Brazing method for welding titanium-based high-entropy alloy and silicon nitride ceramic

A technology of silicon nitride ceramics and high-entropy alloys, which is used in welding equipment, metal processing equipment, tin feeding devices, etc. Simple and reliable, high shear strength, excellent comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation of solder paste is a general process of weighing and mixing, and the innovation is not very obvious, but the mass ratio of 9:1 is the result obtained after many tests.

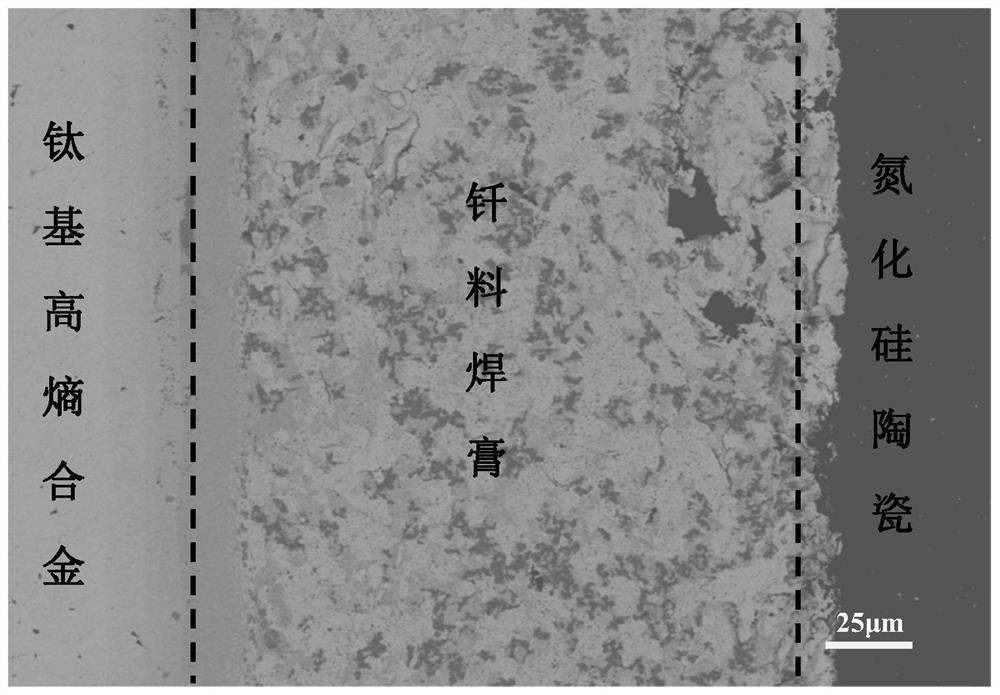

[0029] 2) Stack the titanium-based high-entropy alloy and silicon nitride ceramics pretreated in step 1) layer by layer in the order of titanium-based high-entropy alloy / brazing paste / silicon nitride ceramics to obtain a brazing block . That is, the brazing block is composed of titanium-based high-entropy alloy, brazing paste and silicon nitride ceramics. The titanium-based high-entropy alloy is at the top, the middle is brazing paste, and the bottom layer is silicon nitride ceramics. In order to improve the welding strength, the thickness of the brazing solder paste in the brazing block can be set to 100-200 μm.

[0030] Then put the brazing block into the graphite mold, or directly stack the titanium-based high-entropy alloy, brazing paste and silicon nitride ceramics in the graphite ...

Embodiment 1

[0034] Silver-based brazing material (68.8Ag-26.7Cu-4.5Ti) and brazing flux are prepared in a ratio of 9:1 to form a solder paste. The surfaces of titanium-based high-entropy alloy and silicon nitride ceramics were successively polished step by step with 80-2000 mesh metallographic sandpaper, and then the samples to be welded were cleaned with alcohol after polishing the surface of the samples. Then stack the titanium-based high-entropy alloy / brazing paste / silicon nitride ceramic layer by layer in a graphite mold, and place a vacuum brazing furnace for brazing after placing a compact on the top layer. Wherein, the thickness of the brazing solder paste is 100 μm to 200 μm, and a certain pressure is applied by placing the pressing block to ensure the wetting and spreading of the solder and the base material.

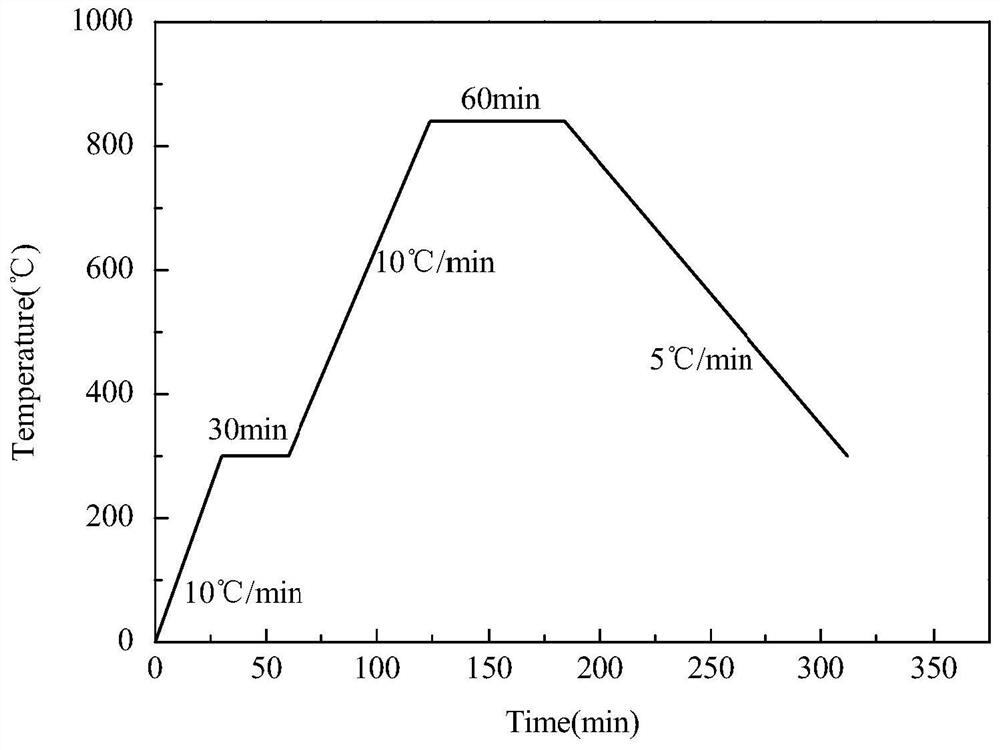

[0035] Using the step-up brazing process and different heating and cooling rates, the vacuum degree of the vacuum brazing furnace is controlled at not less than 8×10 -3 P...

Embodiment 2

[0038]Using the same method as in Example 1 to prepare solder solder paste and braze the titanium-based high-entropy alloy and silicon nitride ceramics, the difference is that the titanium-based high-entropy alloy and silicon nitride ceramics are brazed up to brazing The welding target temperature is 820° C. and then kept for 60 minutes, and the rest of the process is the same as in Example 1.

[0039] The shear strength of the joint between the brazed titanium-based high-entropy alloy and the silicon nitride ceramic was detected by a universal testing machine to be 53 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com