Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Reduce void defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

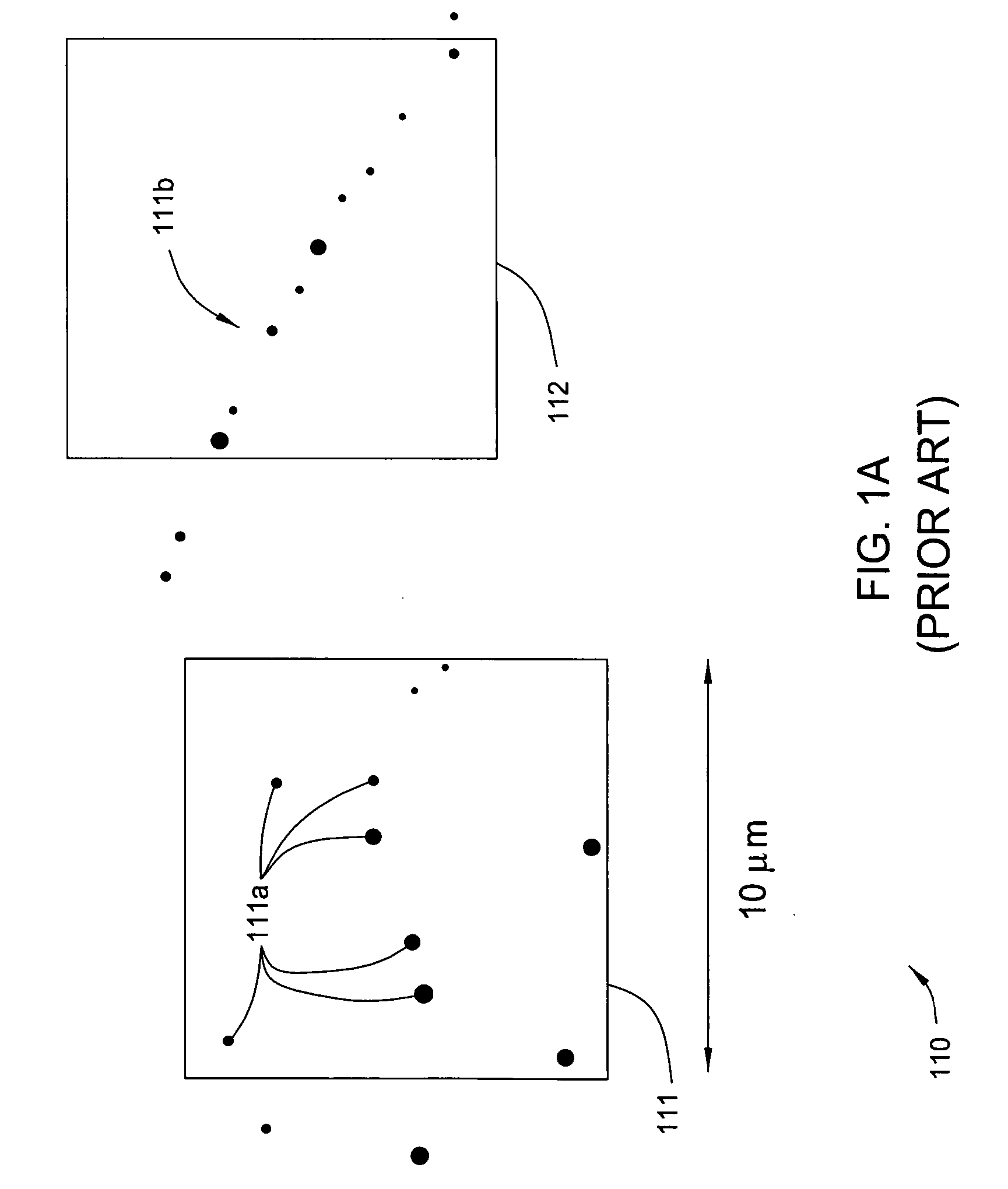

Pre-treatment to eliminate the defects formed during electrochemical plating

InactiveUS20070080067A1Reduce formationPromote wettingVacuum evaporation coatingSemiconductor/solid-state device manufacturingHigh ratePre treatment

Embodiments of the invention provide methods for reducing formation of void-type defects on the surface of a substrate during electrochemical plating. Embodiments of the invention provide methods to improve the wetting of a substrate surface prior to immersion and thereby minimize adhesion of bubbles to the substrate surface during immersion. A thin uniform metal oxide is formed on a metal layer on the substrate immediately prior to substrate immersion. In one aspect, exposing the substrate to an oxygen-containing gas, e.g. air, forms the metal oxide. The oxygen-containing gas may be flowed over the substrate or the substrate may be rotated at a high rate in the presence of an oxygen-containing gas. In another aspect, non-uniform metal oxides are first removed from the substrate in an anneal process and a thin uniform metal oxide is subsequently re-formed. An optimized substrate immersion method may also be used to further reduce void defects.

Owner:APPLIED MATERIALS INC

Aluminum foil used for 6811 alloy automotive radiator and preparing method thereof

The invention discloses aluminum foil used for a 6811 alloy automotive radiator and a preparing method thereof. The aluminum foil comprises, by weight, 0.45%-0.55% of iron, 1.05%-1.25% of manganese, 0.44%-0.58% of silicon, 0.01%-0.05% of magnesium, 0.10%-0.15% of copper and 1.4%-1.6% of zinc, the weight percentage of titanium, the weight percentage of nickel, the weight percentage of chromium and the weight percentage of zirconium are smaller than 0.045%, the content of unavoidable single impurity is smaller than 0.05%, the total content of unavoidable impurities is smaller than 0.15%, and the balance aluminum. The process is simple, energy is saved, and the yield is higher than that of hot rolling by 15%; a researched and developed product is low in cost, good in plate shape, excellent in welding performance and conducting performance, and stable in quality and performance when used by users.

Owner:江阴新仁铝业科技有限公司

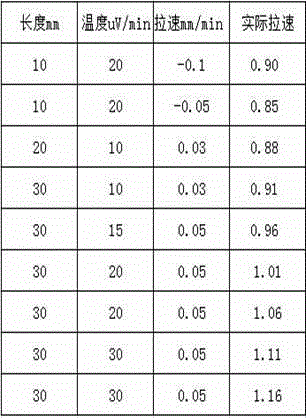

Production method of solar-grade czochralski silicon

InactiveCN104451872AReduce black chipsReduce the problem of dark cornersPolycrystalline material growthBy pulling from meltCrystal rotationSingle crystal

The invention discloses a production method of solar-grade czochralski silicon, and relates to the technical field of czochralski silicon. The production method comprises the following eight steps of charging, melting, stabilizing the temperature, seeding, shouldering, performing equal-diameter growth and ending. According to the production method disclosed by the invention, in the seeding process, the crystal rotation and the crucible rotation are set to be 8 revolutions per minute. The production method is simple and convenient to operate, easy to realize, capable of effectively reducing crystal defects which possibly appear in a crystallization process, lowering a problem of producing black chips and black angle plates in the czochralski silicon, remarkably improving the quality of the single crystal and prolonging the service life of the single crystal, avoiding returned goods due to product quality defects and saving unnecessary fund waste for the enterprises.

Owner:XINGTAI JINGLONG ELECTRONICS MATERIAL

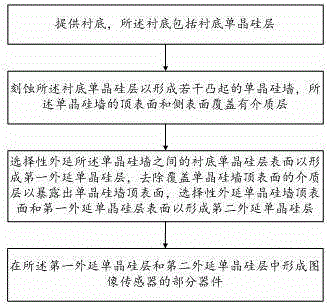

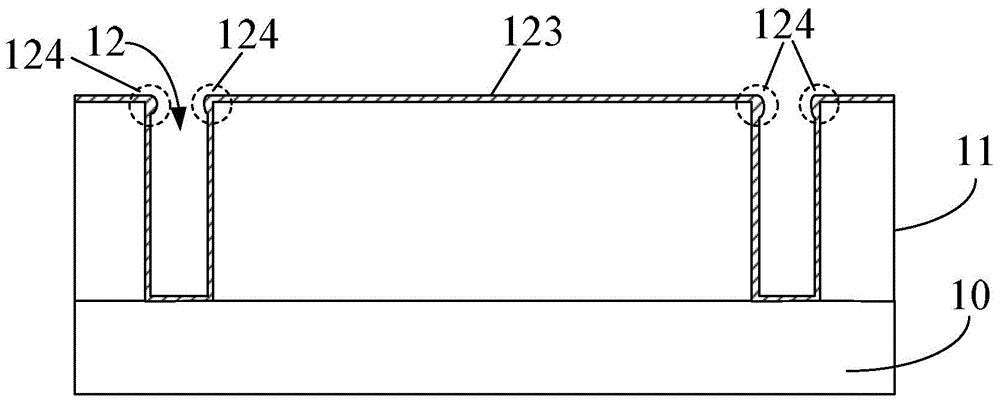

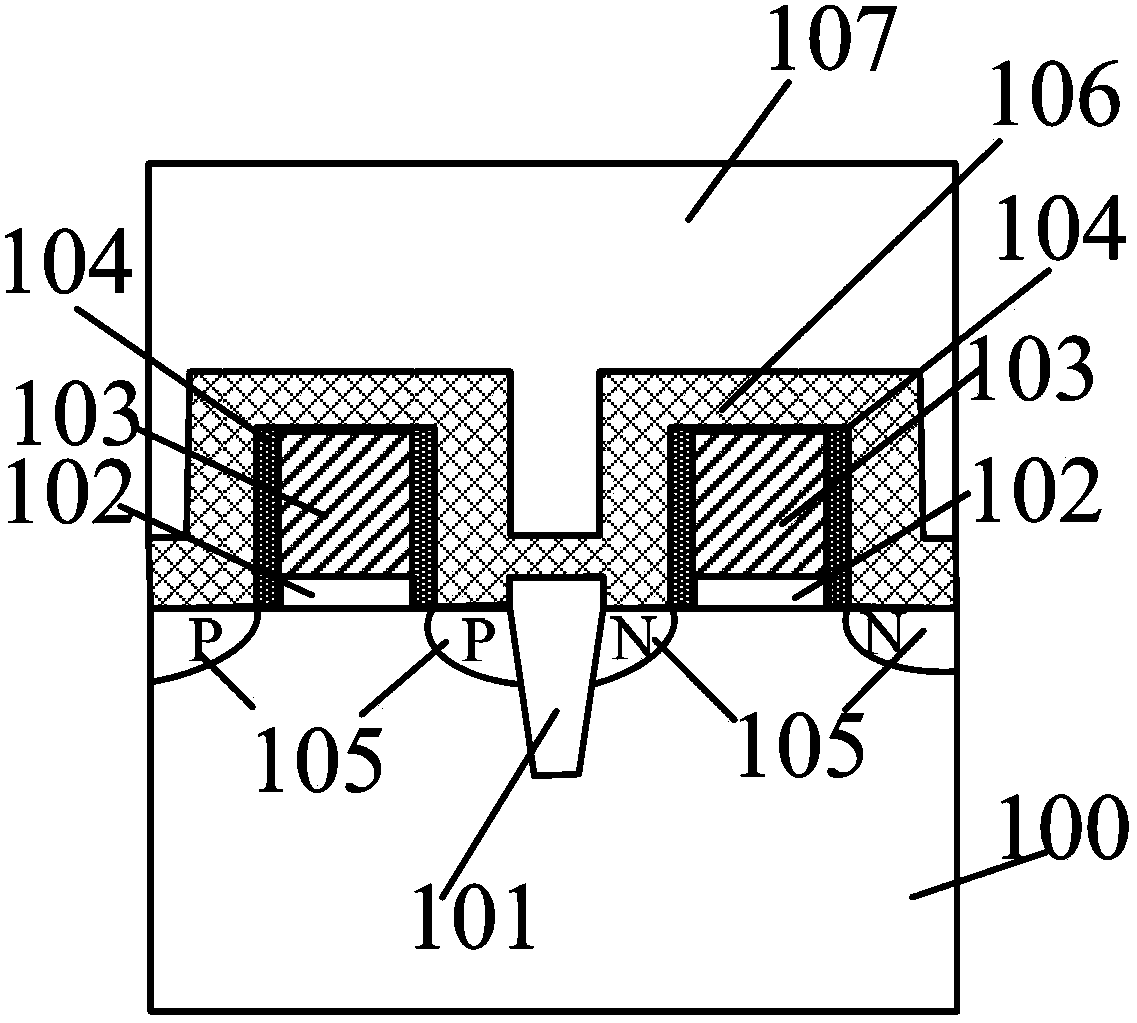

Manufacturing method of image sensor using deep trench isolation

InactiveCN104952896AQuality assuranceSimple interfaceSemiconductor/solid-state device manufacturingRadiation controlled devicesOptoelectronicsDielectric layer

The invention provides a manufacturing method of image sensor using deep trench isolation. The manufacturing method includes: providing a substrate which comprises a substrate monocrystalline layer; etching the substrate monocrystalline layer to form a plurality of monocrystalline walls raised, the top and lateral surfaces of each which are covered with a dielectric layer; subjecting the surface of the substrate monocrystalline layer between the monocrystalline walls to selective epitaxy so as to form a first epitaxial monocrystalline layer, removing the part, covering the top surfaces of the monocrystalline walls, of the dielectric layer so as to expose the top surfaces of the monocrystalline walls, and subjecting the top surfaces of the monocrystalline walls and the surface of the first epitaxial monocrystalline layer to selective epitaxy so as to form a second epitaxial monocrystalline layer; forming part of components of the image sensor in the first and second epitaxial monocrystalline layers. The manufacturing method has the advantages that the defects of the isolation structure of the epitaxial monocrystalline layers are effectively decreased, functional damage to the components of the image sensor is avoided, and quality of the components of the image sensor is improved.

Owner:GALAXYCORE SHANGHAI

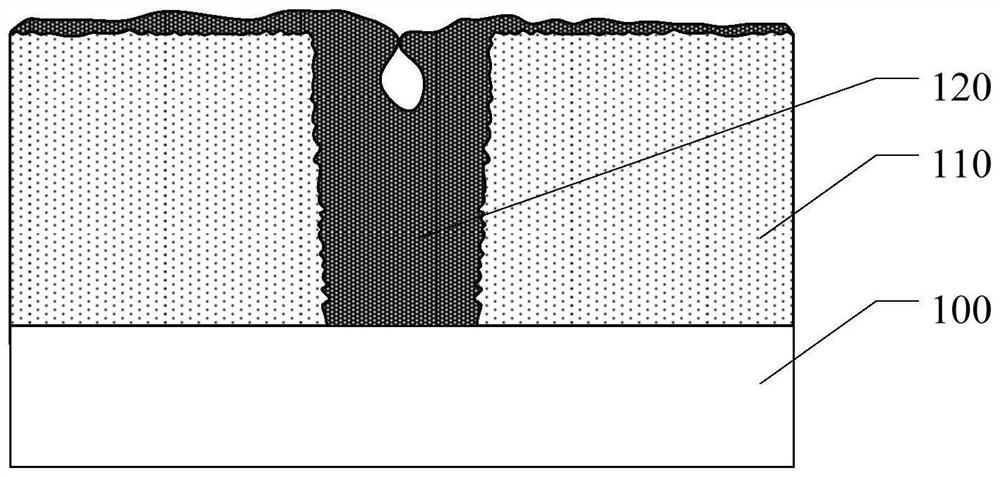

Formation method of metal interconnection structure

InactiveCN105575888AReduce void defectsReduce the problem of early closureSemiconductor/solid-state device manufacturingInterconnectionSemiconductor

The invention provides a formation method of a metal interconnection structure. The method comprises that a metal seed crystal layer is formed at the surface of a semiconductor substrate and in grooves of the semiconductor substrate, and then a shield layer is formed at the surface of the metal seed crystal layer; and the shield layer at the bottom of the grooves is removed to expose the metal seed crystal layer at the bottom of the grooves, and the shield layer which covers the sidewalls of the grooves is reserved. In the subsequent process that a metal layer is formed on the metal seed crystal layer, the metal layer cannot be formed at the sidewalls of the grooves due to that the sidewalls of the grooves are covered with the shield layer, and the metal layer can be only formed from bottom to top gradually on the metal seed crystal layer, which is exposed at the bottom of the grooves, till the grooves are filled; the defect that gaps are formed in the metal layer in the grooves due to the fact that openings of the grooves are closed too early when the grooves are not full of metal layer; and further, the performance of the metal interconnection structure formed in the grooves subsequently and the performance of a semiconductor device formed subsequently are improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Method for eliminating electroplating cavity defects on wafer surface

InactiveCN105552022AGood step coverageReduce void defectsSolid-state devicesSemiconductor/solid-state device manufacturingPower flowReverse current

The invention discloses a method for eliminating electroplating cavity defects on a wafer surface. Through using a current direction controllable circuit in carrying out electroplating filling to the grooves or through holes of the wafer surface, a current magnitude and direction adjustable circuit is formed; forward and reverse currents are applied to a wafer alternately so as to form an electroplating / etching sequence; in the electroplating process, the wafer surface can be electroplated; the coating film on the wafer surface can be dissociated; therefore, relatively good step coverage rate and good groove (through hole) opening are obtained; the perfect filling process is realized; and the cavity defects formed in the filling process can be reduced.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

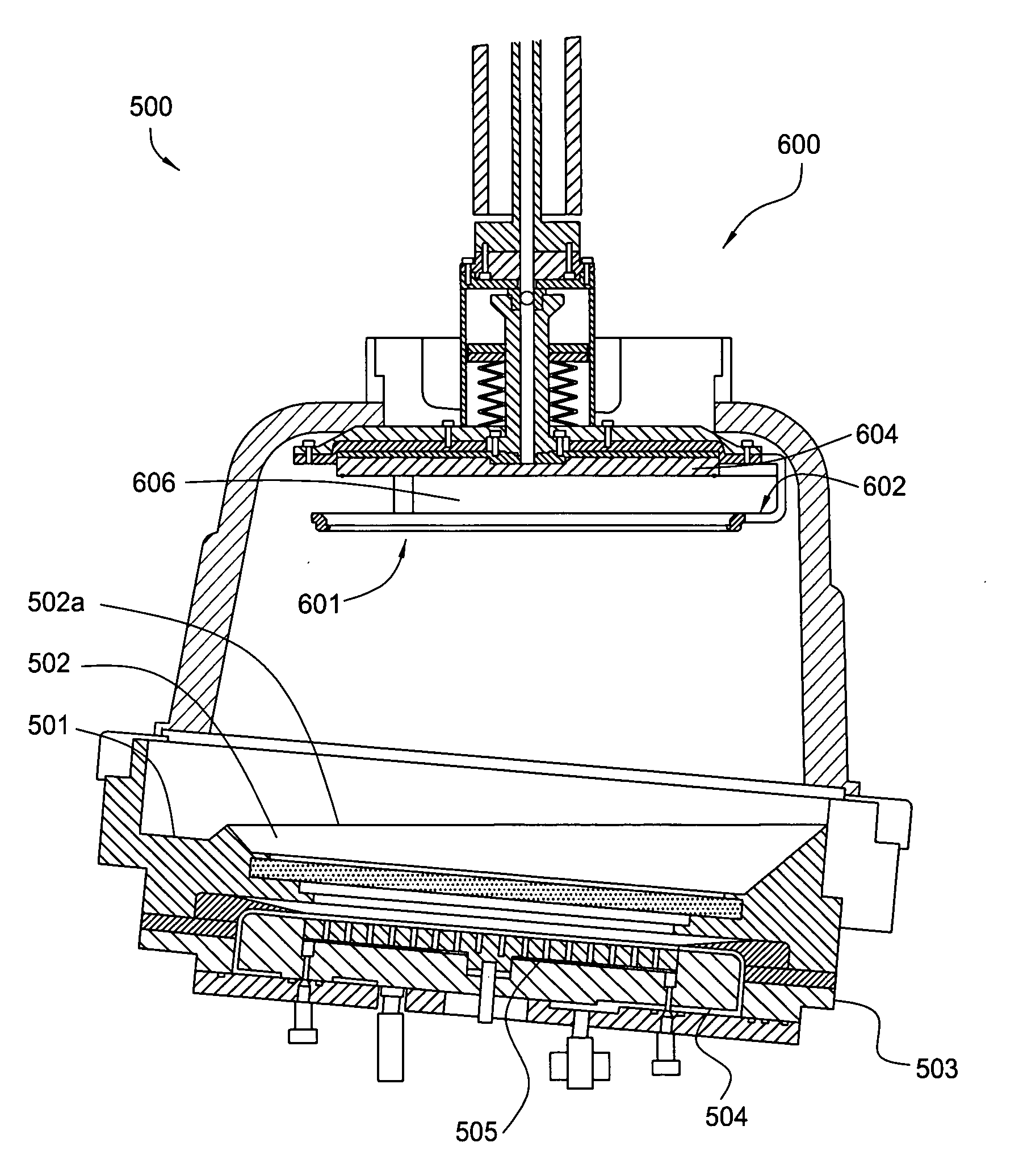

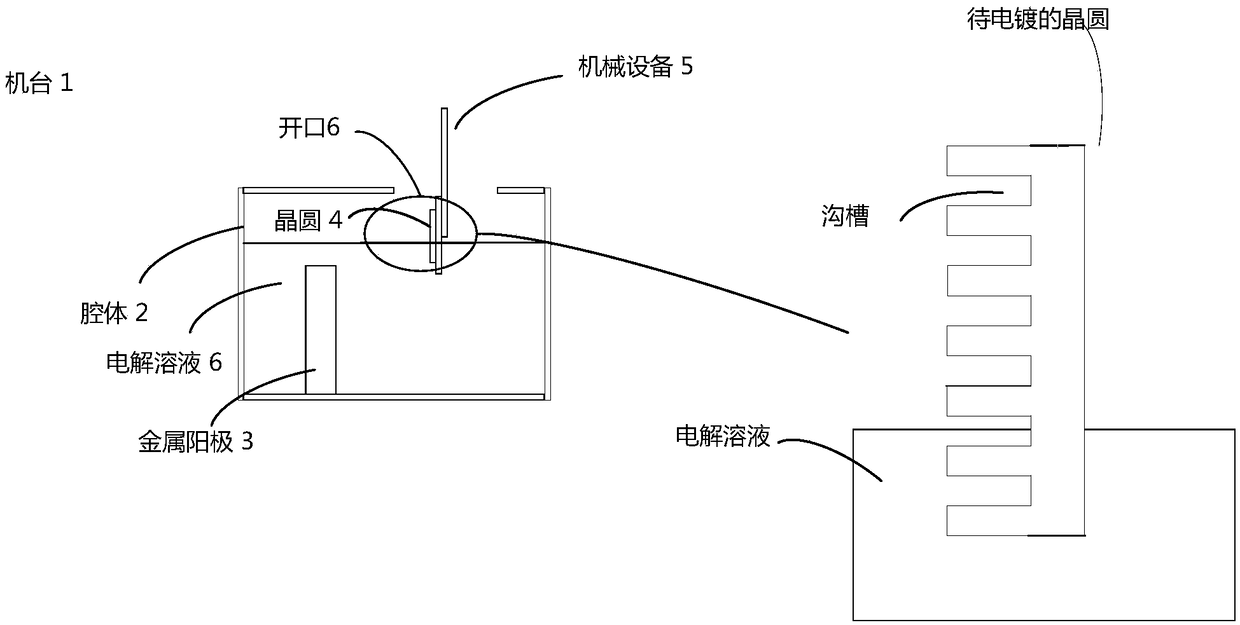

Equipment and method for reducing defects of wafer holes

InactiveCN108118377AImprove contact effectGood hole filling abilityElectrolysis componentsSemiconductor devicesMetalMaterials science

The application relates to a machine board for electroplating a wafer. The machine board comprises a cavity, wherein an opening is formed in the surface of the cavity and used for receiving the waferso as to feed the wafer into the cavity; a metal anode is arranged in the cavity and can be filled with an electrolytic solution; the metal anode is basically perpendicular to the liquid level of theelectrolytic solution.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

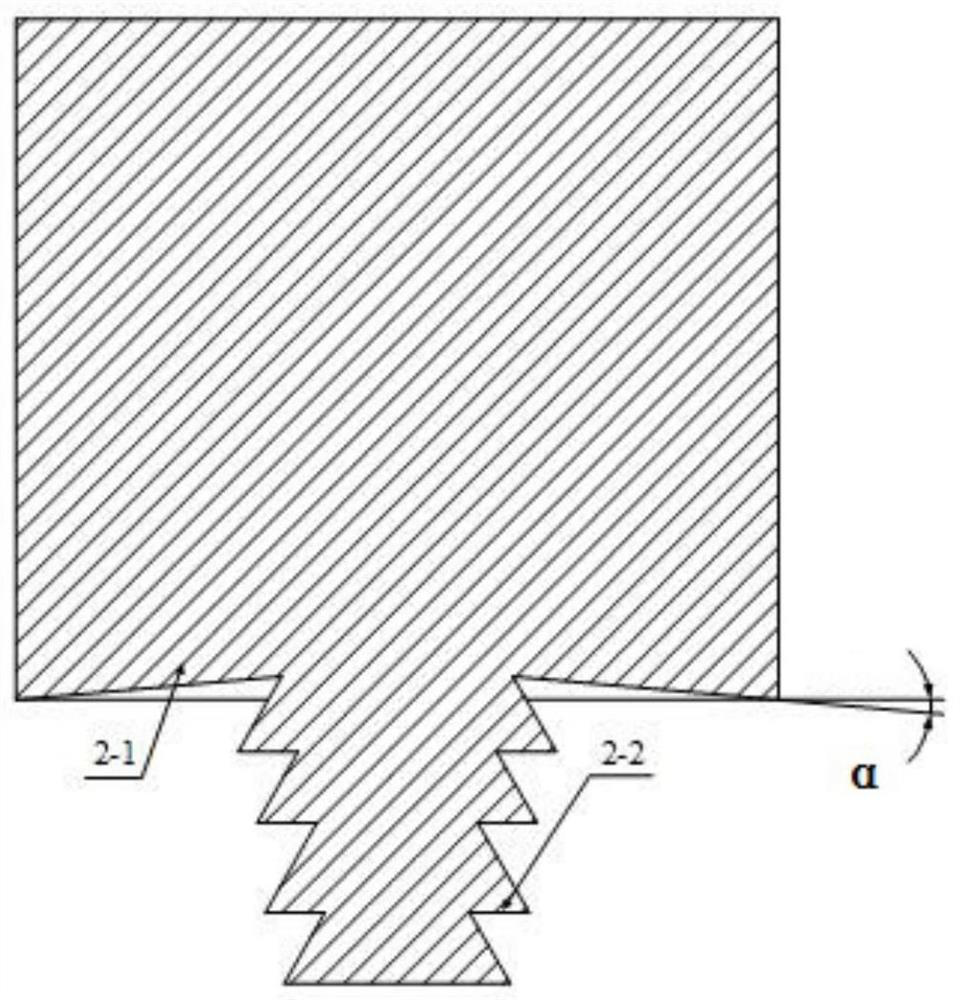

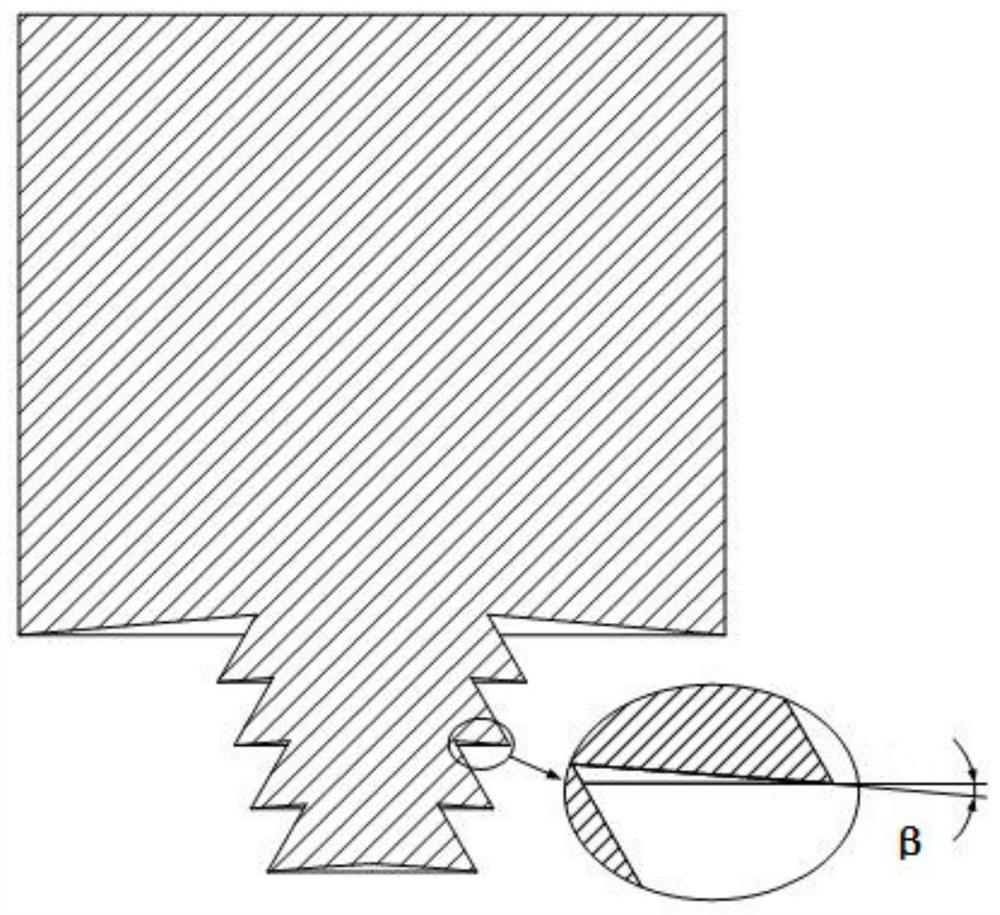

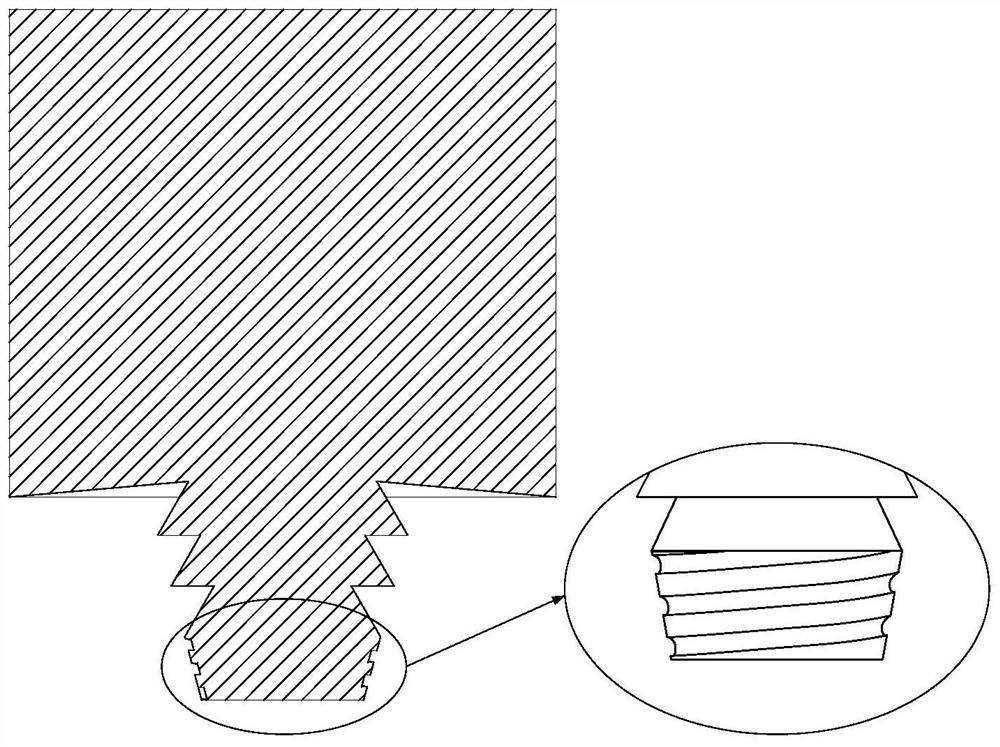

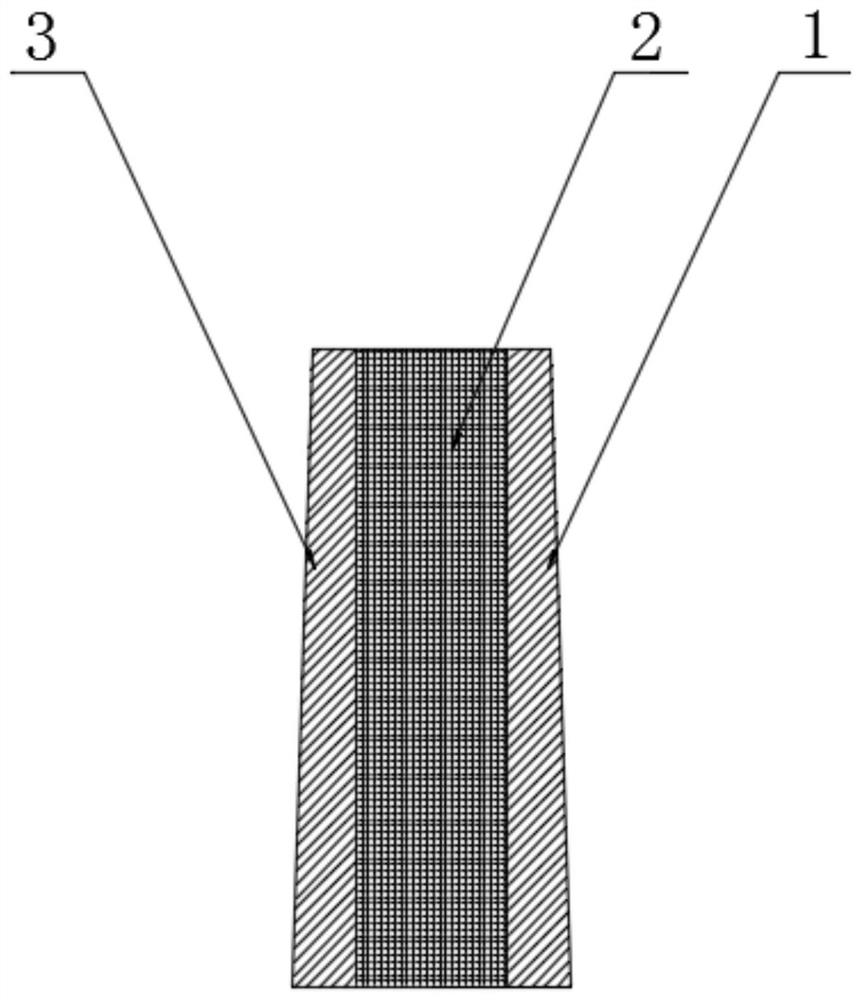

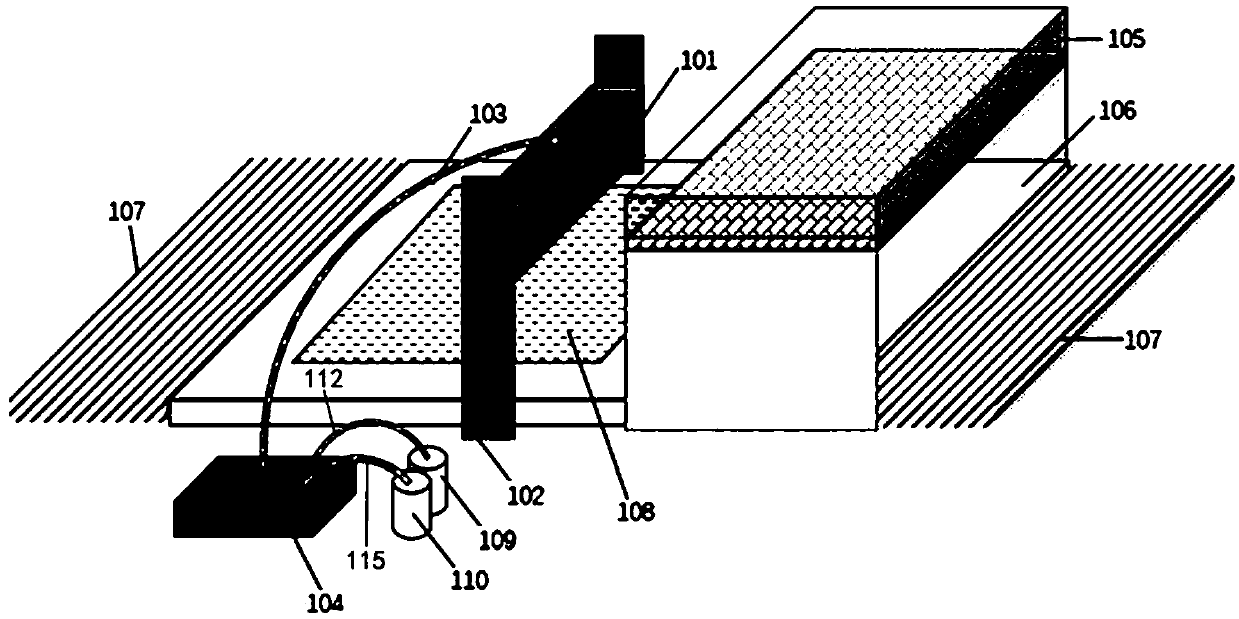

Stirring head for welding metal and thermoplastic polymer and welding method

ActiveCN113020776AImprove surface forming qualityImprove the sealing effectNon-electric welding apparatusJoint surfaceSlow cooling

The invention provides a stirring head for welding metal and a thermoplastic polymer and a welding method, and belongs to the field of new material connection. The stirring head is characterized by a concave shaft shoulder and an inverted-tower-shaped stirring needle with a multi-stage flow blocking circular truncated cone structure of the stirring head. The welding method is characterized in that friction stir lap welding is completed by heating the two sides of the upper surface of a welding seam through a resistance type auxiliary heating strip, and an auxiliary heat source can provide the effects of preheating before welding and slow cooling after welding for a welded plate. According to the stirring head for welding the metal and the thermoplastic polymer and the welding method, the flow choking appearance design of the stirring head can inhibit the overflow of a thermoplastic polymer material and improve the surface quality of the welding seam; and the welding auxiliary heating process for the metal and the thermoplastic polymer material is based on the thoughts of isothermal peak rotation speed reduction and stress reduction anti-pulling-off, the rotation speed of the stirring head is reduced under the condition that the same welding temperature is guaranteed, and therefore joint surface forming is improved, internal defects are eliminated, the interface structure is optimized, and the quality of a heterogeneous joint is comprehensively improved.

Owner:SHENYANG AEROSPACE UNIVERSITY

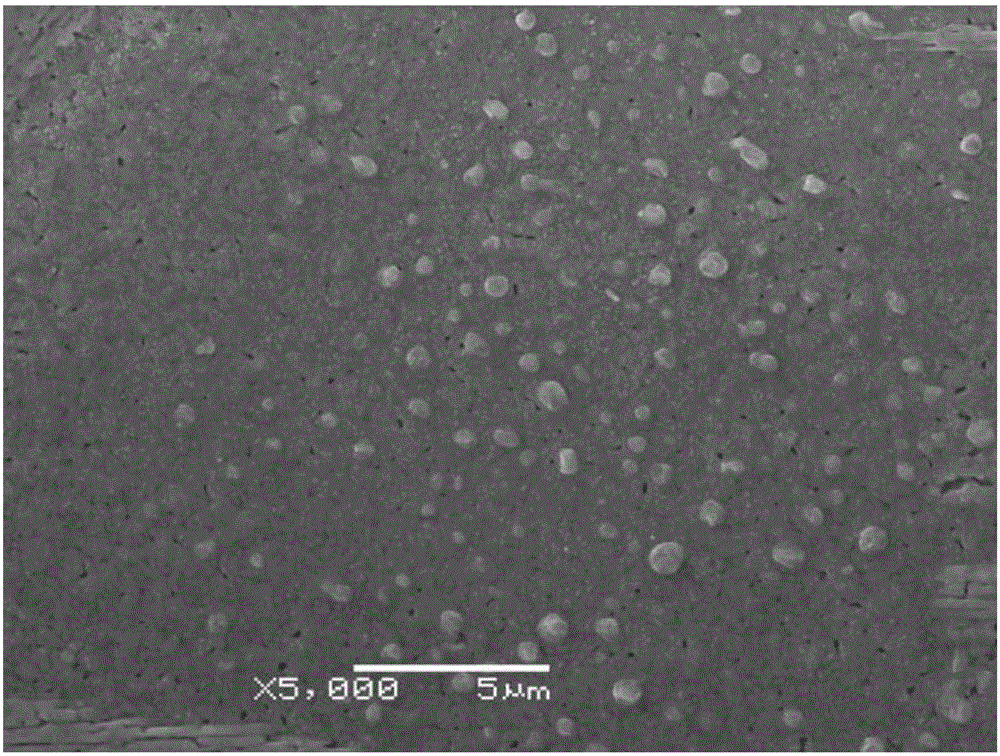

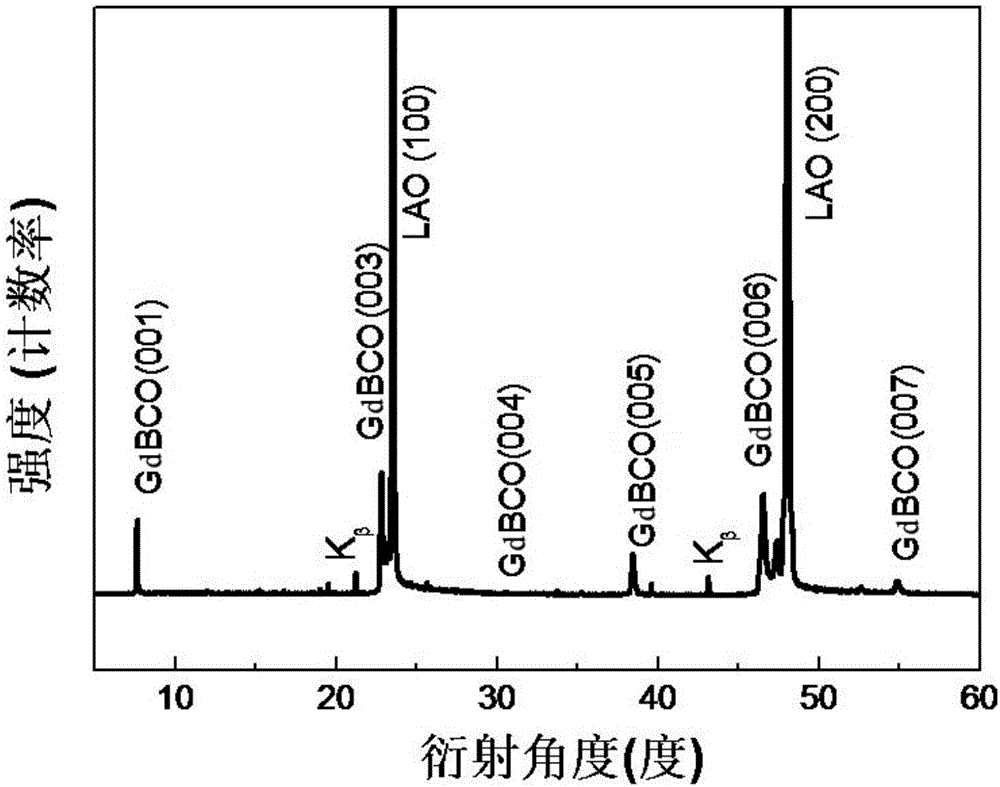

Production method of high-temperature superconductive REBCO film

ActiveCN106242553ASolving the problem of poor superconductivityInhibit carbon contentFluorine containingHeat treated

The invention provides a production method of a high-temperature superconductive REBCO film. The method comprises the following steps: 1, preparing a fluorine-free precursor solution according to an atom ratio of RE:Ba:Cu of 1:1.75:3; 2, preparing a fluorine-containing precursor solution according to an atom ratio of RE:Ba:Cu of 1:(1.5-2):3; 3, uniformly coating a LaAlO3 substrate with the fluorine-free precursor solution through adopting a spin coating technology, and carrying out heat treatment to obtain a fluorine-free monolayer precursor film; 4, uniformly coating the fluorine-free monolayer precursor film with the fluorine-containing precursor solution through adopting the spin coating technology, and carrying out heat treatment to obtain a fluorine-free / fluorine-containing bilayer precursor film; and 5, carrying out heat treatment on the fluorine-free / fluorine-containing bilayer precursor film to obtain the REBCO superconductive film. The production method is simple, allows the produced high-temperature superconductive REBCO film to have sharp cubic orientation and excellent superconductive performance, and improves the current carrying performance of the high-temperature superconductive REBCO film at 77 K.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

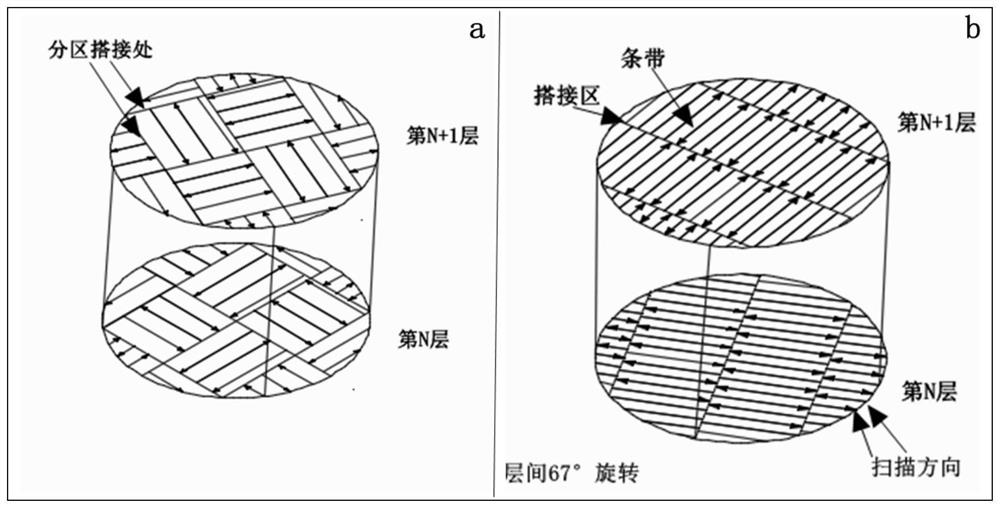

Method for repairing defects of lap joint positions of adjacent sub-areas formed by selective laser melting

InactiveCN111974990AHigh densityEliminate weld pool defectsAdditive manufacturing apparatusSelective laser meltingLaser scanning

The invention discloses a method for repairing defects of lap joint positions of adjacent sub-areas formed by selective laser melting. According to the method, a laser scanning speed is adjusted, anda melting channel state that the tail end of a melting channel and the interior of the melting channel are uniform in morphology and no obvious hole is formed in the tail end of the melting channel isobtained; on the basis of forming uniform parameters of the morphology of the tail end of the melting channel and the interior of the melting channel, the laser jump speed between the adjacent melting channels is adjusted, and a defect molten pool with multiple layers of built-in keyholes fused through due to too high laser energy input at the lap joint of the adjacent sub-areas during selectivelaser melting forming is effectively removed; and the density of an IN718 test block can be improved from 98.3% to 99.4% only aiming at the defects at the lap joint positions of the sub-areas.

Owner:TIANJIN UNIV

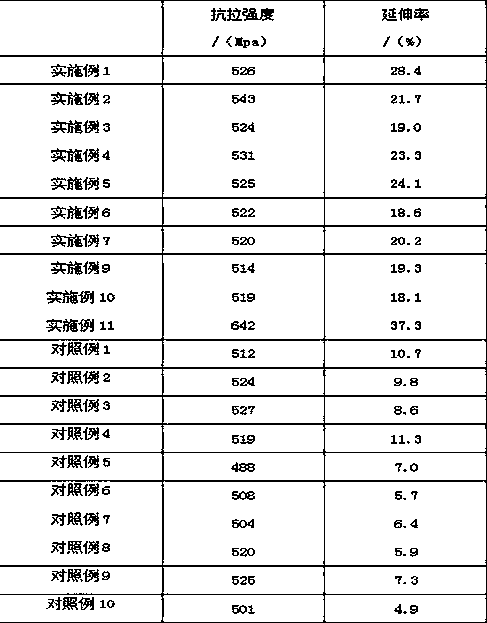

High-plasticity aluminum alloy processing technology

The invention discloses a high-plasticity aluminum alloy processing technology. The two elements of silicon and aluminum are used as an alloy main body, and a certain amount of Cu, Zn and Sr are addedand hot working treatment is carried out so as to prepare the aluminum alloy with high plasticity. According to the high-plasticity aluminum alloy processing technology, the two elements of silicon and aluminum are used as the alloy main body, and the certain amount of Cu, Zn and Sr are added and the hot working treatment is carried out, thus a compact metal-rich intermetallic compound with uniform and dense crystal grains and uniform component and dispersed distributed on a matrix and a defect-free tissue are obtained, the plasticity of the alloy can be remarkably improved on the basis thatthe strength of the alloy is not reduced.

Owner:新沂市中诺新材料科技有限公司

Modified glass material for repairing carbon/carbon composite material SiC coating based on laser cladding method and preparation and use methods

ActiveCN112341000AReduce energy lossImprove absorption rateGlass furnace apparatusCarbon compositesRare-earth element

The invention relates to a modified glass material for repairing a carbon / carbon composite material SiC coating based on a laser cladding method as well as a preparation method and a use method of themodified glass material. Borosilicate glass is modified by rare earth element samarium, so that the absorptivity of the material to a laser band covered by an optical fiber laser is remarkably improved; on one hand, the cladding quality of the modified borosilicate glass can be improved, and the oxidation resistance of a repaired carbon / carbon composite material SiC coating sample is improved; and on the other hand, the energy loss of laser can be effectively reduced, and the development goals of greenness, environmental protection and cost saving are achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Local vacuum casting method for aluminum alloy

The invention provides a local vacuum casting method for aluminum alloy. A raw material is sequentially added step by step, and ultrasonic vibration treatment and mechanical stirring treatment are combined, so refinement of a melt structure can be remarkably promoted, the dendritic crystal spacing is reduced, and the dendritic crystal spacing is stable; an alloy casting is formed under the actionof vacuum and pressure formed at the upper part of a crystallizer through the local vacuumizing casting method, the grain diameter is small, the structure is compact, and the hole defects are few; theconnection among a filter chamber box, a molten aluminum inlet and a crystallizer is always kept in a vacuum state, so the situations of segregation, turbulence, easy gas entrapment and oxidation ofthe aluminum alloy in the production process are reduced, the shifting amplitude of the liquid level of the aluminum alloy is stable, and the slag entrapment phenomenon can be obviously improved; andthe local vacuumizing casting method for aluminum alloy has the advantages of simple device, and easiness in operation, and the prepared aluminum alloy has no obvious defects such as cracks, pits andslag inclusion on the surface, and has the advantages of large tensile strength, good yield strength and high extrudability.

Owner:佛山市三水凤铝铝业有限公司 +1

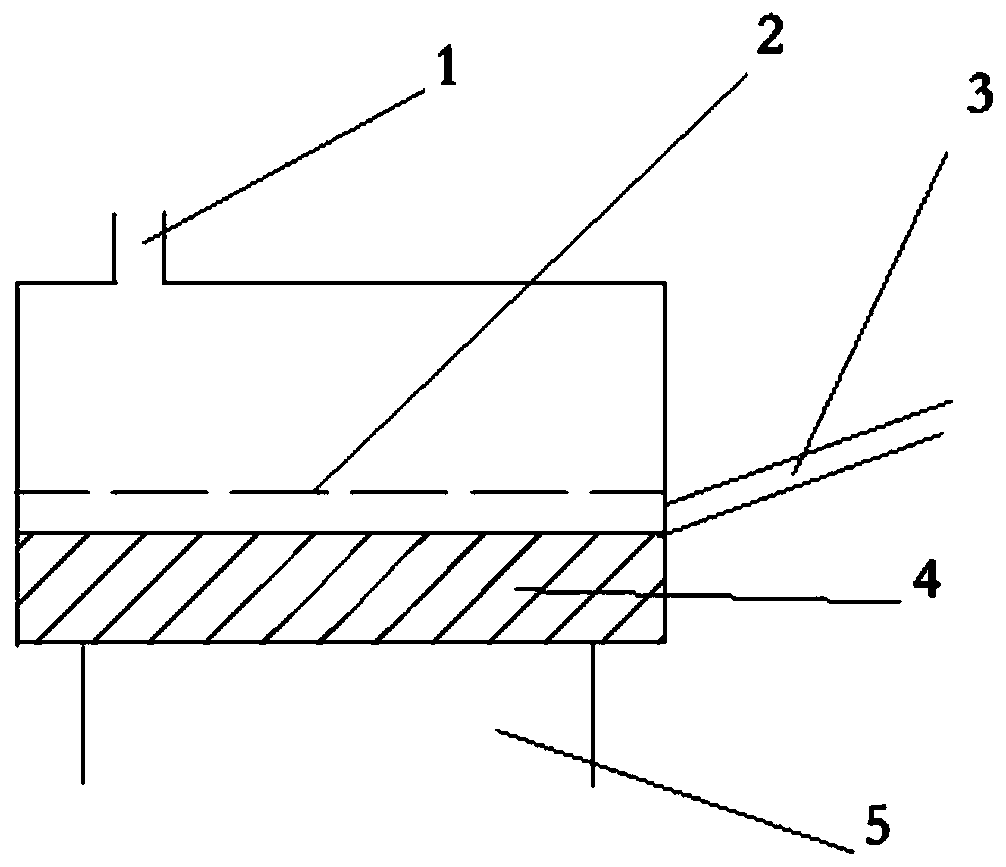

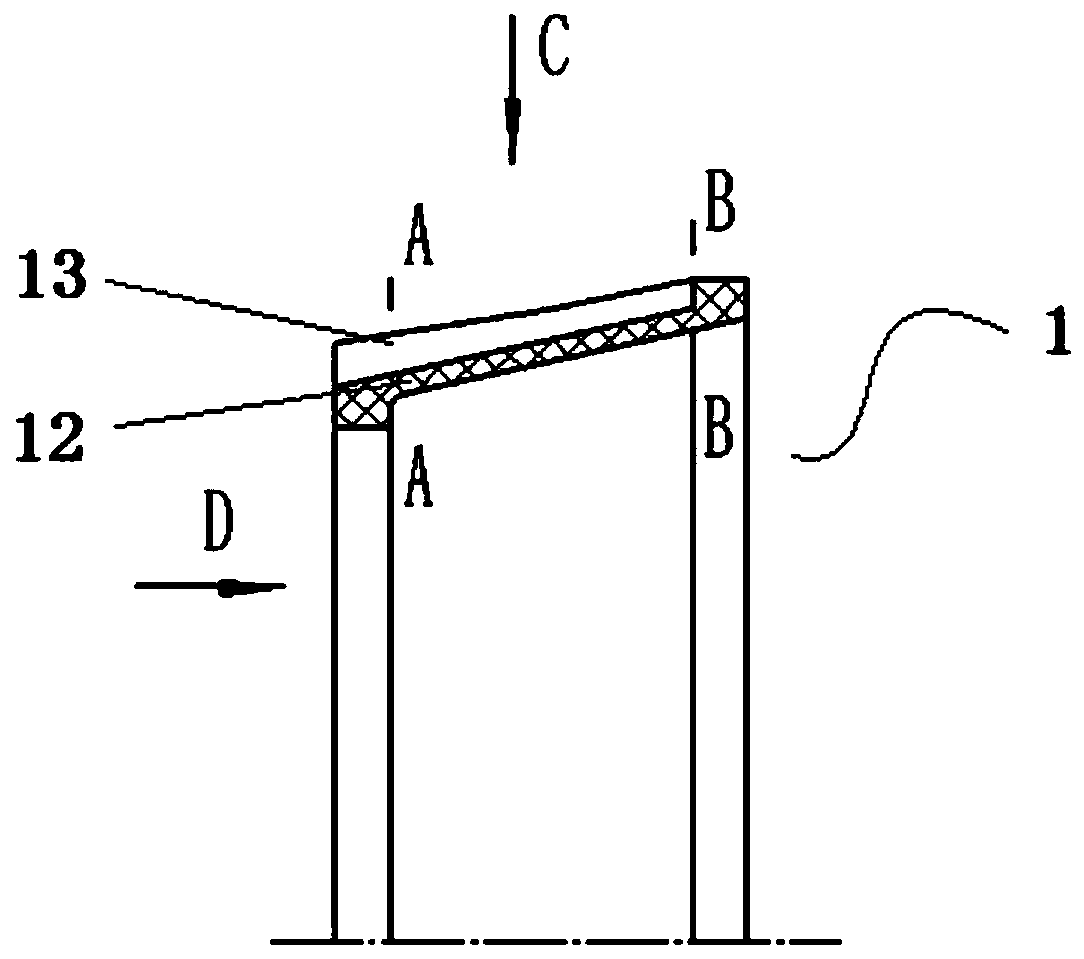

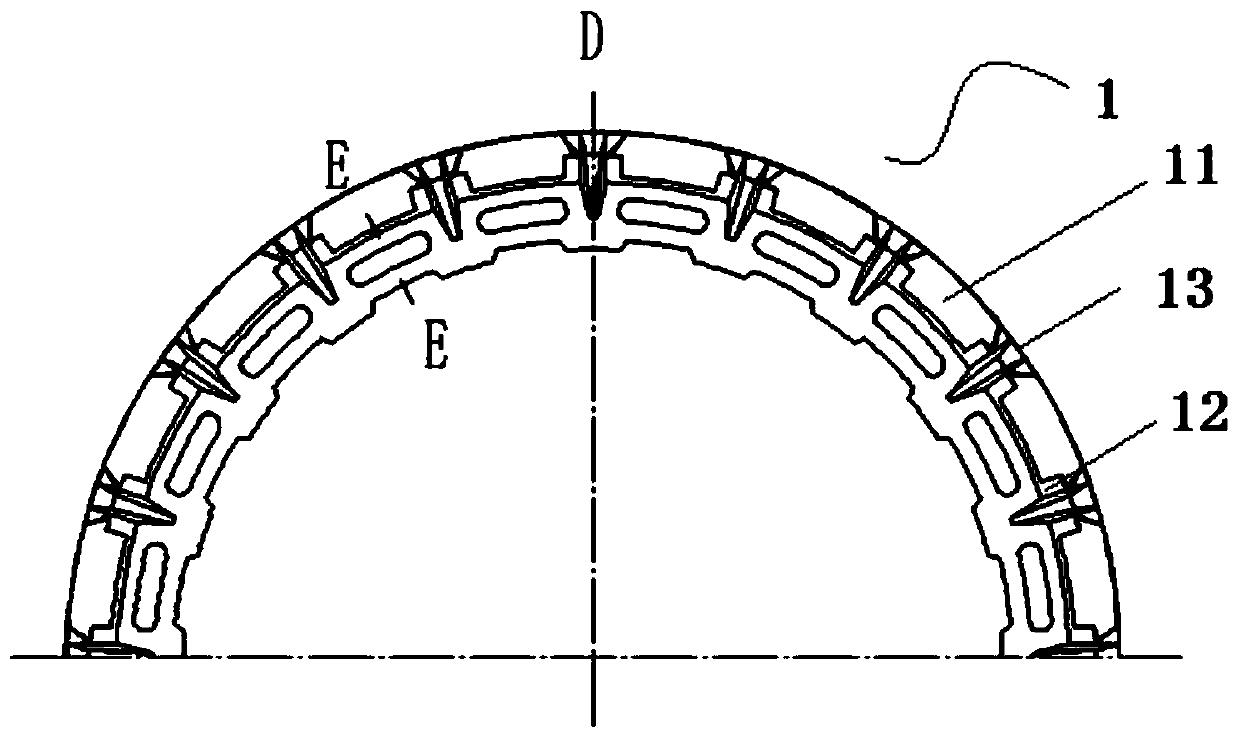

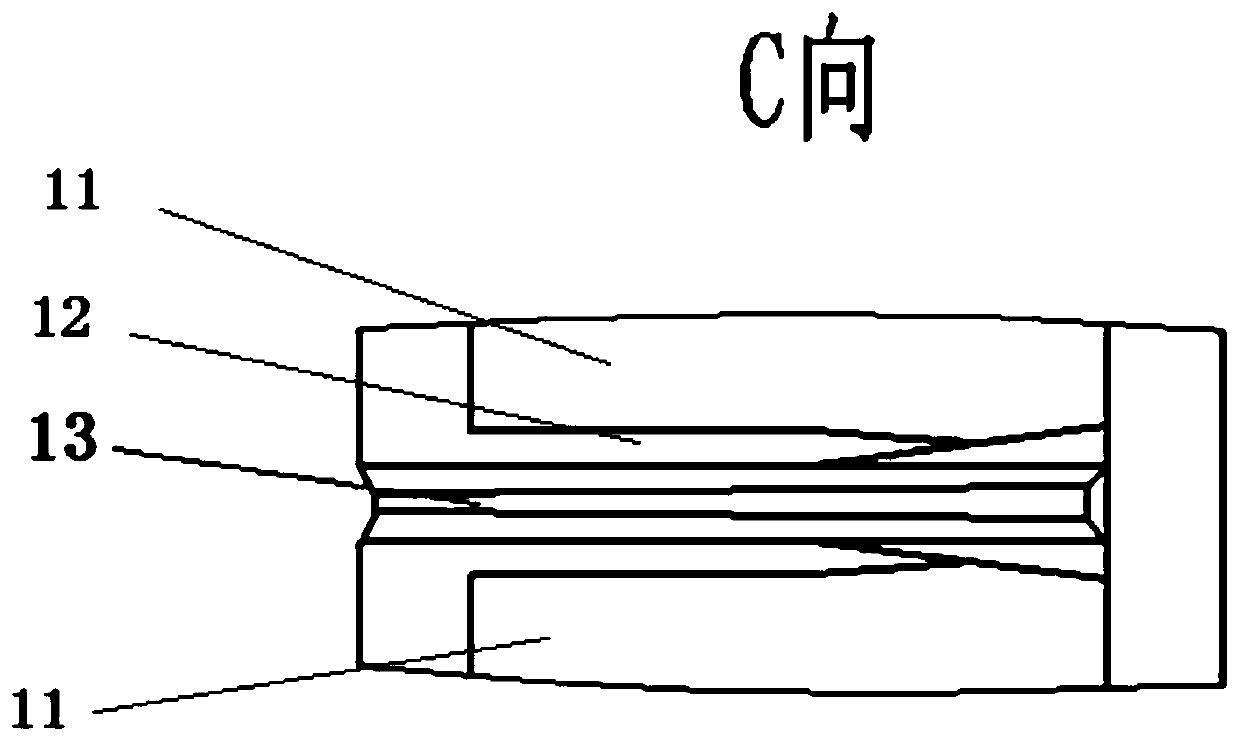

Engineering plastic bearing cage

PendingCN111022504AReduce wall thicknessHigh precisionShaftsBearing componentsClassical mechanicsEngineering plastic

The invention discloses an engineering plastic bearing cage. The engineering plastic bearing cage is characterized by comprising a bearing cage body, a plurality of window openings used for installingrollers are formed in the bearing cage body at intervals in the circumferential direction of the bearing cage body, and a window beam is formed between every two adjacent window openings. Notches areformed in the outer-diameter sides of the window beams respectively. The wall thickness of the window beams of the bearing cage body can be reduced, the wall thickness of the bearing cage body is more uniformly and stably shrunk in the injection molding process, and the precision of the engineering plastic bearing cage is improved.

Owner:北京隆轩橡塑有限公司

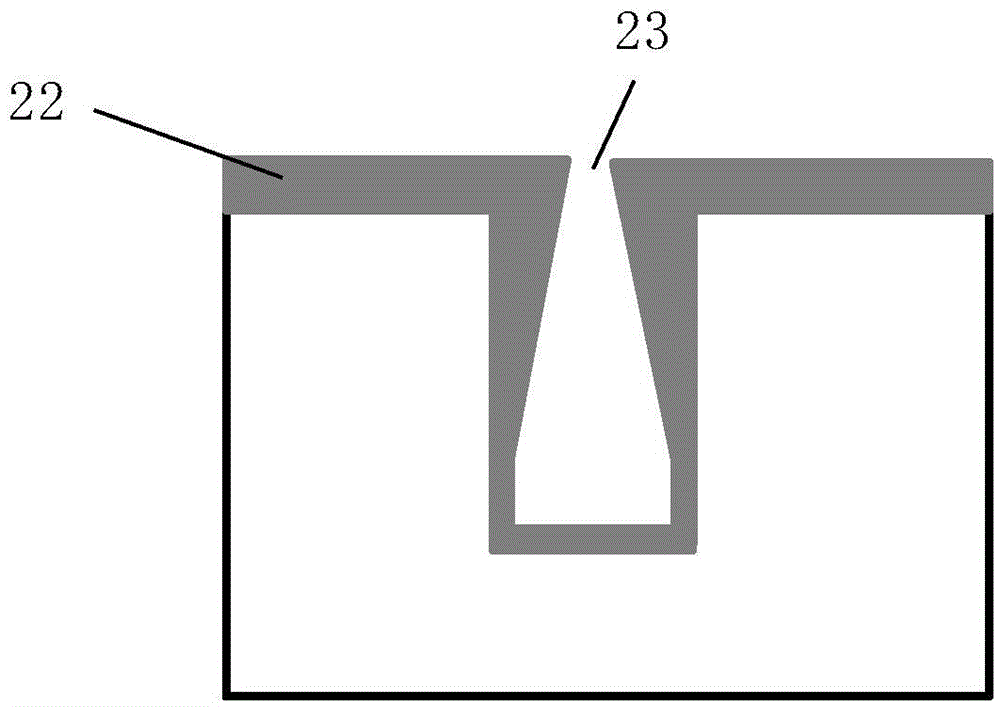

Step-by-step cyclic etching method for 3D NAND gate line slit trench

ActiveCN107978605AGood lookingEasy to fillSolid-state devicesSemiconductor devicesProcess qualityNAND gate

A step-by-step cyclic etching method for a 3D NAND gate line slit trench is provided. By splitting two etching steps ME1 and ME2 in a 3D NAND gate line slit trench etching process into multiple sub-steps, alternately performing the multiple sub-steps of the ME1 and ME2, and performing an OE step after the sub-steps are performed cyclically, the etching rate of a oxidizing dielectric layer and theetching rate of an nitride dielectric layer are balanced by the alternate etching of the ME1 and ME2. By implementing the step-by-step cyclic etching process, a deep trench structure with good morphology can be obtained, and the window of an etching process is expanded, so that the gate line slit trench is prepared into a good conical morphology, which is beneficial to subsequent injection of thetungsten. Thus, the process quality after a dry etching method is improved, void defects are reduced, and a product yield is improved.

Owner:YANGTZE MEMORY TECH CO LTD

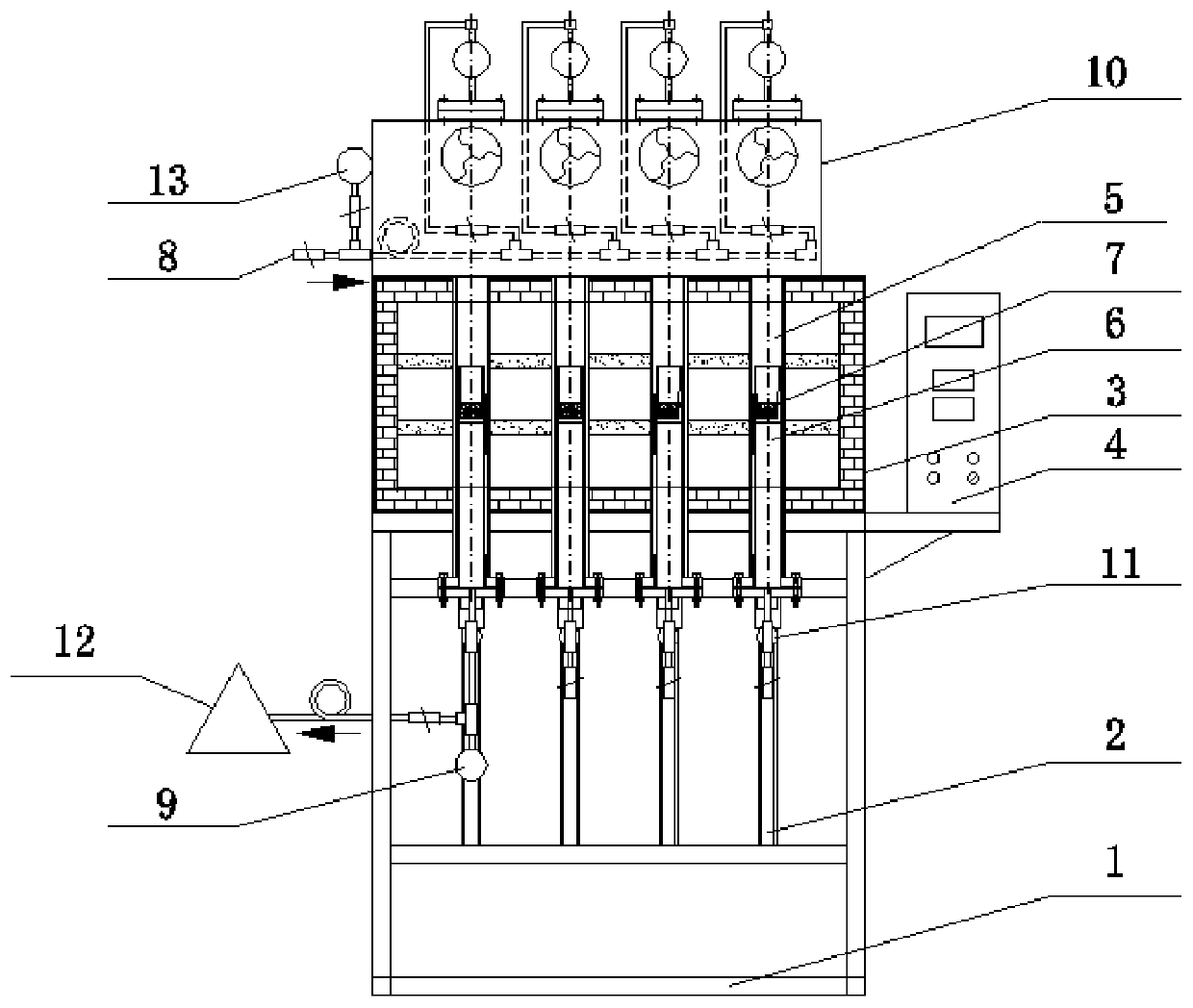

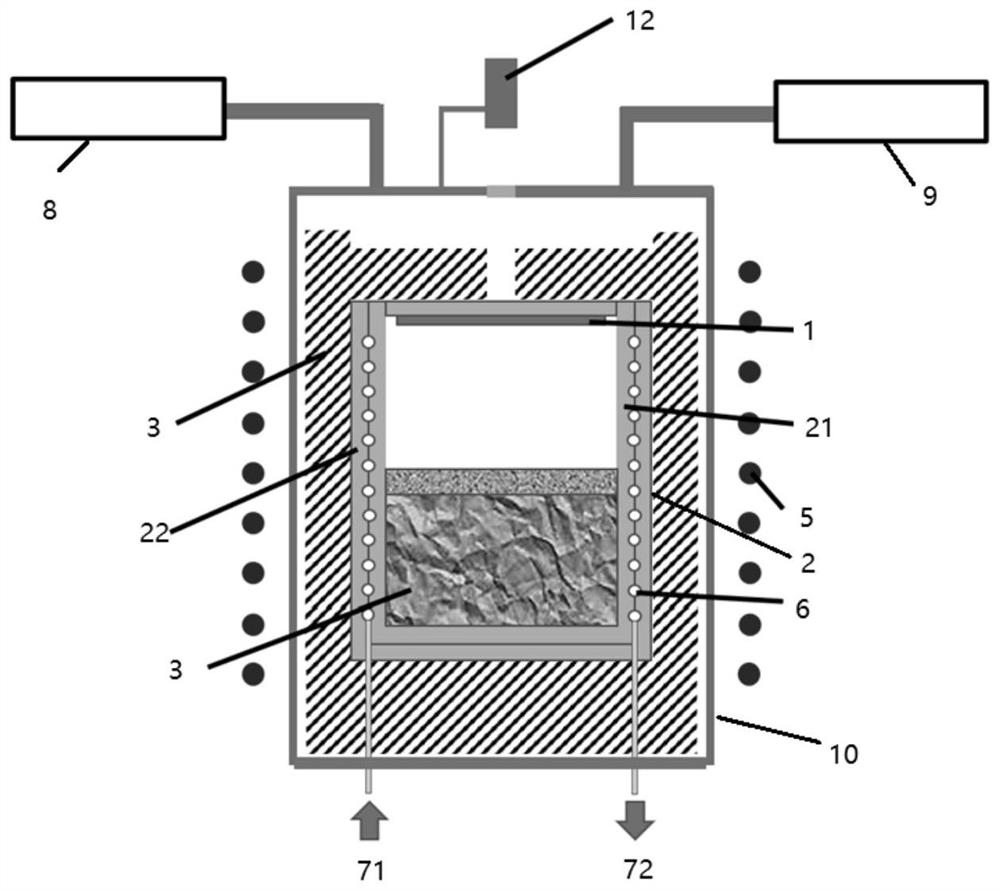

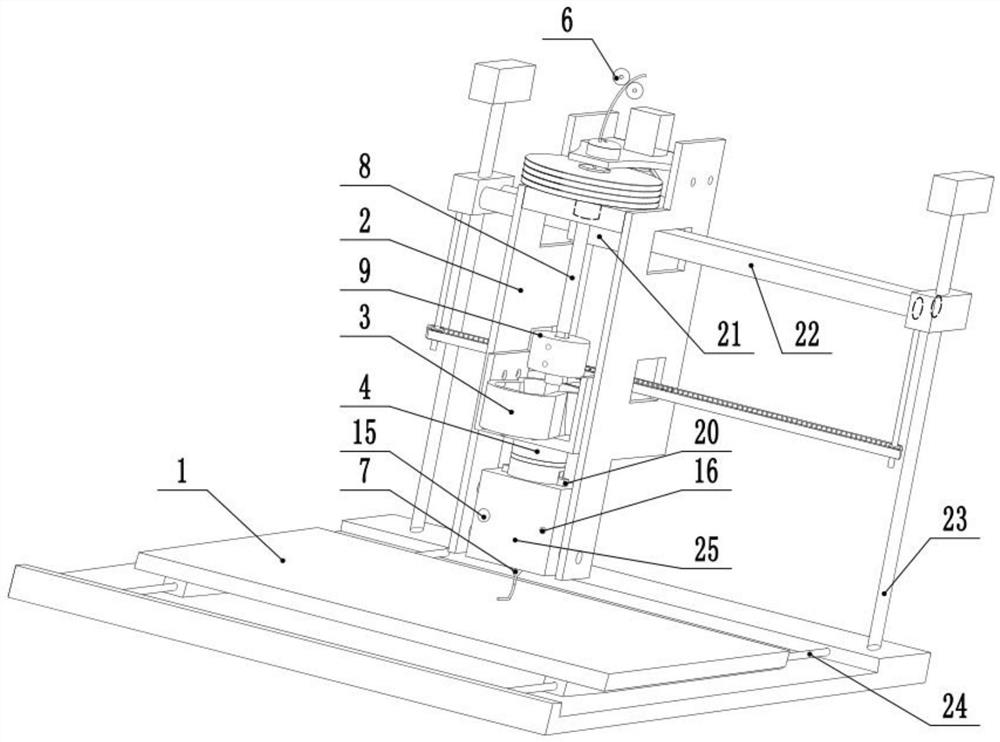

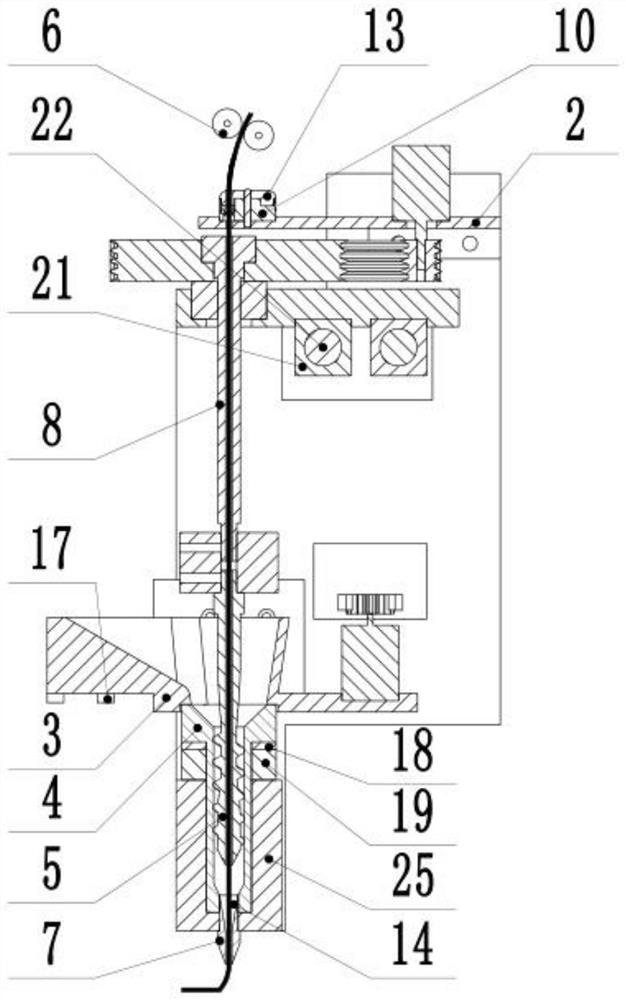

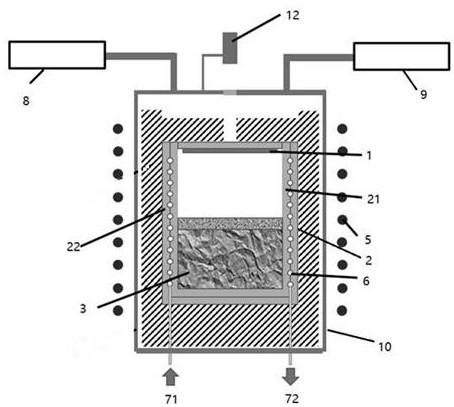

Pressure infiltration preparation device and preparation method for aluminum matrix composite

The invention belongs to the field of metal matrix composite preparation, and discloses a pressure infiltration preparation device and preparation method for an aluminum matrix composite. The device comprises a rack, multiple lifting mechanisms, a resistance furnace, an infiltration pressure control system, a vacuum control system and an electric control machine box, and each lifting mechanism canascend into the resistance furnace through an independent furnace pipe. The device adopts the multiple furnace pipes, the use rate of inner space of a hearth of the resistance furnace is improved, the preparation efficiency of the composite is improved, multiple composite samples are prepared at the same time under the same conditions, stability of composite preparation is improved, and consistency of composite performance is guaranteed. Simultaneous preparation of different pressure infiltrations can be achieved in the different furnace pipes according to needs.

Owner:SOUTH CHINA UNIV OF TECH

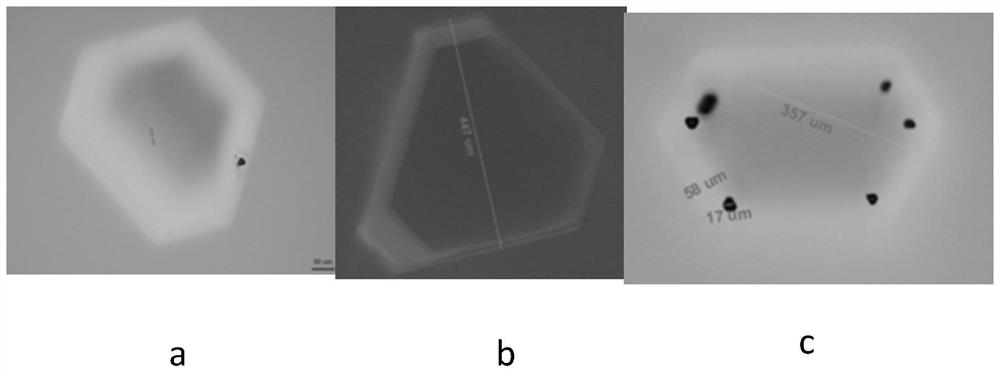

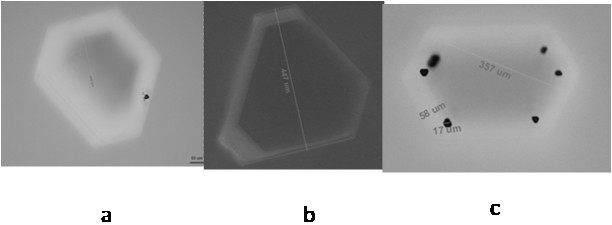

Silicon carbide wafer, silicon carbide ingot and preparation method thereof

ActiveCN112501687AReduce in quantityReduce defect densityPolycrystalline material growthFinal product manufactureWaferingSemiconductor materials

The invention relates to a silicon carbide wafer, a silicon carbide ingot and a preparation method thereof, and belongs to the field of semiconductor materials. The silicon carbide single crystal wafer contains nitrogen, the number of hexagonal color spots of the silicon carbide single crystal wafer is not more than 50, the edge parts forming the hexagonal color spots are perpendicular to the <10-10> direction, and the number of holes contained in the edge parts of each hexagonal color spot is not more than 10. According to the invention, novel defects, i.e. hexagonal color spots and cavity defects on the hexagonal color spots, existing in the nitrogen-containing silicon carbide wafer are discovered, the hexagonal color spots enable the resistivity of the silicon carbide wafer to be non-uniform and seriously influence the electrical properties of a semiconductor device prepared from the silicon carbide wafer, for example, the device made on the silicon carbide wafer is invalid, and theexistence of the cavities not only influences the performance of the silicon carbide wafer, such as breakdown field intensity, but also may extend to a device manufactured by taking the silicon carbide single crystal wafer as a substrate. The present application provides a silicon carbide wafer and a silicon carbide ingot including hexagonal spots and a small number of cavities.

Owner:SICC CO LTD

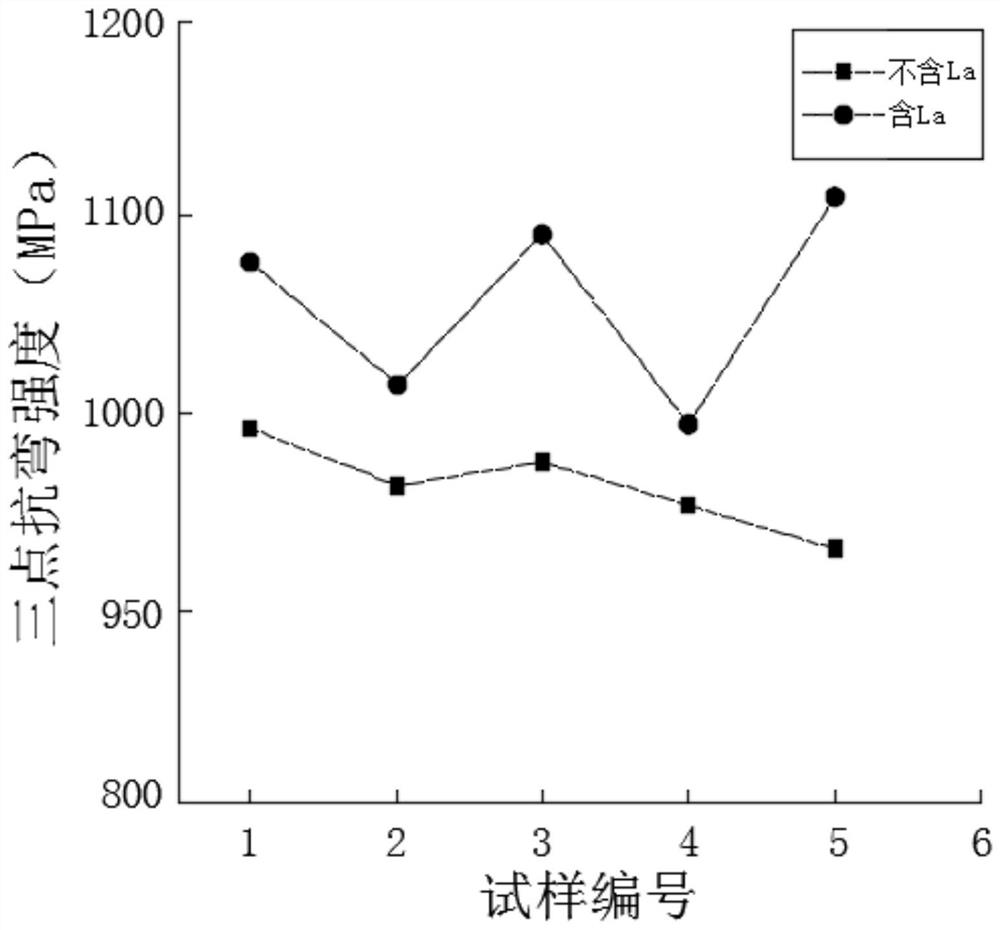

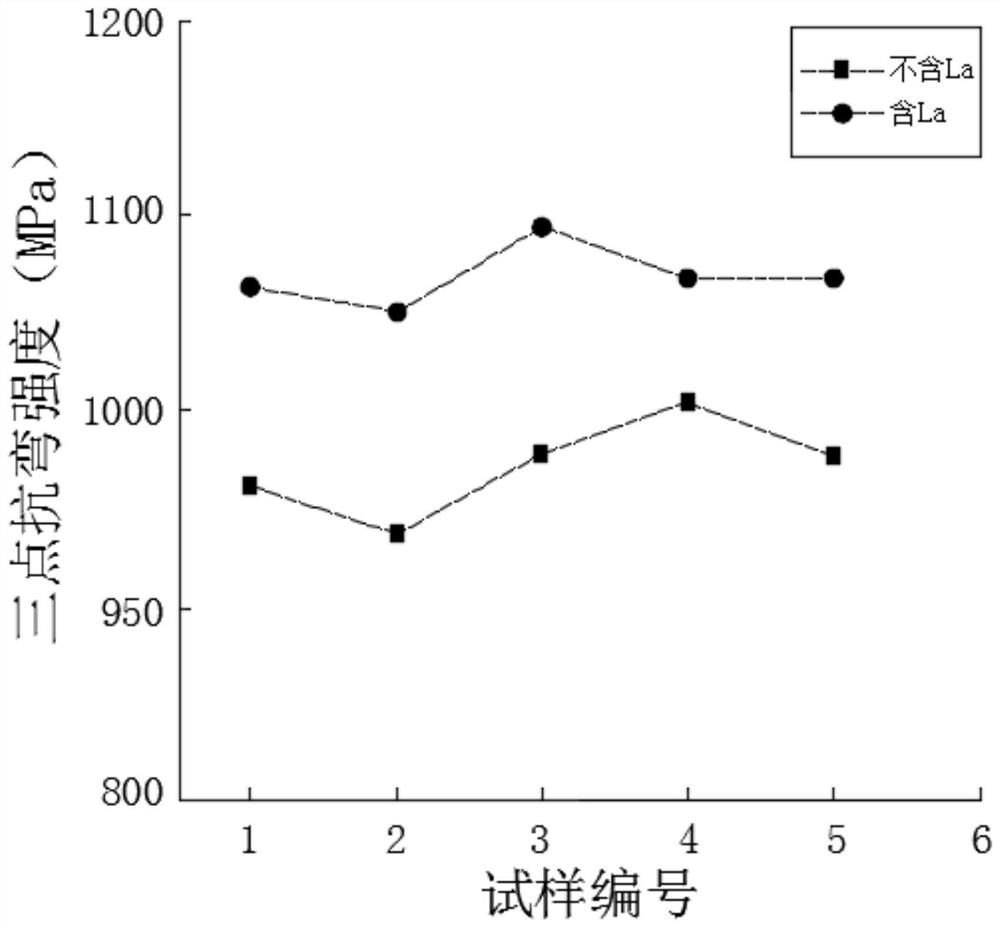

Low-price gang saw tool bit product and preparation method thereof

InactiveCN112091218AGuaranteed lifeGuaranteed sintering effectTransportation and packagingMetal-working apparatusTool bitRare-earth element

The invention discloses a low-price gang saw tool bit product and a preparation method thereof, and particularly relates to the field of gang saw tool bits. A tool bit material adopted by the tool bitproduct is formed by mixing and sintering metal powder, liquid paraffin and diamond, wherein the metal powder is prepared from the following powder raw materials in part by weight: 35-45 parts of cobalt, 25-35 parts of iron, 25-35 parts of copper, 1-5 parts of nickel and 0.8 part of La, the liquid paraffin accounts for 1-1.2 parts, and the diamond accounts for 30% of the volume of the tool bit material. According to the low-price gang saw tool bit product and the preparation method thereof, by adding different contents of Fe, Cu, Ni and Sn and a small amount of rare earth elements, the hardness HRB, the bending strength and the abrasion ratio of a matrix are kept, so that the mechanical property and the abrasion resistance of the gang saw tool bit to the matrix are met; and the characteristics of the matrix are matched by using the diamond with the fixed grade and granularity, the holding force of the matrix on the diamond and the edge exposure effect are ensured, and the cutting sharpness and the service life of a cobalt-based product are achieved by using a sintering process matched with the characteristics of the matrix.

Owner:QINGDAO SHINHAN DIAMOND INDUSTRY CO LTD

Black polyimide film with high electrical strength and high shielding property, and preparation process thereof

The invention discloses a black polyimide film with high electrical strength and high shielding property, and a preparation process thereof, and relates to the technical field of polyimide films. Theblack polyimide film comprises polyamide acid resin, a black pigment, a shielding agent and a dispersing agent, wherein the black pigment is formed by compounding carbon black and fluorinated graphene. The preparation method comprises the following steps: mixing, grinding and dispersing the black pigment, the shielding agent, the solvent and the dispersing agent to obtain a black slurry, adding the black slurry into the polyamide acid resin, stirring to obtain black polyamide acid resin, casting the black polyamide acid resin to form a film, and carrying out thermal imidization, longitudinal stretching and transverse stretching to obtain the black polyimide film. The prepared black polyimide film has low light transmittance and pinhole rate, excellent electrical strength and ideal comprehensive performance, the light transmittance is smaller than 0.2%, and the electrical strength is larger than or equal to 150%.

Owner:ANHUI GUOFENG PLASTIC

Preparation process of mesophase pitch based protofilament continuous filament

InactiveCN108385179AReduce wire breakageReduce void defectsSpinning solution filteringSpinning solution de-aeratingFiber bundleGas bubble

The invention discloses a preparation process of a mesophase pitch based a protofilament continuous filament. The preparation process comprises the following steps of sending mesophase pitch into a screw extruder through a feeder; heating, by a screw of the extruder, the mesophase pitch, and carrying out reduced pressure deaeration when the screw runs; conveying, by the screw extruder, a melted and deaerated melt into a spinning component through a metering pump, spreading the melt into a spinneret through a spure spreader of the spinning component, and extruding through spinneret orifices ofthe spinneret to carry out spinning; oiling an extrusion-molded fiber bundle, drawing by a drawing roll, and then collecting the filament. A reduced pressure deaeration opening in the preparation process is located behind a final zone; on one hand, the melt in a melting zone can be prevented from being evacuated and broken down to cause that a suction gas is dissolved in the melt. The mesophase pitch is completely molten after passing through a screw melting zone, and is uniformly mixed under the shearing action of a twin screw to be capable of forming a layer of thin and uniform melt in a tank; at the moment, gas bubbles in the interior of the melt can be completely separated through the reduced pressure deaeration. The preparation process is good in production efficiency, and moreover, the prepared mesophase pitch based protofilament is good in performance.

Owner:西安天运新材料科技有限公司

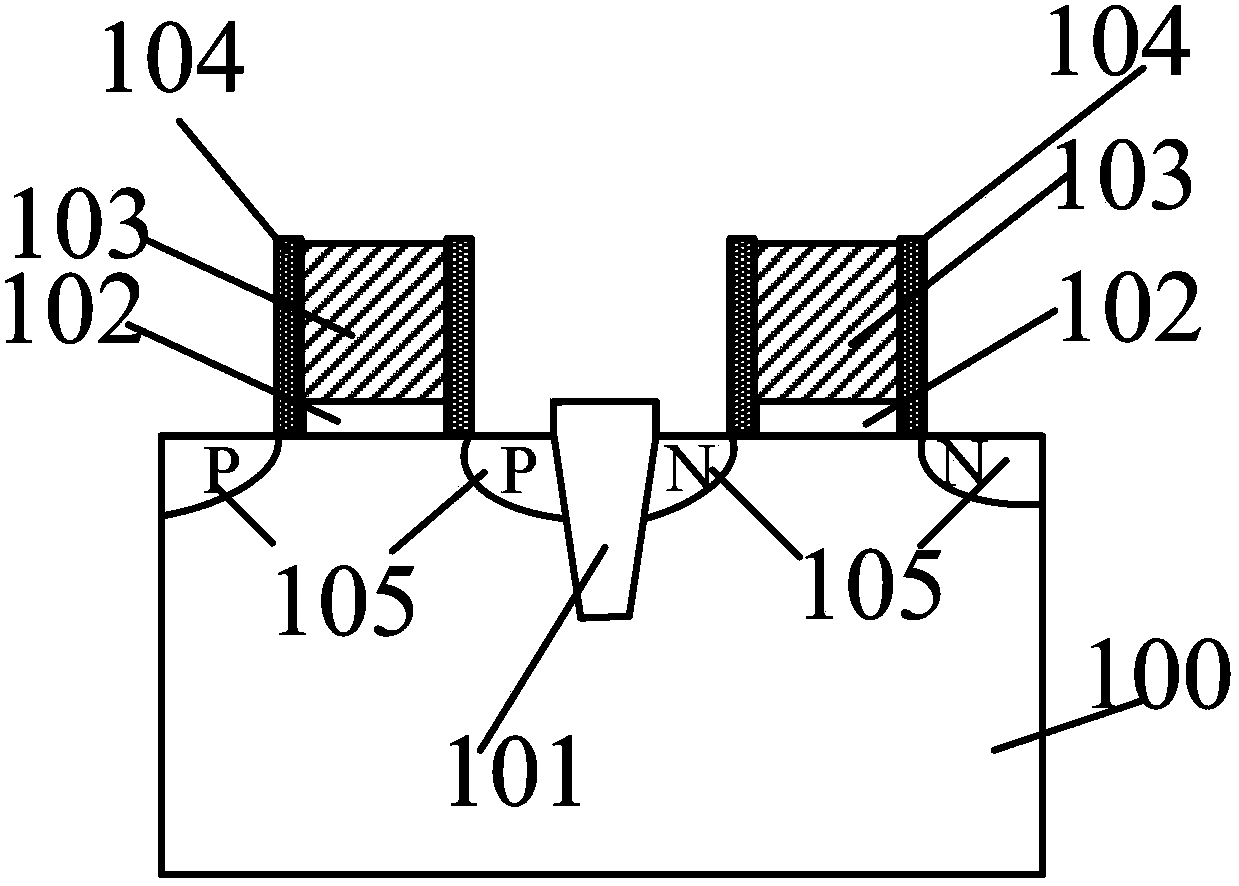

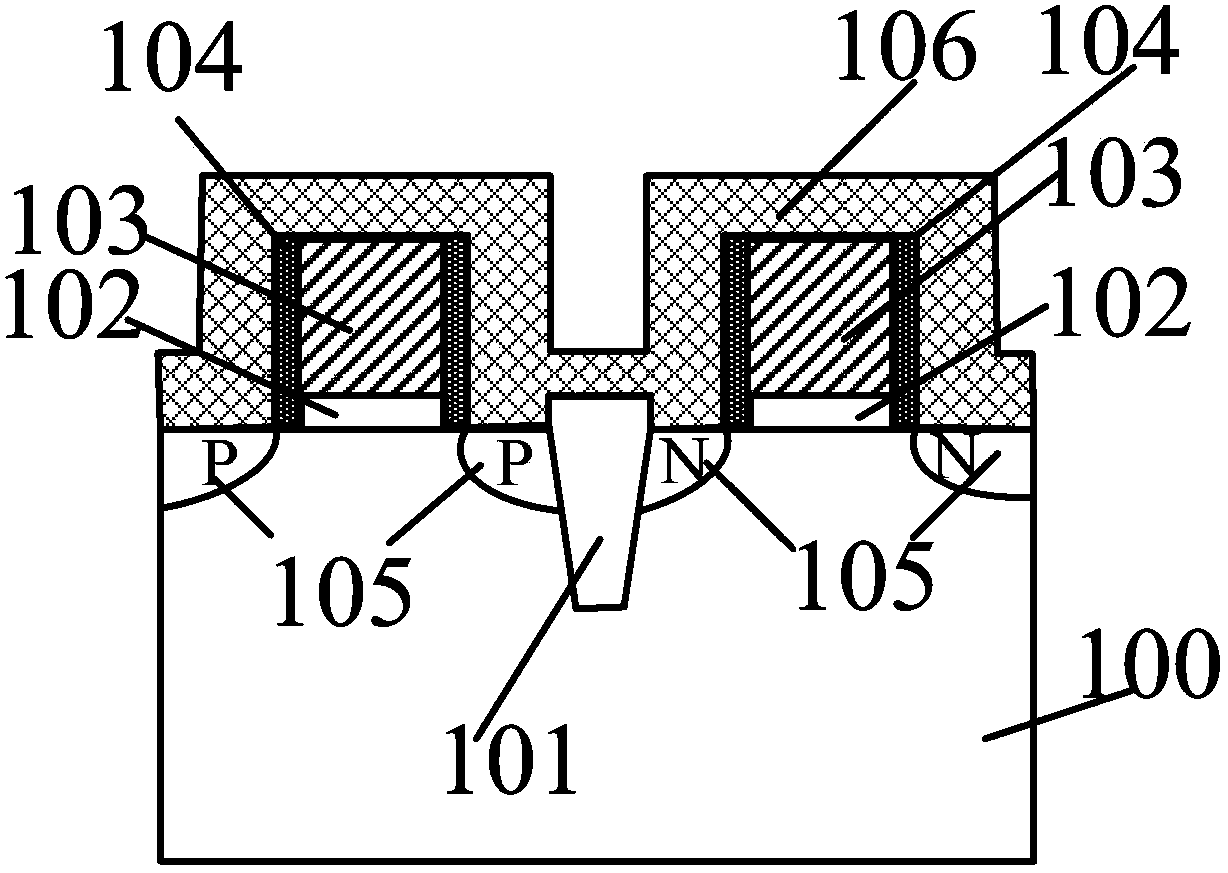

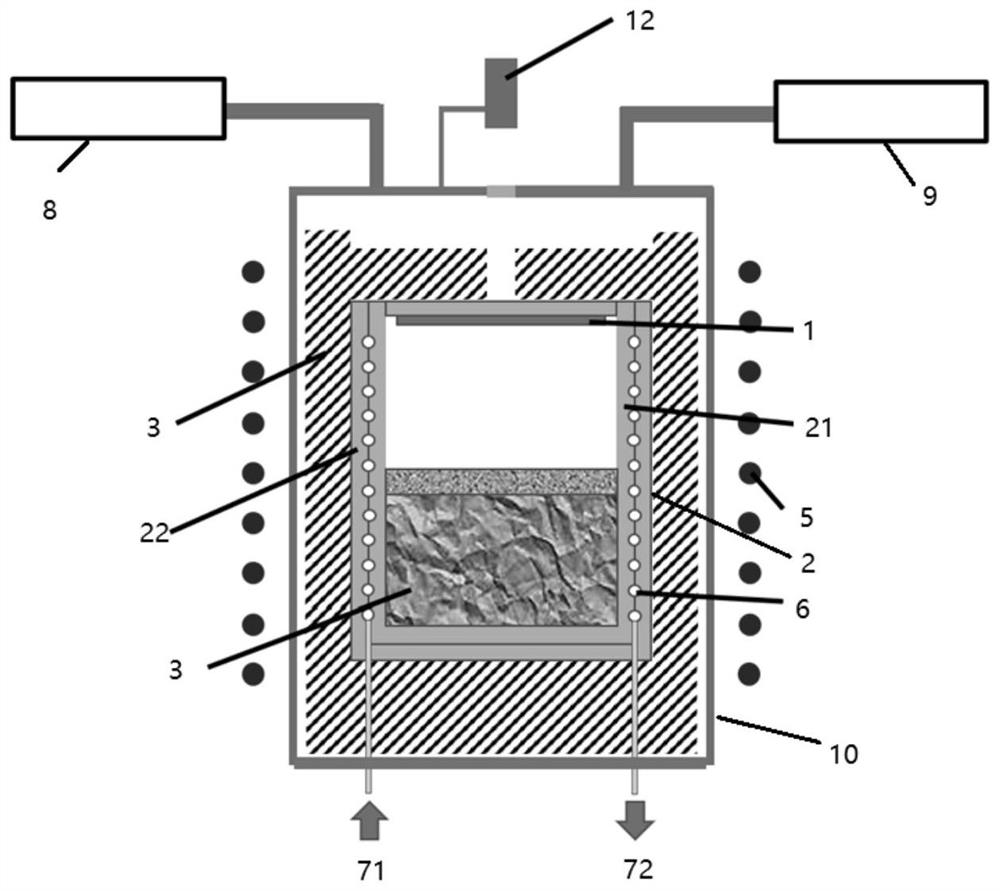

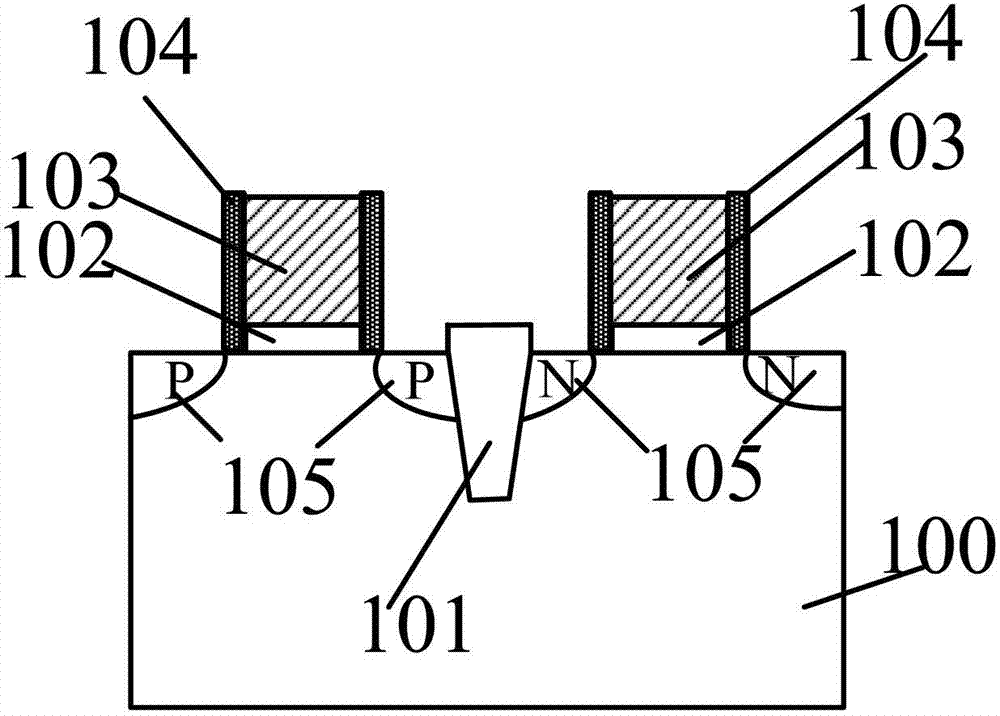

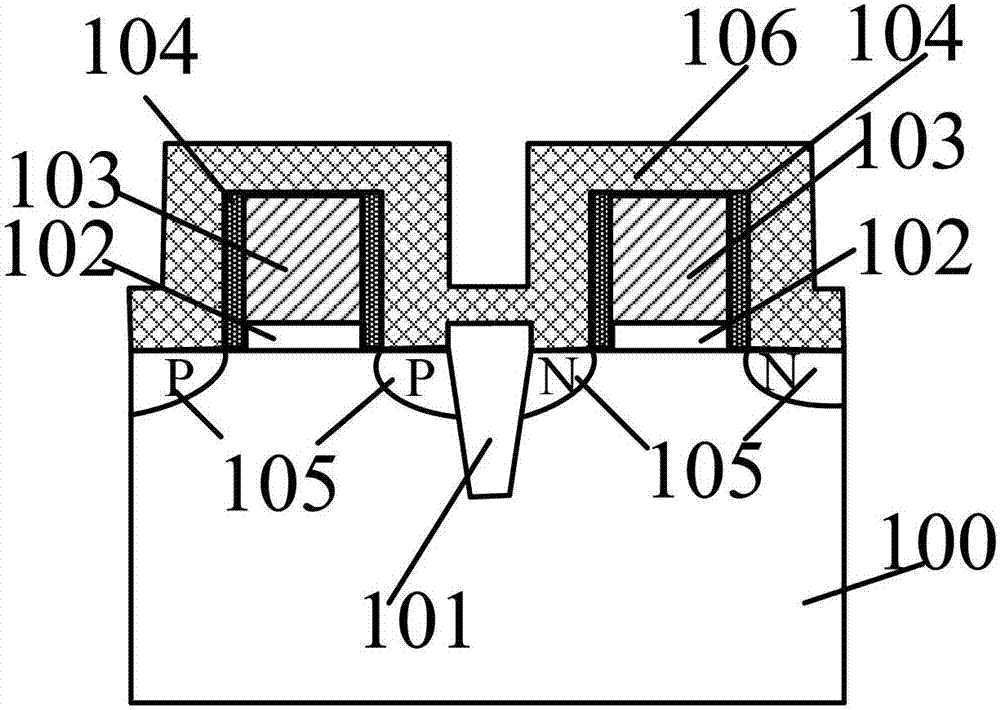

Method for improving gap filling capability of pre-metal dielectric

ActiveCN103681459AChange in growth rateHigh vertical growth rateSolid-state devicesSemiconductor/solid-state device manufacturingDielectricEngineering

The invention discloses a method for improving gap filling capability of a pre-metal dielectric. The method comprises the following steps: taking a shallow groove isolation area in a semiconductor substrate as a boundary, and forming a CMOS structure adopting a PMOS structure and an NMOS structure, wherein both the PMOS structure and the NMOS structure at least comprise gate oxides and polycrystalline silicon grid electrodes formed on the surface of the semiconductor substrate in sequence, side wall layers positioned on the two sides of the polycrystalline silicon grid electrodes and active areas positioned on the two sides of the polycrystalline silicon grid electrodes and in the semiconductor substrate; depositing a stress silicon nitride layer on the surface of the CMOS structure; depositing a silicon oxide layer on the surface of the stress silicon nitride layer, performing anisotropic etching, and reserving a silicon oxide layer on the side walls of the stress silicon nitride layer; performing fluorine treatment on the surfaces of the silicon oxide layer and the stress silicon nitride layer, and improving the growth selection ratio of the pre-metal dielectric on the surface of the stress silicon nitride layer and the surface of the silicon oxide layer; depositing the pre-metal dielectric. Through the adoption of the method, the defect that void is formed between the grid electrodes can be effectively overcome.

Owner:SEMICON MFG INT (SHANGHAI) CORP

A 3D printing device and method for compounding continuous fiber and granular matrix material

ActiveCN112140533BReduce void defectsWide range of optionsManufacturing heating elements3D object support structures3d printedFiber reinforcement

The invention discloses a 3D printing device in which continuous fibers and granular matrix materials are compounded, comprising a nozzle, a hopper, a feeding pipe and a screw. The continuous fibers are transported in the middle. The molten matrix material is located around the continuous fibers, and the continuous fibers are surrounded by molten It is impregnated by the base material, which greatly improves the impregnation effect compared with the existing two-way feeding at the nozzle. The present invention also provides a 3D printing method in which continuous fibers and granular matrix materials are composited, which directly utilizes granular or powdery matrix materials for continuous fiber reinforced printing, which solves the limitation of the traditional wire extrusion process on the form and type of printable matrix materials. Problems, expanding the optional range of matrix materials in fiber reinforced printing; at the same time, there is no need to use a wire drawing machine to make the matrix material into a wire before printing, which simplifies the manufacturing process and reduces equipment and operating costs.

Owner:SHANGHAI UNIV

Silicon carbide single crystal ingot, substrate and preparation method thereof

ActiveCN112626619AUniform resistivityGood electrical propertiesPolycrystalline material growthFrom condensed vaporsCarbide siliconSemiconductor materials

The invention relates to a silicon carbide single crystal ingot, a substrate and a preparation method thereof, and belongs to the field of semiconductor materials. The silicon carbide substrate contains a nitrogen element, the silicon carbide substrate has no more than 50 hexagonal color spots, and the edges forming the hexagonal color spots are perpendicular to the <10-10> direction. The edges of the hexagonal color spots comprise inner side edges and outer side edges, the inner side edges defines a hexagonal area, cavities are formed between the inner side edges and the outer side edges, and the centers of not smaller than 80% of the cavities are located on one side of the central axis between the inner side edges and the outer side edges. The invention provides the nitrogen-containing silicon carbide substrate with novel defects, namely few hexagonal color spots and cavity defects, the resistivity of the silicon carbide substrate is uniform, and a semiconductor device prepared from the silicon carbide substrate is excellent in electrical performance; and the performance of the silicon carbide substrate such as breakdown field intensity is excellent, and the number of cavities generated by extension of the manufactured device is extremely small.

Owner:SICC CO LTD

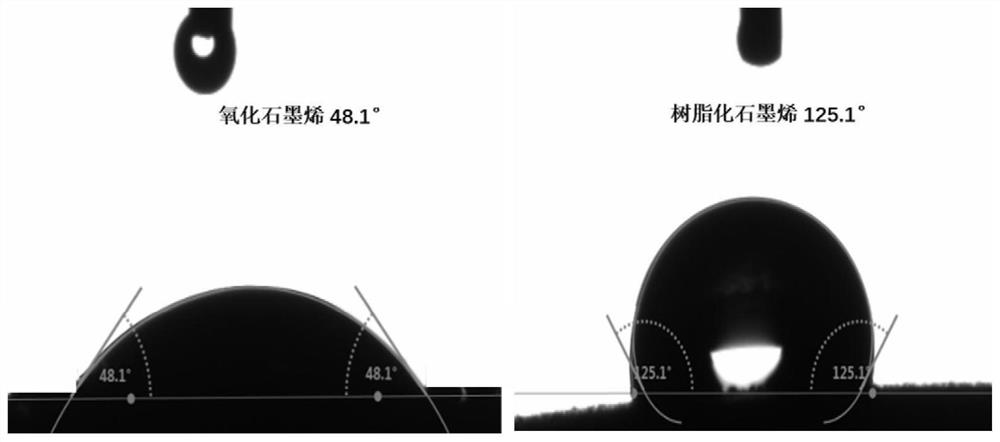

Preparation method of resinified graphene anticorrosive paint based on high-temperature mechanochemistry

PendingCN111777919ARealize chemical reactionReduce void defectsAnti-corrosive paintsPigment treatment with macromolecular organic compoundsCorrosion preventionGraphite oxide

The invention discloses a preparation method of resinified graphene anticorrosive paint based on high-temperature mechanochemistry. The preparation method comprises the following steps: taking graphene or graphene oxide, and adding phenylenediamine into a graphene or graphene oxide aqueous solution for modification pretreatment; adding an organic resin and a solvent, adopting high-temperature mechanochemical method for treatment, and subjecting an obtained solution to centrifugation, suction filtration and drying to obtain a resinified graphene; mixing the resinified graphene with an organic resin, a diluent and an additive, and mechanically stirring to obtain a component A; and uniformly mixing the component A with a component B curing agent to obtain the resinified graphene anticorrosivepaint. According to the invention, the chemical reaction of graphene and the organic resin can be realized through a high-temperature mechanochemical technology; the resinified graphene can be uniformly dispersed in the organic resin, the bonding strength with a film-forming substance is higher, hole defects in a coating are reduced, and the barrier property and mechanical properties of the coating are improved, so that better corrosion resistance is achieved.

Owner:NORTHEASTERN UNIV

Silicon carbide wafer, crystal ingot and preparation method thereof

ActiveCN112501687BReduce in quantityReduce defect densityPolycrystalline material growthFinal product manufactureWaferingSemiconductor materials

Owner:SICC CO LTD

A silica container for pulling up monocrystalline silicon and method for manufacturing same

InactiveCN103649383AAvoid it happening againInhibit growthAfter-treatment apparatusPolycrystalline material growthSilicon dioxideGas bubble

A silica container for pulling up monocrystalline silicon, the silica container having a straight trunk, a curved portion, and a base portion, wherein the silica container for pulling up monocrystalline silicon is characterized in that the outer side of the silica container comprises opaque silica glass containing gas bubbles, and the inner side of the silica container is composed of transparent silica glass substantially devoid of gas bubbles, a silica-glass layer measuring 20 to 1,000 mum in thickness and containing OH groups in a concentration of greater than 300 mass ppm and equal to or less than 3,000 mass ppm or less being formed on the inner surface of the bottom portion. Provided thereby is an inexpensive silica container for pulling up monocrystalline silicon enabling cavity defects, i.e., voids and pinholes, to be minimized in pulled-up monocrystalline silicon.

Owner:SHIN ETABU QUARTZ PRODS

A method for forming a semiconductor structure

PendingCN114068399AImprove performanceImprove reliabilitySemiconductor/solid-state device manufacturingCrystallographySemiconductor structure

A method for forming a semiconductor structure comprises the steps of providing a substrate, where a metal structure is arranged in the substrate, and the metal structure is exposed out of the surface of the substrate; forming a dielectric structure on the surface of the metal structure; forming an opening penetrating through the dielectric structure in the dielectric structure; after the opening is formed, performing densification treatment on the side wall surface of the opening and the surface of the dielectric structure; and after the densification treatment, forming an interconnection structure in the opening by adopting a selective metal growth process. Therefore, the performance and the reliability of the semiconductor device are improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Method for Improving Gap Filling Ability of Pre-Metal Dielectric Layer

ActiveCN103681459BChange in growth rateHigh vertical growth rateSolid-state devicesSemiconductor/solid-state device manufacturingSilicon oxideEngineering

Owner:SEMICON MFG INT (SHANGHAI) CORP

Coating device for mixed solution of precursor and surfactant and use method of coating device

PendingCN110880555AReduce shrinkageIncrease coverageSolid-state devicesSemiconductor/solid-state device manufacturingThin membraneActive agent

The invention relates to a coating device for a mixed solution of a precursor and a surfactant. The device comprises a coating die head, a die head lifting table, a post-processing device, a coating platform and a conveying device, a to-be-coated substrate is coated by the coating die head and then is conveyed to the post-processing device by the conveying device for post-processing, and under thedriving of the conveying device, the relative movement is generated between the die head lifting table and the coating platform. The coating die head is communicated with an injection pump with a mixing cavity through a guide pipe, the injection pump is communicated with at least two raw material bottles, one raw material bottle is filled with a divalent precursor solution, and the other raw material bottle is filled with a surfactant solution. The injection pump respectively and simultaneously sucks the divalent precursor solution and the surfactant solution and injects the divalent precursor solution and the surfactant solution into the mixing cavity for mixing, and the mixed solution is conveyed to the coating die head for use. The invention further discloses a using method and application of the coating device. According to the present invention, the coverage rate of the coating film and the flatness of the surface of the coating film are improved, and the perovskite thin film with more uniform film thickness distribution is obtained.

Owner:HANGZHOU MICROQUANTA SEMICON CO LTD

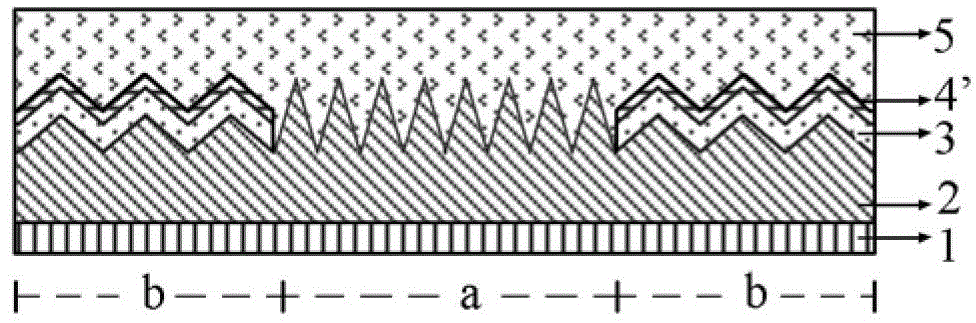

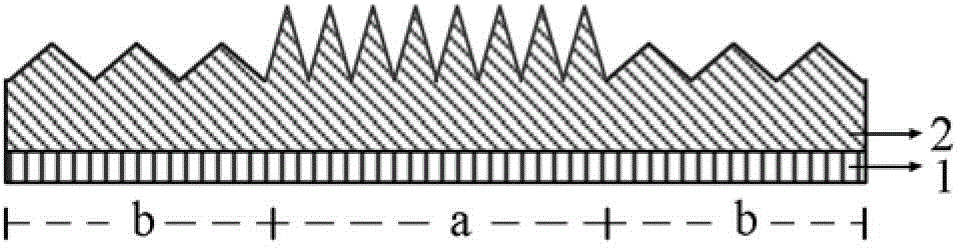

A kind of method for preparing optical anti-counterfeiting element

ActiveCN103963510BLow costSimple processDiffraction gratingsInformation cardsOptical securityMaterials science

Owner:ZHONGCHAO SPECIAL SECURITY TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com