Preparation method and application of temperature sensitive type Y2SiO5:Eu intelligent thermal barrier coating

A temperature-sensitive, thermal barrier coating technology, applied in coatings, thermometers, metal material coating processes, etc., can solve the problems of inability to evaluate the thermal insulation effect of thermal barrier coatings, inability to non-destructively monitor temperature online, and application problems. , to achieve good anti-CMAS performance, efficient preparation, good combination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

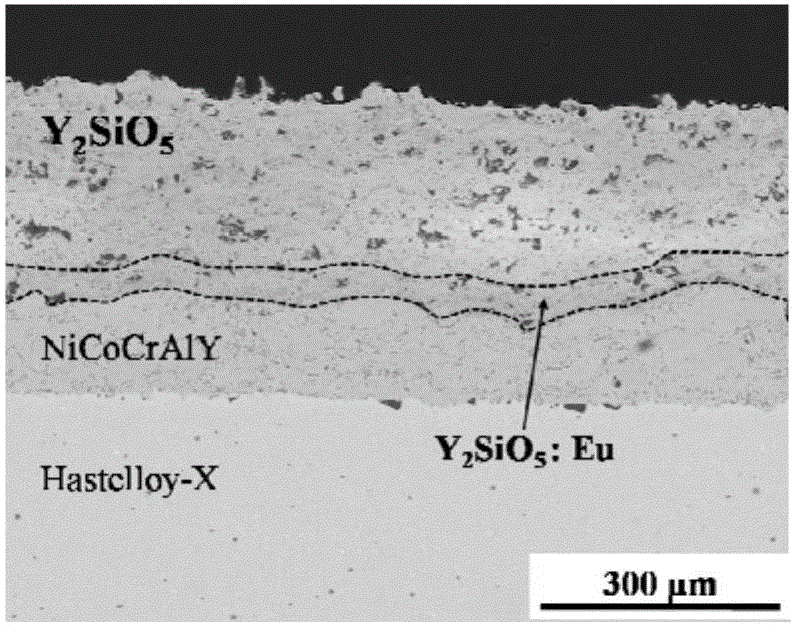

[0030] A temperature-sensitive Y 2 SiO 5 : The preparation method of Eu intelligent thermal barrier coating adopts the following steps:

[0031] (1) get nanometer yttrium oxide (Y 2 o 3 ) powder (100nm) and micron silicon dioxide (SiO 2 ) powder (10μm) was mixed according to the molar ratio of 1:10, and then a certain amount of nano europium oxide (Eu 2 o 3 ) powder (100nm), its addition is controlled to be 0.1wt%, while adding 1mol% LiYO 2 Use the powder as a sintering aid; then use isopropanol as the ball milling medium, use a planetary ball mill for 5 hours, control the ball milling speed to 100r / min, and then dry it in an oven at 30°C for 4 hours to obtain a uniform reaction precursor mixture A;

[0032] (2) Put the reaction precursor mixture A into a 1500°C high-temperature furnace for sintering and heat preservation for 1h, control the heating rate and cooling rate to 2°C / min, and use isopropanol as the ball milling medium again to pass the obtained ceramic powder ...

Embodiment 2

[0038] A temperature-sensitive Y 2 SiO 5 : The preparation method of Eu intelligent thermal barrier coating adopts the following steps:

[0039] (1) get nanometer yttrium oxide (Y 2 o 3 ) powder (300nm) and micron silicon dioxide (SiO 2 ) powder (30μm) according to a certain molar ratio mixed 1:1, and then add a certain amount of nano europium oxide (Eu 2 o 3 ) powder (100-300nm), its addition is controlled to be 1.0wt%, while adding 5mol% of LiYO 2 Use the powder as a sintering aid; then use isopropanol as the ball milling medium, use a planetary ball mill for 3 hours, control the ball milling speed to 300r / min, and then dry it in a 40°C oven for 2 hours to obtain a uniform reaction precursor mixture A;

[0040] (2) Put the reaction precursor mixture A into a 1400°C high-temperature furnace for sintering and heat preservation for 2.5 hours, control the heating rate and cooling rate to 5°C / min, and use isopropanol as the ball milling medium again to pass the obtained cer...

Embodiment 3

[0047] A temperature-sensitive Y 2 SiO 5: The preparation method of Eu intelligent thermal barrier coating adopts the following steps:

[0048] (1) get nanometer yttrium oxide (Y 2 o 3 ) powder (200nm) and micron silicon dioxide (SiO 2 ) powder (20μm) was mixed according to a certain molar ratio of 10:1, and then a certain amount of nano europium oxide (Eu 2 o 3 ) powder (100-300nm), the control and control of its addition is 2.0wt%, while adding 8mol% LiYO 2 Use the powder as a sintering aid; then use isopropanol as the ball milling medium, use a planetary ball mill for 5 hours, control the ball milling speed to 400r / min, and then dry it in an oven at 50°C for 1 hour to obtain a uniform reaction precursor mixture A;

[0049] (2) Put the reaction precursor mixture A into a 1200°C high-temperature furnace for sintering and heat preservation for 4 hours, control the heating rate and cooling rate to 8°C / min, and use isopropanol as the ball milling medium again to pass the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com