Preparation method of iron-doped zirconium oxide polishing solution

A technology of zirconia and polishing liquid, which is applied in the field of preparation of iron-doped zirconia polishing liquid, can solve the problems of high price, few products and production enterprises, performance that cannot achieve precision polishing, etc., achieve good cutting rate, increase contrast, The effect of improving polishing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

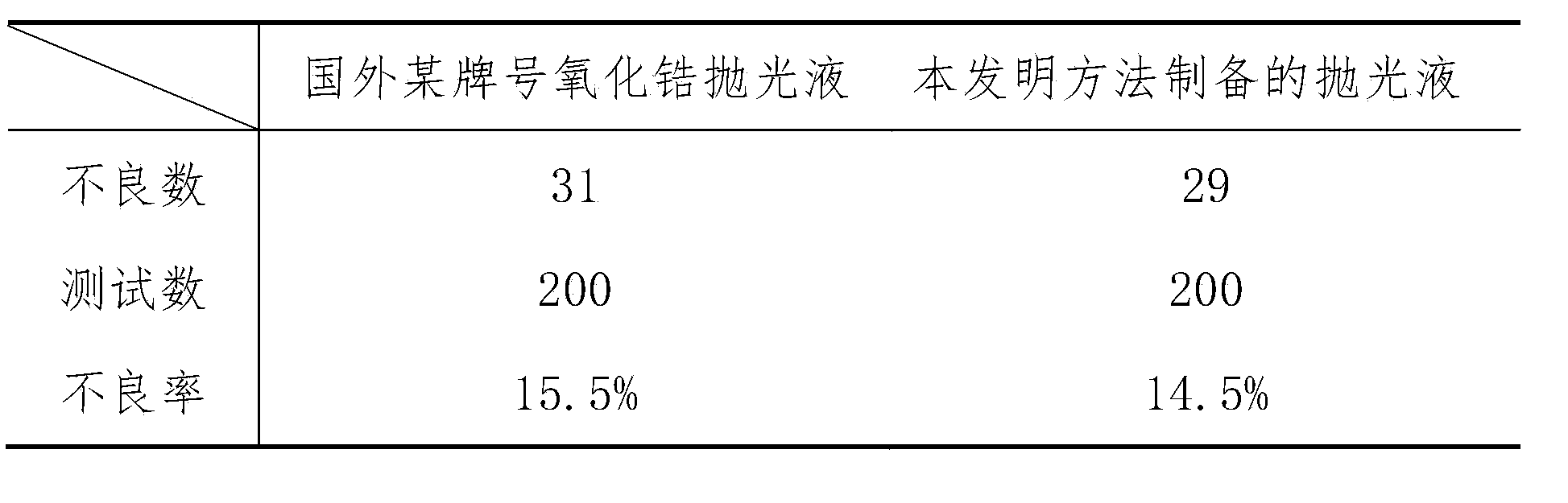

Examples

Embodiment 1

[0028] The specific preparation steps of this embodiment are as follows (the unit of measurement in parts by weight in this example is 1 kilogram):

[0029] 1. Prepare materials: get 2 kilograms of zirconium oxychloride and 20 grams of Fe(NO 3 ) 3 9H 2 O, standby;

[0030] 2. Preparation of symbiotic solution: firstly, the spare zirconium oxychloride is dissolved in 10 kilograms of deionized water to become an aqueous solution of zirconium oxychloride; then, the spare Fe(NO 3 ) 3 9H 2 O is added to the zirconium oxychloride aqueous solution, stirred until completely dissolved, and becomes an iron-zirconium symbiotic solution, which is set aside;

[0031] ③. Preparation of symbiotic precipitation: Slowly add ammonia water with a concentration of 20% into the spare iron-zirconium symbiotic solution, and keep stirring until all zirconium ions and iron ions are precipitated, and continue to add ammonia water, adjust the pH value to 5-7, and prepare Zirconium hydroxide and fe...

Embodiment 2

[0038] The specific preparation steps of this embodiment are as follows (the unit of measurement in parts by weight in this example is 10 kilograms):

[0039] ①, material preparation: take 20 kilograms of zirconium nitrate and 400 grams of FeCl respectively 3 ·6H 2 O, standby;

[0040] 2. Preparation of symbiotic solution: slowly add spare zirconium nitrate into 100 kg of rapidly stirred deionized water to form zirconium nitrate aqueous solution; then, add spare FeCl 3 ·6H 2 O is added to the zirconium nitrate aqueous solution, stirred until it is completely dissolved, and becomes an iron-zirconium symbiotic solution, which is set aside;

[0041] ③. Preparation of symbiotic precipitation: Slowly add 10% NaOH solution into the spare iron-zirconium symbiotic solution, and keep stirring until all zirconium ions and iron ions are precipitated, and continue to add NaOH solution to adjust the pH value to 5-7. Make the symbiotic precipitation that zirconium hydroxide and ferric h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com