Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85 results about "Di-t butyl peroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

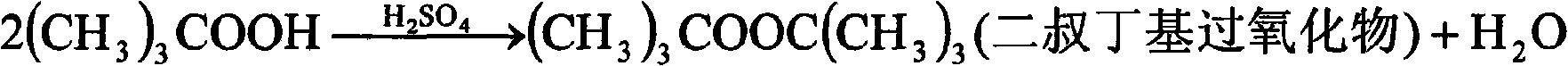

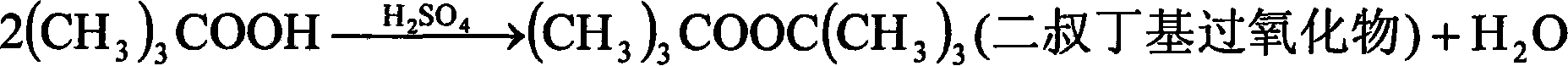

Preparation of tert-butyl hydrogen peroxide and di-tert-butyl peroxide

ActiveCN101298429AMild reaction conditionsHigh yieldOrganic chemistryDi-tert-butyl peroxideOil phase

The invention discloses a preparation method of tert-butyl hydroperoxide and di-t-butyl peroxide which includes the following steps: after mixing vitriol, oxyful and phosphotungstic acid with certain concentration, adding tertiary butyl alcohol into a mixed liquor or adding the mixed liquor into the tertiary butyl alcohol; reacting for 0.5 to 5 hours under 20 to 60 DEG C; obtaining an oil phase after carrying out liquid separation on the crude product of the reaction; obtaining the tert-butyl hydroperoxide and di-t-butyl peroxide products by carrying out decompressing and rectifying on the oil phase; the method has the advantages of simple and convenient operation, low manufacture cost, safety, high efficiency and high yield; in addition, the method of the invention can adjust the relative content of the two reaction products by changing the reaction conditions. The reaction products of tert-butyl hydroperoxide and di-t-butyl peroxide are separated by decompressing and rectifying, thus avoiding the working procedures of acid cleaning and caustic wash in the traditional technique, solving the defect of overlarge waste water amount in the traditional technique, being beneficial to protecting the environment, reducing the manufacture cost and being capable of greatly increasing the enterprise benefits.

Owner:ZHEJIANG JINKE CHEM

Peroxide crosslinking polyethylene tubes and machining method thereof

ActiveCN102093580AGood thermal creep resistanceStrong impact resistanceTubular articlesMicrometerAntioxidant

The invention relates to peroxide crosslinking polyethylene tubes and a machining method thereof. The polyethylene tubes comprise the following components in percentage by mass: 0.5 to 0.6 percent of peroxide di-tert-butyl ether, 0.3 percent of antioxidant and the balance of polyethylene powder, wherein the average particle size distribution of the polyethylene powder is between 200 and 300 micrometers, the bulk density is between 0.35 and 0.40 g / cm<3>, the density is between 0.947 and 0.950 g / cm<3>, and the polyethylene powder has a uniform short-branched chain structure; the crosslinking degree of the peroxide crosslinking polyethylene tubes is more than or equal to 80 percent; and the particle size of the polyethylene powder for forming the tubes by crosslinking can be distributed relatively and reasonably without subsequent crushing, and the same and even higher crosslinking degree can be reached in the crosslinking process under the condition of less peroxides. The polyethylene tubes have high heat-resisting creep properties, high impact resistance, high swelling performance and the like.

Owner:PETROCHINA CO LTD

Method for operating compression ignition internal combustion engine

InactiveUS20060185644A1Improve flammabilityShorten the overall cycleNon-fuel substance addition to fuelInternal combustion piston enginesHomogeneous charge compression ignitionDi-tert-butyl peroxide

An object is to provide a method for operating a compression ignition internal combustion engine which, using a single fuel, can produce diesel combustion when the load is high, or homogeneous-charged compression ignition combustion when the load is low. The operating method includes: employing a fuel containing 95 to 99.5 wt. % of a base fuel made of one or more compounds selected from the group consisting of a hydrocarbon, an alcohol, an ether and a fatty ester, and 0.1 to 5 wt. % of an additive made of one or more compounds selected from the group consisting of an organic peroxide, a nitric ester, a nitrite ester and an azo compound; and producing diesel combustion when the load is high, or homogeneous-charged compression ignition combustion when the load is low. The organic peroxide is di-tert-butyl peroxide. The nitric ester is n-pentyl nitrate. The nitrite ester is n-pentyl nitrite. The azo compound is 2,2-azobis(2,4-dimethylvaleronitrile).

Owner:HONDA MOTOR CO LTD

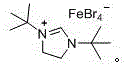

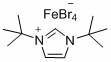

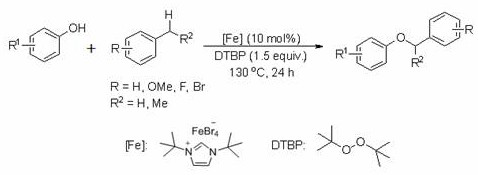

Method for preparing carboxylate compounds

ActiveCN105481695AHigh yieldReduce dosageOrganic compound preparationCarboxylic acid esters preparationPtru catalystTert butyl

The invention discloses a method for preparing carboxylate compounds. According to the method, an ionic iron (III) complex which has a molecular formula of [(tBuNCH2CH2NtBu)CH][FeBr4] and contains 1,3-di-tert-butyl-imidazoline cations is taken as a catalyst, di-tert-butyl peroxide is taken as an oxidizing agent, and corresponding benzyl ester carboxylate or allylic ester carboxylate is synthesized by respectively carrying out oxidative cross-coupling on carboxylic acid and alkylbenzene, methyl heterocyclic aromatic hydrocarbon and allyl hydrocarbon compounds; applicable carboxylic acid substrates relate to aliphatic carboxylic acid, aromatic carboxylic acid and heterocyclic carboxylic acid, and applicable hydrocarbon compounds relate to benzyl type compounds and allyl type compounds. The method is the first case for preparing carboxylate by virtue of the oxidative cross-coupling of carboxylic acid, alkylbenzene, methyl heterocyclic aromatic hydrocarbon and allyl hydrocarbon compounds through iron-based catalysts; compared with literature reports, the method has the advantages that the catalytic efficiency is relatively high, and the substrate applicability is relatively wide.

Owner:东营悦来湖园区运营管理有限公司

Synthesis of gamma-undecalactone

The invention discloses a method for synthesizing gamma-undecalactone, which belongs to a synthesis technology of the gamma-undecalactone. The method takes n-octanol as a solvent, boric acid or zinc bromide as a catalyst, acrylic acid as a raw material and di-t-butyl peroxide or dibenzoyl peroxide as an initiator, and comprises the following steps: firstly, adding partial n-octanol and the catalyst into a reaction kettle to be mixed and heated; secondly, mixing the remaining n-octanol, the initiator and the acrylic acid and dipping the mixture into the reaction kettle; thirdly, making the mixture react for a period; and finally obtaining reaction liquid containing the gamma-undecalactone. The method has the advantages that the reaction is carried out at normal pressure, byproducts of tert-butyl alcohol are easy to discharge from a system during the reaction process, and simultaneously the equipment used by the method is simple, the synthesis cost is low and the yield of the gamma-undecalactone is high.

Owner:TIANJIN UNIV

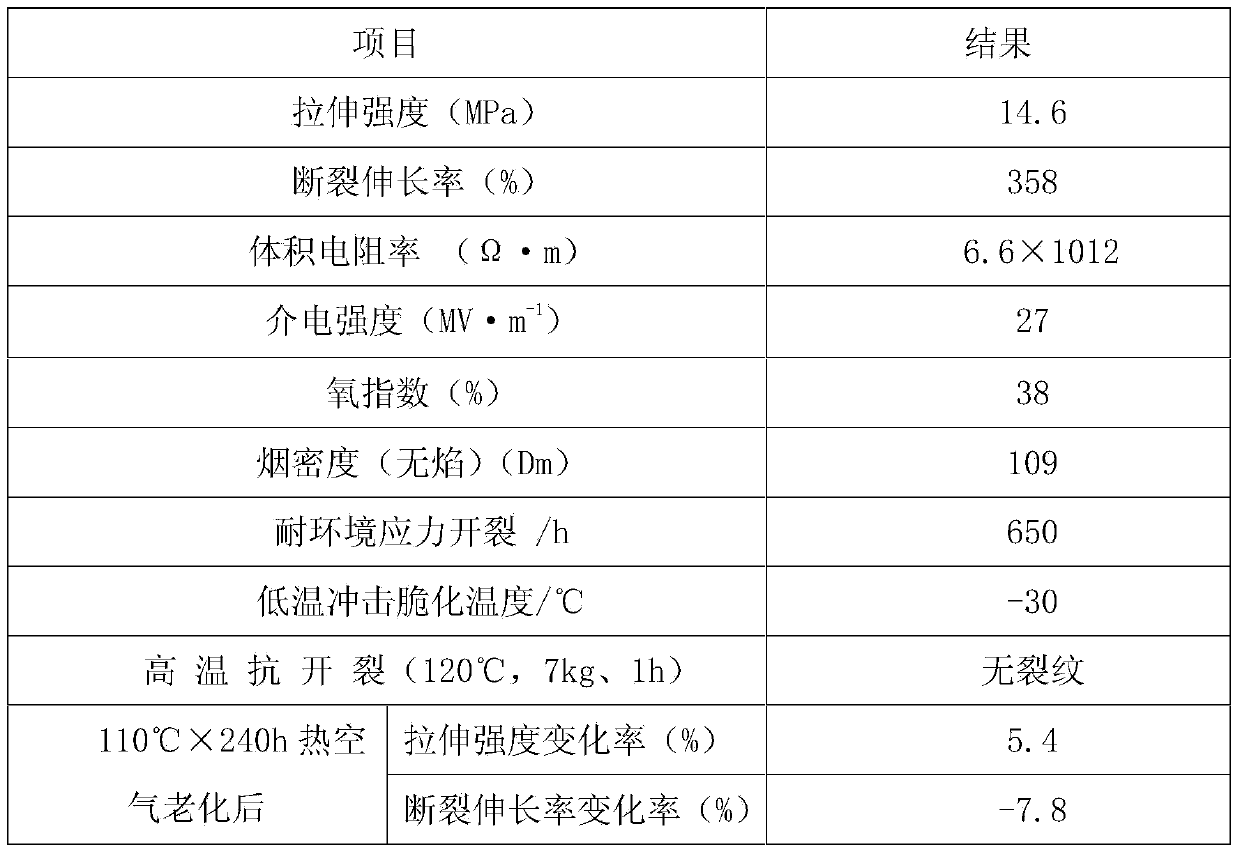

Anti-cracking silicone rubber cable material and preparation method thereof

InactiveCN103467998AGuaranteed insulation performanceGuaranteed flame retardant performanceRubber insulatorsCrack resistanceNano al2o3

The invention discloses an anti-cracking silicone rubber cable material and a preparation method of the material. The anti-cracking silicone rubber cable material is prepared by the following raw materials in parts by weight: 65-75 parts of methyl vinyl silicone rubber, 20-30 parts of nylon 66, 10-15 parts of isotactic polypropylene, 15-20 parts of magnesium hydrate, 5-10 parts of sodium molybdate, 8-12 parts of melamine cyanurate, 2-3 parts of magnesium oxide, 10-15 parts of diisononyl phthalate, 1.5-2.5 parts of methyl tin mercaptide, 5-8 parts of polyethene wax, 0.5-1.5 parts of antioxidant BHT (butylated hydroxytoluene), 0.8-1.2 parts of valcanizer DTBP (di-t-butyl peroxide), 1-2 parts of accelerator TETD (tetraethylthiuram disulfide), 0.5-1.5 parts of scorch retarder CTP (cytidine triphosphate), 15-20 parts of carbon black N660, 12-18 parts of vermiculite powder, 5-10 parts of nano aluminum oxide and 4-7 parts of composite packing. The cable material has excellent cracking resistance and mechanical properties, is free from cracking in a low temperature impact test at -30 DEG C, a high temperature impact test at 120 DEG C and a bending test, can be applied to harsh environments such as low temperature, salt mist, wetness, hot and mould, and is durable in use.

Owner:JING FENG GRP

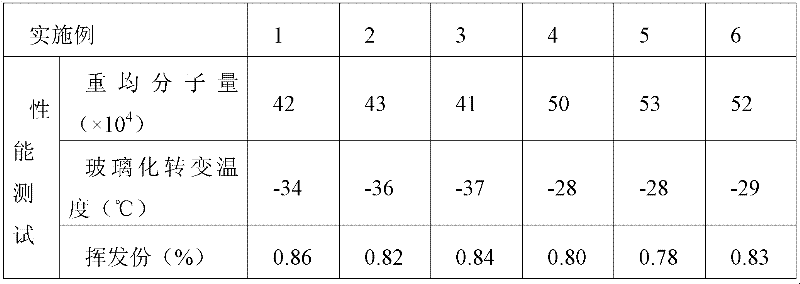

Method for preparing polyacrylate rubber through continuous solution polymerization and devolatilization extrusion

The invention discloses a method for preparing acrylate rubber through continuous solution polymerization and devolatilization extrusion, belonging to synthetic technique of polyacrylate rubber and solving the problems in conventional preparation methods of polyacrylate rubber that the pressure during the polymerization process is high and that the solvent of the polymerisates cnnot be easily got rid of in later period. According to the method disclosed by the invention, acrylate monomer and a small amount of monomer with crosslinking active groups are taken as the raw materials to prepare polyacrylate rubber through the methods of continous solution polymerization and devolatilization extrusion in a solvent under the action of initiator. The acrylate monomer is one or the mixture of methyl acrylate, ethyl acrylate or butyl acrylate; the monomer with crosslinking active groups is epoxypropyl methacrylate; the initiator is benzoyl peroxide or di-t-butyl peroxide; and the solvent is toluene or ethyl acetate. The content of the residual volatile in the acrylate rubber prepared through the method disclosed by the invention is lower than 1% of the content of acrylate rubber.

Owner:CHANGCHUN UNIV OF TECH

LDPE (Low-density polyethylene)/EVA (ethylene-vinyl acetate copolymer)/CPE (chlorinated polyethylene) composite foam material and preparation method thereof

ActiveCN103102567AImprove interfacial bond strengthHigh tensile strengthLow-density polyethylenePhosphoric Acid Esters

The invention discloses an LDPE (low-density polyethylene) / EVA (ethylene-vinyl acetate copolymer) / CPE (chlorinated polyethylene) composite foam material. The foam material is prepared from the following raw materials in parts by weight: 80-100 parts of LDPE, 30-40 parts of EVA, 20-30 parts of CPE, 10-20 parts of talcum powder, 10-15 parts of nanometer potassium feldspar powder, 2-3 parts of bis(dioctyl pyrophosphate) ethylene titanate, 1-2 parts of vinyl tri(beta-methoxyethoxy) silane, 5-10 parts of zinc borate, 5-8 parts of diethyl azodicarboxylate, 5-8 parts of tributyl citrate, 1-1.5 parts of di-tert-butyl peroxide, 2-3 parts of zinc oxide, 1-2 parts of stearic acid, 1-2 parts of tribasic lead sulfate, 2-3 parts of polyethylene wax, 3-5 parts of modified wood ash, 1-2 parts of ultraviolet light absorber UV-531 and 2-3 parts of antioxidant 1035. The produced LDPE foam material is light and soft, has high strength, good resilience, an ideal foaming effect, uniform, fine and dense pores and good flame retardance, is resistant to chemical corrosion and aging and is durable in use.

Owner:HEFEI LANGSHENG NOVEL MATERIAL CO LTD

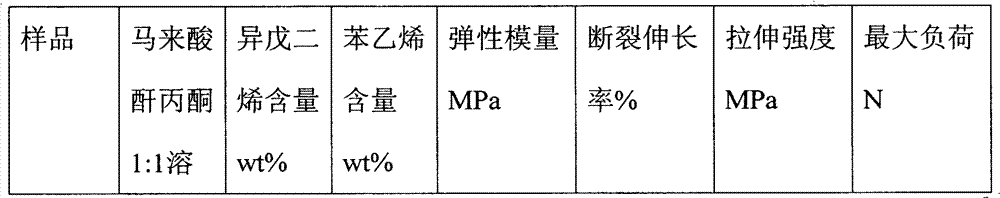

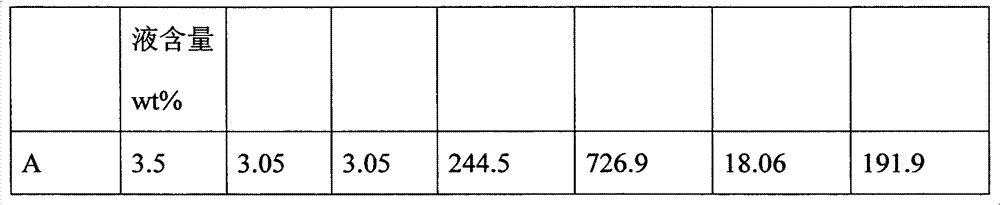

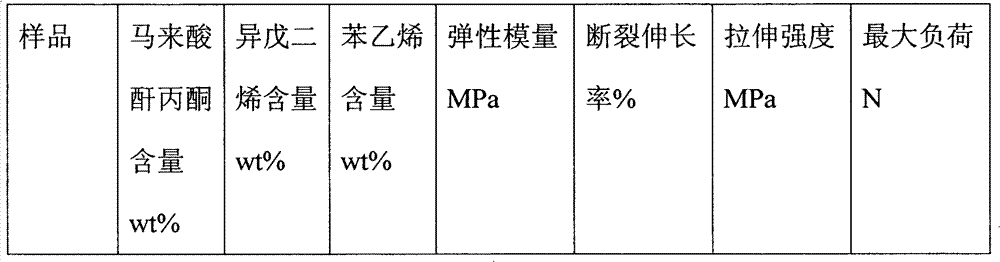

Method for preparing styrene/isoprene/maleic anhydride multi-block polymer with polyolefin as carrier

The invention relates to a method for preparing a styrene / isoprene / maleic anhydride multi-block polymer through reactive extrusion. Raw materials for the polymer comprise polyolefin, maleic anhydride, styrene, isoprene and a peroxide initiator, i.e., a di-tert-butyl peroxide compound. The method is characterized in that: polypropylene is added from a main feeding inlet at a first section of a twin-screw extruder; maleic anhydride and the initiator are dissolved in acetone and are added from a liquid feeding inlet at a third section of the extruder through a pipeline and a metering pump; isoprene and styrene are simultaneously added from the liquid feeding inlet at the third section of the extruder through another pipeline and another metering pump, temperature of a reaction section of the extruder is controlled to be 170 to 230 DEG C, and then polymerization is carried out. Compared with the prior art, the invention has the advantage that bulk polymerization is carried out on monomers by directly using the twin-screw extruder as a reactor. Meanwhile, the reactive extrusion method provided by the invention can prepare the styrene / isoprene / maleic anhydride polymer grafted on polypropylene, and the polymer can be used as an adhesive.

Owner:EAST CHINA UNIV OF SCI & TECH

Paint special for high density plate material and its preparation method

InactiveCN1903955AGood weather resistanceImprove water resistanceLiquid surface applicatorsCoatingsCyclohexanoneAdjuvant

The present invention relates to a special-purpose coating for high-density plate material and its preparation method. It is made up by mixing high-molecular film-forming material, pigment, adjuvant and solvent. It is characterized by that the main component of high-molecular film-forming material of said coating is formed from (by weight portion) 40-50 portions of butyl methacrylate (BMA), 30-40 portions of styrene (ST), 10-20 portions of hydroxyethyl methacrylate (HEMA), 0.1-0.5 portion of methyl acrylic acid (MAA), 1-5 portions of initiating agent di-t-butyl peroxide (DTBP), 1-5 portions of organic silicon compound and 1-5 portions of chlorinated polypropylene. The described mixed solvent includes 60-90 portions of butyl acetate, 20-28 portions of cyclohexanone, and 1-6 portions of limonene, in which the fire-resisting agent and UV-ray absorbing agent can be added.

Owner:TIANJIN LIUHONG TECH DEV

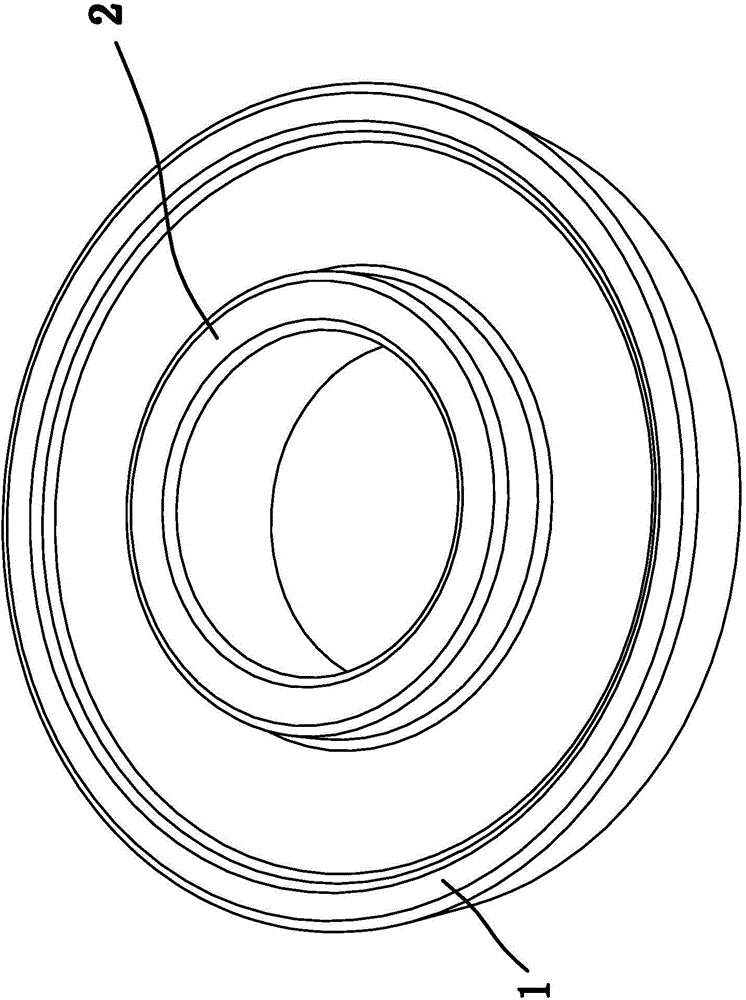

O-shaped seal ring for automobile fuel pump and manufacturing process of O-shaped seal ring

InactiveCN104945695AReasonable raw materialsReasonable formulaPump componentsPumpsVulcanizationDi-tert-butyl peroxide

The invention provides an O-shaped seal ring for an automobile fuel pump and a manufacturing process thereof, and solves the technical problems that a conventional rubber seal ring cannot be normally used in low-temperature or high-temperature environments, is poor in high-low temperature resistance and has no manufacturing process. The O-shaped seal ring for the automobile fuel pump comprises a circular-ring-shaped seal ring body, wherein a sealing lip is arranged in the middle of the seal ring body and extends outwards; the seal ring body and the sealing lip adopt an integral structure; the seal ring body comprises butadiene-acrylonitrile rubber, sulfur, an antiager mercaptobenzimidazole, zinc oxide, stearic acid, paraffin oil, alumina powder, dibutyl phthalate, an acid-base balance agent, and a vulcanization accelerator di-t-butyl peroxide. The invention also provides a manufacturing process of the O-shaped seal ring. The O-shaped seal ring has the advantages of good high-low temperature resistance and high yield.

Owner:HAINING ZHONGTENG AUTOMOTIVE SEALS

Methanol gasoline additive

InactiveCN104449904AReduce pollutionIncrease motivationLiquid carbonaceous fuelsOil additiveDiethyl ether

The invention discloses a methanol gasoline additive which is prepared from the following raw materials in parts by weight: 6-14 parts of di-tert-butyl peroxide, 3-8 parts of naphtha, 5-9 parts of hydroquinone, 4-7 parts of propyl alcohol, 6-11 parts of acetylacetone, 3-9 parts of methyl tertiary butyl ether, 4-6 parts of benzotriazole, 1-5 parts of octadecylamine, 4-7 parts of liquefied petroleum gas, 2-6 parts of butane, 3-5 parts of carbon 12, 3-5 parts of ethanol, 4-9 parts of diethyl ether and 1-5 parts of isopropyl alcohol. The methanol gasoline additive disclosed by the invention has the beneficial effects of improving the power, simultaneously increasing the utilization rate of fuel oil and reducing pollution to air.

Owner:QINGDAO KANGTAIXIN ENVIRONMENTAL PROTECTION TECH

Heat-dissipation coating containing nanometer diatomite

The invention discloses a heat-dissipation coating containing nanometer diatomite. The heat-dissipation coating comprises the following raw materials in parts by weight: 40-50 parts of a material A and 50-60 parts of a material B, wherein the material A comprises the following raw materials in parts by weight: 40-50 parts of ketone-aldehyde resin, 1-2 parts of a diffusing agent NNO, 2-4 parts of beryllium oxide, 0.3-0.5 part of Urotropine, 1-2 parts of nanometer diatomite powder, 1-2 parts of di-t-butyl peroxide, 2-4 parts of nanometer titanium dioxide, 2-5 parts of zeolite powder, 1-2 parts of sorbitol ester and 3-5 parts of dimethicone. The heat-dissipation coating disclosed by the invention has the advantages of high cooling performance and convenience in application, and is used for decreasing the surface temperature of glass lamps and other objects to achieve the cooling effect, and a preferable protection effect is achieved by the reasonable combination and synergistic action of inorganic materials containing nanometer diatomite and the like and rest materials.

Owner:ANHUI MENGNIU COLOR PRINTING&PACKAGING

Preparation of tert-butyl hydrogen peroxide and di-tert-butyl peroxide

The invention discloses a preparation method of tert-butyl hydroperoxide and di-t-butyl peroxide which includes the following steps: after mixing vitriol, oxyful and phosphotungstic acid with certain concentration, adding tertiary butyl alcohol into a mixed liquor or adding the mixed liquor into the tertiary butyl alcohol; reacting for 0.5 to 5 hours under 20 to 60 DEG C; obtaining an oil phase after carrying out liquid separation on the crude product of the reaction; obtaining the tert-butyl hydroperoxide and di-t-butyl peroxide products by carrying out decompressing and rectifying on the oil phase; the method has the advantages of simple and convenient operation, low manufacture cost, safety, high efficiency and high yield; in addition, the method of the invention can adjust the relative content of the two reaction products by changing the reaction conditions. The reaction products of tert-butyl hydroperoxide and di-t-butyl peroxide are separated by decompressing and rectifying, thus avoiding the working procedures of acid cleaning and caustic wash in the traditional technique, solving the defect of overlarge waste water amount in the traditional technique, being beneficial to protecting the environment, reducing the manufacture cost and being capable of greatly increasing the enterprise benefits.

Owner:ZHEJIANG JINKE CHEM

Application of iron (III) complex containing 1,3-di-tert-butyl imidazole cations in synthesis of aryl benzyl ether compounds

ActiveCN112694375AOxidative couplingReduce usageOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHalohydrocarbonPtru catalyst

The invention discloses an application of an iron (III) complex containing 1,3-di-tert-butyl imidazole cations in synthesis of aryl benzyl ether compounds, and particularly relates to a method for synthesizing corresponding aryl benzyl ether compounds by taking di-tert-butyl peroxide as an oxidizing agent and carrying out oxidative coupling reaction on phenolic compounds and toluene compounds. According to the method, the iron (III) complex is used as the catalyst for the first time, and oxidative coupling of the phenolic compound and the toluene compound is realized. The method is the first oxidative coupling reaction of phenolic compounds and benzyl C(sp3)-H bonds, and a new method is provided for synthesizing aryl benzyl ether compounds. Compared with an existing synthesis method, the method provided by the invention avoids using toxic and polluting halogenated hydrocarbon and strong base, has better atom economy, and conforms to the development concept of green synthetic chemistry.

Owner:SUZHOU UNIV

High temperature-resisting anti-corrosion cable for ship

The invention discloses a high temperature-resisting anti-corrosion cable for a ship. The high temperature-resisting anti-corrosion cable comprises a conductor and a jacket layer sleeved on the outer side of the conductor, wherein the jacket layer comprises the following raw materials in parts by weight: 25-35 parts of fluorinated silicone rubber, 70-90 parts of chlorinated rubber, 1.4-2 parts of 202 resin, 1.4-2.2 parts of di-tert-butyl peroxide, 25-35 parts of shell powder, 25-45 parts of modified asbestos fiber, 1.5-2.5 parts of polyphenylene sulfide, 4-6 parts of phenyl triethoxy silane, 0.6-1 part of coal tar, 0.4-0.8 part of epoxidized soybean oil, 0.4-0.8 part of epoxy rice bran butyl oleate, 1-2 parts of disproportionated rosin, 4-10 parts of saw dust, 1.5-2.5 parts of gamma-(ethylenediamine) propyl methyl dimethoxy silane, 1-1.6 parts of butyl titanate and 1.5-3.5 parts of maleic anhydride. The high temperature-resisting anti-corrosion cable for the ship, provided by the invention, has excellent corrosion resistance and is easy to degrade after being abandoned.

Owner:JINYUAN ELECTRIC GRP

Cold-resistant and antibacterial plastic

InactiveCN103665646AHas natural antibacterial ingredientsImprove antibacterial propertiesFuranPolyvinyl chloride

The invention relates to a cold-resistant and antibacterial plastic which comprises components of raw materials in parts by weight as follows: 100 parts of PVC (polyvinyl chloride), 15 parts of cylindrin, 6 parts of modified calcium chloride, 5 parts of talcum powder, 3 parts of sodium chloride, 3 parts of sodium sulfate, 3 parts of calcium sulfate, 3.5 parts of modified nano calcium carbonate, 2.5 parts of di-tert-butyl peroxide, 1.5 parts of furocoumarin, 1.5 parts of beta-sitosterol, 1 part of lactone of bamboo leaves and 1 part of phenolic ketone of bamboo leaves. The plastic comprises natural antibacterial ingredients, has a durable antibacterial effect and is resistant to low temperature, and the cold-resistant temperature can be up to subzero 60 DEG C.

Owner:QINGDAO KECHUANG PLASTIC MACHINERY

Environmental-friendly waterproof cable material for computer

InactiveCN105778367AIncrease the degree of cross-linkingImprove toughnessPlastic/resin/waxes insulatorsEnvironmental resistanceBenzoyl peroxide

The invention discloses an environmental-friendly waterproof cable material for a computer. The environmental-friendly waterproof cable material is prepared from the following components in parts by weight: 50-80 parts of polytetrafluoroethylene, 1-2 parts of nilox resin, 0.4-0.9 part of polyphenylene sulfide, 0.5-1.5 parts of polybenzoate, 1-3 parts of magnesium stearate, 0.5-1.2 parts of antimonous oxide, 1-2 parts of C5 petroleum resin, 0.5-1.5 parts of coal tar, 2-8 parts of nanometer talcum powder, 10-16 parts of modified microcrystalline cellulose, 0.5-1.2 parts of di-tert-butyl peroxide, 0.5-1.2 parts of 2,4-dichloro benzoyl peroxide, 1-3 parts of maleic anhydride, 1-2 parts of gamma-(quadrol) propyl emthyl dimethoxy silane and 1-2 parts of butyl titanate. The environmental-friendly waterproof cable material achieves environmental friendliness, is good in water resistance and flame resistance and is excellent in mechanical property.

Owner:ANHUI SPECIAL CABLE GRP

Water-tree-retardant crosslinked polyethylene cable material and cable prepared from same

InactiveCN104910503AEffective protectionNot easily oxidizedInsulated cablesInsulated conductorsLinear low-density polyethyleneLow-density polyethylene

The invention belongs to the technical field of materials and wire cables, and relates to a water-tree-retardant crosslinked polyethylene cable material. The invention is characterized in that the cable material is prepared from linear low-density polyethylene, styrene, polyurethane thermoplastic elastomer, polyethyleneglycol, ethylene-ethyl acetate copolymer, polyethylene wax or paraffin, commercially available nucleator 4030 for wire cable plastics, di-tert-butyl peroxide, benzoperoxide, commercially available antioxidant 300 for plastics or commercially available antioxidant 1010 for plastics or commercially available antioxidant 168 for plastics, and carbon black, wherein the weight ratio of the linear low-density polyethylene to the styrene is 8-10. The invention also relates to a preparation method of the cable material and a water-tree-retardant cable using the cable material. The cable has the advantages of favorable waterproofing effect, simple structure, more stable electric / mechanical / environmental properties, higher reliability and the like, is easy to produce and does not generate water trees.

Owner:JIANGSU ZHONGLI GRP CO LTD

Polyethylene/SBR (Styrene Butadiene Rubber) coating coconut husk powder particle blending foaming material and preparation method thereof

The invention discloses a polyethylene / SBR (Styrene Butadiene Rubber) coating coconut husk powder particle blending foaming material, which is prepared from the following raw material according to parts by weight: 60-80 parts of LLDPE, 20-40 parts of HDPE, 30-40 parts of SBR, 10-15 parts of potassium feldspar, 15-20 parts of water glass, 5-10 parts of coconut husk powder, 1-2 parts of benzene isopropyl tri(dioctylpyrophosphate) titanate, 5-8 parts of ammonium polyphosphate, 4-6 parts of dioctyl sebacate, 5-8 parts of phthalic acid ester, 3-5 parts of foaming agent, 1-2 parts of di-tert-butyl peroxide, 0.5-1 parts of lead sulfate tribasic, 1-2 parts of magnesium oxide, 1-2 parts of barium stearate, 2-3 parts of ethylene bis oleamide, 3-5 parts of modified tree ash, and 1-2 parts of antioxidant DLTP. The polyethylene / SBR (Styrene Butadiene Rubber) coating coconut husk powder particle blending foaming material produced in the invention is light and soft, high in strength, good in rebound elasticity, ideal in foaming effect, uniform in foaming, fine and compact, good in fire resistance, resistant to chemical corrosion, ageing-resistant and durable in use.

Owner:惠州宏康包装科技有限公司

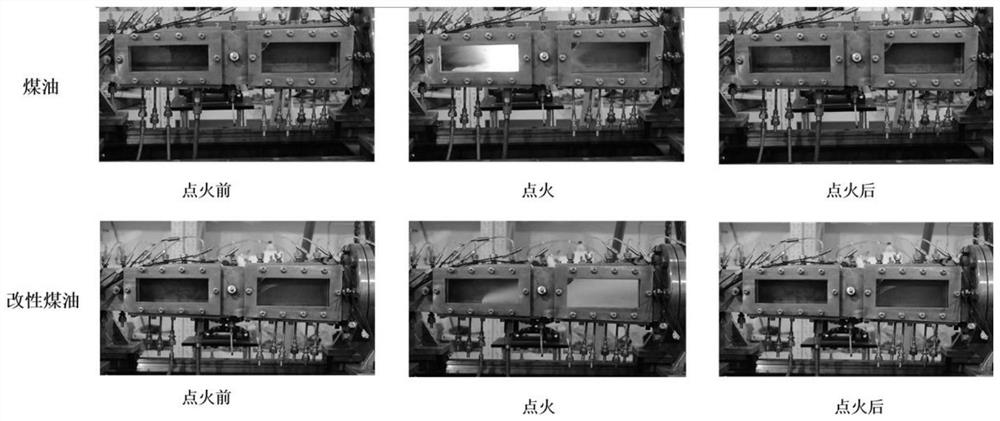

Implementation method of kerosene-based fuel for scramjet engine started by low Mach number

An implementation method of kerosene-based fuel for a scramjet engine started at a low Mach number comprises the following steps of: adding a borane triethylamine complex into a mixed fuel of 1-octene and RP-3 kerosene, and carrying out hydroboration reaction to obtain initial modified kerosene; and mixing the initial modified kerosene with di-tert-butyl peroxide serving as a free radical ignition enhancer and benzoquinone serving as a free radical stabilizer to obtain kerosene-based fuel. Starting of the scramjet engine when the incoming flow Mach number is 1.5 can be achieved through electric spark ignition, and good stability is achieved during contact with air in a normal-temperature environment. Starting and stable combustion of the scramjet engine under the low Mach number are achieved by synthesizing the kerosene-based fuel, the operation is easy, and the practicability is high.

Owner:SHANGHAI JIAO TONG UNIV

Antibacterial coating

InactiveCN104356699AHas natural antibacterial ingredientsImprove antibacterial propertiesAntifouling/underwater paintsAlkali metal silicate coatingsSODIUM METAPHOSPHATESodium phosphates

The invention relates to an antibacterial coating which comprises the following raw materials in parts by weight: water glass, alpha-ethyl cyanoacrylate, titanium dioxide, talcum powder, cylindrin, di-tert-butyl peroxide, glyoxal, sodium hexametaphosphate, sodium chloride, sodium sulfate, ethylene glycol, borax, furocoumarin and bamboo leaf phenolic ketone. The coating contains natural antibacterial components, is lasting in antibacterial effect, strong in adhesive power and good in mould forming property, and can be widely applied to the surfaces of various objects.

Owner:QINGDAO TONGSHENGTONG RUBBER & PLASTIC

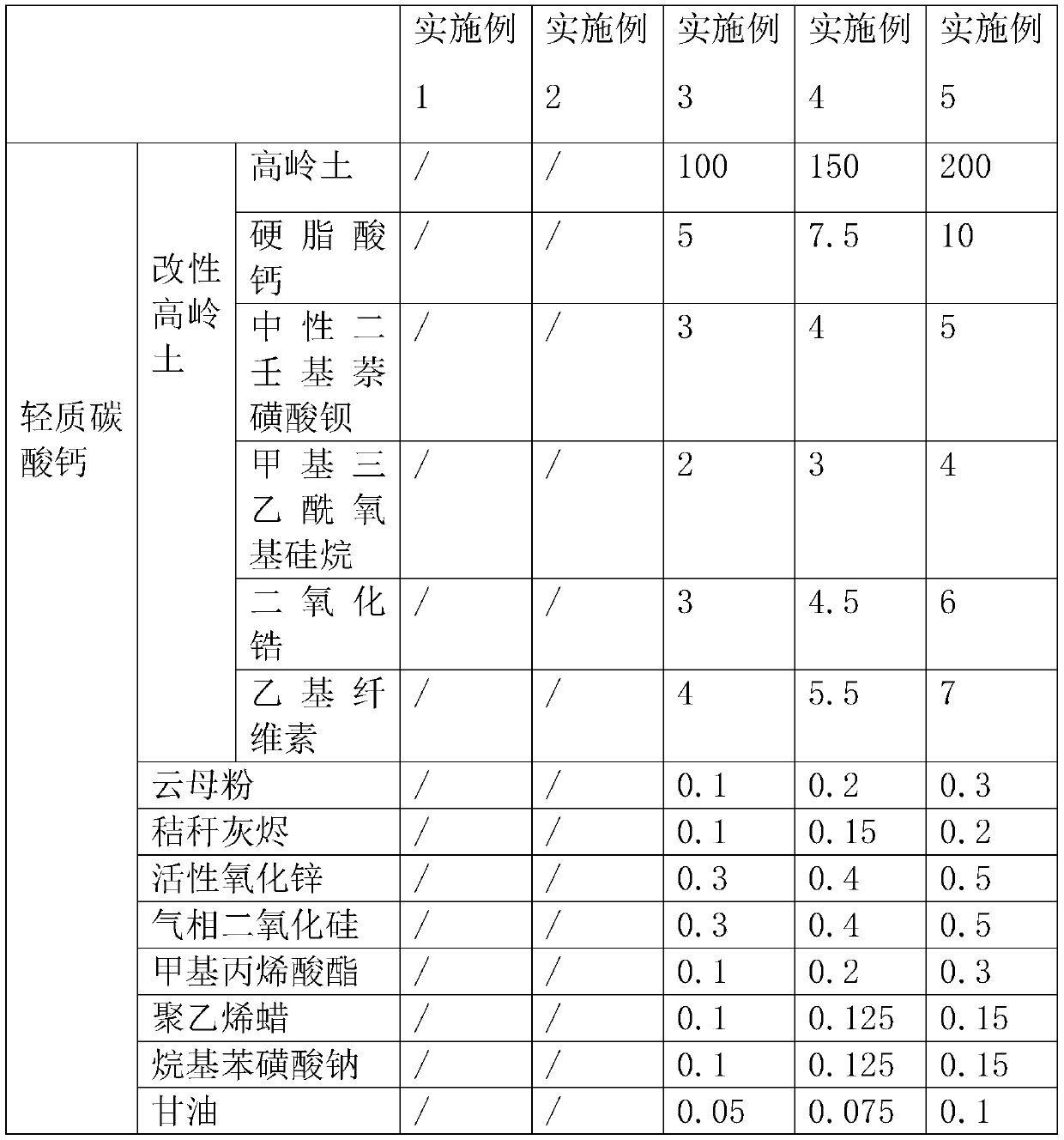

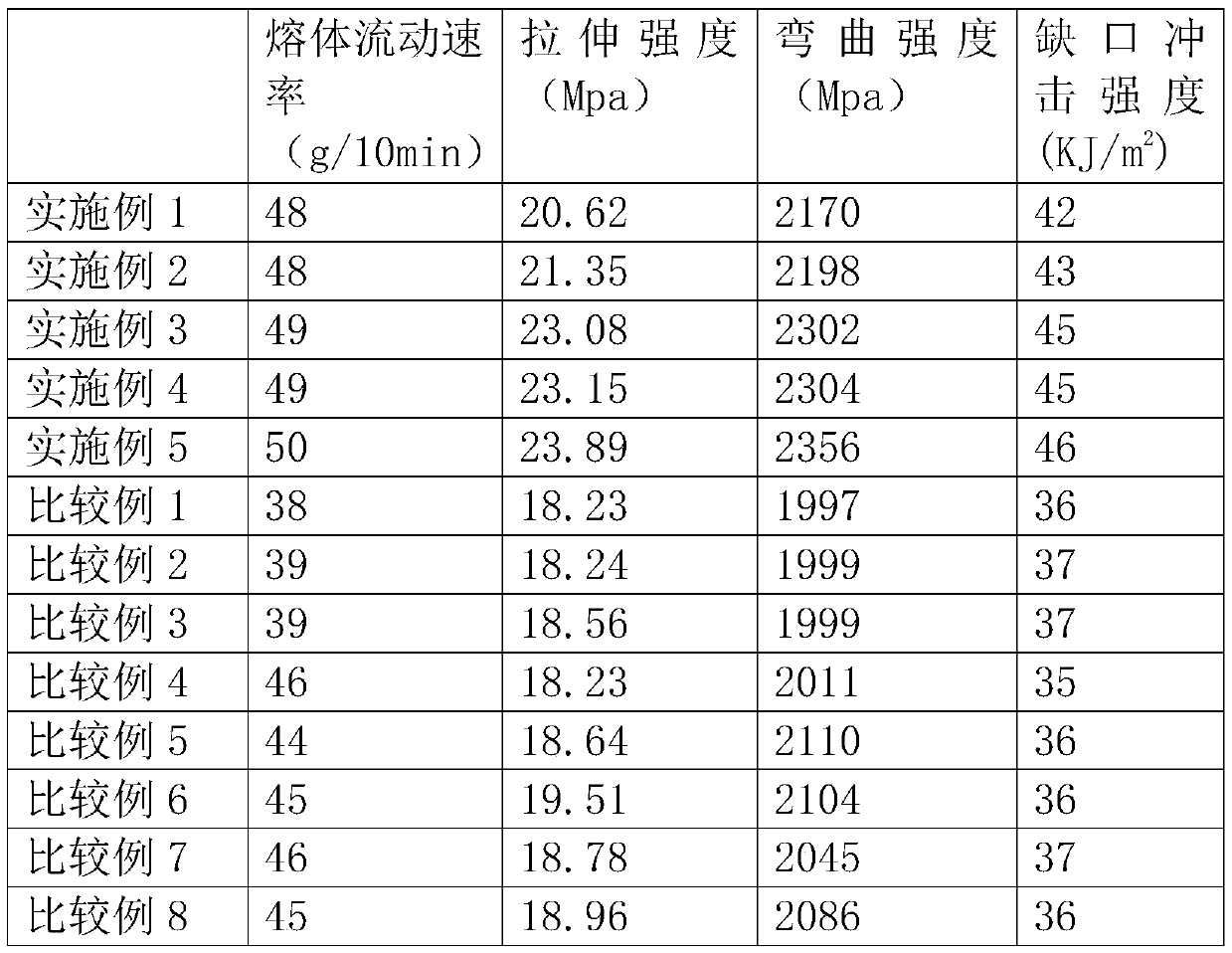

PP flow master batch

The invention relates to the technical field of master batch preparation, in particular to a PP flow master batch. The master batch comprises, by weight, 90-100 parts of polypropylene resin, 2.5-7.5 parts of an initiator and 0.5-1.5 parts of light calcium carbonate, wherein the flowing speed of a polypropylene resin melt is 19-27 g / 10 min, and the initiator is composed of di-tert-butyl peroxide and tert-butyl hydroperoxide in the ratio of 1:(1.2-1.5). The master batch has the advantages that the PP flow master batch is applied to polypropylene thin-wall injection molding, the fluidity of the polypropylene melt is improved, and meanwhile, an injection molded polypropylene thin-wall injection molding finished product has good mechanical properties.

Owner:东莞市恒彩塑胶颜料有限公司

Wear-resistant and oil-resistant rubber material for inner sheath of mining power cable and preparation method for rubber material

InactiveCN105176099AImprove interface performanceImprove flame retardant performanceRubber insulatorsRubber materialShellac

The present invention discloses a wear-resistant and oil-resistant rubber material for an inner sheath of a mining power cable and a preparation method for the rubber material. The wear-resistant and oil-resistant rubber material is prepared from the following raw materials in parts by weight: 26-34 parts of fluorosilicone rubber, 15-25 parts of chloroprene rubber, 13-19 parts of high-cis polybutadiene rubber, 7-13 parts of di-iso-octyl sebacate, 4-6 parts of shellac cera, 3-5 parts of sulfur dichloride, 5-8 parts of poly alpha olefin, 2-3 parts of zinc oxide, 3-4 parts of stearic acid, 2-3 parts of an antioxidant ODA, 1-2 parts of an antioxidant AW-66, 15-20 parts of highly wear-resistant carbon black, 10-15 parts of nano-diamond, 3-5 parts of di-t-butyl peroxide, 1-2 parts of an accelerant ETU, 1-2 parts of an accelerant TMTD, 0.5-1 part of an accelerant ZDC, 10-15 parts of electrolytic aluminum slag and 16-22 parts of flame retardant particles. According to the material prepared by the present invention, the oil resistance and wear resistance are greatly improved, and meanwhile the mechanical property is not influenced.

Owner:TIANCHANG FUXIN ELECTRONICS

The preparation method of di-tert-butyl peroxide

ActiveCN106380437BAvoid damageShort process stepsOrganic compound preparationSulfuric acid esters preparationHydrogen SulfateOrganic synthesis

A method of preparing di-tert-butyl peroxide is disclosed and belongs to the technical field of organic synthesis. The method includes a step of adding tert-butyl alcohol and sulfuric acid into a first reaction device, reacting under stirring, and controlling the temperature and reaction time of the reaction under stirring in the first reaction device to obtain a tert-butyl hydrogen sulfate liquid, a step of adding a recovered mother liquor into a second reaction device, adding crude tert-butyl alcohol and the tert-butyl hydrogen sulfate liquid into the second reaction device, and controlling the temperature and reaction time of a reaction under stirring in the second reaction device to obtain a reaction product, a step of feeding the reaction product to a liquid separating tank, and performing liquid separating to obtain an upper oil phase that is the di-tert-butyl peroxide and a lower water phase that is a mother liquor adopted as a recovery mother liquor for a next turn of reactions. The method is simple and short in process steps, and can allow the content of the di-tert-butyl peroxide in the upper oil phase to be 97.5% or above, thus meeting requirements on industrial scaled-up production. The method avoids environment pollution, saves raw materials, reduces the cost and achieves circular economy.

Owner:江苏强盛功能化学股份有限公司

Liquid nano combustion material and preparation method thereof

InactiveCN111732978AImprove stabilityImprove durabilityLiquid carbonaceous fuelsCyclohexylaminesSalicylic acid

The invention discloses a liquid nano combustion material and a preparation method thereof. The liquid nano-combustion material is prepared from the following raw materials in parts by weight: 20.0 to 40.0 parts of gasoline, 40.0 to 80.0 parts of methanol, 0.5 to 2.5 parts of modified nano nickel powder, 0.3 to 1.0 part of calcium alkyl salicylate, 5.0 to 8.0 parts of di-tert-butyl peroxide, 1.0to 2.0 parts of tert-butyl dimethyl chlorosilane, 0.05 to 0.10 part of diethylene glycol monoethyl ether, 0.01 to 0.04 part of dibenzoyl peroxide, 2.0 to 4.0 parts of cyclohexylamine and 1.5 to 4.5 parts of catalytic combustion improver. According to the liquid nanometer combustion material prepared by the invention, the compatibility of all the components is good, the components are synergistic,the combustion heat value of the liquid nanometer combustion material can be increased, energy waste is reduced, environmental pollution is reduced, and resources are saved.

Owner:保蓝行福建环保技术研究院有限责任公司

Preparation method of di-tert-butyl peroxide

InactiveCN112521324AEasy to operateIncrease productivityOrganic compound preparationPeroxy compound preparationExhaust fumesProcess engineering

The invention discloses a preparation method of di-tert-butyl peroxide. The preparation method comprises the following steps of: adding hydrogen peroxide and sulfuric acid into a reaction kettle, sufficiently mixing the hydrogen peroxide and the sulfuric acid under an ice bath condition to obtain a mixed solution, and continuously stirring the mixed solution for 30 minutes; dropwise adding tert-butyl alcohol after violently stirring the mixed solution, controlling the dropwise adding speed, and ensuring that the reaction temperature does not exceed 5 DEG C; after dropwise adding the tert-butylalcohol, naturally heating the solution to room temperature, and continuously stirring the solution for 4 hours to obtain a reaction crude product solution; and making the solution stand still, introducing the solution into a liquid separation tank for liquid separation to obtain an upper-layer organic phase, washing the organic phase with a 30% NaOH solution, washing the organic phase with water, and drying the organic phase with anhydrous MgSO4 to obtain stimulated colorless liquid which is di-tert-butyl peroxide. The preparation method has the advantages of simplified operation, higher yield, shortened reaction time, effectively controlled reverse reaction decomposition and raw material-saving performance / Waste gas mother liquor is recycled, so that raw materials are saved, the production cost is reduced; and the discharge of the waste liquor is reduced, the subsequent treatment cost is saved, and the environmental protection is achieved; and the sustainable development is realized, and the production profits of enterprises are greatly improved.

Owner:宁夏顺邦达新材料有限公司

Medical rubber ice bag and preparation method thereof

The invention relates to a medical rubber ice bag and a preparation method thereof. The medical rubber ice bag comprises components in parts by mass as follows: 50-70 parts of butyronitrile rubber, 20-40 parts of butadiene rubber, 5-15 parts of cellulose, 5-15 parts of glass wool, 0.8-1.5 parts of stearic acid, 0.5-1 part of an anti-aging agent MB, 0.3-0.7 parts of medical Vaseline, 60-72 parts of white carbon black, 0.1-0.3 parts of iron oxide red, 3-7 parts of hydroxyl silicone oil, 0.2-0.6 parts of an organic pigment, 0.2-0.5 parts of isopropyl xanthogen, 0.4-0.9 parts of thiazole, 0.1-0.3 parts of di-tert-butyl peroxide and 1-2 parts of sulfur. The medical rubber ice bag has excellent tensile strength and elongation at break, the material of the ice bag is not prone to cracking or ageing, and the ice bag has a good thermal insulation effect and long service life.

Owner:SUZHOU COSMETIC MATERIALS

Shielding and protecting polyester adhesive tape

InactiveCN105969231AImprove tensile propertiesHigh elongationFilm/foil adhesivesPolyesterAdhesive cement

The invention discloses shielding and protecting polyester adhesive tape. The adhesive tape mainly solves the problem of existing protecting adhesive tape that adhesive failure occurs often due to temperature and bonding time. The adhesive tape comprises a base material layer, a mold release agent layer arranged over the base material layer, and an adhesive layer arranged under the base material layer, wherein the adhesive layer is formed by a silicone adhesive, and the base material layer is prepared from, by weight, 70-80 parts of polyethylene terephthalate, 1-5 parts of polymethyl triethoxy silane, 1-5 parts of vinyl phenyl silicone oil, 5-10 parts of silicone and 1-5 parts of di-tert-butyl peroxide. The adhesive tape has high tensile resistance and adhesive force, and adhesive failure does not occur after long-time bonding at high temperature.

Owner:CHENGDU HUIJIA ADHESIVE PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com