Method for preparing styrene/isoprene/maleic anhydride multi-block polymer with polyolefin as carrier

A technology of maleic anhydride and isoprene, which is applied in the field of preparing styrene/isoprene/maleic anhydride multi-block polymers, and achieves the effect of simple processing technology, simple equipment and good product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

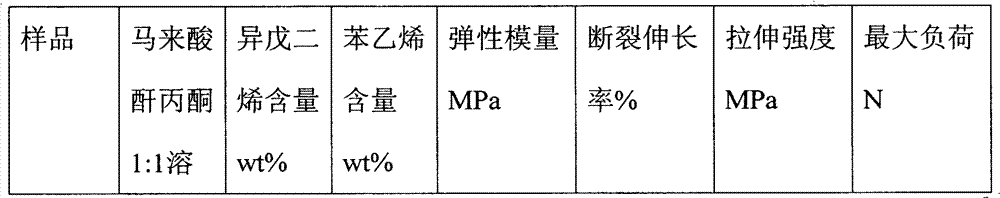

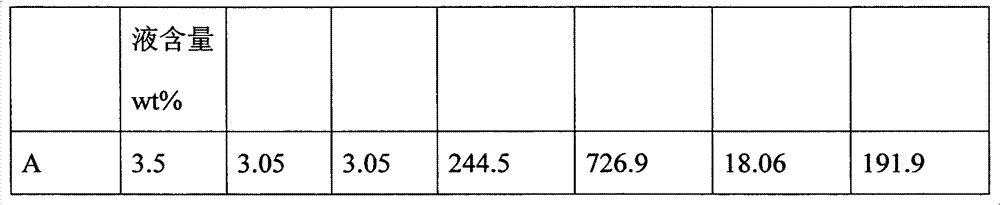

Embodiment 1

[0022] At room temperature, dissolve 0.175kg maleic anhydride and 0.016kg di-tert-butyl peroxide in 0.175kg acetone, mix 0.305kg isoprene and 0.305kg styrene; pre-set the nine-stage heating cylinder of the twin-screw extruder The temperature along the extrusion direction is 68°C, 103°C, 170°C, 200°C, 200°C, 200°C, 200°C, 190°C, 215°C, and the screw speed is 100r / min; when the temperature of the heating cylinder reaches the predetermined temperature 10kg of polypropylene pellets with a melt index of 1.84g / 10min are fed into the extruder from the main feeding port located in the first section of the extruder, and the feeding speed is 0.1kg / min; The acetone solution of the agent is injected at a rate of 0.0035kg / min from the third stage of the liquid feed port of the extruder through a metering pump, and the 1:1 solution of isoprene and styrene is injected from the third stage of the liquid feed port through another metering pump. Inject at a speed of 0.0061kg / min; carry out vacu...

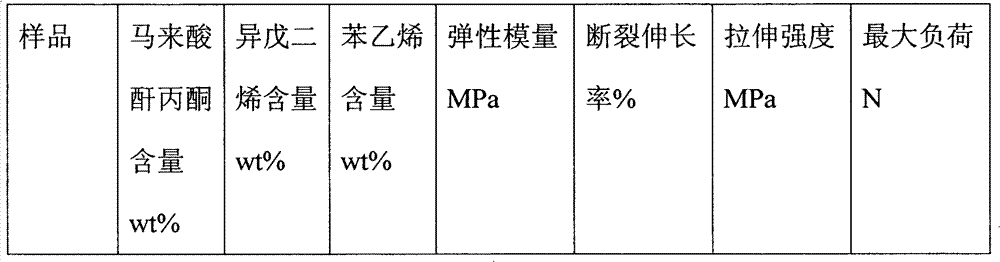

Embodiment 2

[0029] At room temperature, dissolve 0.3kg of maleic anhydride and 0.027kg of di-tert-butyl peroxide in 0.3kg of acetone, mix 0.6kg of isoprene and 0.6kg of styrene; pre-set the nine-stage heating cylinder of the twin-screw extruder The temperature along the extrusion direction is 68°C, 103°C, 170°C, 200°C, 200°C, 200°C, 200°C, 190°C, 215°C, and the screw speed is 100r / min; when the temperature of the heating cylinder reaches the predetermined temperature 10kg of polypropylene pellets with a melt index of 1.84g / 10min are fed into the extruder from the main feeding port located in the first section of the extruder, and the feeding speed is 0.1kg / min; The acetone solution of the agent is injected at a rate of 0.006kg / min from the third stage of the liquid feed port of the extruder through a metering pump, and the 1:1 solution of isoprene and styrene is injected from the third stage of the liquid feed port through another metering pump. Inject at a speed of 0.012kg / min; carry out...

Embodiment 3

[0036] At room temperature, dissolve 0.685kg of maleic anhydride and 0.061kg of di-tert-butyl peroxide in 0.685kg of acetone, mix 1.135kg of isoprene and 1.135kg of styrene; pre-set the nine-stage heating cylinder of the twin-screw extruder The temperature along the extrusion direction is 68°C, 103°C, 170°C, 200°C, 200°C, 200°C, 200°C, 190°C, 215°C, and the screw speed is 100r / min; when the temperature of the heating cylinder reaches the predetermined temperature 10kg of polypropylene pellets with a melt index of 1.84g / 10min are fed into the extruder from the main feeding port located in the first section of the extruder, and the feeding speed is 0.1kg / min; The acetone solution of the agent is injected at a rate of 0.0137kg / min from the third liquid feeding port of the extruder through a metering pump, and the 1:1 solution of isoprene and styrene is injected from the third liquid feeding port through another metering pump. Inject at a speed of 0.0227kg / min; carry out vacuum de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com