O-shaped seal ring for automobile fuel pump and manufacturing process of O-shaped seal ring

An O-ring, fuel pump technology, used in pumps, pump components, non-variable-capacity pumps, etc., can solve problems such as poor high and low temperature resistance, normal use of rubber seals, and no manufacturing process, and achieve high and low temperature resistance. Good performance, overcoming grease leakage, good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

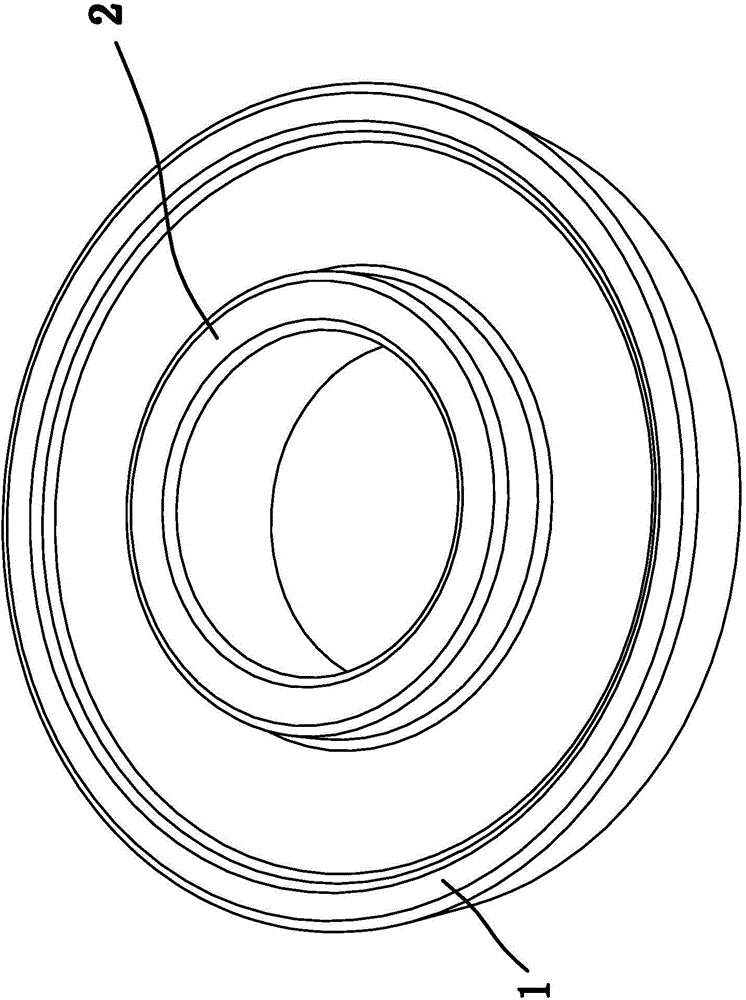

[0033] Such as figure 1 As shown, the O-ring of the automotive fuel pump includes a ring-shaped sealing ring body 1. The middle part of the sealing ring body 1 has a sealing lip 2, and the sealing lip 2 extends outward. This structure increases the storage capacity of the lip. The oil space overcomes the defects of grease leakage inside the bearing and external impurities entering the bearing, and has a good protective effect; the sealing ring body 1 and the sealing lip 2 are of an integrated structure, and the sealing ring body 1 includes nitrile rubber, sulfur, and anti-aging agent mercapto Benzimidazole, zinc oxide, stearic acid, paraffin oil, aluminum oxide powder, dibutyl phthalate, acid-base balance agent and vulcanization accelerator di-tert-butyl peroxide, each component is as follows by mass percentage: Nitrile rubber accounts for 70%-80%, sulfur accounts for 10%-20%, antioxidant mercaptobenzimidazole accounts for 1%-3%, zinc oxide accounts for 0.5%-0.8%, and stearic ...

Embodiment 2

[0036] Such as figure 1As shown, the O-ring of the automotive fuel pump includes a ring-shaped sealing ring body 1. The middle part of the sealing ring body 1 has a sealing lip 2, and the sealing lip 2 extends outward. This structure increases the storage capacity of the lip. The oil space overcomes the defects of grease leakage inside the bearing and external impurities entering the bearing, and has a good protective effect; the sealing ring body 1 and the sealing lip 2 are of an integrated structure, and the sealing ring body 1 includes nitrile rubber, sulfur, and anti-aging agent mercapto Benzimidazole, zinc oxide, stearic acid, paraffin oil, aluminum oxide powder, dibutyl phthalate, acid-base balance agent and vulcanization accelerator di-tert-butyl peroxide, each component is as follows by mass percentage: Nitrile rubber accounts for 70%-80%, sulfur accounts for 10%-20%, antioxidant mercaptobenzimidazole accounts for 1%-3%, zinc oxide accounts for 0.5%-0.8%, and stearic a...

Embodiment 3

[0039] Such as figure 1 As shown, the O-ring of the automotive fuel pump includes a ring-shaped sealing ring body 1. The middle part of the sealing ring body 1 has a sealing lip 2, and the sealing lip 2 extends outward. This structure increases the storage capacity of the lip. The oil space overcomes the defects of grease leakage inside the bearing and external impurities entering the bearing, and has a good protective effect; the sealing ring body 1 and the sealing lip 2 are of an integrated structure, and the sealing ring body 1 includes nitrile rubber, sulfur, and anti-aging agent mercapto Benzimidazole, zinc oxide, stearic acid, paraffin oil, aluminum oxide powder, dibutyl phthalate, acid-base balance agent and vulcanization accelerator di-tert-butyl peroxide, each component is as follows by mass percentage: Nitrile rubber accounts for 70%-80%, sulfur accounts for 10%-20%, antioxidant mercaptobenzimidazole accounts for 1%-3%, zinc oxide accounts for 0.5%-0.8%, and stearic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com