Wear-resistant and oil-resistant rubber material for inner sheath of mining power cable and preparation method for rubber material

A technology for oil-resistant rubber and power cords, applied in rubber insulators, organic insulators, etc., can solve the problems that the wear resistance and oil resistance cannot meet the needs of the market, and achieve a wide range of applications, improved oil resistance and wear resistance, and improved compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

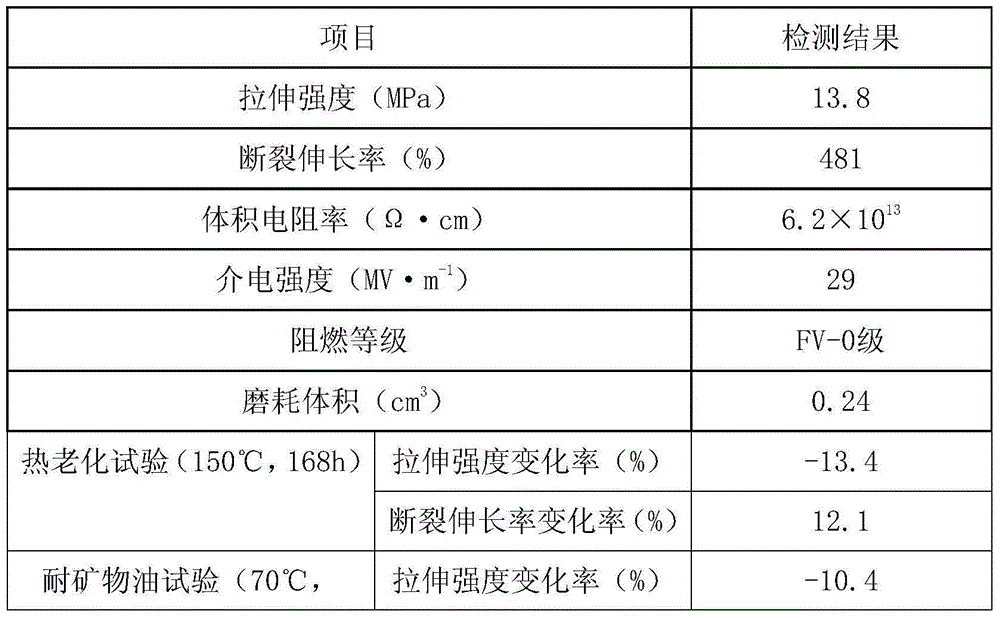

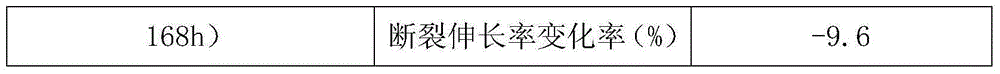

[0014] A wear-resistant and oil-resistant rubber material for the inner sheath of a mining power cord, made of the following raw materials in weight (kg): fluorosilicone rubber 30, neoprene rubber 20, high-cis polybutadiene rubber 16, sebacic acid Diisooctyl ester 11, purple shellac wax 5, sulfur dichloride 4, polyalphaolefin 6, zinc oxide 2.5, stearic acid 3.5, antioxidant ODA2.5, antioxidant AW-661.5, high wear-resistant carbon black 18 , nanodiamond 12, di-tert-butyl peroxide 4, accelerator ETU1.5, accelerator TMTD1.5, accelerator ZDC0.8, electrolytic aluminum slag 12, flame retardant particles 18;

[0015] The preparation method of the flame-retardant particles is as follows: a, take the raw materials of the following weight (kg): colemanite 24, brucite 16, boehmite 12, expanded graphite 10, basic sodium aluminum carbonate 6, basic Magnesium chloride 5, brominated bisphenol A epoxy resin 24, pentabromobenzyl polyacrylate 25, hexaphenoxycyclotriphosphazene 10, dipentaerythr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com