Method for preparing polyacrylate rubber through continuous solution polymerization and devolatilization extrusion

A technology of acrylates and acrylates, which is applied in the field of continuous solution polymerization devolatilization extrusion to prepare acrylate rubber, which can solve the problems of difficult solvent removal, high polymerization reaction pressure, complex synthesis process, etc., and achieves stable polymerization process and easy The effect of control and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

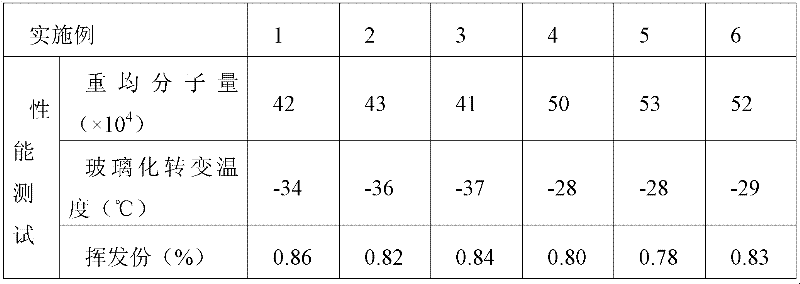

Examples

Embodiment 1

[0025] Mix 10 parts of methyl acrylate, 38.5 parts of butyl acrylate, 1.5 parts of glycidyl methacrylate, 50 parts of toluene and 0.1 part of benzoyl peroxide to form a mixed solution, and replace the air in the reactor with nitrogen , continuously add the mixed solution into the polymerization reactor through the feeding pump, start stirring at a speed of 140 rpm, heat the temperature with an oil bath, keep the temperature of the oil bath at 110°C, and react for 2 hours to obtain a polymerization product, start the feeding pump , start the discharge melt pump and the devolatilization twin-screw extruder at the same time, according to the constant flow rate of the material is 25g / min, adjust the feed rate and discharge rate, make the feed rate and discharge rate consistent, the pressure in the polymerization tank is 2.4 atmospheric pressure; set the temperature of each section of the devolatilization extruder to 150°C for the first and second sections, 160°C for the third and f...

Embodiment 2

[0027] Mix 14 parts of methyl acrylate, 53.9 parts of butyl acrylate, 2.1 parts of glycidyl methacrylate, 30 parts of toluene and 0.07 parts of benzoyl peroxide to form a mixed solution, and replace the air in the reactor with nitrogen , continuously add the mixed solution into the polymerization reactor through the feed pump, start stirring at a speed of 140 rpm, heat the temperature with an oil bath, keep the temperature of the oil bath at 130°C, and react for 2.5 hours to obtain a polymerization product, start the feed pump , start the discharge melt pump and the devolatilization twin-screw extruder at the same time, according to the constant flow rate of the material is 30g / min, adjust the feed rate and discharge rate, so that the feed rate and discharge rate are consistent, the pressure in the polymerization tank is 2.6 atmospheric pressure; set the temperature of each section of the devolatilization extruder to 150°C for the first and second sections, 160°C for the third ...

Embodiment 3

[0029]Mix 16 parts of methyl acrylate, 61.6 parts of butyl acrylate, 2.4 parts of glycidyl methacrylate, 20 parts of toluene and 0.04 parts of benzoyl peroxide to form a mixed solution, and replace the air in the reactor with nitrogen , continuously add the mixed solution into the polymerization reactor through the feeding pump, start stirring at a speed of 140 rpm, and use an oil bath to heat up the temperature. After the oil bath temperature is kept at 150°C, react for 2 hours to obtain a polymerization product, and start the feeding pump , start the discharge melt pump and the devolatilization twin-screw extruder at the same time, adjust the feed rate and discharge rate according to the constant flow rate of the material, so that the feed rate and discharge rate are kept consistent, and the pressure in the polymerization tank is 2.8 atmospheric pressure; set the temperature of each section of the devolatilization extruder to 150°C for the first and second sections, 160°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com