Preparation method of resinified graphene anticorrosive paint based on high-temperature mechanochemistry

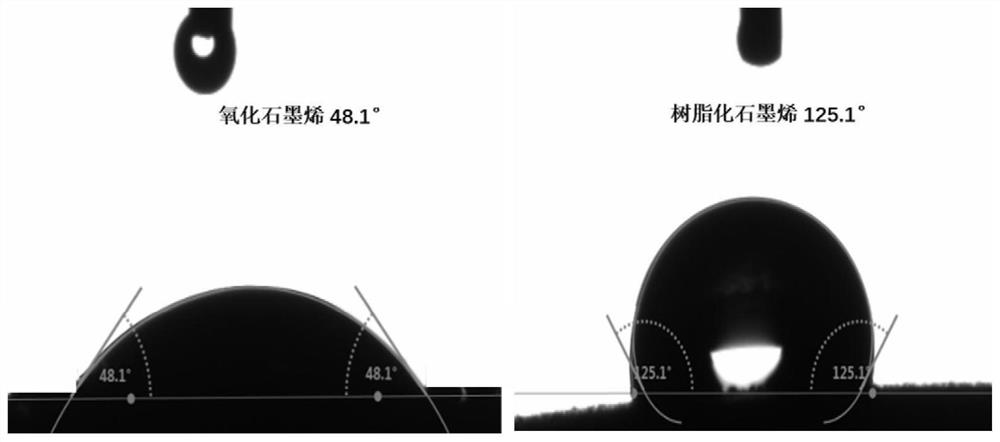

A mechanochemical and anti-corrosion coating technology, applied in anti-corrosion coatings, epoxy resin coatings, chemical instruments and methods, etc., can solve the problem that graphene anti-corrosion coatings cannot achieve the use effect and protective ability, and the compatibility of oily organic coatings is poor. , graphene fillers are easy to agglomerate, etc., to achieve good coating anti-corrosion effect and compactness, good anti-corrosion ability, and the effect of reducing hole defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In the present embodiment, the specific steps of the preparation method of the resinized graphene anticorrosion coating based on high temperature mechanochemistry are as follows:

[0025] (1) get graphene or graphene oxide and add phenylenediamine in described graphene or graphene oxide aqueous solution and carry out modification pretreatment;

[0026] (2) Get pretreated graphene or graphene oxide in step (1) and add organic resin and solvent, adopt high-temperature mechanochemical method to process, gained solution obtains resinized graphite after centrifugation, suction filtration, drying alkene;

[0027] (3) Resinized graphene is mixed with organic resin, diluent and additive in step (2), and A component is obtained after mechanical stirring;

[0028] (4) The A component and the B component curing agent are evenly mixed to obtain the resinized graphene anticorrosion coating. In step (1), the phenylenediamine can be one or more of its three isomers—n-phenylenediamin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com