Production method of high-temperature superconductive REBCO film

A high-temperature superconducting and thin-film technology is applied in the field of preparation of high-temperature superconducting REBCO thin films, which can solve the problems of reduced performance of REBCO superconducting thin films, non-oriented nucleation, and excessive liquid phase formation, etc. Superconducting properties, the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The method for preparing the high-temperature superconducting YBCO film in this embodiment comprises the following steps:

[0028] Step 1. Preparation of fluorine-free precursor solution: Dissolve yttrium propionate, barium propionate, and copper propionate in a mixed solvent of propionic acid and ethanol according to the atomic ratio of Y:Ba:Cu=1:1.75:3. Under the condition of stirring for 2h to completely dissolve, the total cation molar concentration is 1.5mol / L fluorine-free precursor solution; the volume ratio of propionic acid and ethanol in the mixed solvent is 1:5.5;

[0029] Step 2, preparation of fluorine-containing precursor solution: dissolve the organic salt of yttrium propionate, barium, copper propionate in the mixed solvent of propionic acid and ethanol by Y:Ba:Cu=1:1.75:3 atomic ratio, at 70 Stirring under the condition of ℃ for 2h until completely dissolved, the fluorine-containing precursor solution with a total molar concentration of cations of 1.8mo...

Embodiment 2

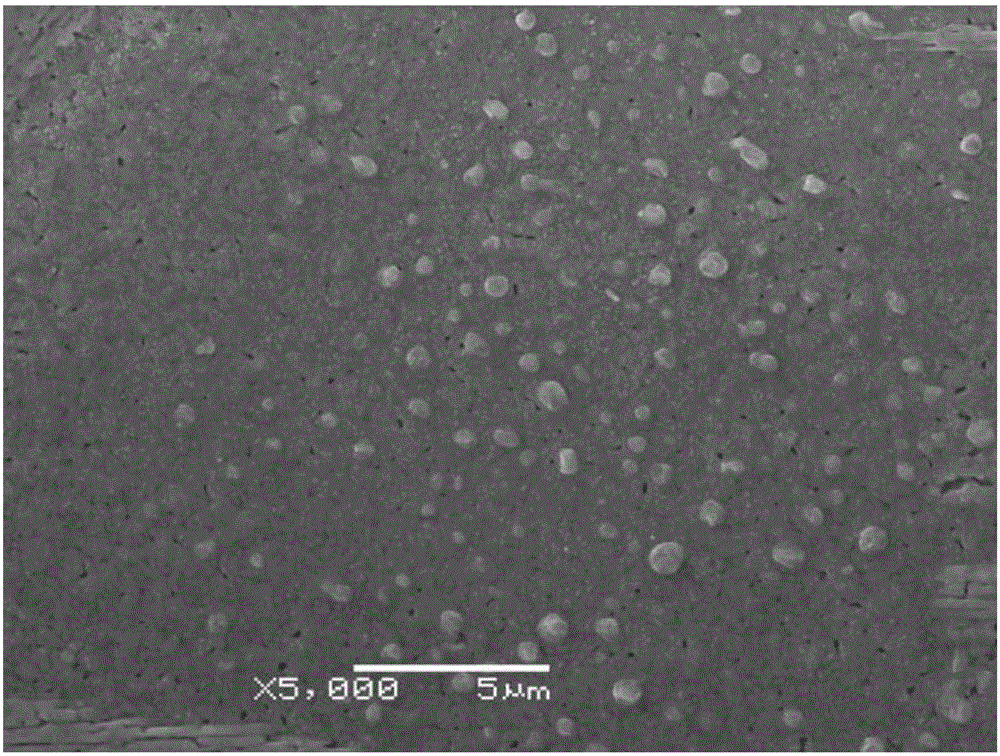

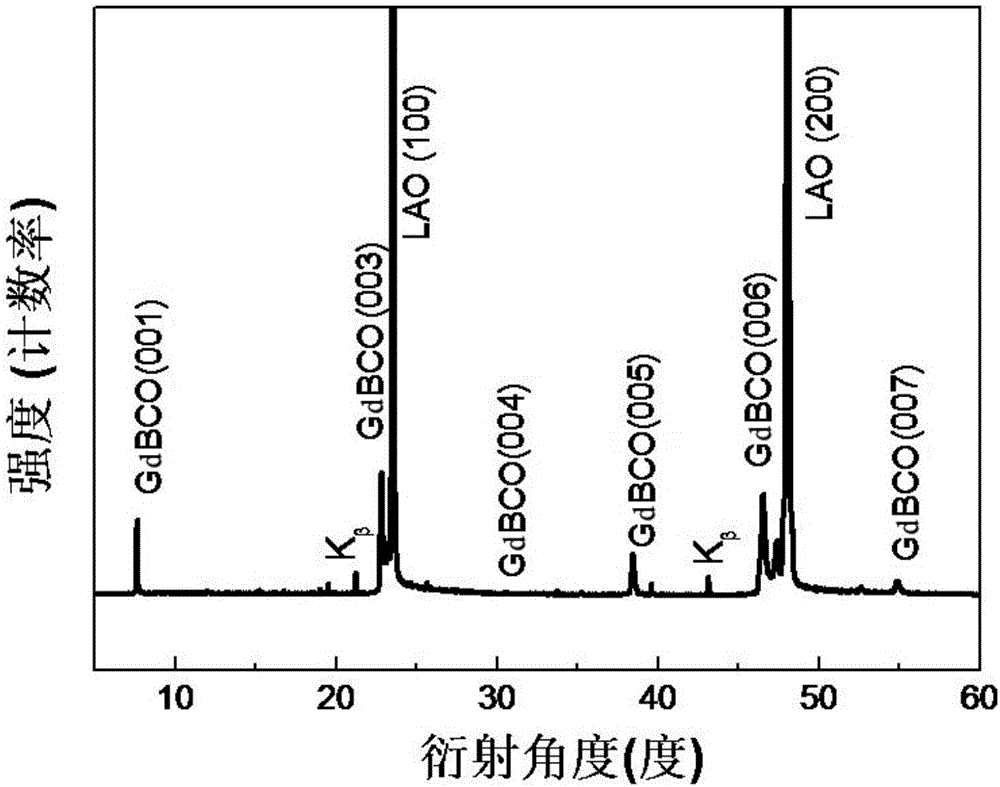

[0036] The method for preparing the high-temperature superconducting GdBCO film in this embodiment comprises the following steps:

[0037] Step 1. Preparation of fluorine-free precursor solution: Dissolve gadolinium propionate, barium propionate, and copper propionate in a mixed solvent of propionic acid and ethanol according to the atomic ratio of Gd:Ba:Cu=1:1.75:3. Under the condition of stirring for 3h to completely dissolve, the total cation molar concentration is 1.5mol / L fluorine-free precursor solution; the volume ratio of propionic acid and ethanol in the mixed solvent is 1:5;

[0038] Step 2, preparation of fluorine-containing precursor solution: dissolving gadolinium propionate, organic salt of barium, and copper propionate in a mixed solvent of propionic acid and ethanol at an atomic ratio of Gd:Ba:Cu=1:1.8:3, Stirring under the condition of ℃ for 3h until completely dissolved, the fluorine-containing precursor solution with a total molar concentration of cations of...

Embodiment 3

[0045] The method for preparing the high-temperature superconducting YBCO film in this embodiment comprises the following steps:

[0046] Step 1. Preparation of fluorine-free precursor solution: Dissolve yttrium propionate, barium propionate, and copper propionate in a mixed solvent of propionic acid and ethanol according to the atomic ratio of Y:Ba:Cu=1:1.75:3. Under the condition of stirring for 1.5h to completely dissolve, the total cation molar concentration is 1.5mol / L fluorine-free precursor solution; the volume ratio of propionic acid and ethanol in the mixed solvent is 1:8;

[0047] Step 2, preparation of fluorine-containing precursor solution: dissolving the organic salt of yttrium propionate, barium, copper propionate in the mixed solvent of propionic acid and ethanol by the atomic ratio of Y: Ba: Cu=1: 1.75: 3, at 80 Stirring under the condition of ℃ for 2h until completely dissolved, the fluorine-containing precursor solution with a total molar concentration of cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com