Vanadium dioxide powder preparation method and application thereof

A technology of vanadium dioxide and vanadium pentoxide, applied in vanadium oxide and other directions, can solve the problems of expensive equipment, unsuitable mass production, low deposition rate, etc., to improve stability and repeatability, improve production efficiency, reduce phase The effect of changing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation method of embodiment 1 vanadium dioxide powder

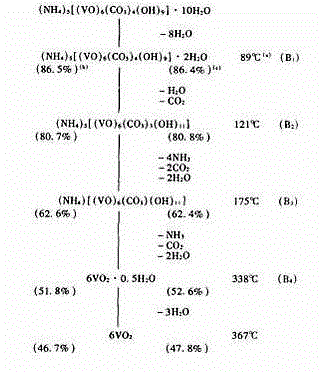

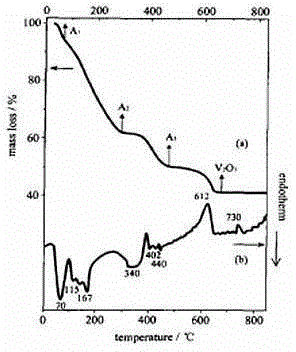

[0021] First, vanadium pentoxide, N 2 h 4 2Hcl, Hcl and NH 4 HCO 3 As raw material, prepared into VOCl 2 solution, and then the prepared solution with (NH 4 ) 2 CO 3 reaction to prepare basic vanadyl ammonium carbonate precursor (NH 4 ) 5 [(VO 6 ) (CO 3 ) 4 (OH) 9 ]·10H 2 O, the crystallization rate of the precursor is about 90%; then the synthesized (NH 4 ) 5 [(VO 6 ) (CO 3 ) 4 (OH) 9 ]·10H 2 The O sample is placed in the NTG-209 linkage thermal analyzer, and N with a purity of 99.99% is introduced. 2 At the same time, the analysis curve determination (thermogravimetric analysis TG and differential thermal analysis DTA such as figure 1 and figure 2 shown), the gas flow rate is 15ml / min, and the heating rate is 5°C / min. When thermally decomposing, take 5.0g sample and place it in a 18mm*130mm quartz tube in a thin layer, then place it in a 23mm diameter tube, and feed it with N at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| crystallization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com