Preparation method of three-dimensional needling carbon/carborundum composite material bolt

A technology of composite materials and silicon carbide, applied in the direction of screws, mechanical equipment, threaded fasteners, etc., can solve the problems of difficult industrial mass production, low mechanical properties of bolts, long production cycle, etc., and achieve short densification cycle and small wear , The effect of reducing the number of times of entering the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

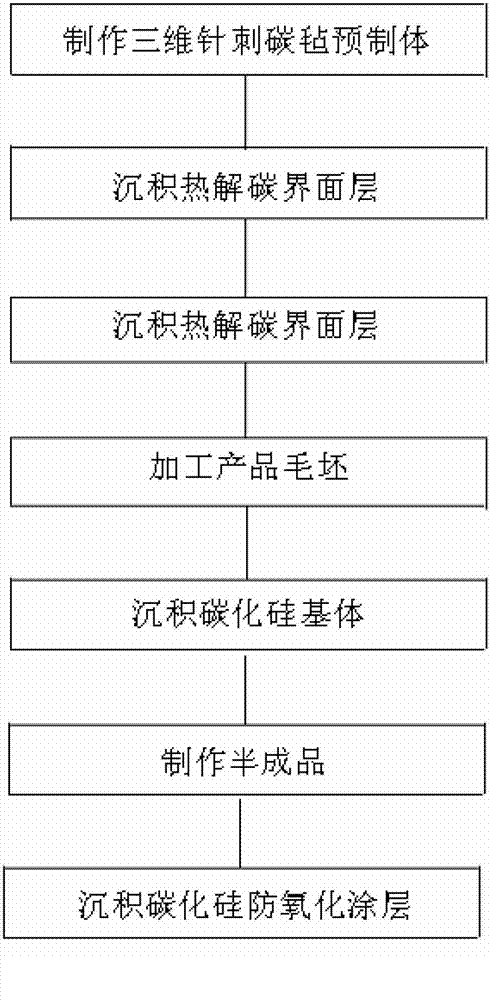

[0022] This embodiment is a method for preparing a three-dimensional needle-punched carbon / silicon carbide composite bolt, and its specific process is:

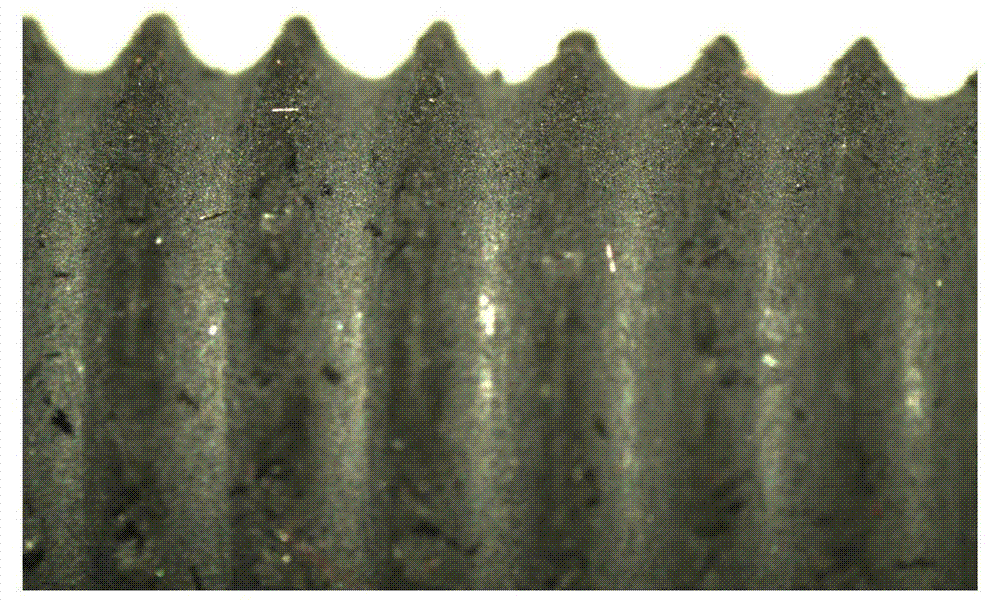

[0023] Step 1, making a three-dimensional needle-punched carbon felt preform. The tire mesh is made of 12K T700 carbon fiber. The single layer of 0° no-weft cloth, single layer of tire mesh, single layer of 90° no weft cloth and single layer of tire mesh are stacked in sequence until the layer reaches the design thickness. The fibers in the tire net are vertically pierced between the non-weft fabrics by means of relay needle punching to make a plate-shaped three-dimensional needle punched carbon felt prefabricated body, such as figure 1 shown. The carbon fiber volume fraction is 35%, and the density is 0.6g / cm 3 . 0° no weft fabric and 90° no weft fabric refer to the orthogonal stacking of 0° / 90° no weft fabric.

[0024] Step 2, depositing a pyrolytic carbon interface layer. Deposit the pyrolytic carbon interface layer ...

Embodiment 2

[0032] This embodiment is a method for preparing a three-dimensional needle-punched carbon / silicon carbide composite bolt, and its specific process is:

[0033] Step 1, making a three-dimensional needle-punched carbon felt preform. The tire mesh is made of 12K T700 carbon fiber. The single layer of 0° no-weft cloth, single layer of tire mesh, single layer of 90° no weft cloth and single layer of tire mesh are stacked in sequence until the layer reaches the design thickness. The fibers in the tire net are vertically pierced between the non-weft fabrics by means of relay needle punching to make a plate-shaped three-dimensional needle punched carbon felt prefabricated body, such as figure 1 shown. The carbon fiber volume fraction is 35%, and the density is 0.6g / cm 3 . 0° no weft fabric and 90° no weft fabric refer to the orthogonal stacking of 0° / 90° no weft fabric.

[0034] Step 2, depositing a pyrolytic carbon interface layer. Deposit the pyrolytic carbon interface layer ...

Embodiment 3

[0042] This embodiment is a method for preparing a three-dimensional needle-punched carbon / silicon carbide composite bolt, and its specific process is:

[0043] Step 1, making a three-dimensional needle-punched carbon felt preform. The tire mesh is made of 12K T700 carbon fiber. The single layer of 0° no-weft cloth, single layer of tire mesh, single layer of 90° no weft cloth and single layer of tire mesh are stacked in sequence until the layer reaches the design thickness. The fibers in the tire net are vertically pierced between the non-weft fabrics by means of relay needle punching to make a plate-shaped three-dimensional needle punched carbon felt prefabricated body, such as figure 1 shown. The carbon fiber volume fraction is 35%, and the density is 0.6g / cm 3 . 0° no weft fabric and 90° no weft fabric refer to the orthogonal stacking of 0° / 90° no weft fabric.

[0044] Step 2, depositing a pyrolytic carbon interface layer. Deposit the pyrolytic carbon interface layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com