phase transition property; the production cost is greatly reduced.

Owner:SHENZHEN UNIV

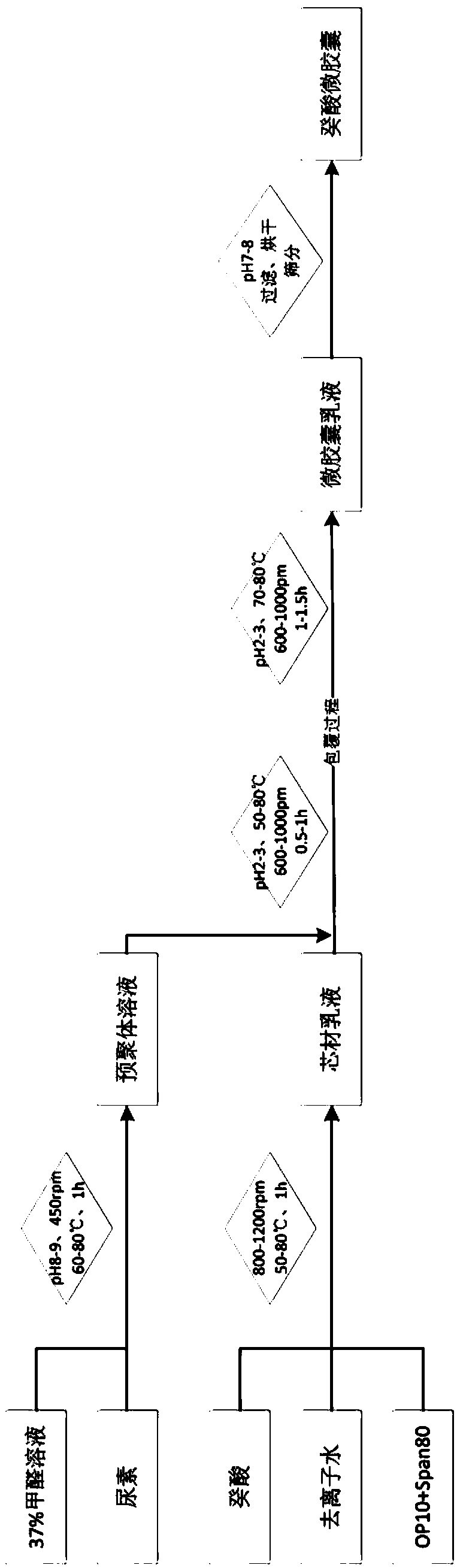

Decanoic acid microcapsules and preparation method thereof

ActiveCN108854878AGood lookingUniform particle size distributionHeat-exchange elementsMicroballoon preparationEmulsionMelamine

The invention discloses decanoic acid microcapsules and a preparation method thereof. The method comprises the following steps: 1, mixing urea with a formaldehyde solution, adjusting the pH value of asystem to 8-9, and adding melamine in batches when the solution is clear so as to obtain a prepolymer solution; 2, adding decanoic acid and an emulsifying agent into deionized water to obtain a decanoic acid emulsion; 3, pouring the prepolymer solution obtained in the first step into the decanoic acid emulsion obtained in the second step, adjusting the pH value of the reaction system to 2-3, andcarrying out a thermostatic reaction for 0.5-1h at 50-80 DEG C, wherein the stirring speed is 600-1000 rpm; 4, heating up to 70-80 DEG C, adding 0.44-0.5 part by mass of a curing agent into the mixture obtained in the third step, and carrying out a thermostatic reaction for 1-2h, wherein the stirring speed is 600-1000 rpm; 5, filtering, washing, drying and screening the product obtained in the fourth step to obtain the decanoic acid microcapsules. The decanoic acid microcapsules obtained by method is low in cost, simple in operation, high in repeatability and lower in requirements for equipment and raw materials, thus being suitable for industrial production.

Owner:NANCHANG UNIV

Encapsulated and networked regenerated cellulose phase-change fiber and preparation method thereof

ActiveCN106048761AGood phase change performanceEasy to shapeMonocomponent cellulose artificial filamentMicroballoon preparationPhase changePhase-change material

The invention provides a preparation method of an in-situ encapsulated and networked regenerated cellulose phase-change fiber, comprising the following steps: adding glycerol tristearate phase-change material into chitosan solution, stirring well, adding N,N-methylenebisacrylamide crosslinking agent and ammonium persulfate initiator, stirring well to form a microcapsule solution; adding sodium alginate powder and nano silver powder into the regenerated cellulose solution, stirring well, adding glutaric dialdehyde crosslinking agent, and stirring well to form cellulose spinning matrix; loading the microcapsule solution to a spraying device, spraying the microcapsule solution evenly to the cellulose spinning matrix, stirring at high speed, dropwise adding ammonium persulfate initiator, and heating and stirring to form spinning dope; subjecting the spinning dope to vacuum suction filtering and defoaming, and coagulating via wet spinning to form the capsulated networked regenerated cellulose phase-change fiber.

Owner:浙江铠悦新材料科技股份有限公司

Silica gel composition and preparation method thereof

The invention provides a silica gel composition. The silica gel composition comprises a silica gel body consisting of components A and B in a mass ratio of 1 to 5, wherein the component A comprises, by mass, 34-83% of dimethyl polysiloxane, 12-65% of polymethylhydrosiloxane and 1-5% of catalysts; the component B is prepared from, by mass, 34-83% of dimethyl polysiloxane, 12-65% of polymethylhydrosiloxane and 1-5% of cross-linking agent; the silica gel composition further contains, based on the total mass of the silica gel body, 0.4-1% of fumed silica, 3.3-4% of prefoamed polymer microspheres and 20-30% of phase change paraffin or 40-50% of solid-state phase change microcapsules; wherein, the prefoamed polymer microspheres are prefoamed polystyrene microspheres, and shells of the prefoamed polystyrene microspheres are made of polystyrene. The silica gel composition is low in specific gravity and weight, has high thixotropy and a good phase change function and is particularly suitable for preparing silica gel prosthesis products. The invention further provides a preparation method of the silica gel composition. According to the preparation method, steps are few, the process is short, operation is easy and convenient, and preparation cost is low.

Owner:SUZHOU MEISHANZI GARMENTS CO LTD

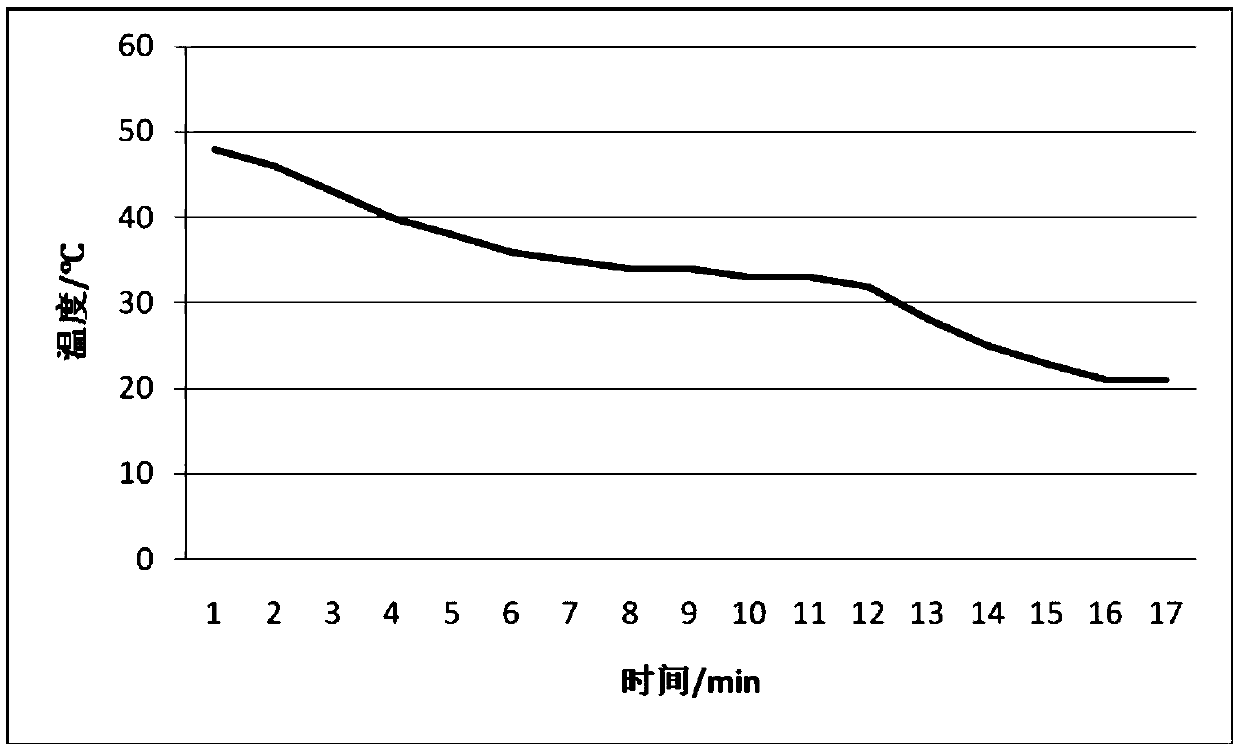

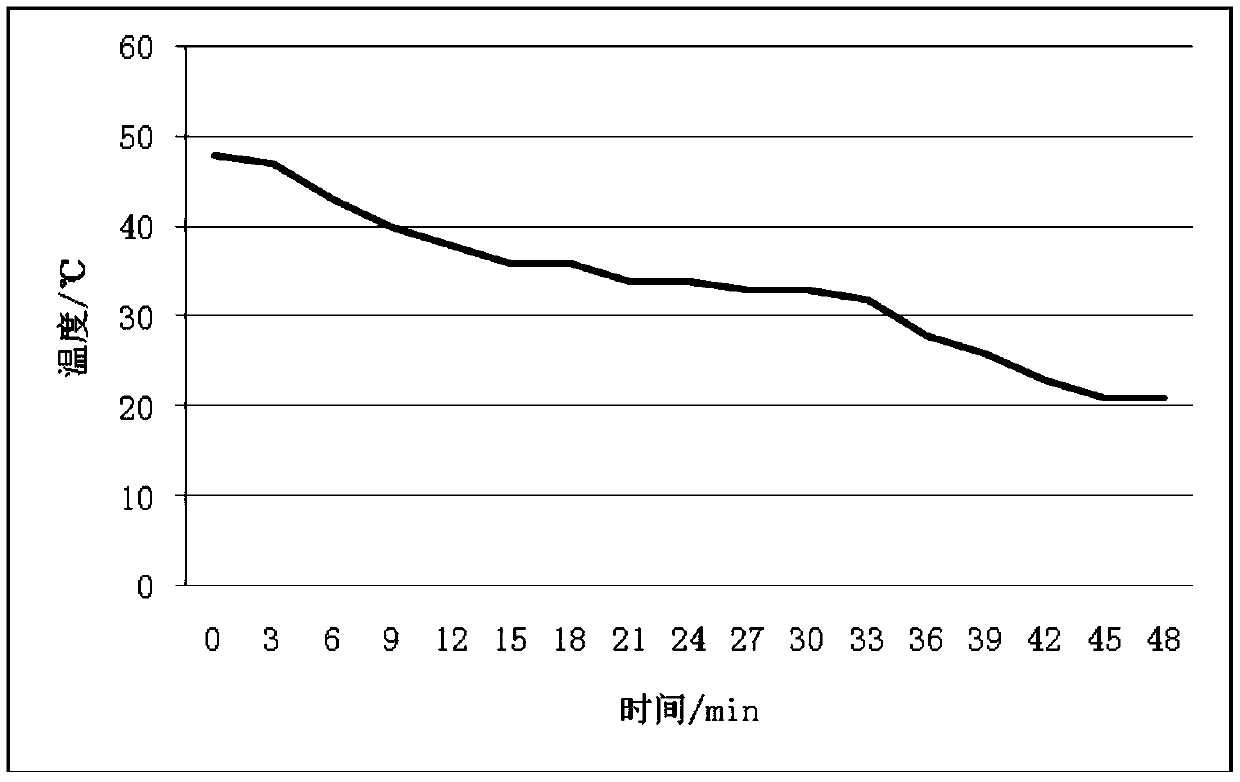

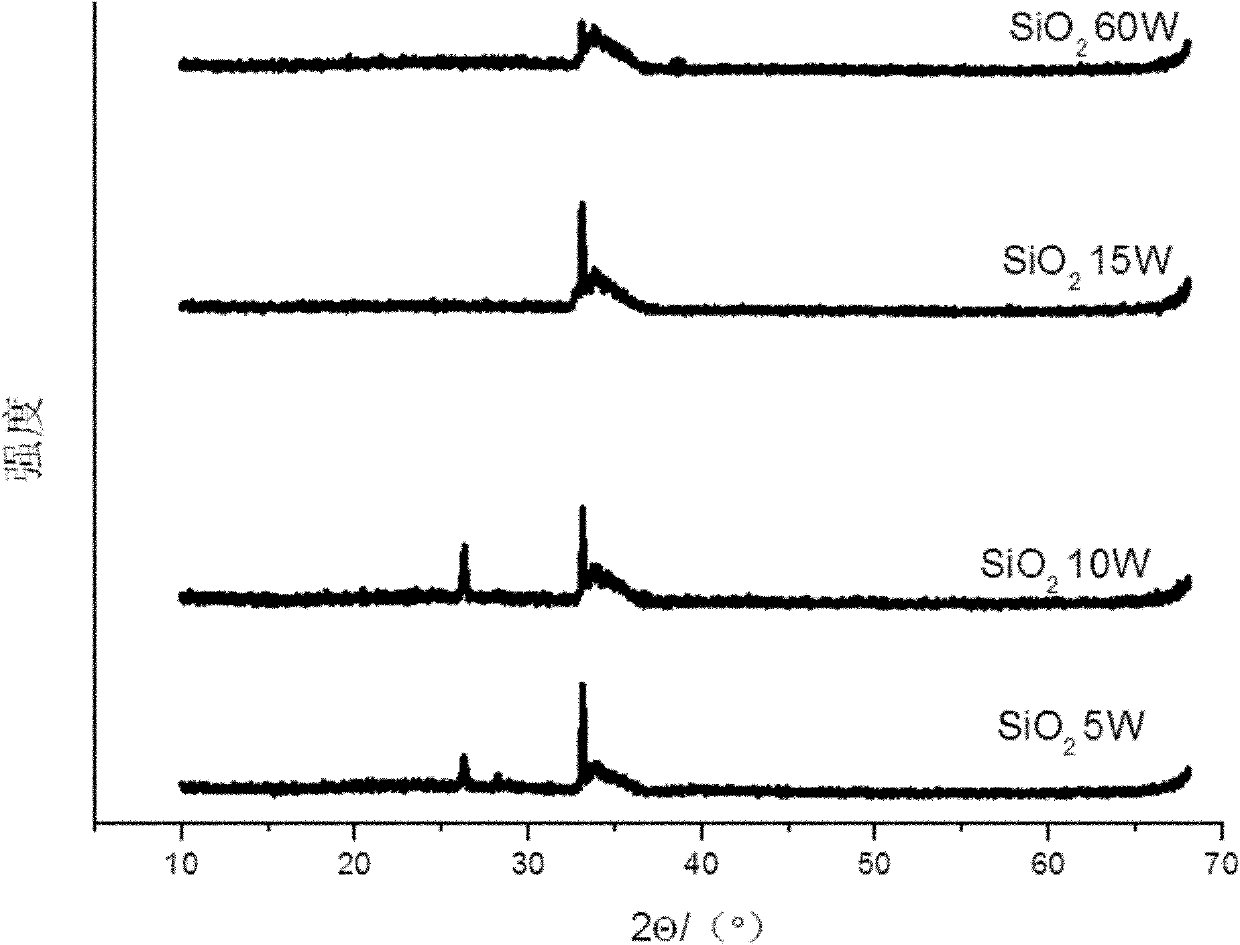

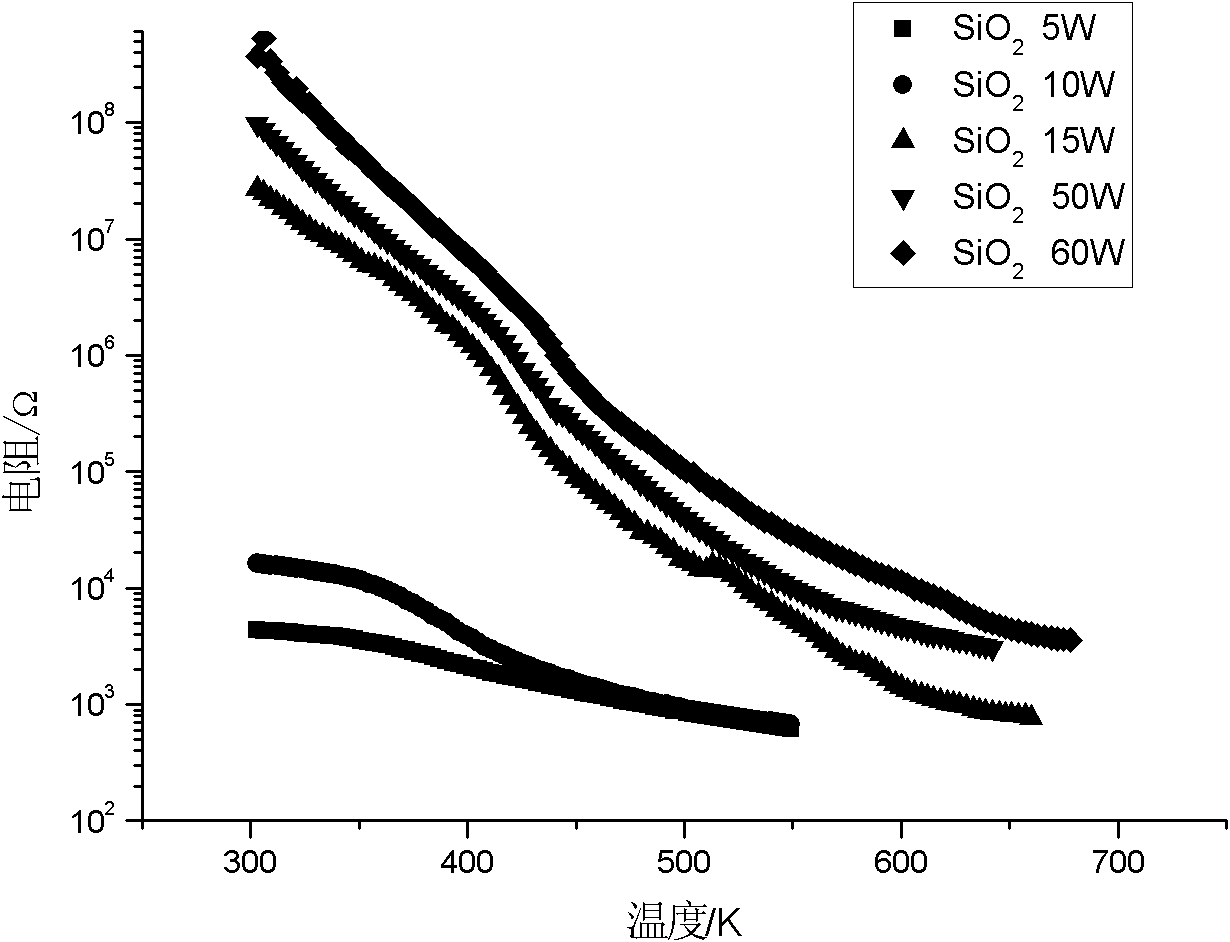

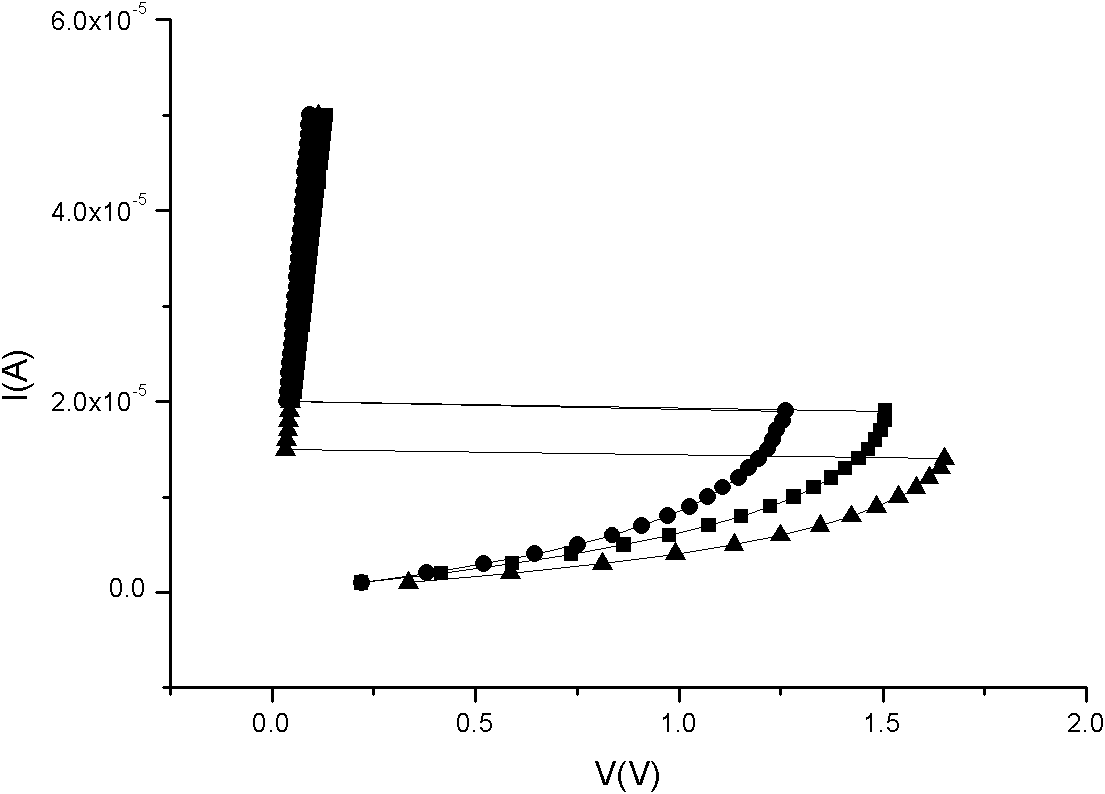

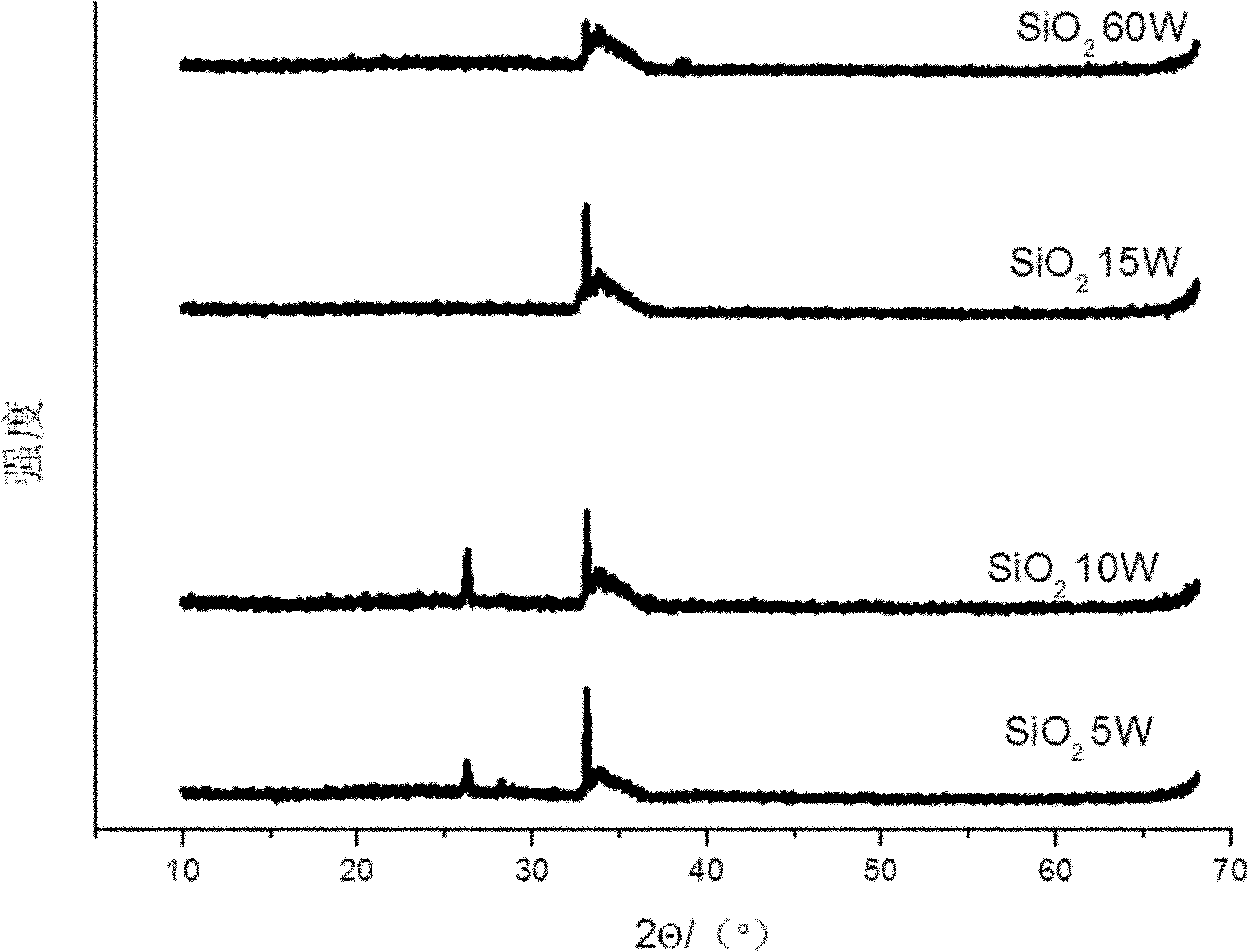

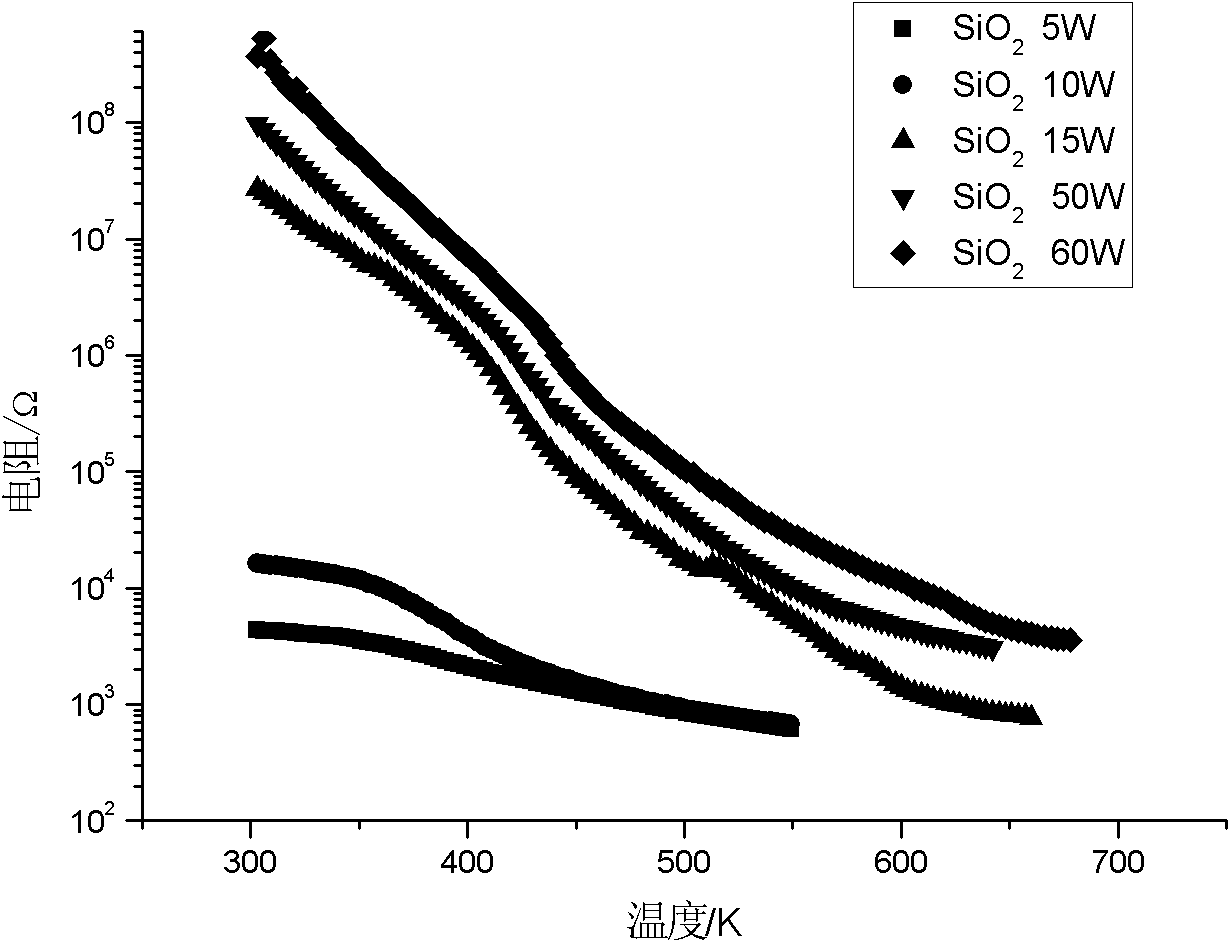

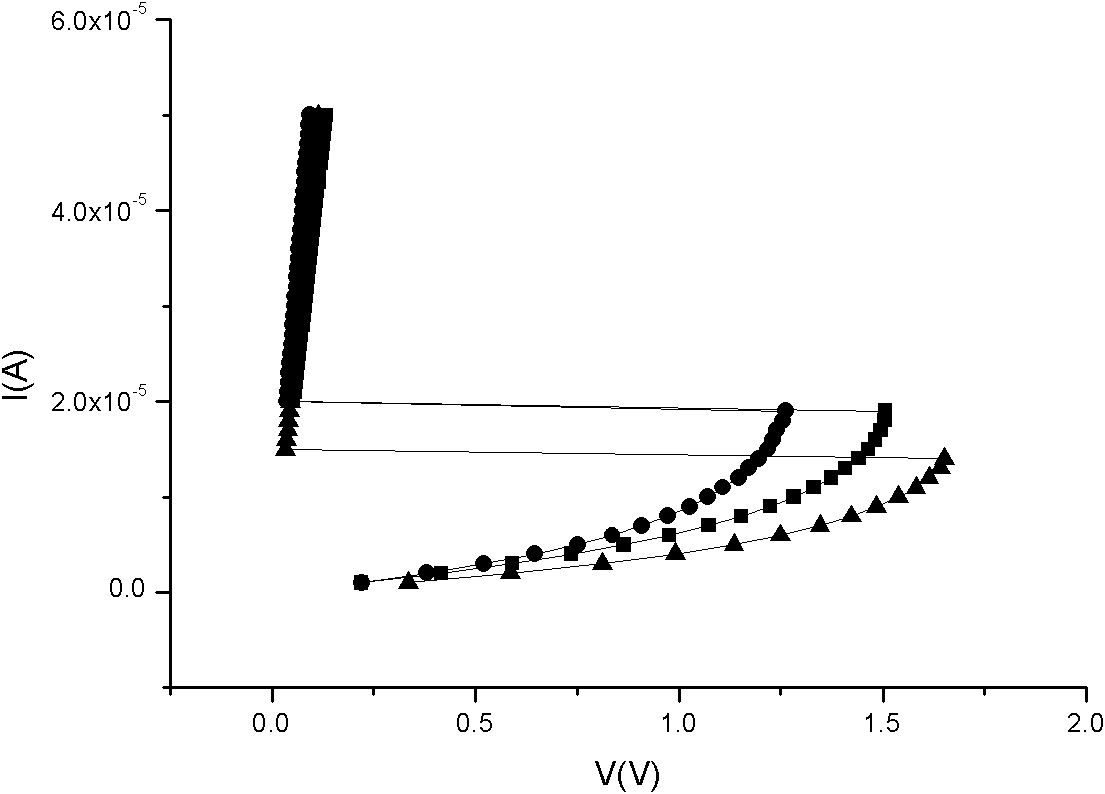

Sb2Tex-SiO2 nano composite phase change material used on phase change memory and preparation method of Sb2Tex-SiO2 nano composite phase change material

ActiveCN102487119AHigh resistivityRaise the crystallization temperatureElectrical apparatusPhase-change memoryCrystallization temperature

The invention discloses a Sb2Tex-SiO2 nano composite phase change material used on a phase change memory. The material is formed by compositing a phase change material Sb2Tex with SiO2 and has a chemical formula of (Sb2Tex)y(SiO2)1-y, wherein x is larger than or equal to 0.5 but smaller than or equal to 3 and y is larger than or equal to 0.2 but smaller than 1. The Sb2Tex-SiO2 nano composite phase change material has the advantages that through doping the SiO2 into the phase change material, the phase change material with a reversible phase change ability is isolated into areas with nanoscales by the amorphous state SiO2, and a composite structure is formed, so the resistivity and the crystallization temperature of the phase change material are increased and the heat conductivity of the phase change material is reduced. Due to the increase of the crystalline state resistance of the phase material, a Reset current of the phase change memory device can be reduced, and thereby the barrier that the Reset current of the phase change is overlarge is overcome; due to the rising of the crystallization temperature, the stability of the Sb2Tex-SiO2 phase material device can be improved; dueto the decline of the melting temperature, the power consumption of the Sb2Tex-SiO2 phase material device is effectively reduced; and due to the reduction of the heat conductivity, the utilization rate of energy can be improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

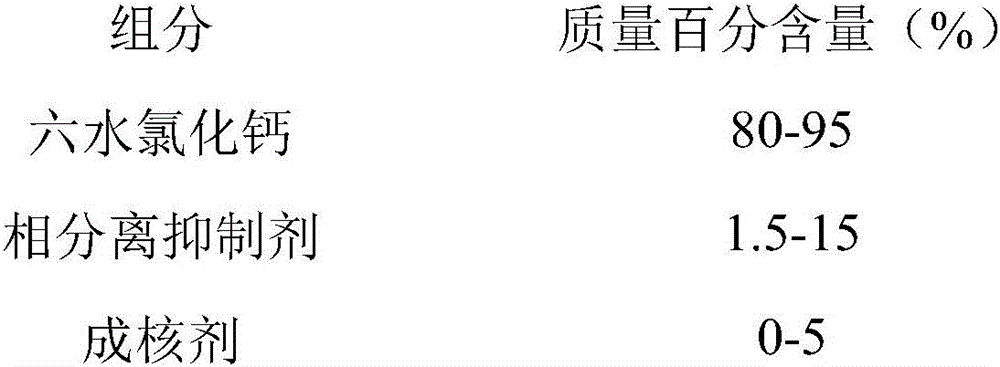

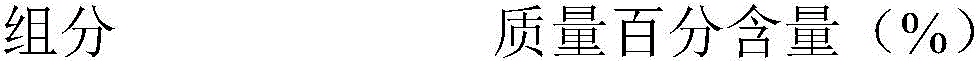

Composite phase-change energy storage material, and preparation method and application thereof

ActiveCN106634858AExtended service lifeIncrease energy storageHeat-exchange elementsHigh energyCalcium Chloride Hexahydrate

The invention relates to a composite phase-change energy storage material and a preparation method thereof. The composite phase-change energy storage material is composed of the following components in percentage by mass: 80-95% of calcium chloride hexahydrate, 1.5-15% of phase separation inhibitor and 0-5% of nucleator. The preparation method of the composite phase-change energy storage material comprises the following steps: weighing equal mass of anhydrous calcium chloride and water, and stirring until the anhydrous calcium chloride is completely dissolved, thereby obtaining a first solution; adding the nucleator into the first solution, and stirring to obtain a second solution; and adding the phase separation inhibitor into the second solution, and stirring to obtain the liquid composite phase-change energy storage material. By using the calcium chloride hexahydrate as the phase-change material, the energy storage material has low degree of supercooling, can still keep the phase change complete after repeated circulations, has high energy storage rate, and is more suitable for practical application.

Owner:CHINA BUILDING MATERIALS ACAD

High-efficiency and energy-saving composite shape-stabilized phase change material and preparation method thereof

ActiveCN109321213AImprove adhesion performanceSuitable phase transition temperature rangeHeat-exchange elementsPolyesterPhase change

The invention relates to a high-efficiency and energy-saving composite shape-stabilized phase change material and a preparation method thereof, belonging to the technical field of building materials.In order to solve the existing problems of poor insulation performance and easy leakage, the invention provides the high-efficiency and energy-saving composite shape-stabilized phase change material and the preparation method thereof; the material is prepared from 50-60 parts of a sludge shale ceramsite porous material, 30-40 parts of an organic phase change composite material and 15-2530-40 partsof a modified cement material, wherein the organic phase change composite material is a mixture of a polybasic fatty acid materials and degradable polyester, and the mass ratio of the polybasic fattyacid materials to the degradable polyester is equal to 1 to (0.05-0.2); the organic phase change composite material is absorbed in the pores of ceramsite; the modified cement material covers the surface of the ceramsite. The above-mentioned degradableed polyester and polybasic fatty acid organic phase change composite materials are heated and melted, atomized, and sprayed on the ceramsite; micro-encapsulation treatment is carried out to form a coating layer, and a corresponding composite shape-stabilizedd phase change material is obtained. The high-efficiency and energy-saving composite shape-stabilized phase change material can achieve the effects of high phase change heat storage density and low leakage.

Owner:ZHEJIANG FANGYUAN BUILDING MATERIALS TECH

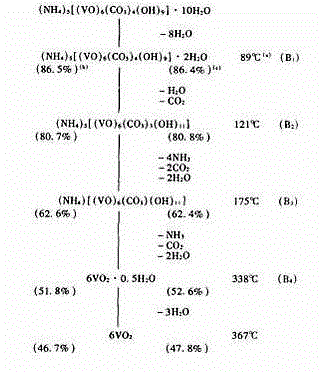

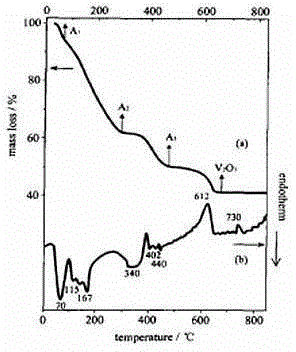

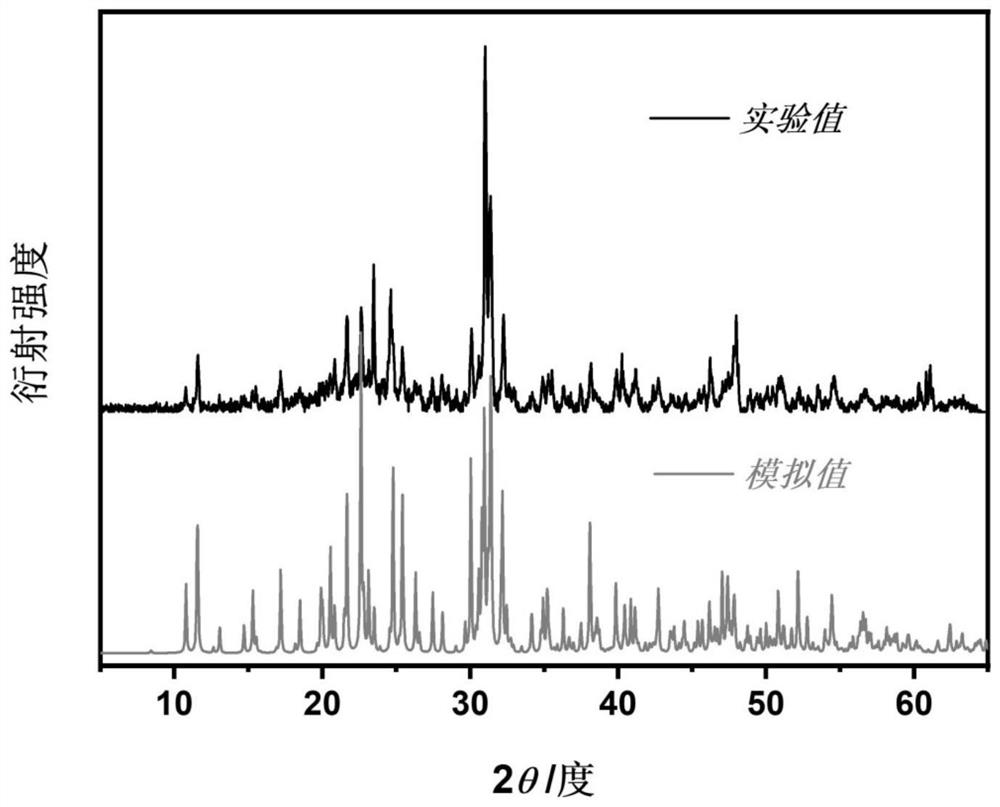

Vanadium dioxide powder preparation method and application thereof

InactiveCN104528826ALarge variation range of photoelectric performanceGood phase change performanceVanadium oxidesVanadium dioxideNitrogen gas

The invention provides a vanadium dioxide powder preparation method. The method comprises the steps that 1, N2H4.2HCl and H2CO4.2H2O are adopted in a hydrochloric acid medium for reducing vanadium pentoxide to obtain a VOCL2 solution; 2, the VOCL2 solution reacts with (NH4)2CO3 to obtain an alkaline-mode vanadyl ammonium carbonate precursor; 3, the obtained precursor is ultrasonically broken in absolute ethyl alcohol to achieve the granularity being smaller than 2 micrometers, the product is placed into a furnace with nitrogen to be heated and decomposed, and then vanadium dioxide powder is obtained, wherein when the product is heated and decomposed in the step 3, the nitrogen flow speed is 15 ml / min, and the temperature increasing speed is 5 DEG C / min.

Owner:NANTONG HANRUI IND

Porous carbon-based shaped composite phase-change material, preparation and application

ActiveCN110819307ANo leaksGood phase change performanceChemical industryHeat-exchange elementsSodium bicarbonateSucrose

The invention discloses a preparation method of synthesizing a porous carbon-based shaped composite phase-change material capable of being used for heat storage through high-temperature calcination and vacuum impregnation. According to the method, sucrose and sodium bicarbonate are used as raw materials, a porous carbon supporting carrier is prepared through a high-temperature calcination method,then an organic phase-change material is added, the phase-change material is loaded into porous carbon through a vacuum heating impregnation method, and finally the porous carbon-based shaped composite phase-change material is prepared, wherein in the preparation process of the porous carbon carrier, holes of different structures can be prepared by changing the ratio of the sucrose to the sodium bicarbonate, and then shaped composite phase-change materials with different loads are obtained after vacuum impregnation. According to the composite phase-change material synthesized through the method, the porous carbon and the phase-change material are combined through a physical relation, so that the stability is good, and the material can be used for heat storage and waste heat recovery of industrial equipment, solar photo-thermal conversion and other aspects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method of preparing solid-solid phase change material through grafting copolymerization

PendingCN107602795AThere is heat-resistant performance and processing function improvementWide range of applicationsHeat-exchange elementsMonocomponent polyesters artificial filamentSolid phasesPhase-change material

The invention discloses a method of preparing a solid-solid phase change material through grafting copolymerization and belongs to the technical field of functional materials. The method comprises thesteps of: 1) pretreatment of raw materials; 2) complete reaction; 3) post-treatment of a crude product. The method preferably including the steps of: treating the surface of porous nano-powder with acid to graft carboxyl groups on the surface of porous nano-powder; performing esterification reaction to the carboxyl groups with hydroxyl groups on a phase-change material, PEG, so as to graft a polyethylene glycol chain terminal onto the framework macromolecules, which have high melting point, high strength and stable structure. Due to the high melting point of the framework macromolecules, macroscopic flowing of the polyethylene glycol is limited, so that solid stage during phase change is guaranteed. The material is free of problems such as separation out, leakage and the like during application.

Owner:WUHAN TEXTILE UNIV

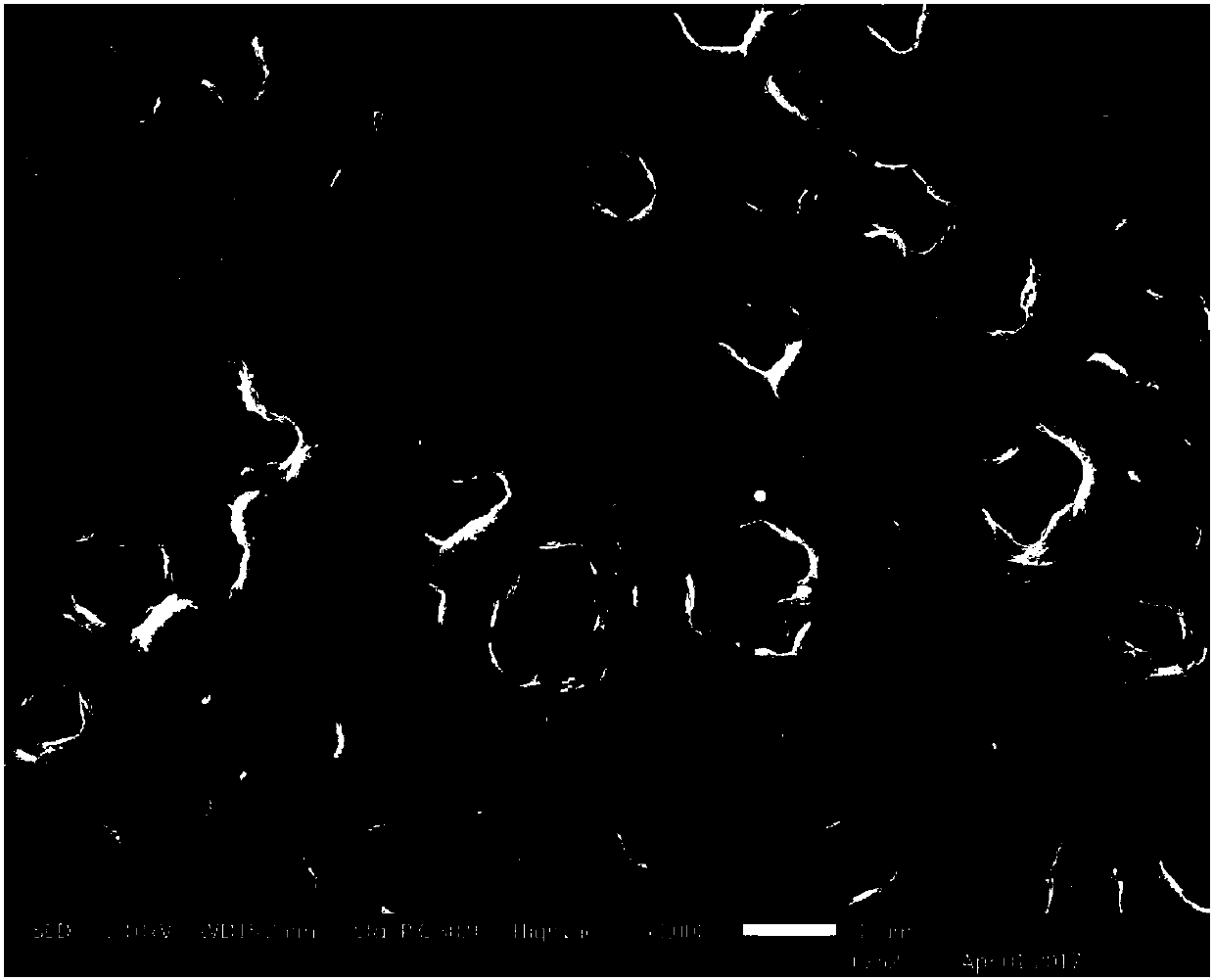

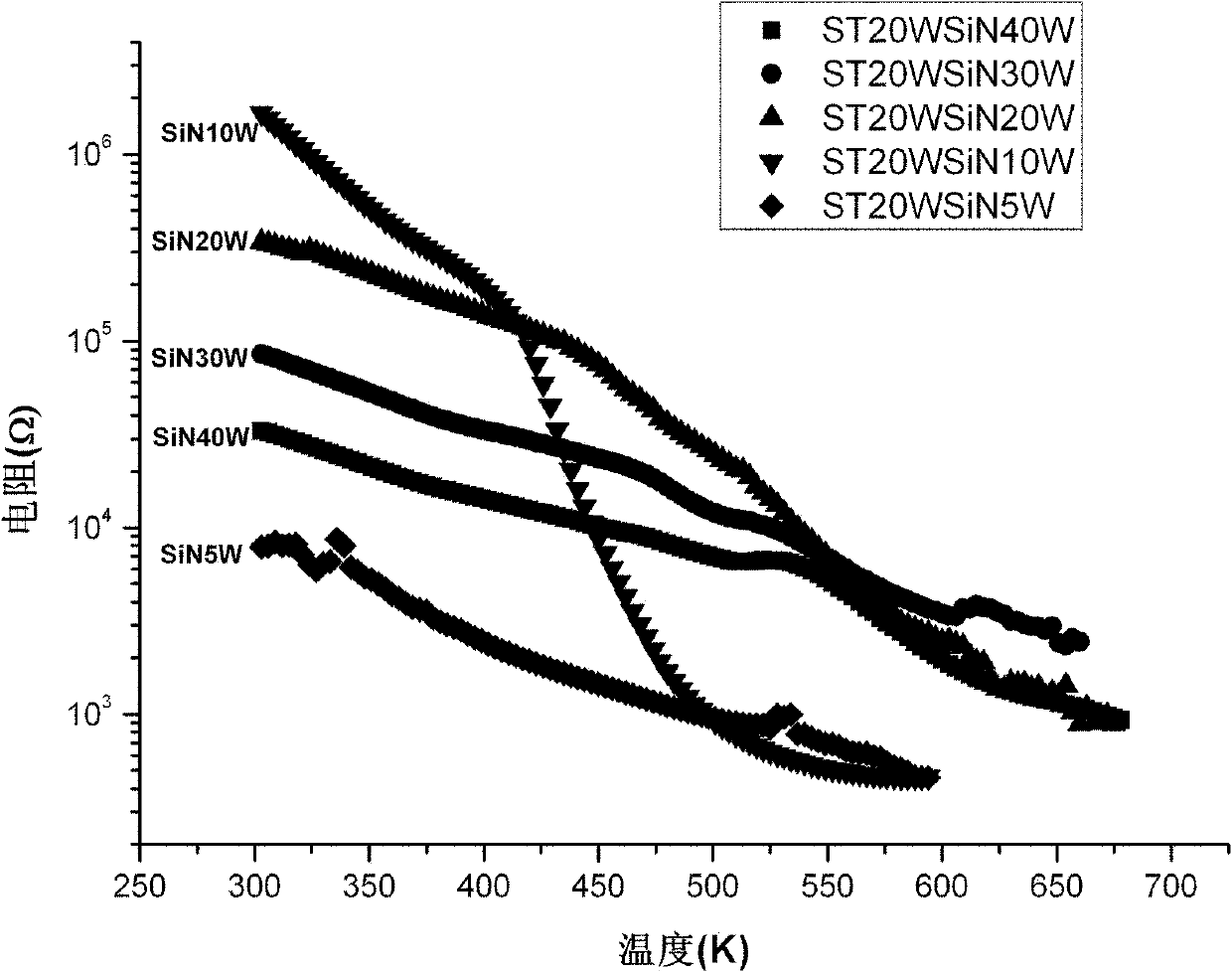

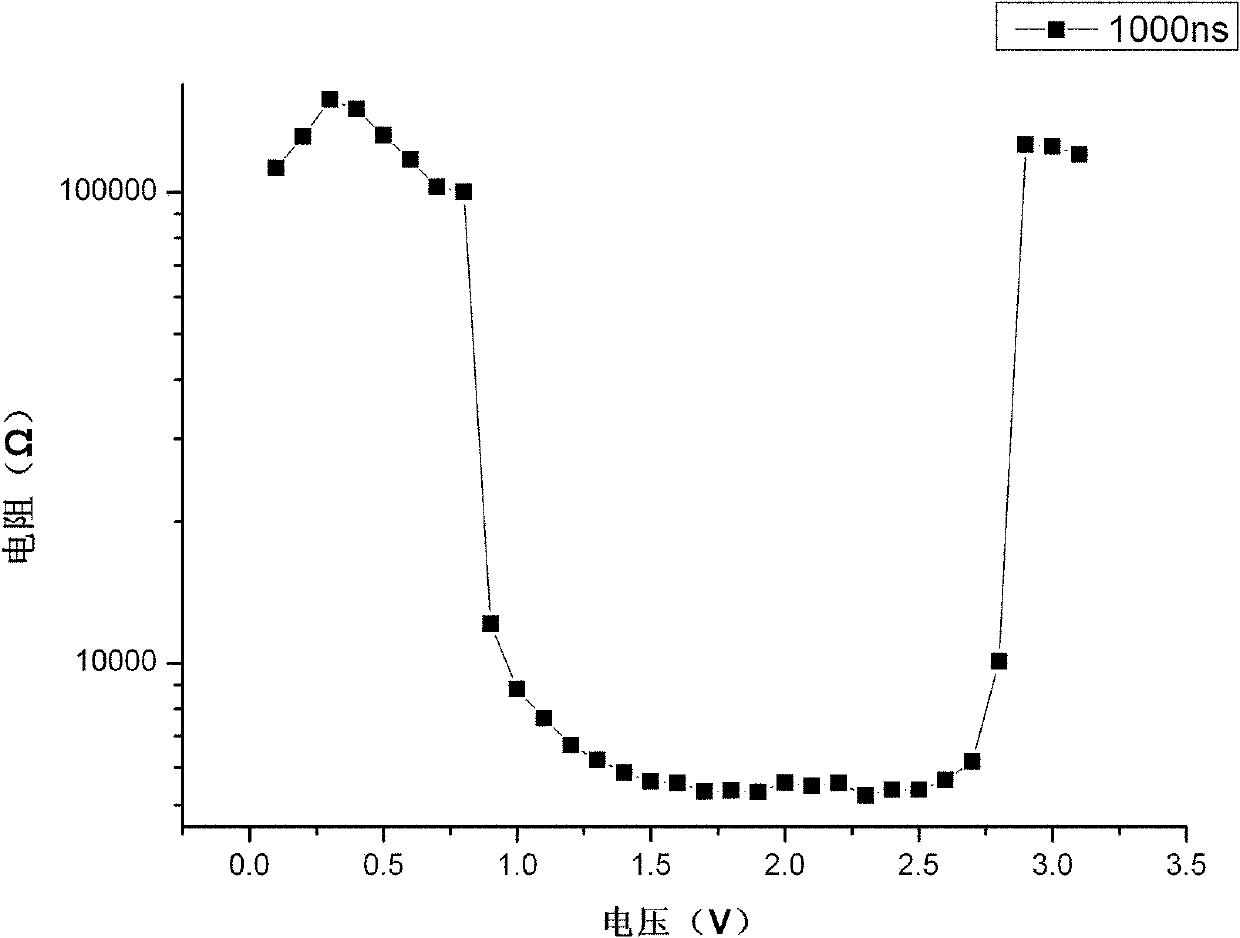

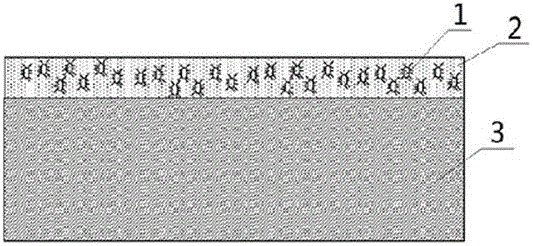

Sb2Tey-Si3N4 composite phase change material for phase change memory and preparation method thereof

ActiveCN102569644ACapable of reversible phase changeReversible phase transition capability does not involveElectrical apparatusPhase-change memoryNanoscopic scale

The invention discloses a Sb2Tey-Si3N4 composite phase change material for a phase change memory and a preparation method thereof. The material is a mixture containing four elements, namely antimony, tellurium, nitrogen and silicon; a Sb2Tey (y is more than 1 and less than 3) phase change material with reversible phase change capability is isolated by amorphous Si3N4 to form a nano-scale region, then a composite structure is formed, and the chemical formula is (Sb2Tey)x(Si3N4)100-x, wherein y is more than 1 and less than 3, and x is more than 60 and less than 100. By regulating the content of Si3N4 in the Sb2Tey-Si3N4 composite phase change material, different crystallization temperatures, melting points and crystallization activation energy can be obtained. Compared with a traditional Sb2Te3 material, the (Sb2Tey)x(Si3N4)100-x has higher crystallization temperature, better thermal stability and data retention and lower melting point; and furthermore, grain size after crystallization is small and energy consumption is low.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Phase change microcapsule self-regulating grc dry powder mortar surface layer material

Owner:江苏倍立达新材料科技有限公司

Phase-change energy storage device

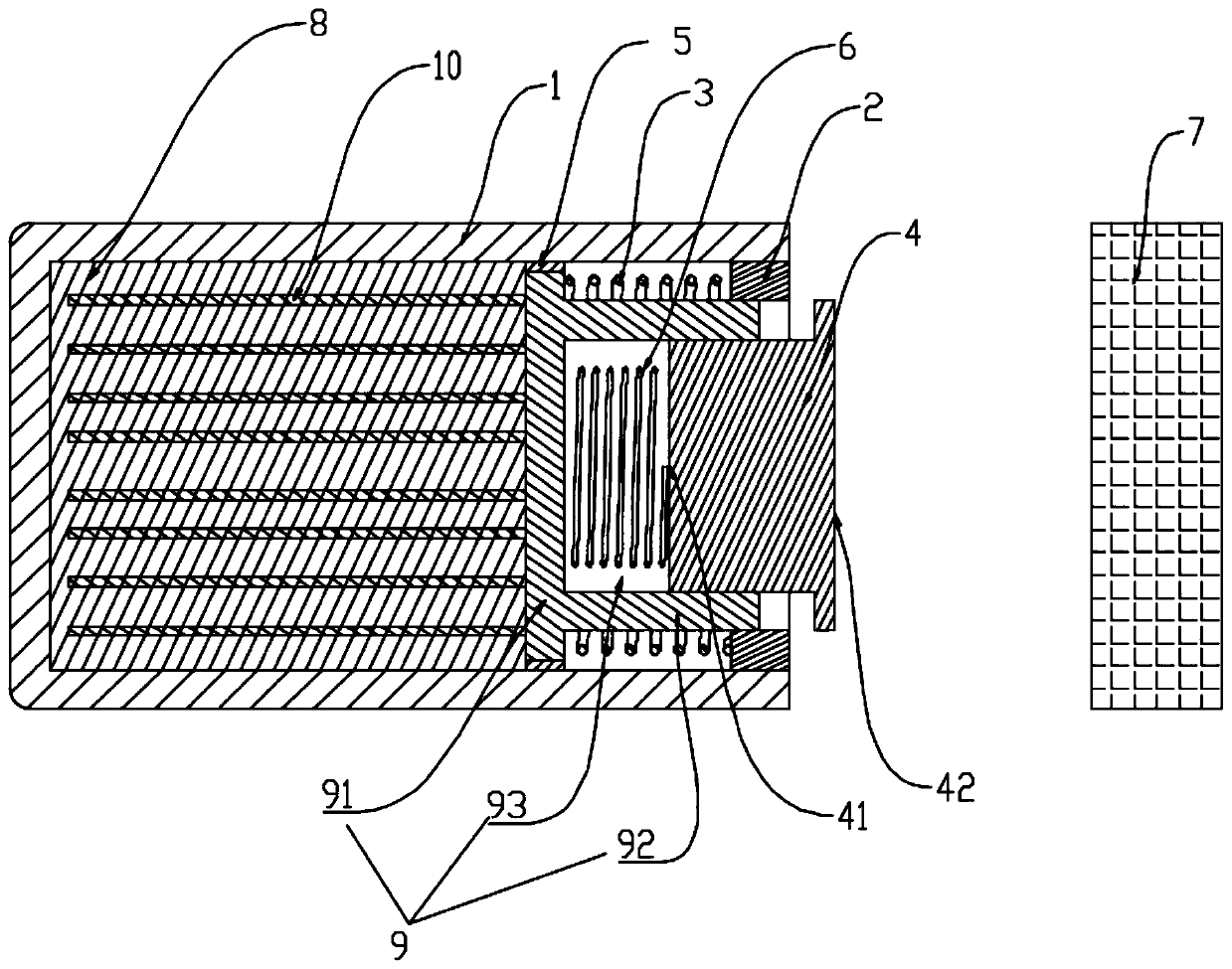

ActiveCN110274503ARealize the heat dissipation functionRealize heat preservation and energy storage functionHeat storage plantsHeat transfer modificationEngineeringPhase change

The invention discloses a phase-change energy storage device. The phase-change energy storage device comprises a heat conduction piston cavity, a phase-change unit, a heat conduction piston, a limiting ring, a first spring, a heat conduction cap and a heat sink; the piston cavity and the heat sink are oppositely arranged on the front surface and the rear surface, the heat sink is arranged in front of the piston cavity, the front end of the piston cavity is open, and the rear end of the piston cavity is sealed; the piston is in sliding fit in the piston cavity, and the piston is in dynamic sealing with the inner wall of the piston cavity; the phase-change unit is filled in a cavity defined by the end part of the rear end of the piston and the piston cavity, the limiting ring is fixedly connected with the inner wall of the front end of the piston cavity, and the first spring is arranged between the limiting ring and the piston; and the two ends of the first spring are respectively abutted against the limiting ring and the piston, the heat conduction cap is connected with the front end of the piston, the front end of the heat conduction cap penetrates out of the piston cavity, and the heat sink is arranged in front of the heat conduction cap. The phase-change energy storage device can dissipate heat generated by high-power equipment on the basis of keeping a small size, the problem of thermal control of the high-power equipment on a satellite is solved, and normal operation of the equipment is guaranteed.

Owner:BEIJING INST OF RADIO MEASUREMENT

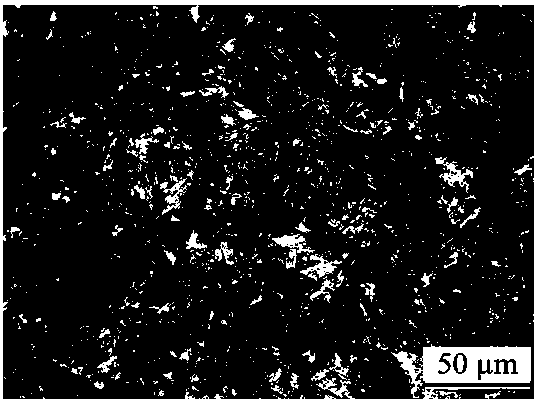

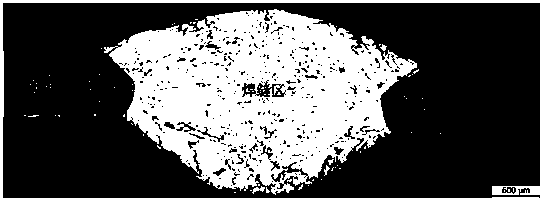

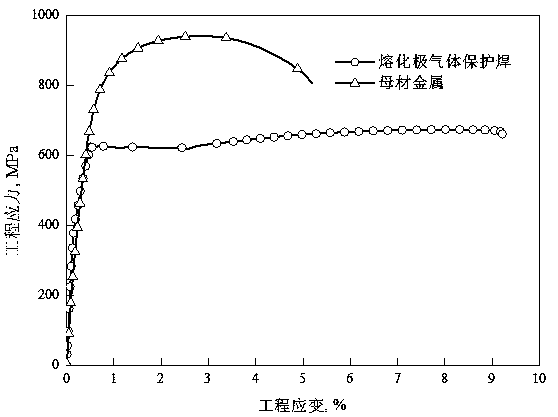

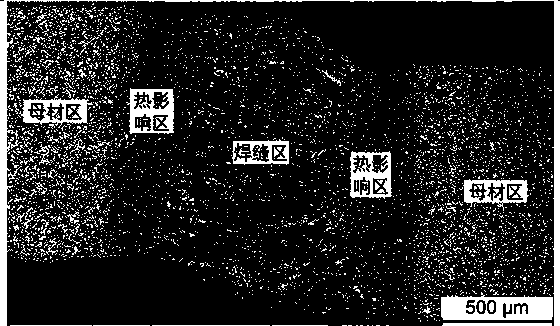

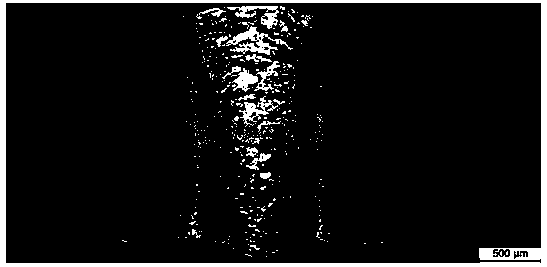

Penetration fusion welding method for high-strength dual-phase steel thick plate through high-speed laser filler wire

ActiveCN107900518AGood phase change performanceHigh hardnessLaser beam welding apparatusFiberHeat-affected zone

The invention discloses a penetration fusion welding method for a high-strength dual-phase steel thick plate through a high-speed laser filler wire. The main welding technical parameters are that theoptical fiber Nd:YAG laser filler wire is used for butt-joint penetration fusion welding, the welding seam prefabricated butt-joint gap is 1.0-1.6 mm, the focal length of a collecting lens is 15 cm, the defocus distance is -10-3 mm, the laser power is controlled to be 1.8-6 kW, the welding speed is controlled to be 10-60 mm.s<-1>, the welding wire diameter is 1.2-2.0 mm, and the wire feed speed is20-240 mm.s<-1>. The width of an obtained welding seam welding heat affected zone is smaller than 0.6 mm, the welding seam zone is of a coarse martensitic structure, the welding heat affected zone take a thin martensitic structure as priority, the hardness of a welded joint is 370-450 HV0.1, and the tensile strength of the welded joint is close to or even exceeds that of a base material. Throughthe effects of rapid cooling martensite strengthening and alloy strengthening, the hardness and strength of the welded joint are greatly improved.

Owner:CENT SOUTH UNIV

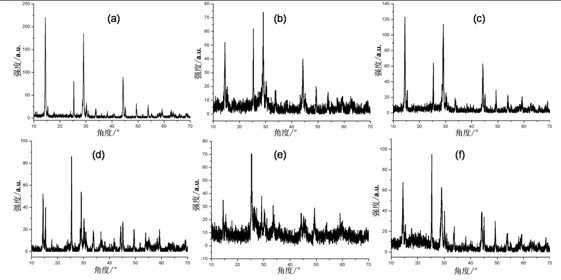

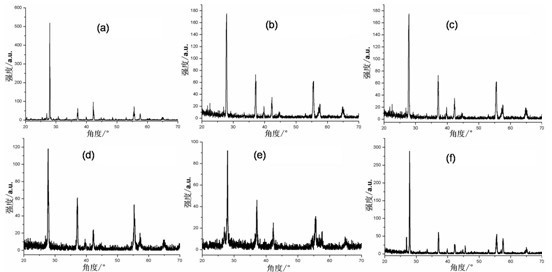

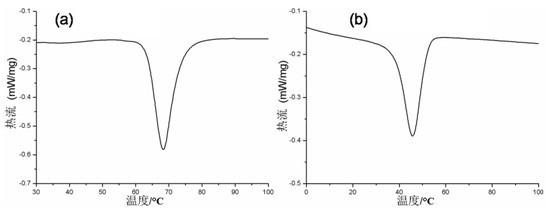

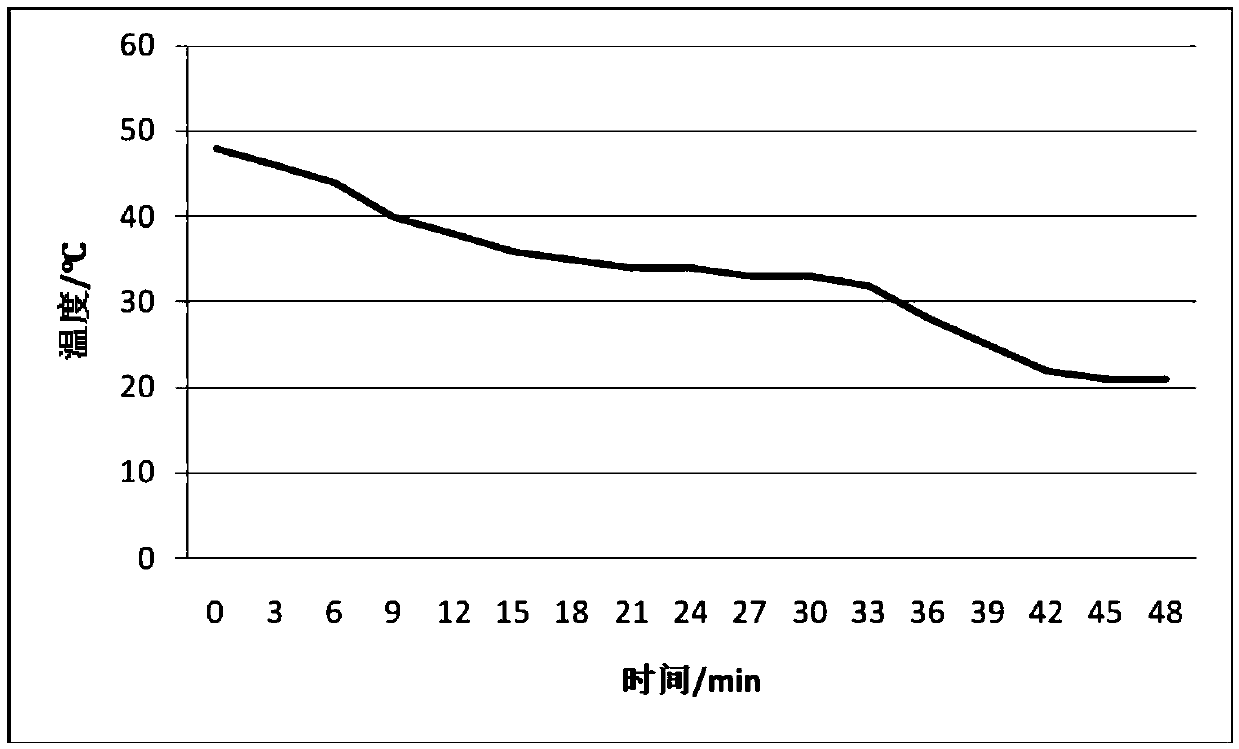

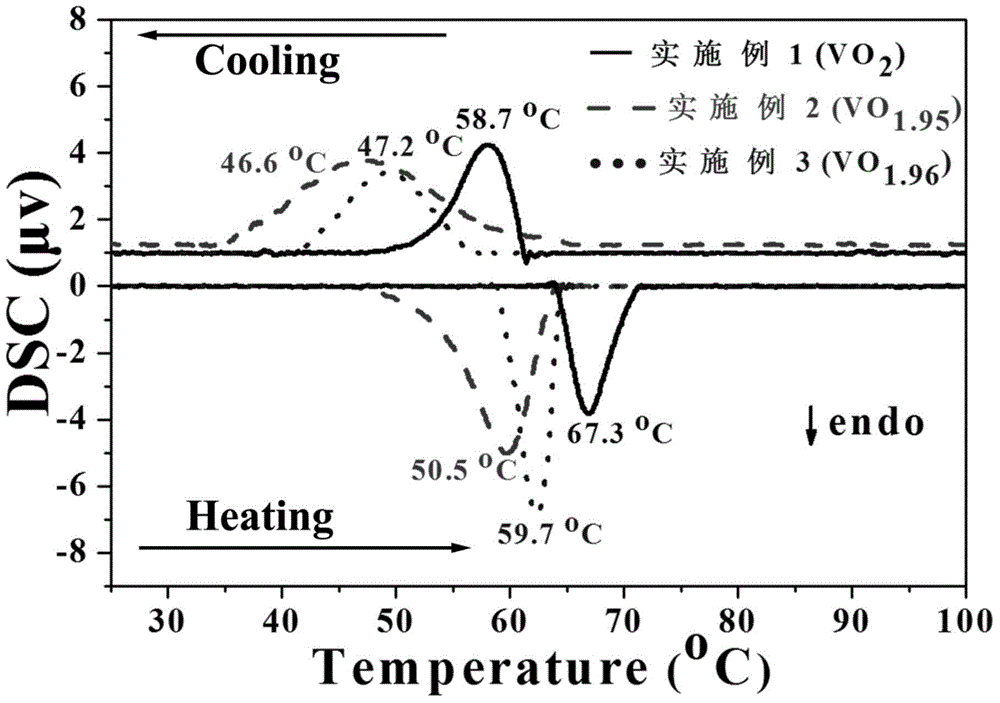

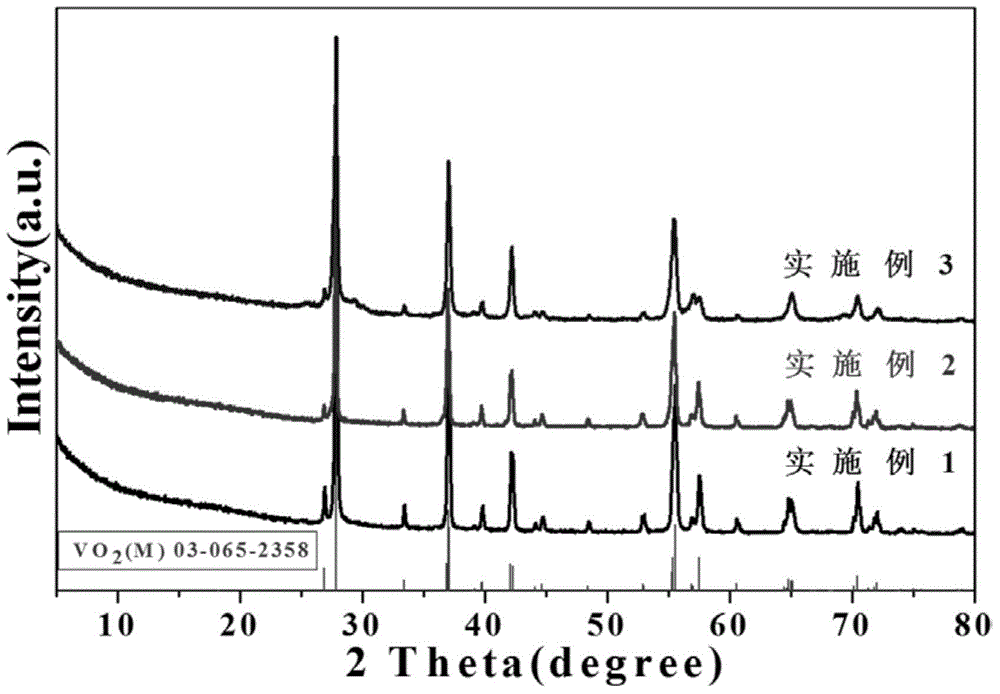

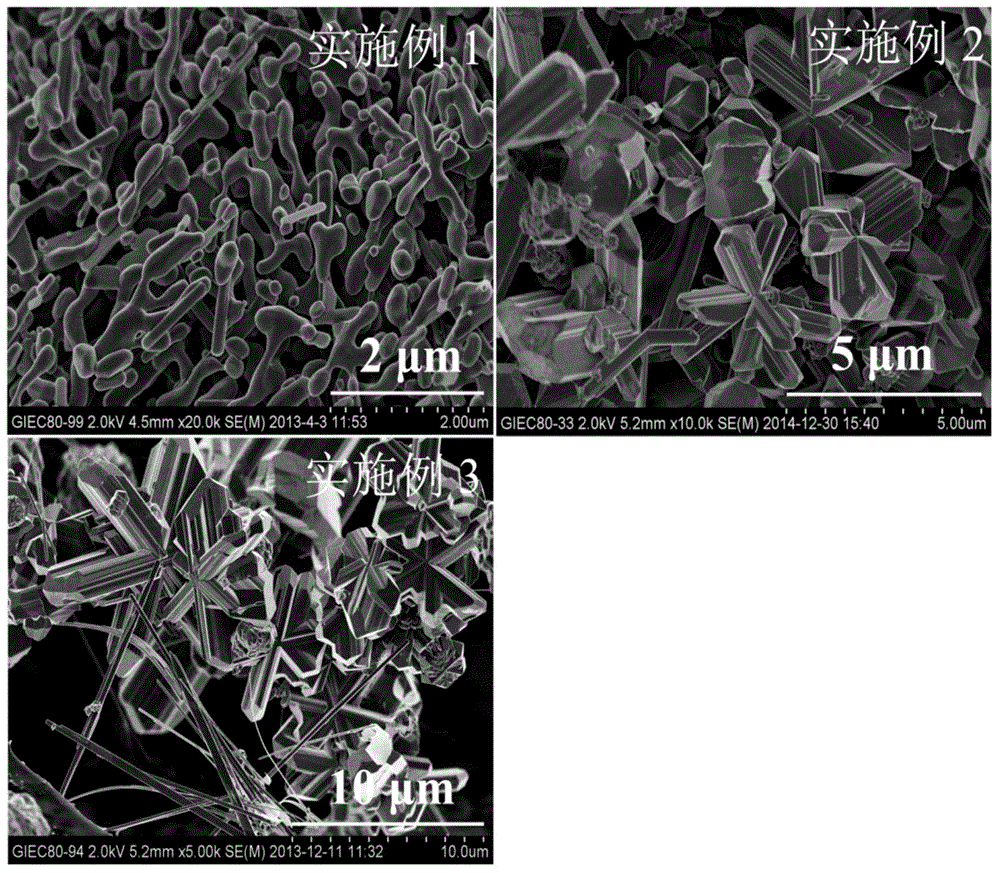

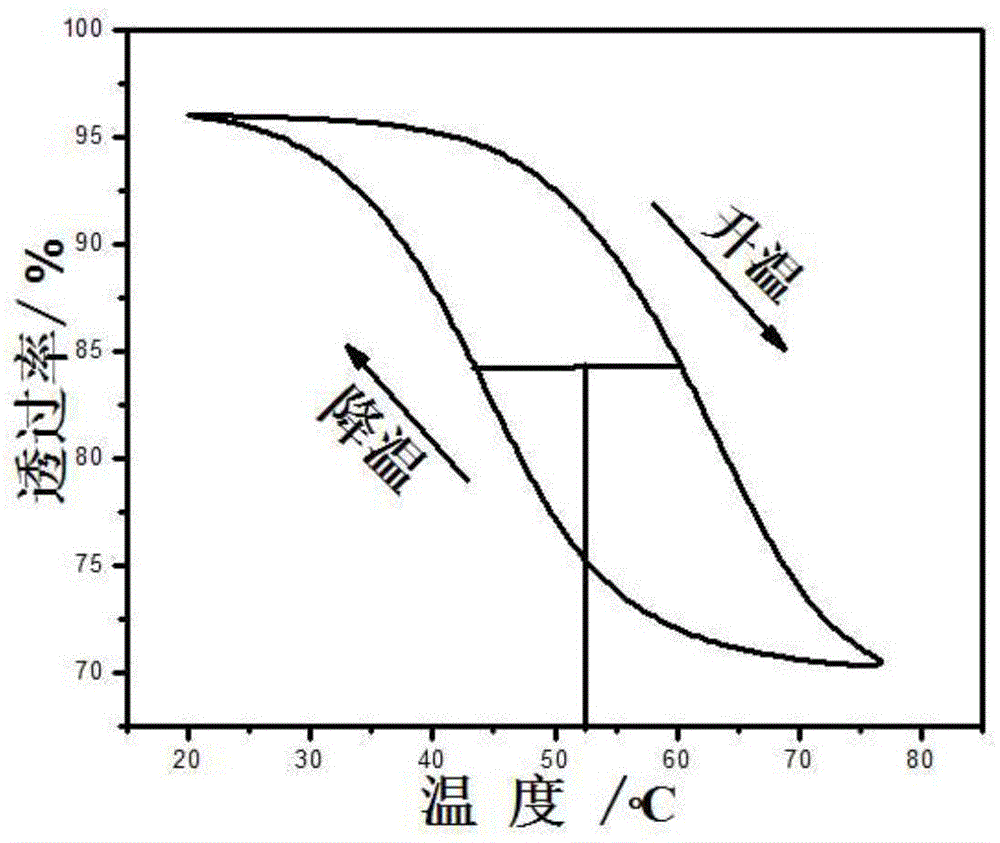

Preparation method for non-stoichiometric ratio type nanometer VO2-x powder for regulating and controlling phase transition temperature

InactiveCN104817113AGood phase change performanceDoes not destroy the crystal structureMaterial nanotechnologyVanadium oxidesIonVanadium dioxide

The invention discloses a preparation method for non-stoichiometric ratio type nanometer VO2-x powder for regulating and controlling phase transition temperature. A target product is obtained through carrying out hydrothermal reaction and annealing treatment on a precursor made of oxalic acid, de-ionized water and vanadium source, the stoichiometric ratio of the product is controllable (x=0-0.05), the phase change temperature can be regulated in the range of Tc=63.0-53.5 degrees centigrade, and the material is more excellent in phase change performance and better for manufacturing a thermochromic smart window, a field effect transistor and the like. The preparation method for the non-stoichiometric ratio type nanometer VO2-x powder for regulating and controlling the phase transition temperature is short in production period, simple in technique, moderate in reaction condition, environmental friendly, low in cost and suitable for large-scale production; the prepared powder can be prepared into a piece of large VO2-x film with adjustable phase change temperature through combining with a powder film forming technology; the preparation method is good for breaking through the application bottleneck of a vanadium dioxide smart window.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Technology of high-strength dual-phase steel sheet welded by high-speed laser wire filling welding

ActiveCN107931835AWeld melting rises rapidlyFacilitate phase transitionWelding/cutting media/materialsSoldering mediaButt weldingHeat-affected zone

The invention discloses a technology of high-strength dual-phase steel sheet welded by high-speed laser wire filling welding. The main technological parameters of welding are as follows that a fiber Nd: YAG laser is used for filling and butt welding; a welding seam prefabricated butt joint gap is 0.2-0.4mm; a focal length of a collecting lens is 15 cm; a defocusing distance is +3-3mm; a laser power is controlled to be 1. 8-6 kW the welding speed is 24-60 mm / s; the diameter of a welding wire ranges from 0.6-1.0 mm; and a wire feeding speed is 20-240 mm / s. The welding seam welding area is quite narrow, and is less than 0.65mm, a residual height is very small; the weld joint area is a thick martensite structure; a welding heat affected zone takes fine martensite tissue as main body and contains a small amount of ferrite. The hardness of a welding joint is in the range of 350-450 HV / 0, and the tensile strength of the welding joint is close to or even more than that of the base material;due to the effects of rapid cooling martensite strengthening and alloy strengthening, the hardness and strength of the welding joint are greatly improved.

Owner:CENT SOUTH UNIV

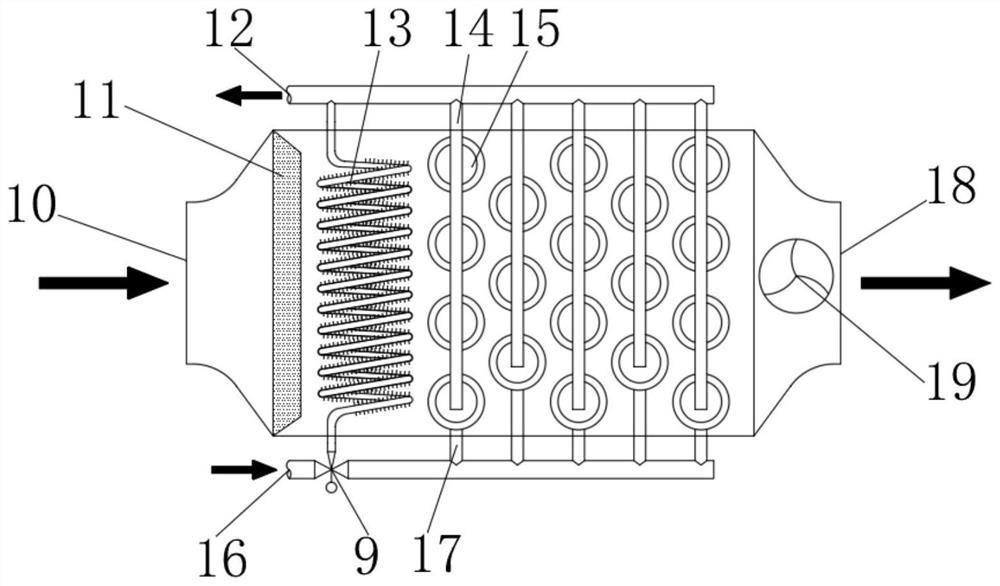

Phase change energy storage fresh air system for cold and hot pretreatment

ActiveCN111649416AAlleviate the contradiction between energy supply and demandAchieve energy saving effectMechanical apparatusLighting and heating apparatusCooling towerAutomatic control

The invention discloses a phase change energy storage fresh air system for cold and hot pretreatment. The system comprises an energy storage module, a water circulation module, an automatic control module and a monitoring module. The energy storage module is composed of a heat preservation shell, a heat exchange coil pipe, a phase change energy storage pipe array structure and a draught fan. The water circulation module comprises a closed cooling tower, a solar heat collection plate, a circulation water pump, a circulation pipeline and a three-way valve set. The monitoring module is used for monitoring the outlet water temperature of the cooling tower, the outlet water temperature of the solar heat collection plate, and the temperature of phase change materials in phase change energy storage pipes. A monitoring device controls the cooling tower, the solar heat collection plate and the energy storage module to be switched on or off according to the monitored temperature. The system canbe used in both winter and summer, efficient utilization of the phase change materials is achieved, the energy saving effect is achieved, and the requirements for fresh air pre-cooling in summer and pre-heating in winter are met.

Owner:YANGZHOU UNIV

Nano VO2 film with superhydrophilic self-cleaning function and intelligent temperature control function and preparation method of nano VO2 film

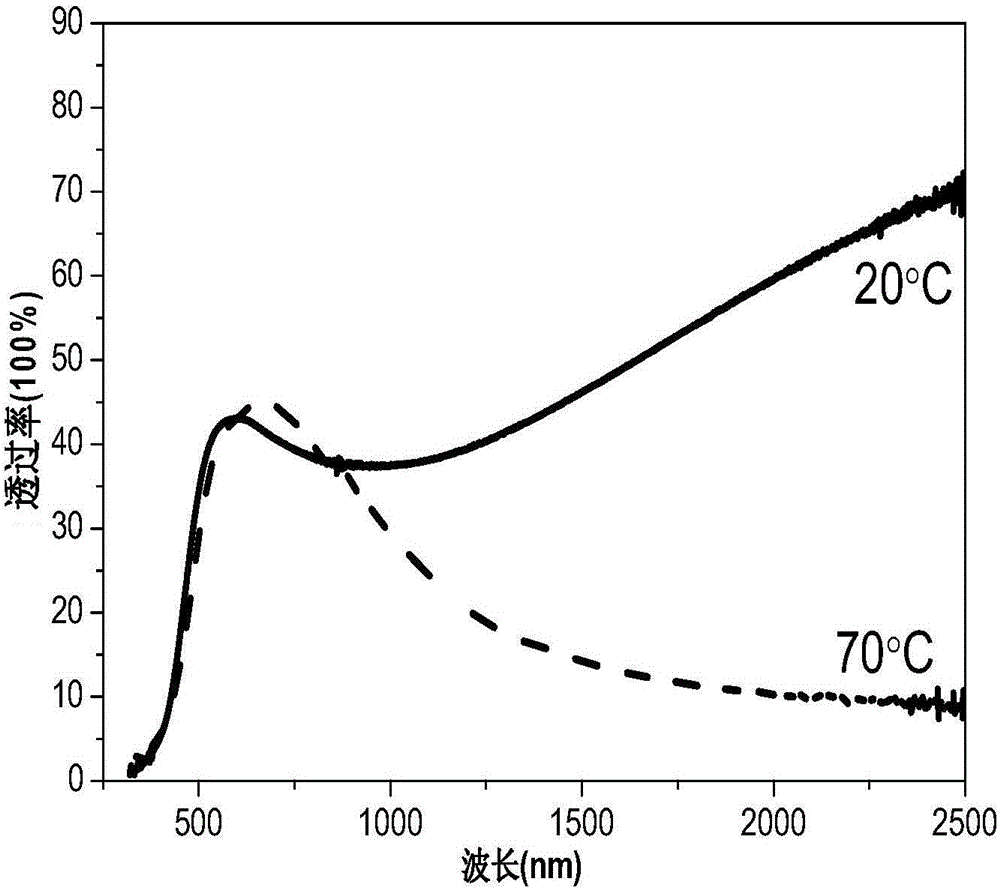

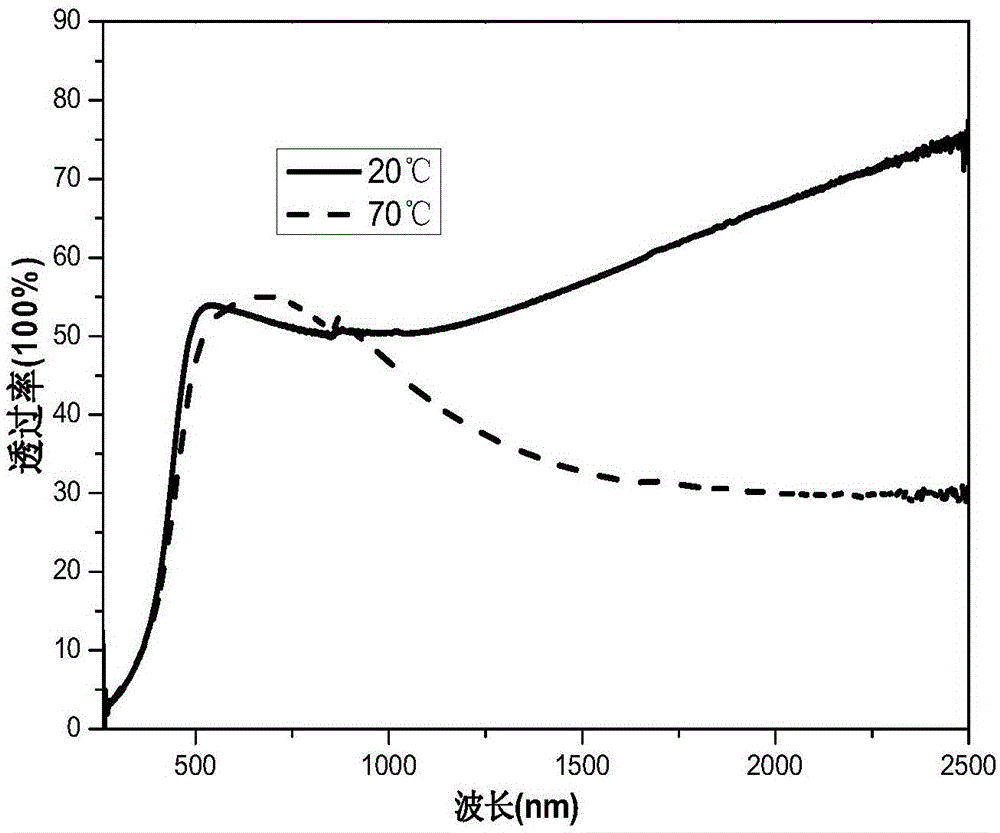

ActiveCN105543810ALow transmittance of infrared lightHigh transmittance of infrared lightLiquid/solution decomposition chemical coatingTransmittanceSol-gel

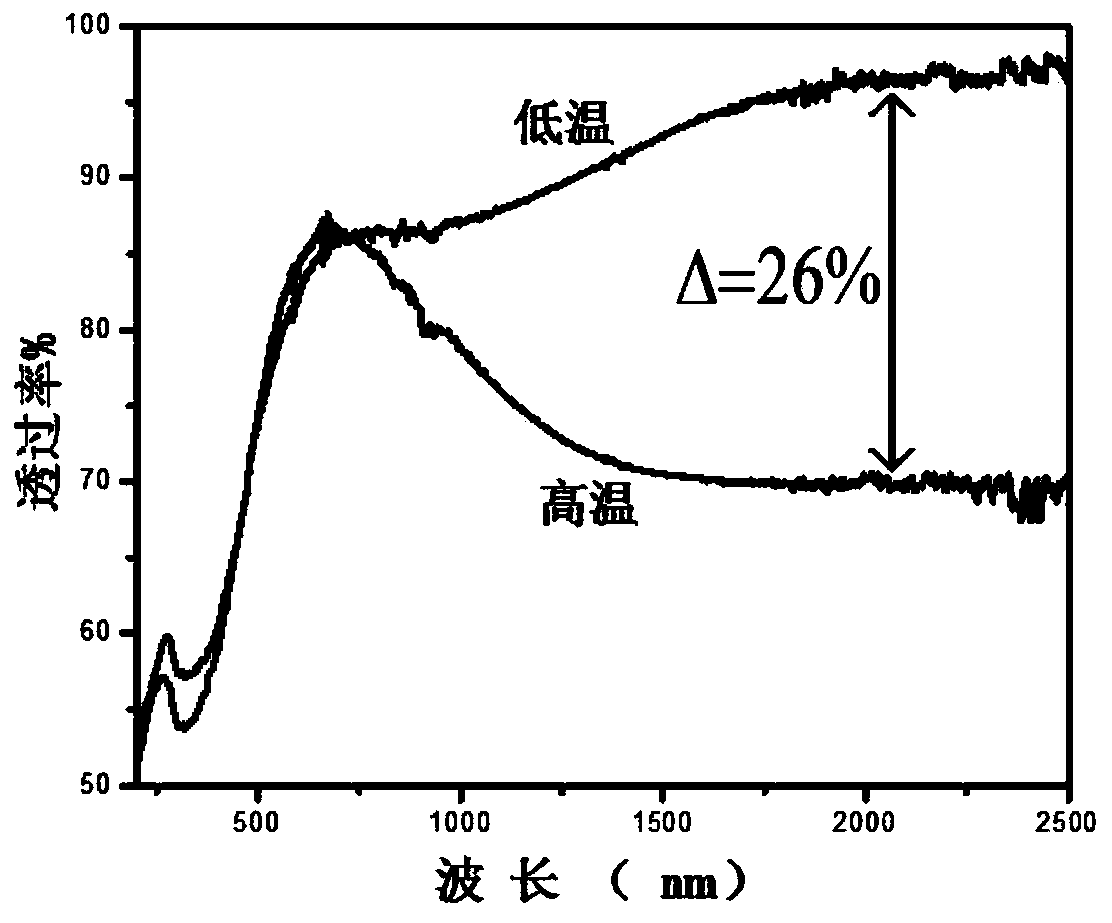

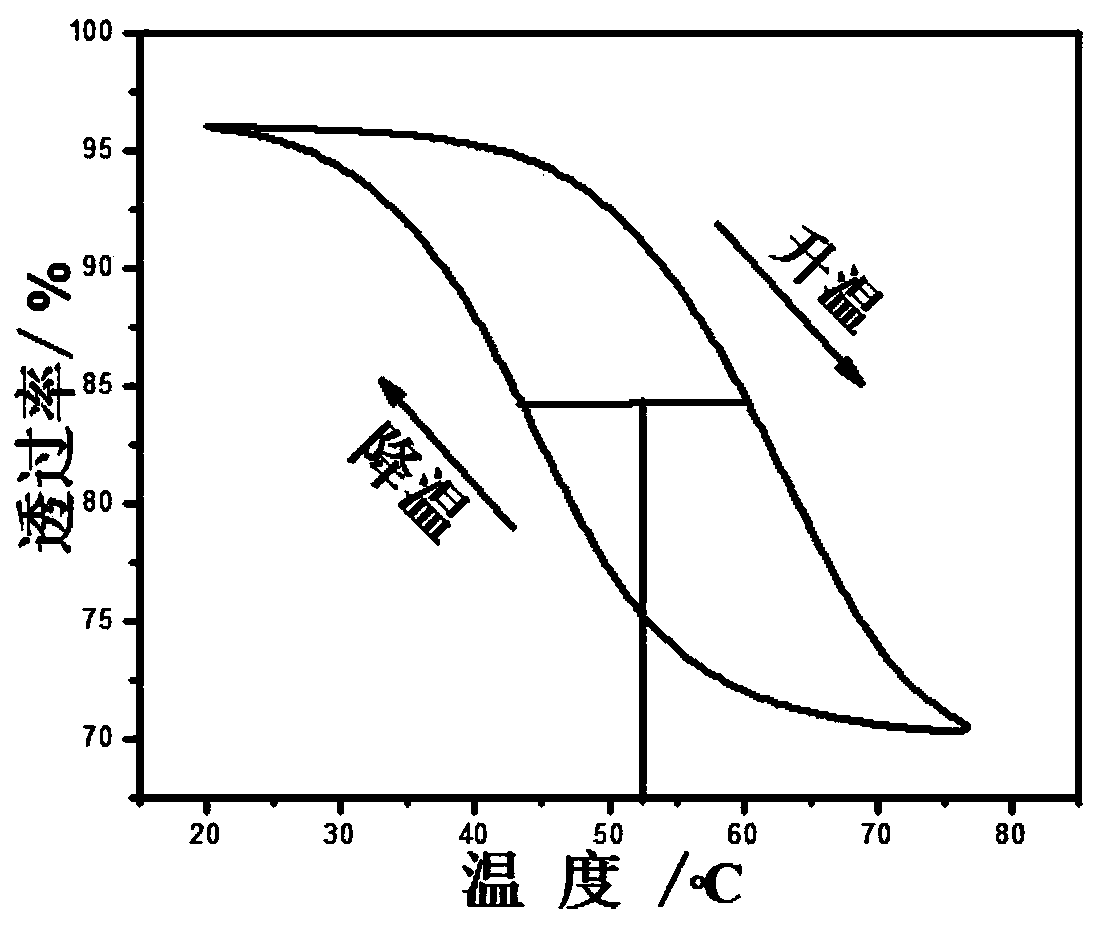

The invention relates to a nano VO2 film with a superhydrophilic self-cleaning function and an intelligent temperature control function and a preparation method of the nano VO2 film. The preparation method of the nano VO2 film comprises the steps that firstly, a precursor solution of vanadium dioxide is prepared through a sol-gel method; then a substrate is evenly coated with the precursor solution; and finally one-step annealing is conducted, so that the nano VO2 film is obtained. A corresponding tungsten-doped VO2 film can be obtained by directly adding a tungsten source in the precursor solution, and the phase-change temperature can be adjusted to 32 DEG C; the crystal sizes of VO2 particles can be changed through tungsten ion doping, a certain micro-nano structure is formed on the surface of the substrate, and the superhydrophilic self-cleaning function at the water contact angle of 12 degrees is achieved; in addition, the difference of the light transmittance before the phase change and the light transmittance after the phase change of the film in the position with the visible light transmittance being 80% and the wavelength being 2000 nm is 26%, and an extremely good intelligent temperature control effect is achieved.

Owner:HUBEI UNIV

A nano-VO2 film with superhydrophilic self-cleaning and intelligent temperature control functions and its preparation method

ActiveCN105543810BSensitive phase transition propertiesReduce transmittanceLiquid/solution decomposition chemical coatingVanadium dioxideNano structuring

Owner:HUBEI UNIV

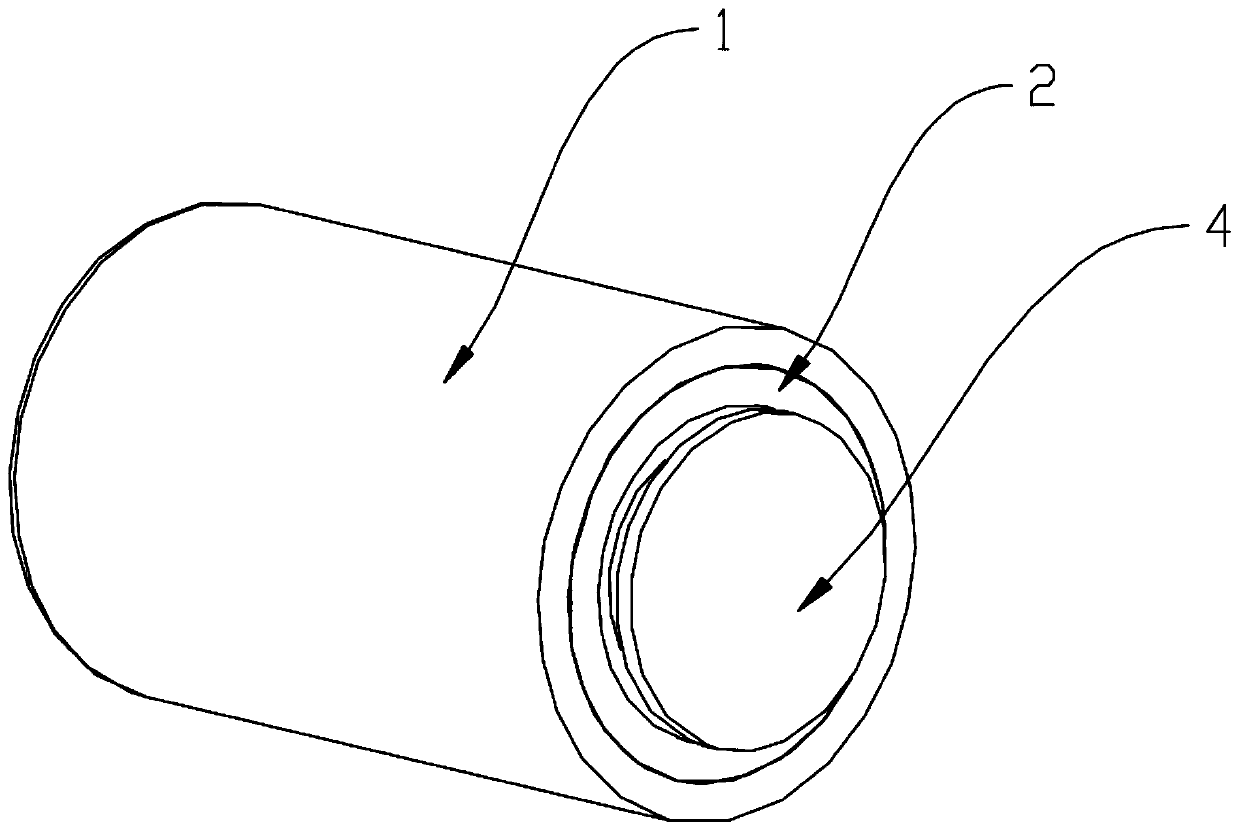

Cooling smoke tube

PendingCN114343235AImprove deformation resistanceSimple structureCigar manufactureCellulosePolyethylene glycol

The invention relates to the technical field of heating non-combustion cigarettes, in particular to a cooling smoke tube which is formed by extruding master batch into a tube shape and then drying the tube shape, and the master batch comprises tobacco powder, hydroxypropyl methyl cellulose, polyethylene glycol, glycerin and oleic acid. In the application, the cooling material composition and the smoke tube prepared by extruding and drying the composition are provided, and the smoke tube has good deformation resistance and a porous structure on the physical level; in the chemical level, the smoke tube has good phase change performance, so that the smoke tube can be used as a supporting outer layer of a heating cigarette cooling material, the supporting effect is provided, and the suction resistance cannot be reduced; and the device can also be directly used as a cooling section for heating cigarettes and has a good cooling effect.

Owner:HUBEI CHINA TOBACCO IND +1

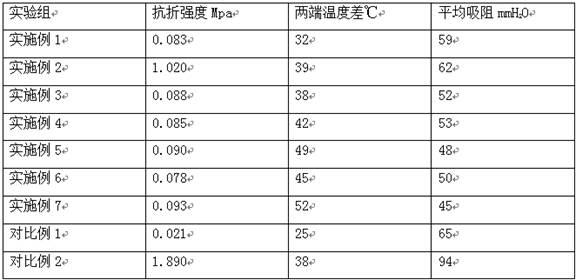

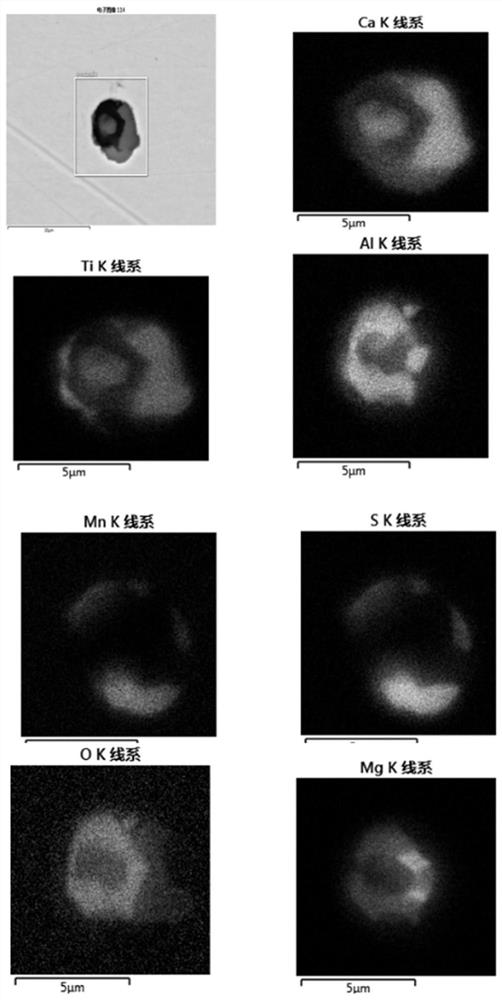

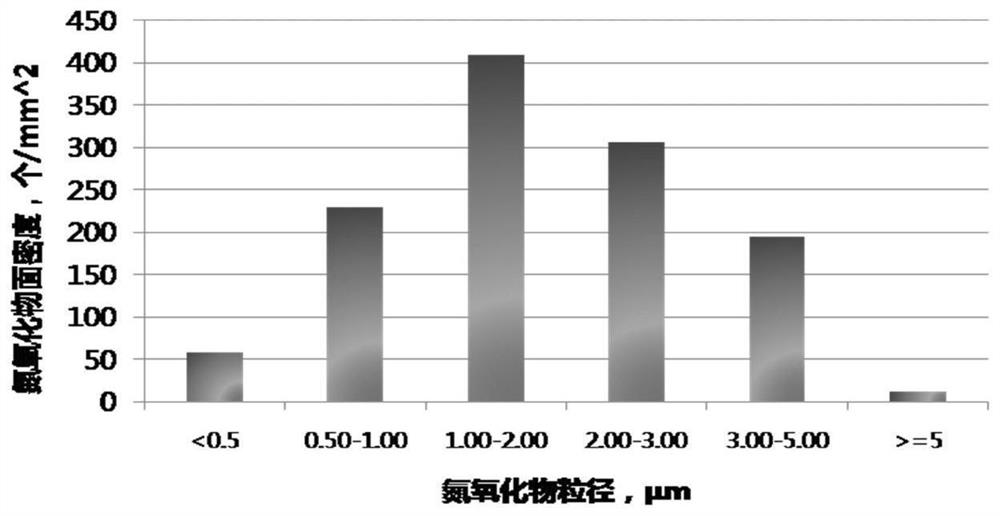

Manufacturing method of aluminum-free low-alloy steel plate suitable for high heat input welding

InactiveCN112921150AGood phase change performanceStable large wire energy welding adaptabilityMolten steelAlloy steel

The invention relates to a smelting method of aluminum-free low-alloy steel suitable for high heat input welding. Through converter, LF refining and RH treatment, molten steel is obtained, and comprises the following components in percentage by weight of less than or equal to 15PPm of free [O], less than or equal to 0.008% of P, less than or equal to 0.30% of Cu, less than or equal to 0.30% of Ni, less than or equal to 0.06% of Mo, more than or equal to 4 * [N]-0.06% of V, less than or equal to 0.003% of S, less than or equal to 0.0008% of B, less than or equal to 0.30% of Cr, less than or equal to 0.007% of Alt, 0.03-0.07% of C, 1.30-1.60% of Mn, 0.15-0.30% of Si, 0.011-0.022% of Ti, 35-60ppm of [N], 0.015-0.025% of Nb and the balance Fe and inescapable impurities in steel. A casting blank produced by taking the molten steel as a raw material can be used for rolling the thick steel plate for high heat input welding by using a TMCP process, the process is simple, the production continuity is good, the component control is accurate, and the high heat input welding performance of a finished product is reliable.

Owner:MINMETALS YINGKOU MEDIUM PLATE

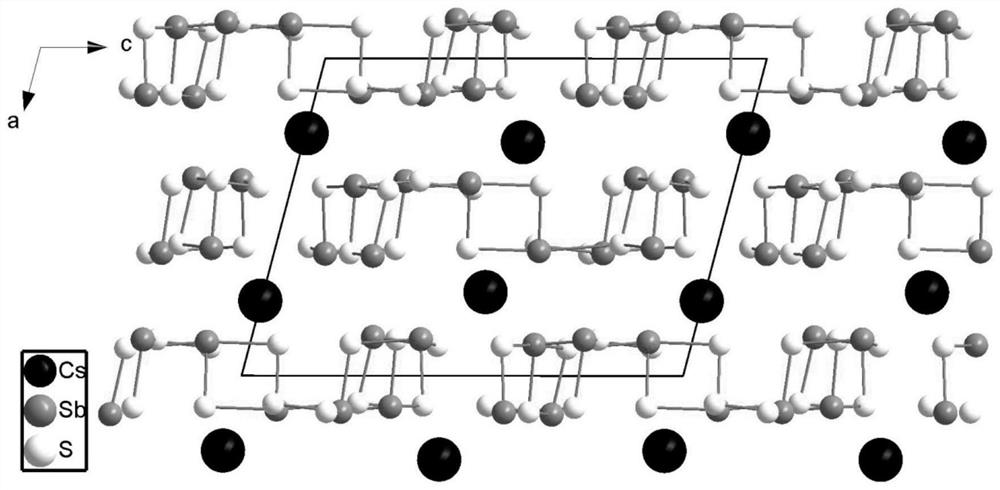

Inorganic compound crystal CsSb5S8 and preparation method and application thereof

ActiveCN113235163AGood phase change performanceSimple processPolycrystalline material growthFrom solid statePhase-change memorySpace group

The invention discloses an inorganic compound crystal CsSb5S8 and a preparation method and application thereof. The chemical formula of the inorganic compound crystal is CsSb5S8, the inorganic compound crystal belongs to a monoclinic system, and the space group is P21 / n. The cell parameter Z is 4. The glass transition temperature of the inorganic compound crystal is about 202 DEG C, the conductivity of the crystalline state is 1.2 times that of the glass state, and the inorganic compound crystal has good phase change performance, is a novel inorganic phase change compound and has excellent application value in the field of phase change memories.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

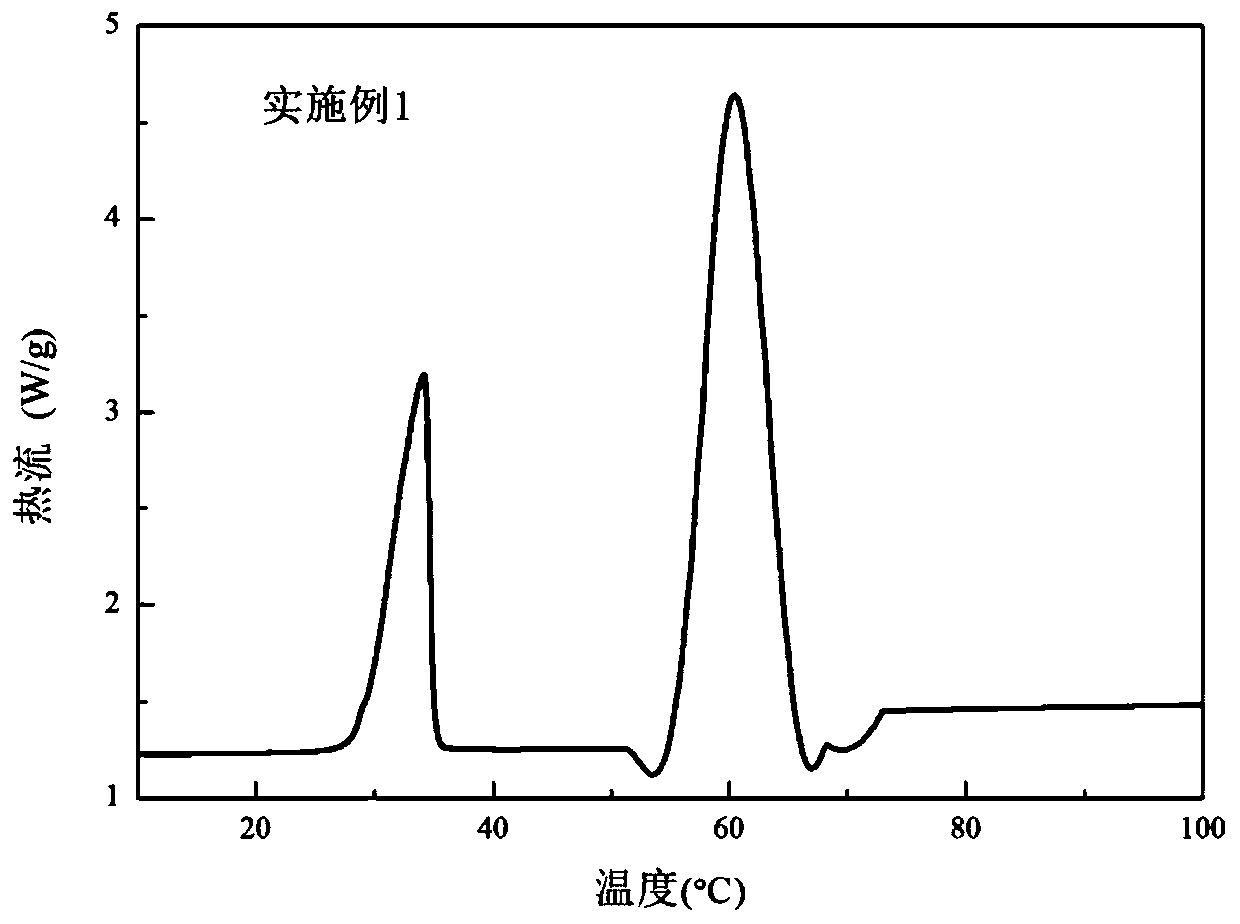

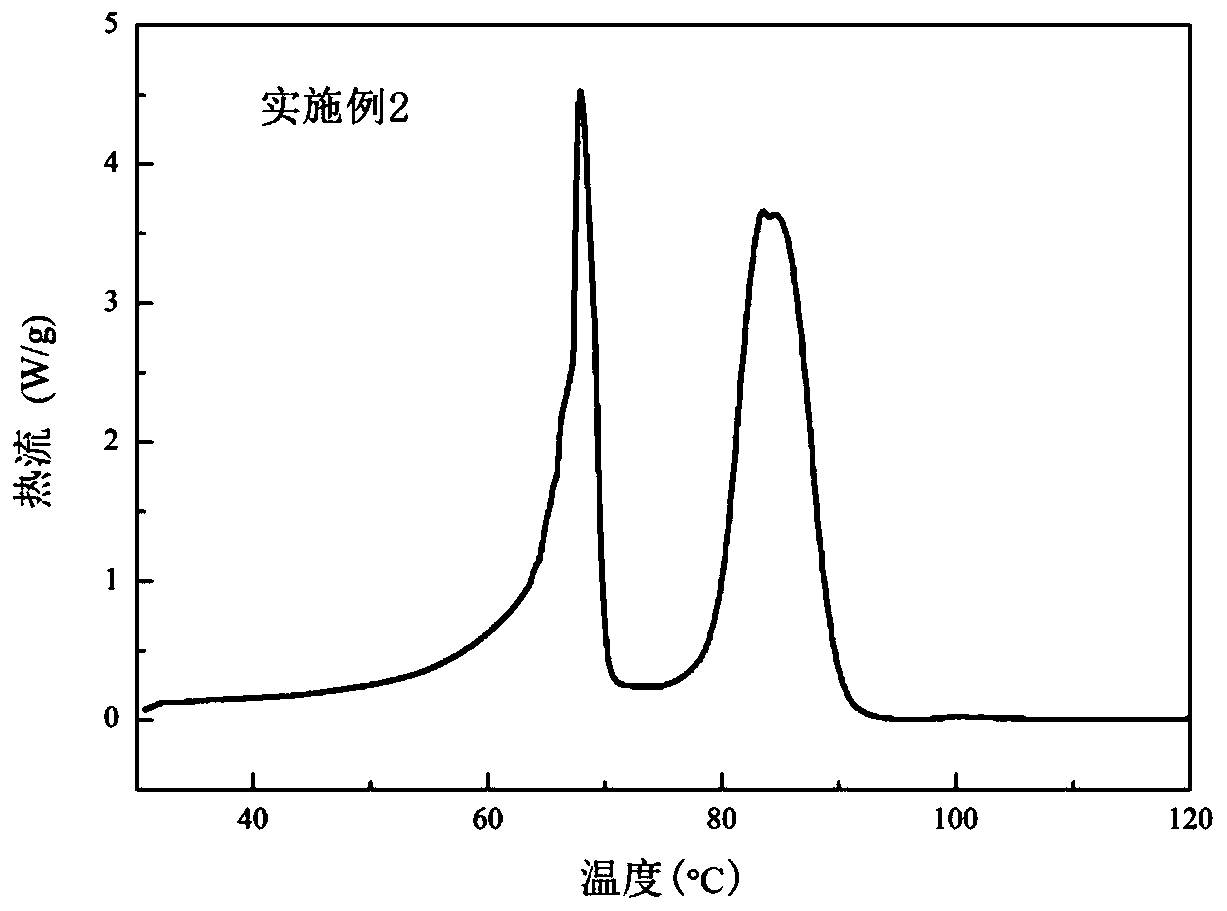

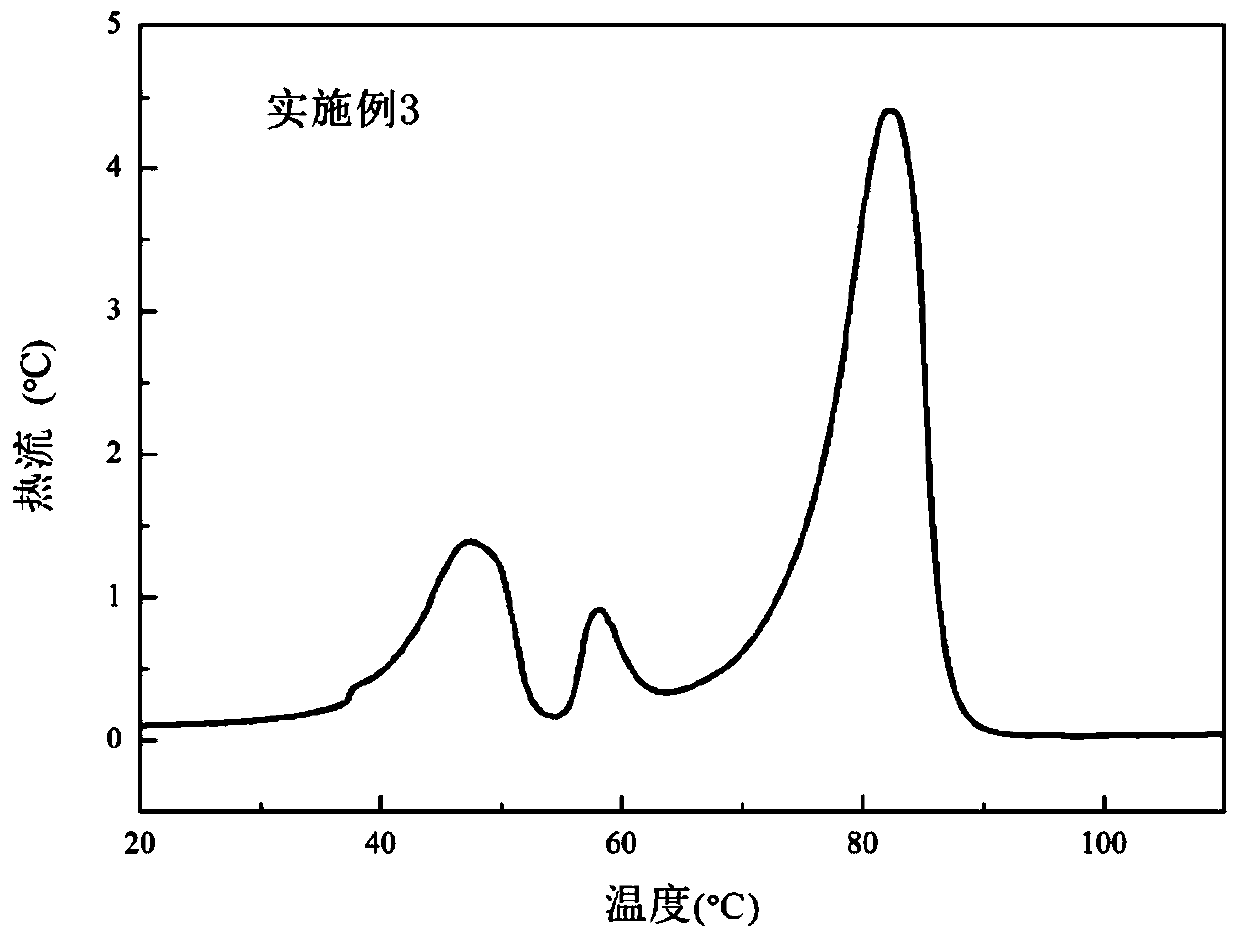

Composite phase change material for segmented heat storage and preparation method thereof

ActiveCN109337653BPlay the role of phase change heat storagePrevent volatilizationHeat-exchange elementsHydration reactionOil phase

The invention discloses a segmented heat storage composite phase change material and a preparation method thereof. The composite phase change material comprises the following raw materials in percentage by mass: 15-50% of a hydrated salt phase change material, 0.5-3% of a nucleating agent, 1-2.5% of an emulsifier, and 55-80% of an organic phase change material. The preparation method comprises thesteps of melting the organic phase change material by heating, maintaining the temperature higher than the phase change temperature of the organic phase change material by 1-10 DEG C, adding the emulsifier, and stirring to obtain a uniform mixture; heating the hydrated salt phase change material till melting, adding the nucleating agent, controlling the temperature of the hydrated salt phase change material to be the same as the temperature of the mixture, and stirring to mix the hydrated salt phase change material and the nucleating agent uniformly; mixing the two materials while stirring toobtain a water-in-oil phase change emulsion, so as to obtain a solid segmented heat storage composite phase change material. The sum of latent heat of the two phase changes of the material reaches 162.7-204.7 J / g, and the problem of volatilization of free water produced after the hydrated salt is melted is solved.

Owner:SOUTH CHINA UNIV OF TECH

Sb2Tex-SiO2 nano composite phase change material used on phase change memory and preparation method of Sb2Tex-SiO2 nano composite phase change material

ActiveCN102487119BHigh resistivityRaise the crystallization temperatureElectrical apparatusElectrical resistance and conductancePhase-change memory

The invention discloses a Sb2Tex-SiO2 nano composite phase change material used on a phase change memory. The material is formed by compositing a phase change material Sb2Tex with SiO2 and has a chemical formula of (Sb2Tex)y(SiO2)1-y, wherein x is larger than or equal to 0.5 but smaller than or equal to 3 and y is larger than or equal to 0.2 but smaller than 1. The Sb2Tex-SiO2 nano composite phase change material has the advantages that through doping the SiO2 into the phase change material, the phase change material with a reversible phase change ability is isolated into areas with nanoscales by the amorphous state SiO2, and a composite structure is formed, so the resistivity and the crystallization temperature of the phase change material are increased and the heat conductivity of the phase change material is reduced. Due to the increase of the crystalline state resistance of the phase material, a Reset current of the phase change memory device can be reduced, and thereby the barrier that the Reset current of the phase change is overlarge is overcome; due to the rising of the crystallization temperature, the stability of the Sb2Tex-SiO2 phase material device can be improved; dueto the decline of the melting temperature, the power consumption of the Sb2Tex-SiO2 phase material device is effectively reduced; and due to the reduction of the heat conductivity, the utilization rate of energy can be improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

A high-speed laser wire-filled deep penetration welding method for high-strength dual-phase steel thick plates

ActiveCN107900518BGood phase change performanceHigh hardnessLaser beam welding apparatusFiberHeat-affected zone

The invention discloses a penetration fusion welding method for a high-strength dual-phase steel thick plate through a high-speed laser filler wire. The main welding technical parameters are that theoptical fiber Nd:YAG laser filler wire is used for butt-joint penetration fusion welding, the welding seam prefabricated butt-joint gap is 1.0-1.6 mm, the focal length of a collecting lens is 15 cm, the defocus distance is -10-3 mm, the laser power is controlled to be 1.8-6 kW, the welding speed is controlled to be 10-60 mm.s<-1>, the welding wire diameter is 1.2-2.0 mm, and the wire feed speed is20-240 mm.s<-1>. The width of an obtained welding seam welding heat affected zone is smaller than 0.6 mm, the welding seam zone is of a coarse martensitic structure, the welding heat affected zone take a thin martensitic structure as priority, the hardness of a welded joint is 370-450 HV0.1, and the tensile strength of the welded joint is close to or even exceeds that of a base material. Throughthe effects of rapid cooling martensite strengthening and alloy strengthening, the hardness and strength of the welded joint are greatly improved.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com