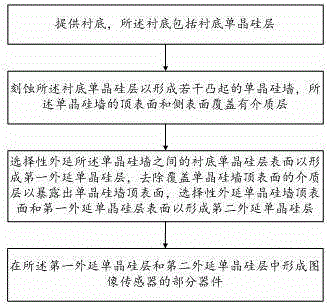

Manufacturing method of image sensor using deep trench isolation

An image sensor and deep trench isolation technology, applied in the field of image sensors, can solve the problems affecting the quality of epitaxial single crystal silicon, dislocation or void defects, etc., and achieve the effect of good shape, not easy to dislocation and void, and excellent interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

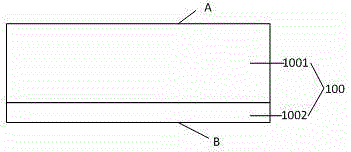

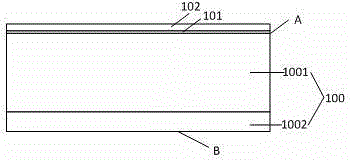

[0019] In the production process of the existing image sensor, an isolation structure composed of a dielectric layer is first formed on the substrate, and then an epitaxial monocrystalline silicon layer covering the isolation structure is formed by selective epitaxy. Since the width of the isolation structure is usually large ( about 100-300nm), when the epitaxial monocrystalline silicon layers grown from the substrate surfaces on both sides of the isolation structure meet at the top of the isolation structure, it is easy to generate dislocations or void defects at the junction, thereby affecting the epitaxial monocrystalline silicon the quality of.

[0020] Therefore, the present invention proposes a method for making an image sensor using deep trench isolation. Before forming an image sensor device, a single crystal silicon wall covered with a dielectric layer is formed on the top surface and side surface as an isolation structure. The surface shape of the isolation structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com