Laser swing welding method for lap joint structure of thermoplastic composite material and aluminum alloy

A technology of composite materials and welding methods, which is applied in the field of laser welding of thermoplastic composite materials and aluminum alloys, and laser swing welding of thermoplastic composite materials and aluminum alloy overlapping structures. problems, to achieve the effect of maintaining integrity, improving the strength of dissimilar connections, and weld integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

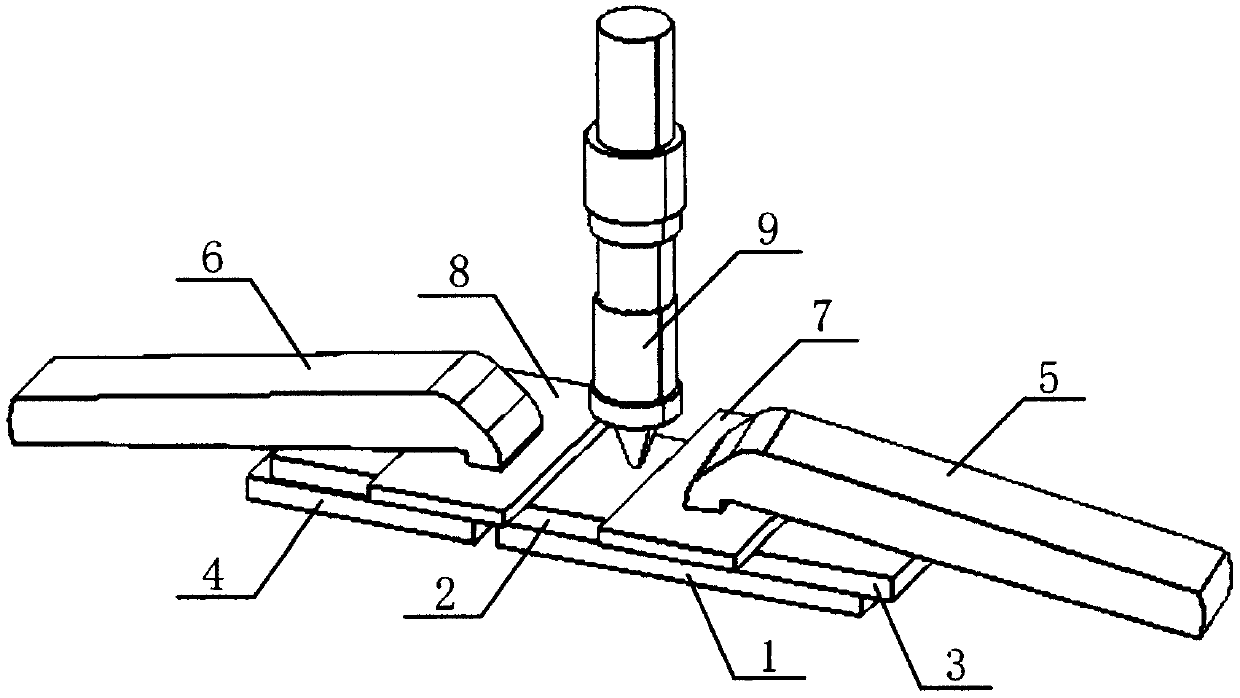

[0012] Please refer to figure 1 As shown, a laser swing welding method of a thermoplastic composite material and an aluminum alloy overlapping structure of the present invention comprises the following steps:

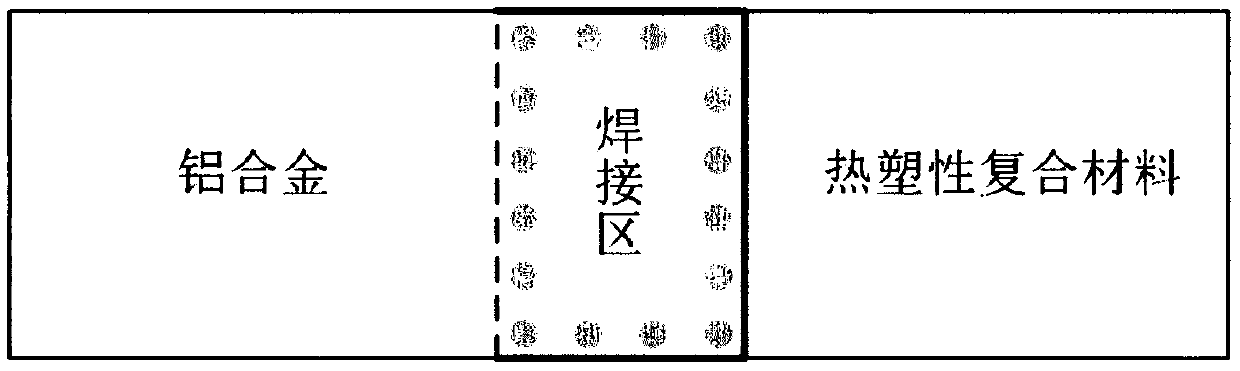

[0013] First, the laser welding surface of aluminum alloy 2 was sandblasted, using 50-mesh silica particles, and the impact of high-speed sand flow was used to clean and roughen the welding surface of aluminum alloy 2 to improve the laser absorption rate of the welding surface of aluminum alloy 1. The nail hook structure is processed by laser on the connecting surface of the aluminum alloy 2, the angle between the nail hook and the surface of the alloy material is 30°-60°, the nail hook size is 0.5-1mm, and the area density is 5%-20%. A certain thickness of resin material is filled at the lap joint interface between thermoplastic composite material 1 and aluminum alloy 2. The filling resin material can be epoxy resin, polyether ether ketone, polyphenylene sulfide, polya...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com