Shielding and protecting polyester adhesive tape

A protective tape and polyester technology, applied in the direction of adhesives, film/sheet adhesives, etc., can solve problems such as degumming, and achieve the effects of excellent heat resistance, good adhesion, and high elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

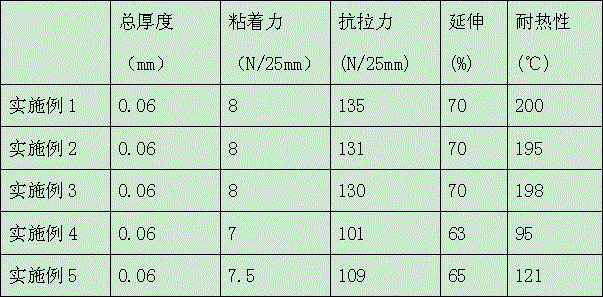

Examples

Embodiment 1

[0022] The polyester masking protective tape includes a substrate layer, a release agent layer disposed above the substrate layer, and an adhesive layer disposed below the substrate layer.

[0023] In this embodiment, the adhesive layer is composed of silicone adhesive, and the substrate layer is composed of the following components by weight:

[0024] 78 parts of polyethylene terephthalate, 4 parts of polymethyltriethoxysilane, 3 parts of vinyl phenyl silicone oil, 5 parts of silicone, 3 parts of di-tert-butyl peroxide.

[0025] The preparation method of the above polyester masking protective tape consists of the following steps:

[0026] (1) Heat the polyethylene terephthalate to a molten state;

[0027] (2) After mixing the polymethyltriethoxysilane, vinylphenyl silicone oil and silicone uniformly, add them to the molten polyethylene terephthalate to make a mixture one;

[0028] (3) Under continuous stirring, add di-tert-butyl peroxide to the mixture one, and then make the base materi...

Embodiment 2

[0031] The difference between this embodiment and embodiment 1 is that the content of each component in the substrate layer is different, and the specific parts by weight of each component in the substrate layer are as follows:

[0032] The substrate layer is composed of the following components by weight:

[0033] 80 parts of polyethylene terephthalate, 3 parts of polymethyltriethoxysilane, 3 parts of vinyl phenyl silicone oil, 6 parts of silicone, and 5 parts of di-tert-butyl peroxide.

Embodiment 3

[0035] The difference between this embodiment and embodiment 1 is that the content of each component in the substrate layer is different, and the specific parts by weight of each component in the substrate layer are as follows:

[0036] The substrate layer is composed of the following components by weight:

[0037] 75 parts of polyethylene terephthalate, 5 parts of polymethyltriethoxysilane, 1 part of vinyl phenyl silicone oil, 8 parts of silicone, 4 parts of di-tert-butyl peroxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com