A kind of method for preparing optical anti-counterfeiting element

An optical anti-counterfeiting and component technology, which is applied in the direction of optical components, optics, diffraction gratings, etc., can solve the problems of difficult quality control, low efficiency, inability to precisely and accurately locate and remove metal hollowing, and achieve low cost, simple process, and feasible process Strong performance and process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the technical solution of the present invention, the flow of the method for preparing an optical anti-counterfeiting element according to the present invention will be described in detail below in conjunction with the accompanying drawings.

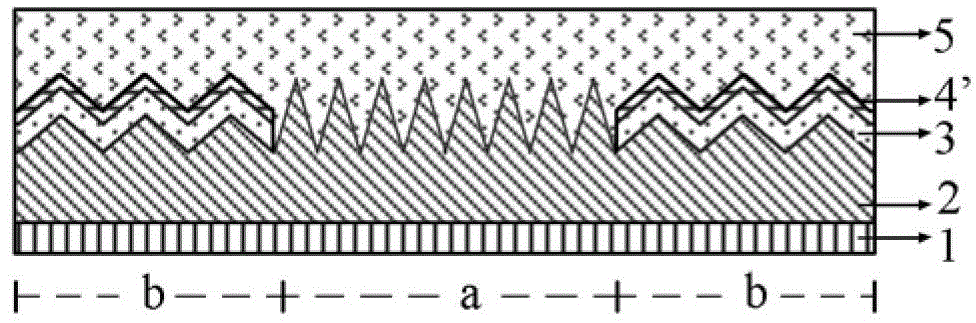

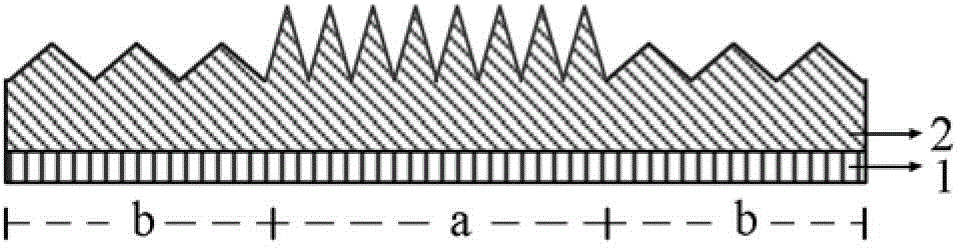

[0020] In order to describe more vividly the method for preparing an optical anti-counterfeiting element according to the present invention, we form figure 1 and figure 2 The exemplary optical security element shown is taken as an example to describe the method according to the present invention, wherein figure 1 is a top view of an exemplary optical security element, figure 2 is along figure 1 An exemplary cross-sectional view as seen on the X-X line, figure 1 The text part in is the display area, which is the same as figure 2 Corresponding to the area b in , in general, for the purpose of anti-counterfeiting, the display area often adopts images with special ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| optical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com