Manufacturing method of aluminum-free low-alloy steel plate suitable for high heat input welding

A technology of alloy steel plate and manufacturing method, which is applied in the smelting field of low alloy steel, can solve the problems of too large welding performance fluctuation, unstable performance and unreliable performance of steel plate, and achieve the effect of stabilizing the welding adaptability of large line energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0059] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals denote the same or similar modules or modules having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

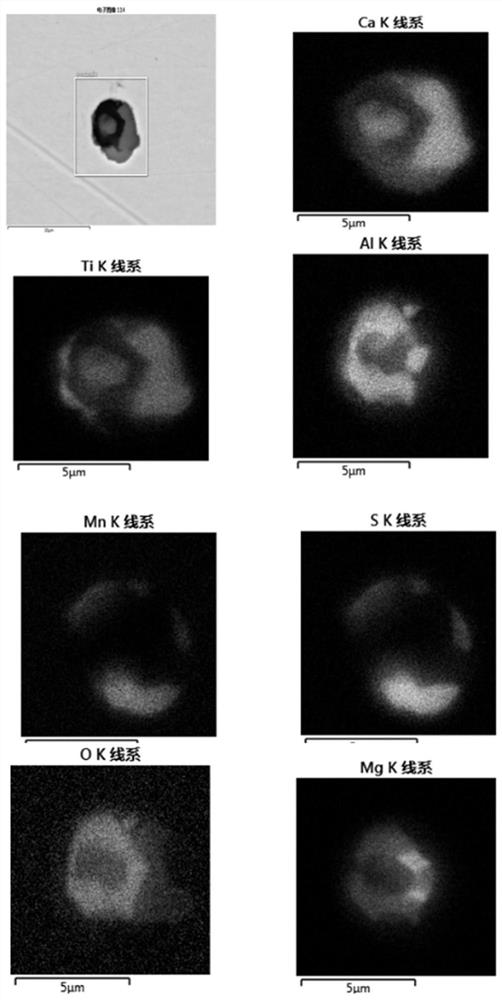

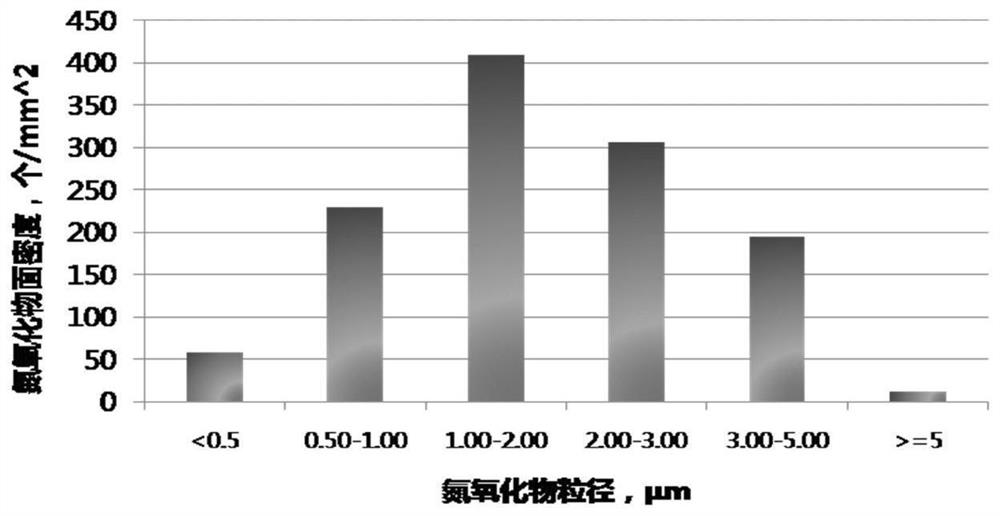

[0060] In the embodiment of the present invention, the production mode of 120 tons converter-LF furnace refining-RH furnace vacuum treatment-250mm section casting machine is used for billet smelting. Converter smelting molten iron requires P≤0.110%, S≤0.010%, molten iron temperature ≥1300°C, after smelting, the steel is deoxidized by elements forming weak oxides during the tapping process, and the feeding sequence of tapping is: active lime-manganese alloy-silicon system alloy. The amount of active lime added is 350-450kg, and 30kg of calciu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com