Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51 results about "Magnesium boride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

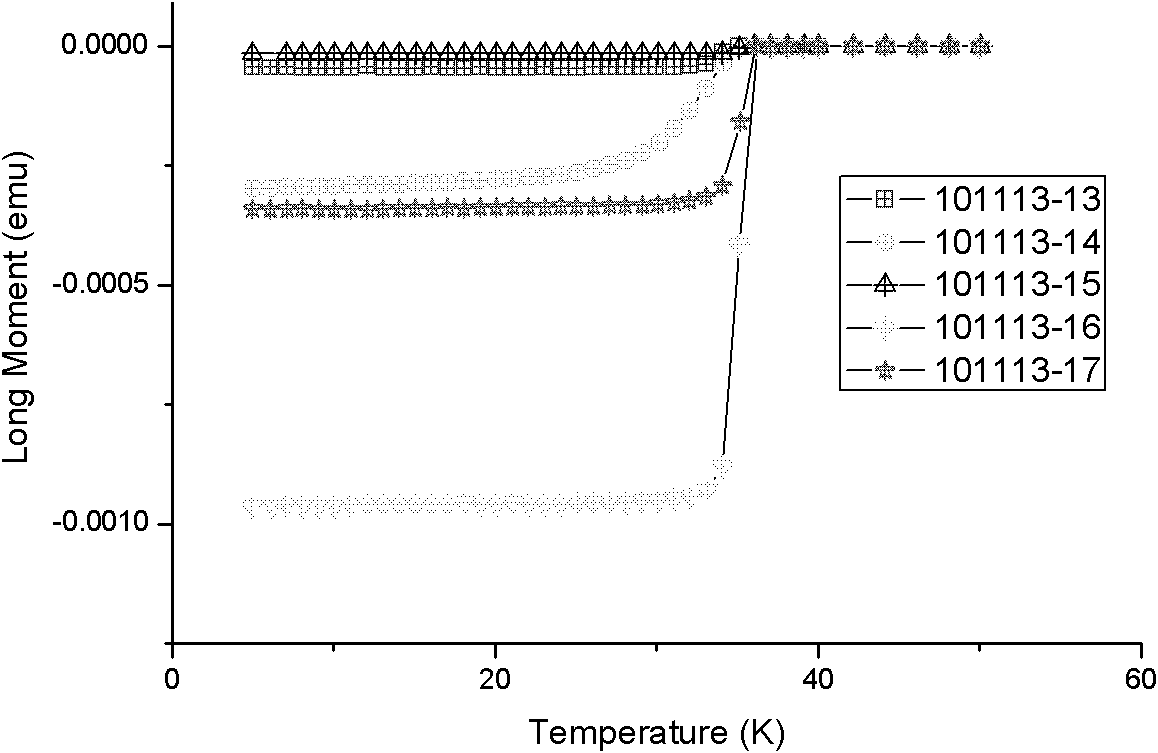

Magnesium diboride is the inorganic compound with the formula MgB 2. It is a dark gray, water-insoluble solid. The compound has attracted attention because it becomes superconducting at T c = 39K. ... Thus magnesium boride has been proposed as fuel in ram jets.

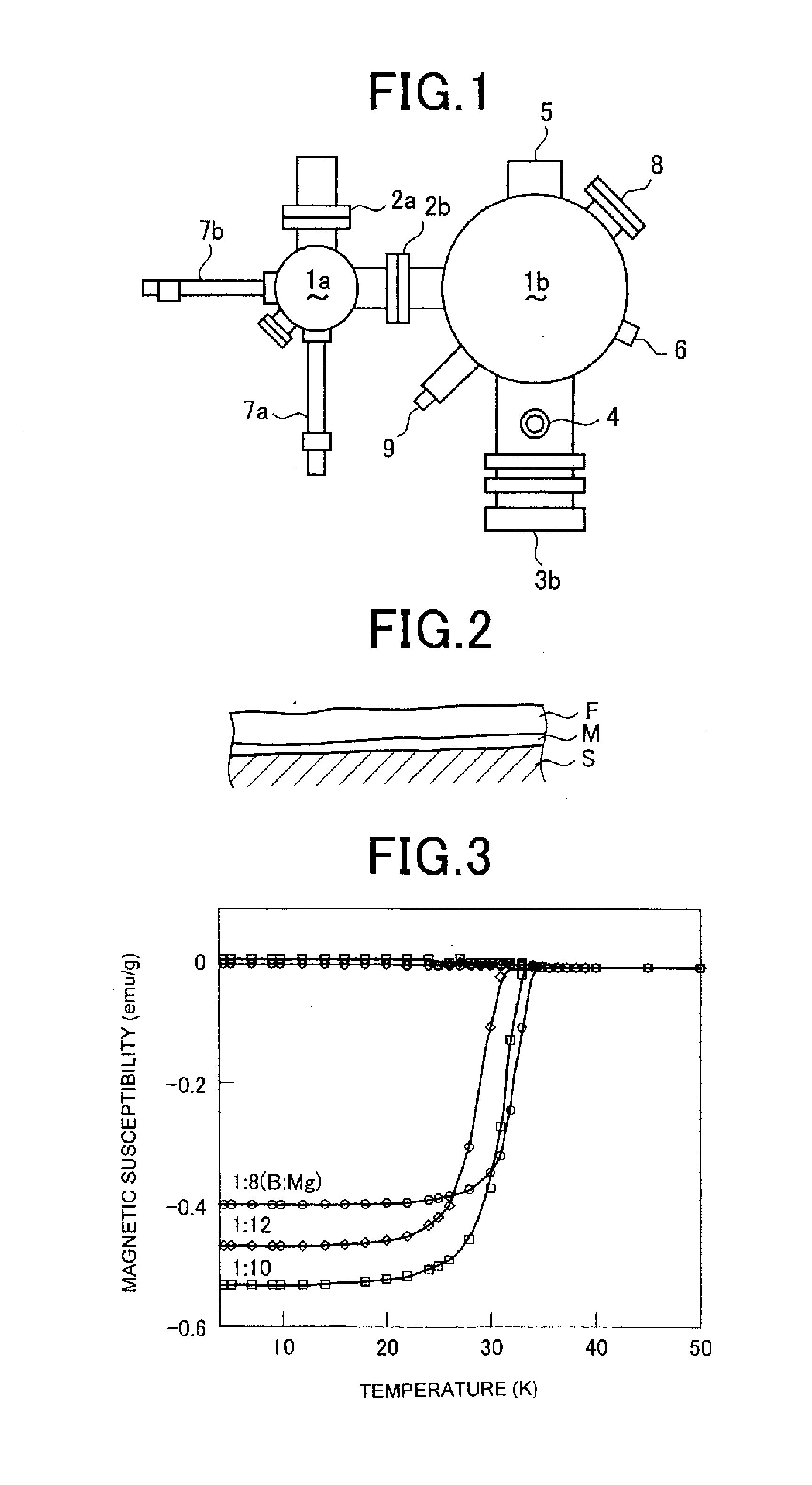

Method for producing doped, alloyed, and mixed-phase magnesium boride films

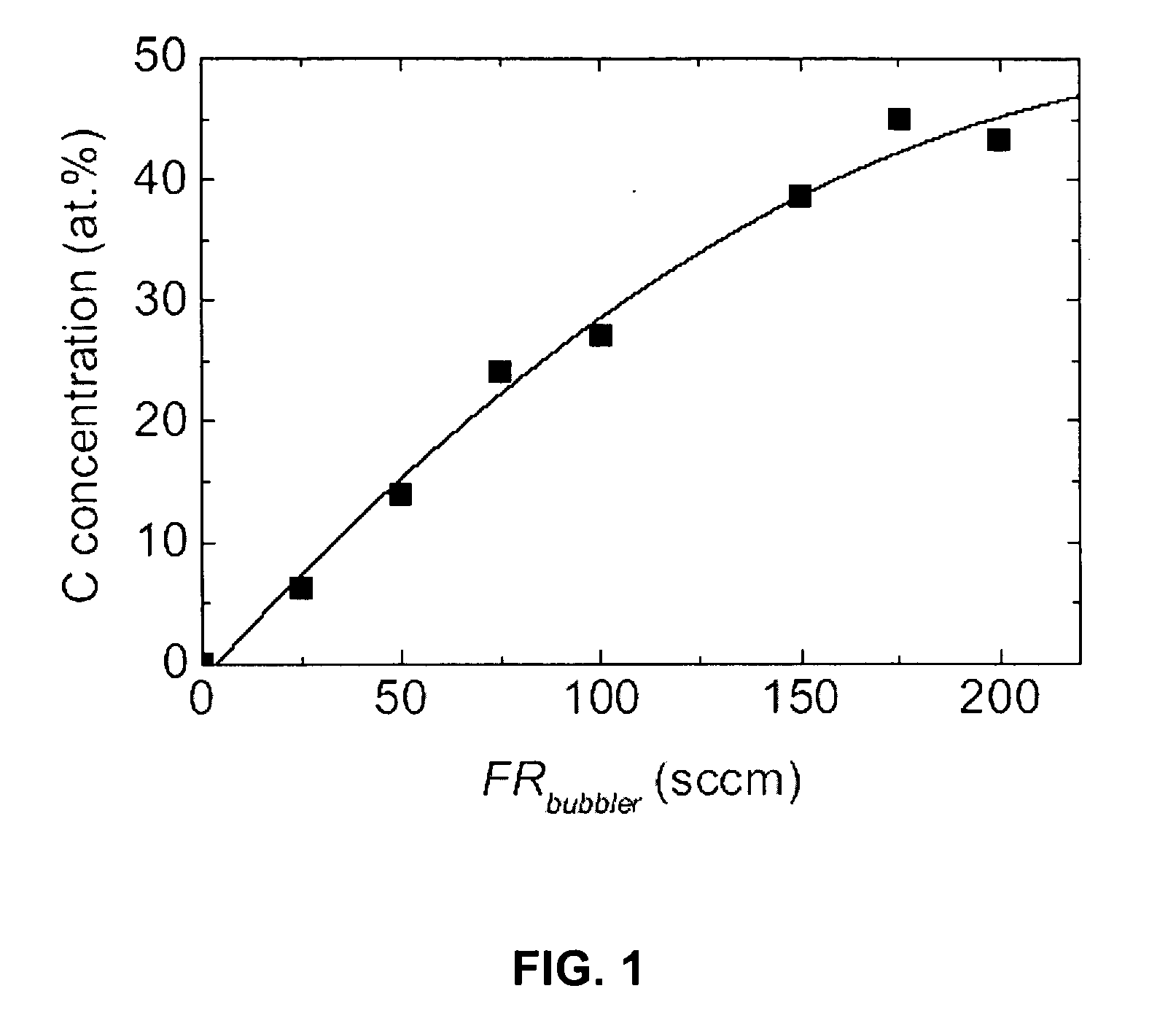

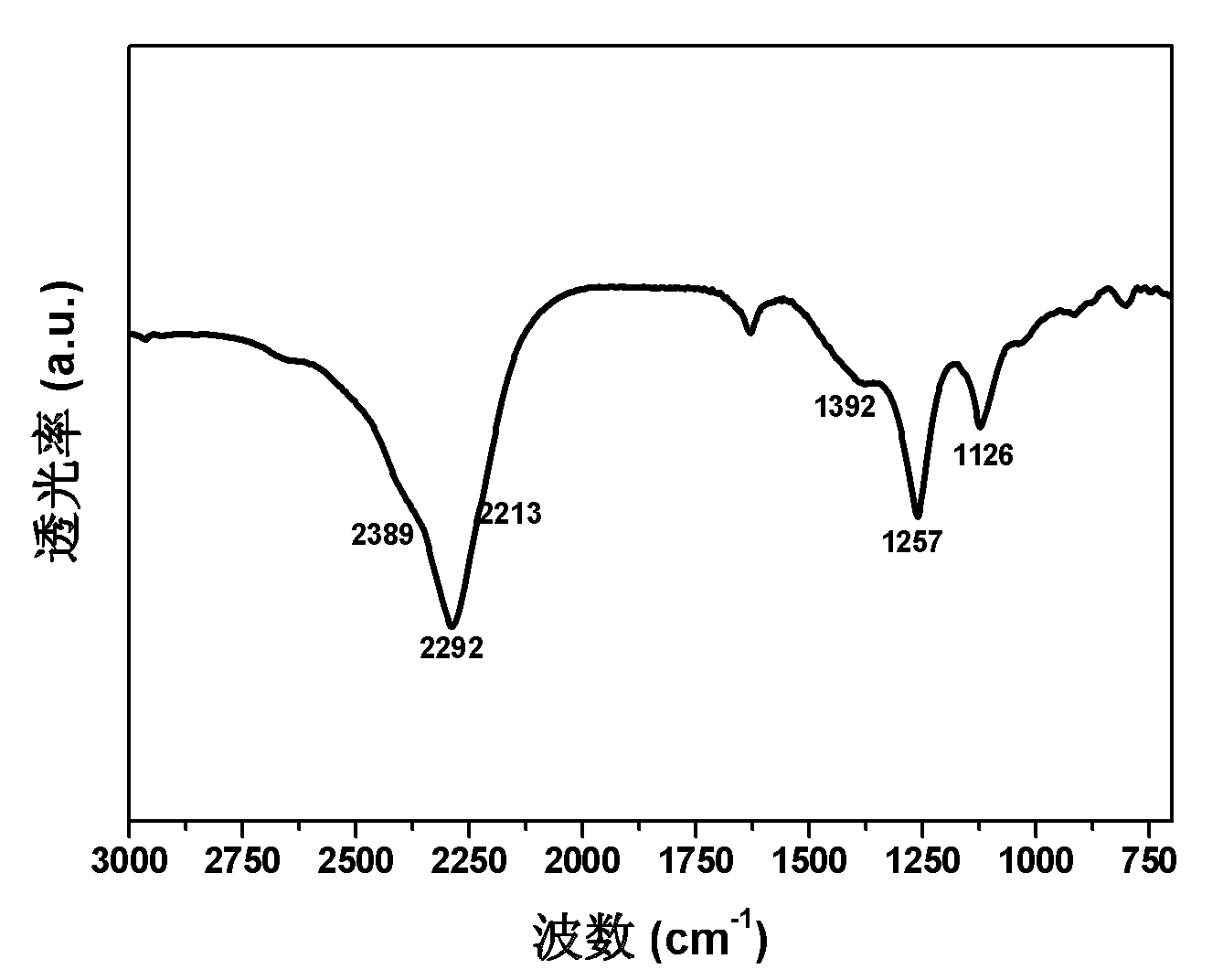

Conducting and superconducting doped, magnesium boride materials are formed by a process which combines physical vapor deposition with chemical vapor deposition by physically generating magnesium vapor in a deposition chamber and introducing a boron containing precursor and a dopant into the chamber which combines with the magnesium vapor to form the material. Embodiments include forming carbon-doped magnesium diboride film and powder with hybrid physical-chemical vapor deposition (HPCVD) by adding a carbon-containing metalorganic magnesium precursor, bis(methylcyclopentadienyl)magnesium, with a hydrogen carrier gas together with a borane precursor in a chamber having a source of magnesium vapor.

Owner:PENN STATE RES FOUND

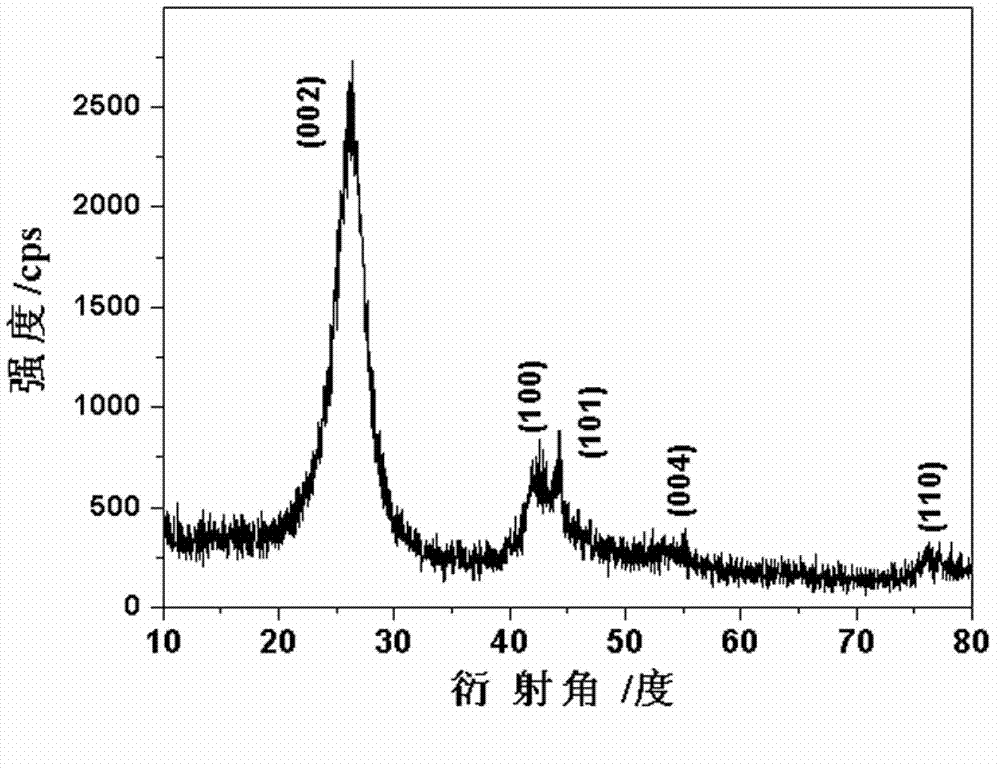

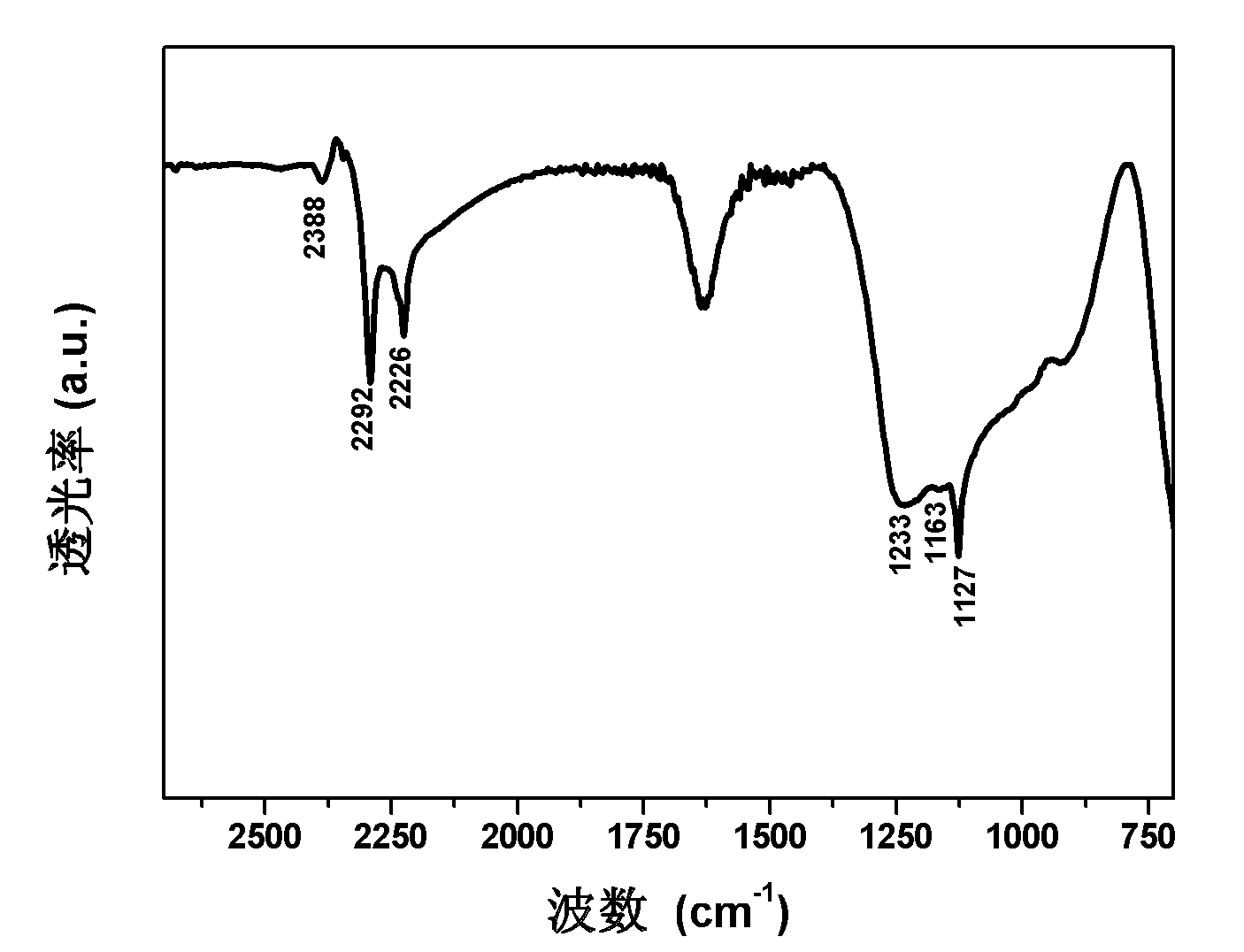

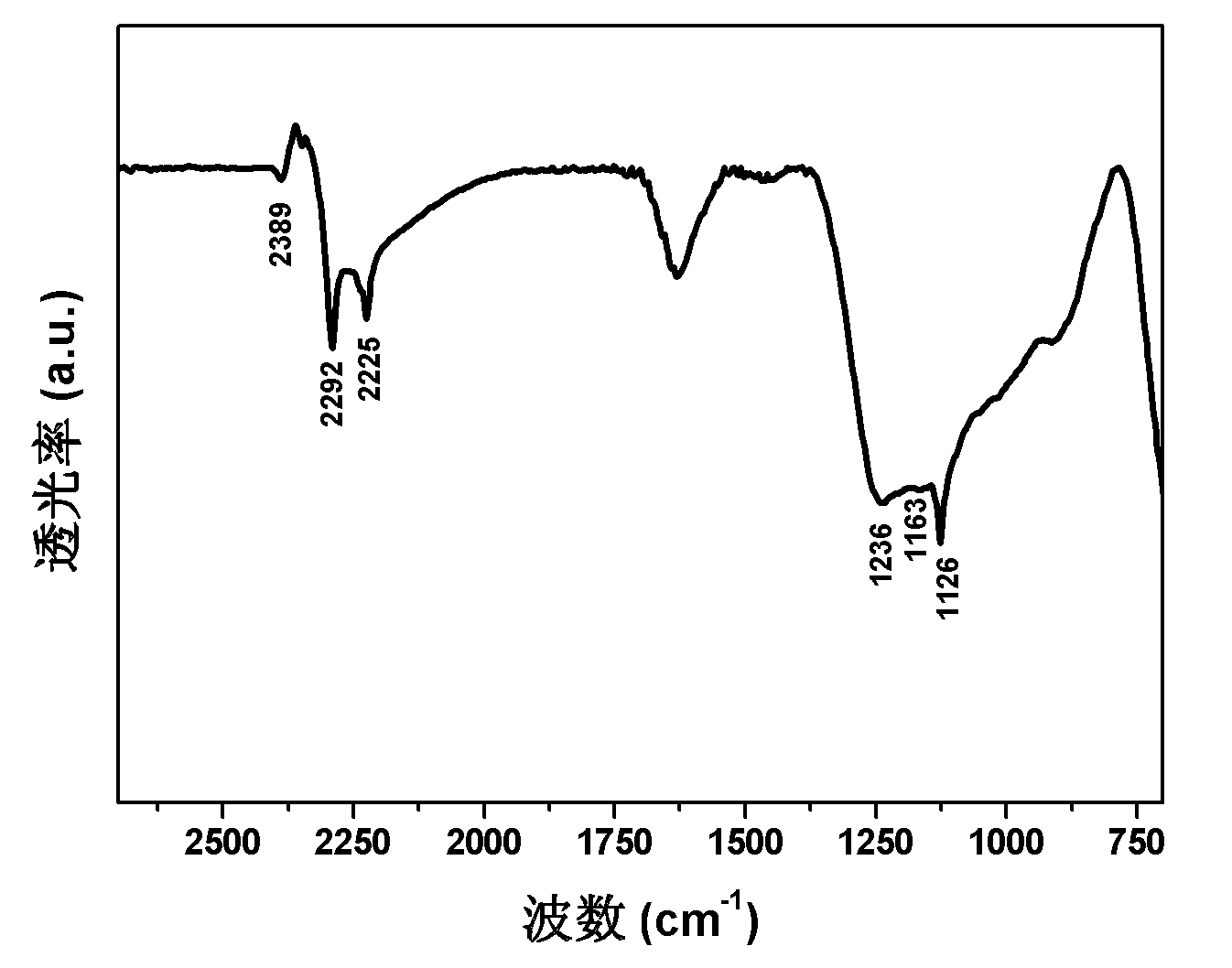

Hexagonal boron nitride two-dimensional ultrathin nanometer sheet as well as preparation method and application thereof

InactiveCN103043634ALow reaction temperatureIncrease productionMaterial nanotechnologyNitrogen compoundsHexagonal boron nitrideHeat stability

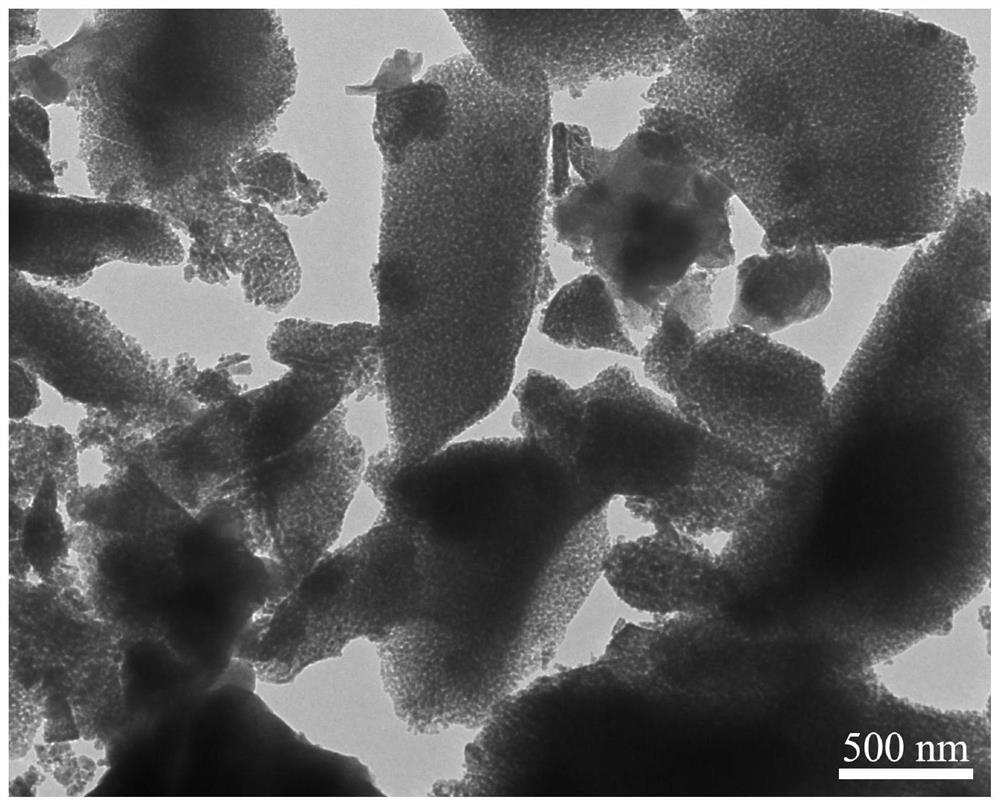

The invention discloses a hexagonal boron nitride two-dimensional ultrathin nanometer sheet as well as a preparation method and application thereof and belongs to the technical field of nanometer materials. According to the invention, metal boride (such as calcium boride, lanthanum boride, magnesium boride, titanium boride and the like) is adopted as a boron resource; ammonium salt (such as ammonium chloride, ammonium bromide, ammonium nitrate and the like) is adopted as a nitrogen source; and the hexagonal boron nitride two-dimensional ultrathin nanometer sheet with the thickness of 0.5-4.0nm is obtained through the reaction under a mild condition (at the temperature of 500-600 DEG C). The invention aims to realize the macro-quantity preparation of the hexagonal boron nitride two-dimensional ultrathin nanometer sheet at the mild temperature by adopting cheaper raw materials; the preparation method has the advantages of saving the energy, simplifying the experimental step and greatly reducing the product cost; and due to the high heat conductivity, heat stability and chemical stability, the hexagonal boron nitride two-dimensional ultrathin nanometer sheet can be applied to the fields of heat dissipation materials, polymer filling materials, catalyst carriers and the like.

Owner:SOUTH CHINA AGRI UNIV

Solid-phase synthesis method of Mg(BH4)2 hydrogen storage material

InactiveCN102730639ANo pollution in the processEasy to operateMonoborane/diborane hydridesHydrogen productionHigh pressure hydrogenHigh pressure

The invention discloses a solid-phase synthesis method of a Mg(BH4)2 hydrogen storage material. Magnesium boride or a mixture of magnesium boride and magnesium hydride is used as a starting material to carry out a mechanochemical reaction in high pressure hydrogen atmosphere, with a catalyst selected from one or more of a transition metal, a transition metal halide, a transition metal hydride and a transition metal oxide, so as to prepare the Mg(BH4)2. The preparation method of the Mg(BH4)2 hydrogen storage material of the invention has advantages of simple synthetic method, easily controlled reaction process, low cost and no organic pollution.

Owner:ZHEJIANG UNIV

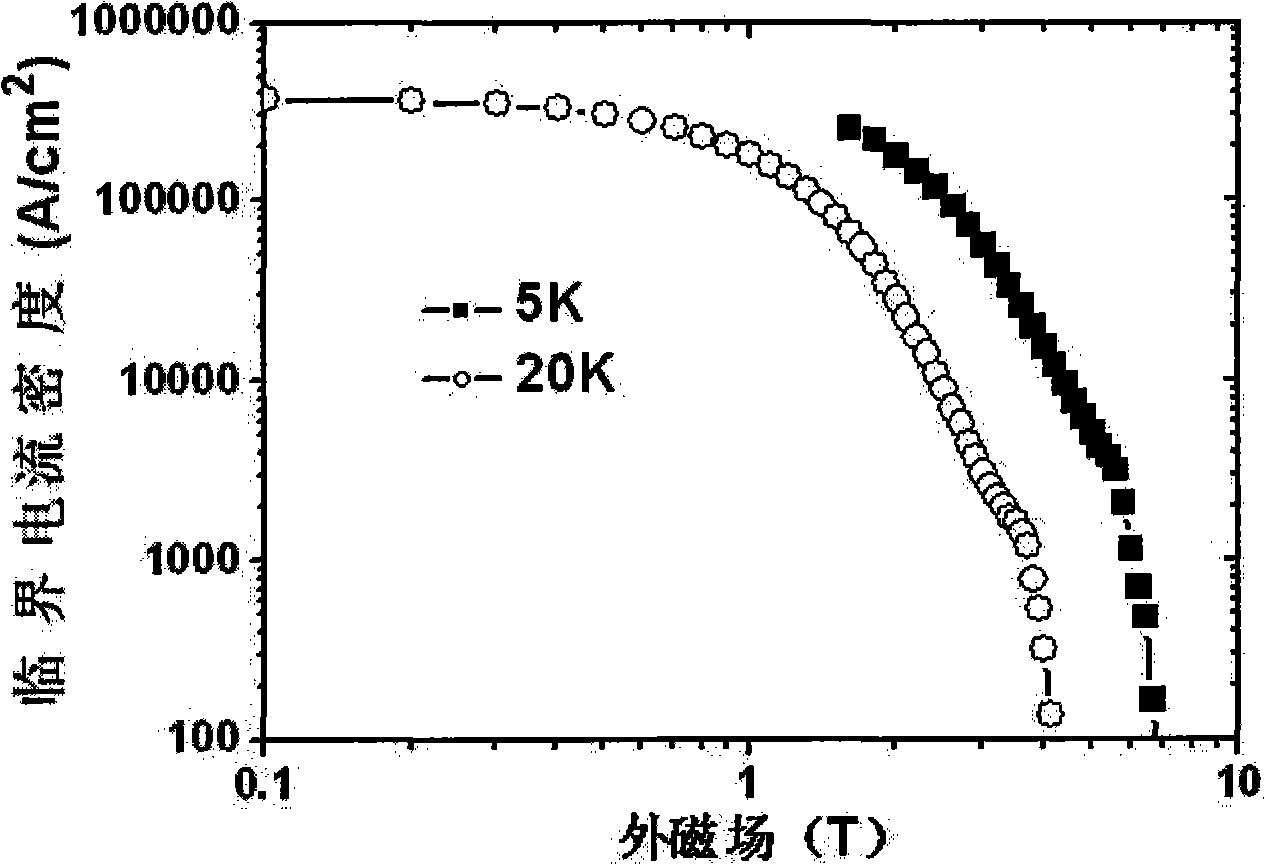

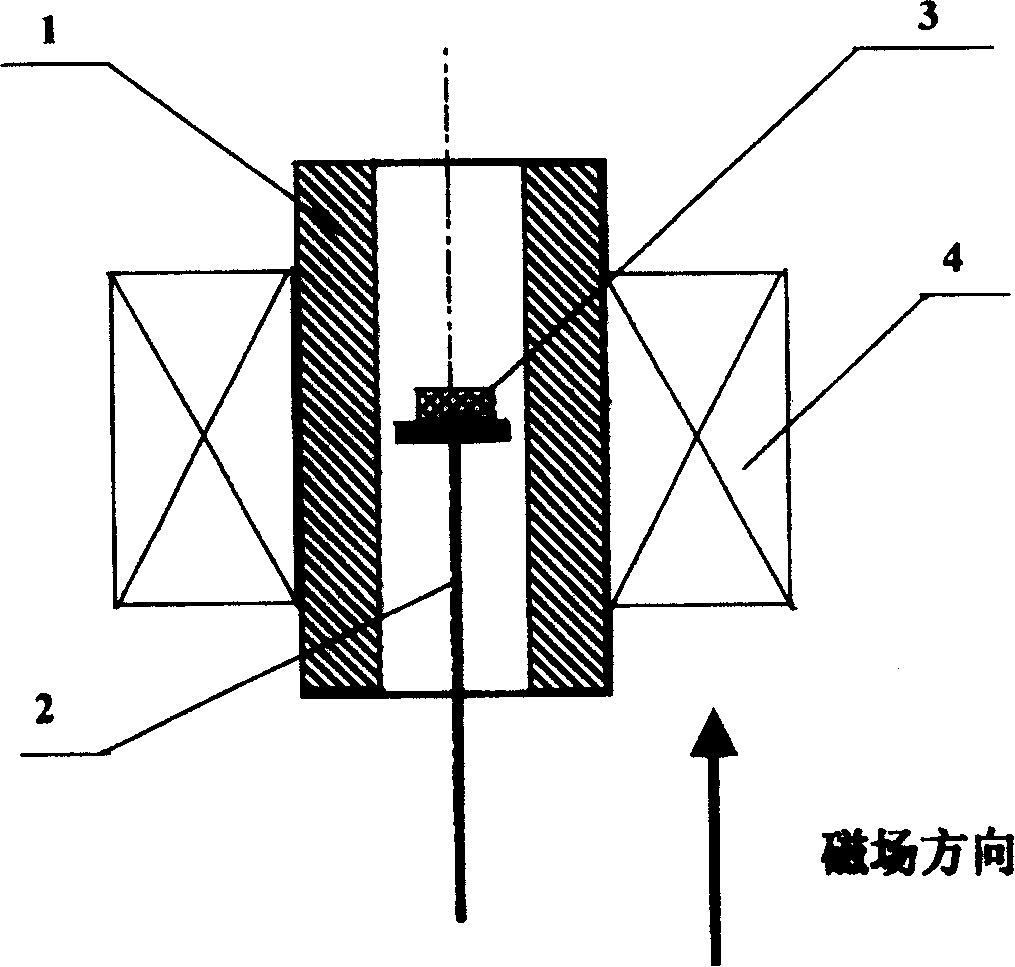

Process for preparing magnesium diboride superconductor

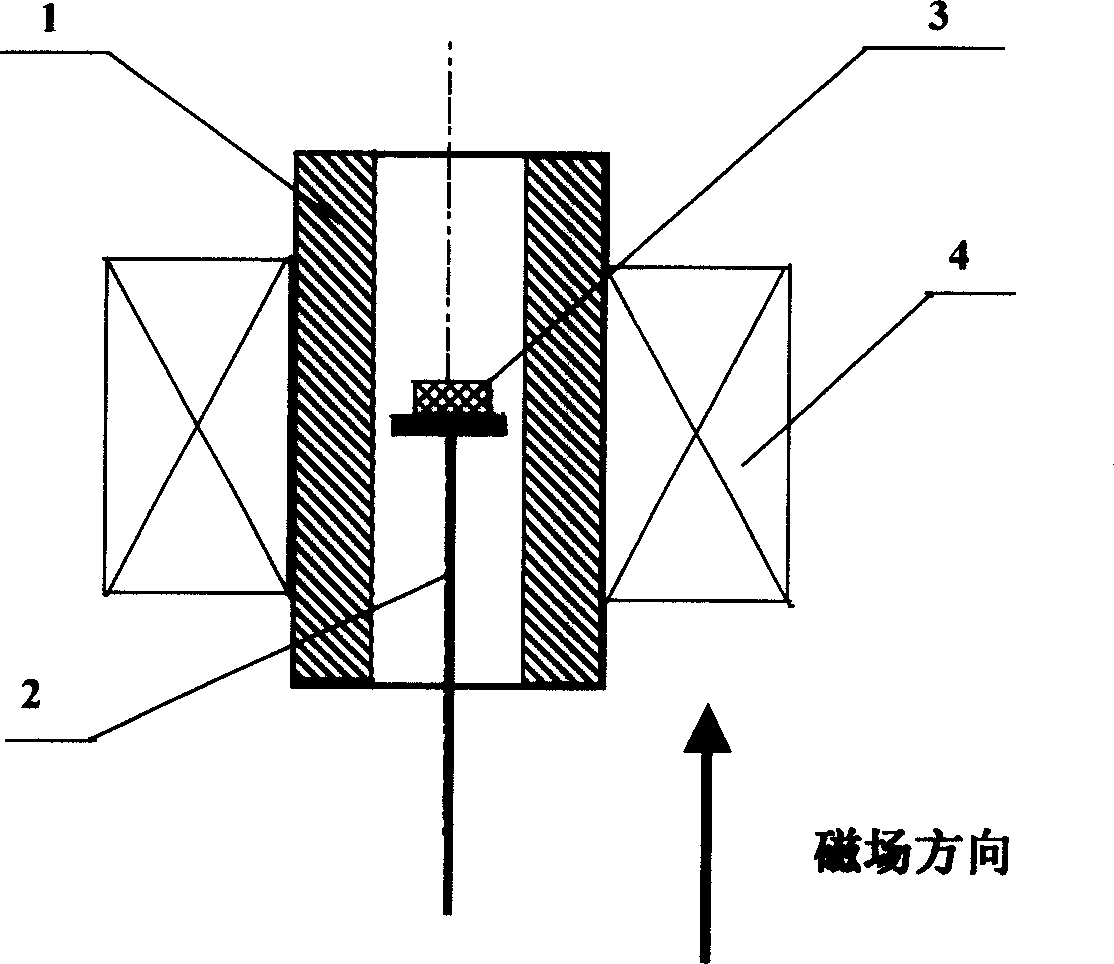

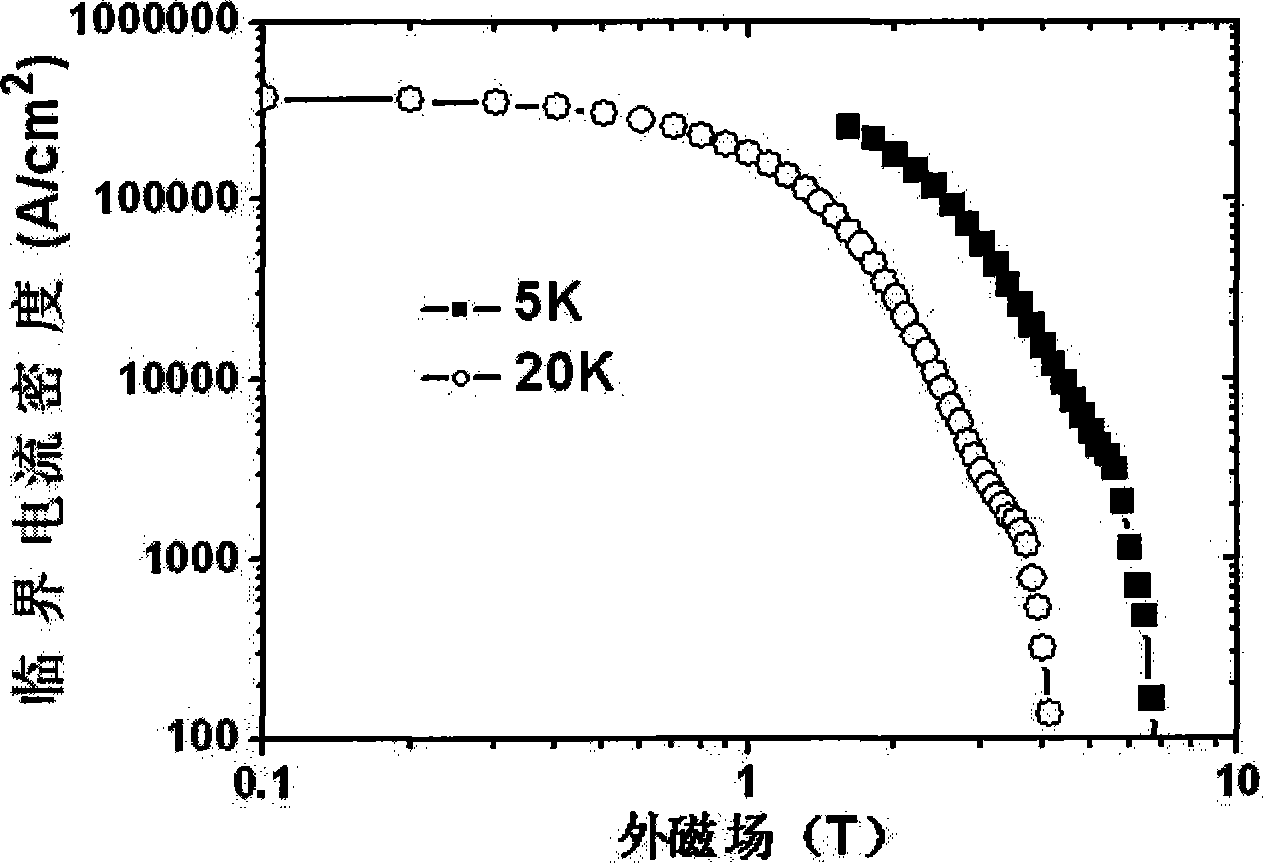

The preparation process of magnesium diboride superconductor features that magnesium diboride superconductor is prepared in strong magnetic field. Magnesium powder and boron powder in stoichiometric ratio are mixed homogeneously, the mixture is prepared into lump or belt sample, and the lump or belt sample is set heating furnace with Ar atmosphere and strong magnetic field and maintained at magnetic field of 0-30 tesla and temperature of 600-950 deg.c for 1-3 hr before the power source for the strong magnetic field and heating is turned off and the sample is cooled to room temperature inside the furnace. The present invention has effectively improved crystal grain connectivity and greatly raised clinical current structure of the magnesium diboride superconductor.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

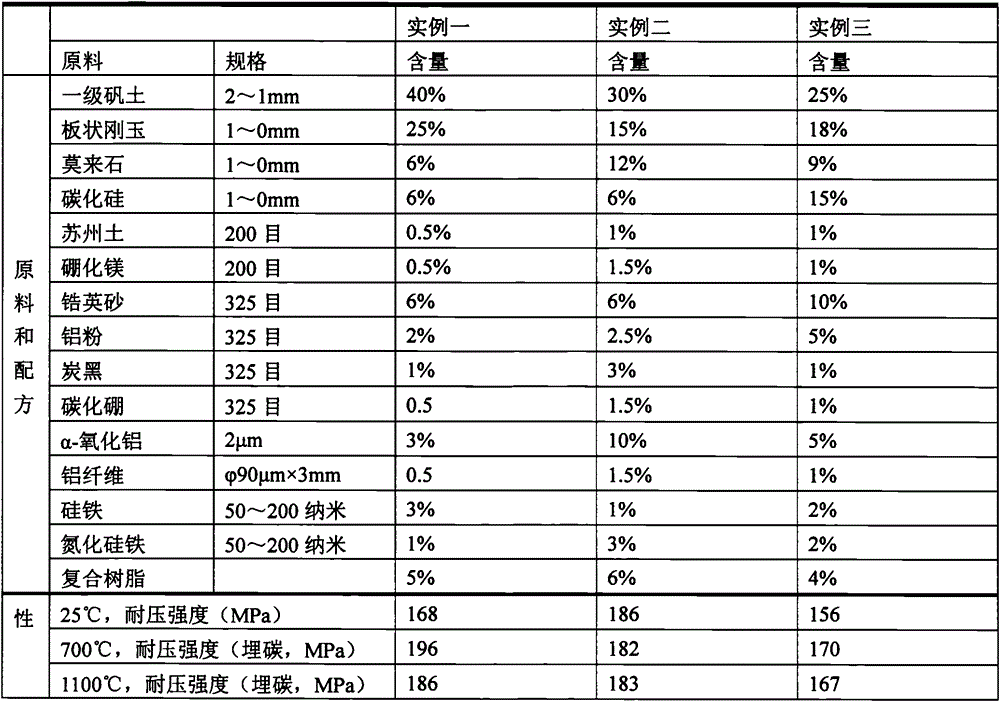

Nano-scale catalytic metal-ceramic bonding firing-free bitumen-impregnation-free environment-friendly slide plate and preparation method thereof

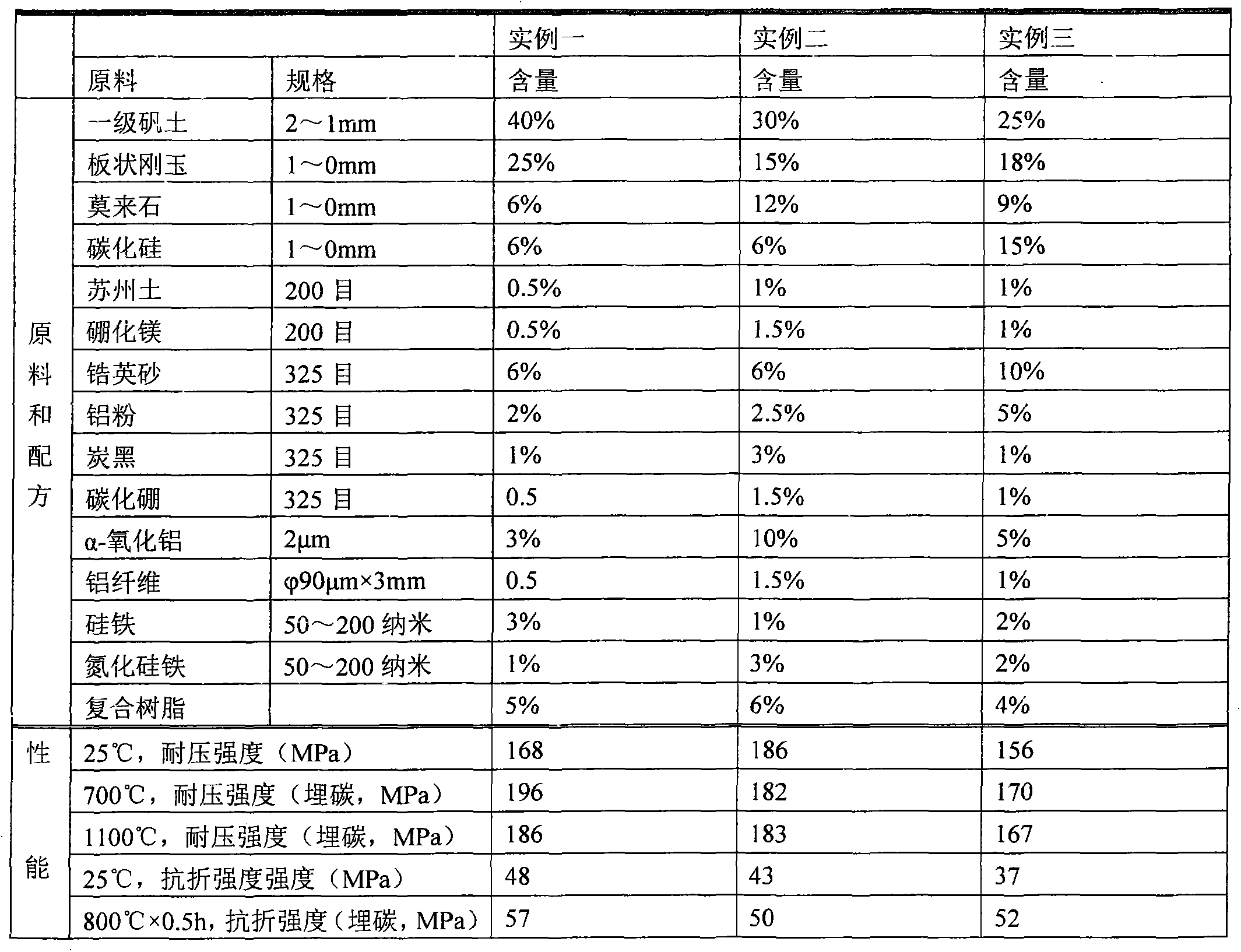

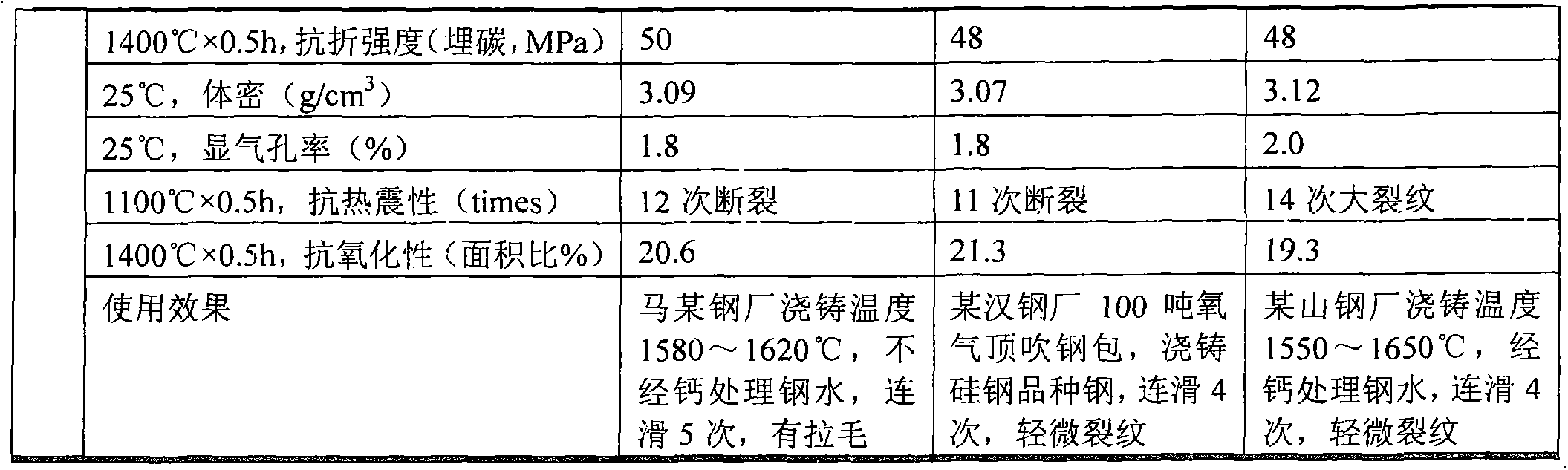

The invention relates to a nano-scale catalytic metal-ceramic bonding firing-free bitumen-impregnation-free environment-friendly slide plate and a preparation method thereof. The invention relates to the firing-free bitumen-impregnation-free environment-friendly slide plate and the process thereof. The invention relates to the field of a refractory material. The material comprises the raw materials of 25-40% granular first-grade alumina, 15-25% of tabular corundum, 6-12% of mullite, 6-15% of silicon carbide fine powder, 0.5-1% of clay, 0.5-2% of magnesium boride, 6-10% of zircon sand, 2-5% of aluminum powder, 1-3% of carbon black, 0.5-1.5% of boron carbide, 3-10% of alumina micro-powder, 0.5-1.5% of aluminum fiber, 1-3% of nano-powder ferrosilicon, 1-3% of iron silicon nitride, and 4-6% of a composite resin binder. The process comprises the following steps: resin, polycarboxylic acid and nano-powder are mixed to prepare the composite resin binder; the granular materials are dry-mixed; premixed powder and the binder are added; and mix grinding, aging, molding, drying, strapping, grinding, shell-applying, and packaging are carried out. The process does not require a firing step, such that energy is saved; and bitumen impregnation is not required, such that pollution is avoided. When the slide plate is applied in a continuous-casting large ladle, the slide plate can be used for continuous sliding more than 4 times. The slide plate can also be used in converter slag stopping.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD +1

Magnesium boride super conductive wire and its preparation method

InactiveCN1411004AStrengthen the die connectionPromote fragmentationSuperconductors/hyperconductorsSuperconductor devicesSwagingCarbon steel

The superconductive line material consists of the line core and the enveloping layer. The material of the line core is MgB2 possessing the superconductive properties. The enveloping layer is the metal cladding composed of low-carbon steel, nickel or tantalum. The preparing steps are as follows. According to mol ratio, Mg powder and B powder being mixed and ground is loaded into the metal tube. When the mixed powder is tight, the two ends of the tube are sealed, which is put into the oxygen free copper tube. Rotary swaging, rolling, vacuum annealing the wire obtain the MgB2 superconductive line. The invention possesses the features of good processability, fine crystal grain of MgB2, intensive connection of crystal grain of MgB2 and no phenomenon of rupture.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

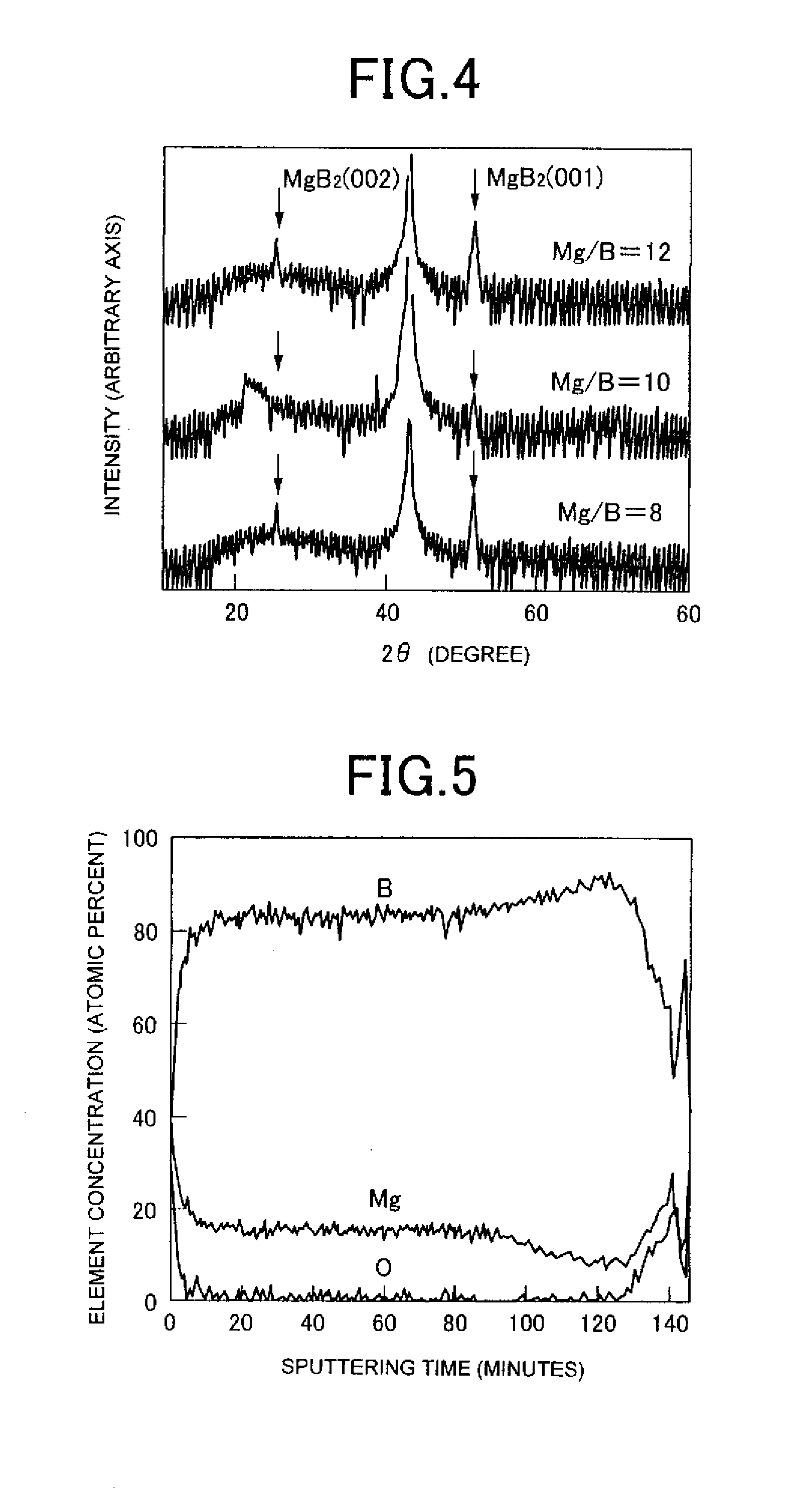

Superconducting magnesium boride thin-film and process for producing the same

InactiveUS20090062128A1High crystallinityPromote film formationSuperconductors/hyperconductorsElectric discharge heatingMetallurgyCrystallinity

A magnesium boride thin film having a B-rich composition represented by the general formula of MgBx (x=1 to 10) and a superconducting transition temperature of 10K or more has superior crystallinity and orientation and is used as a superconducting material. This thin film is formed by maintaining a film forming environment in a high vacuum atmosphere of 4×10−5 Pa or less, and simultaneously depositing Mg and B on a substrate maintained at a temperature of 200° C. or less so as to grow the film at a growth rate of 0.05 nm / sec or less. It is preferable to supply an Mg vapor and a B vapor into the film forming environment at an Mg / B molar ratio of 1 / 1 to 12 / 1.

Owner:IWATE UNIVERSITY

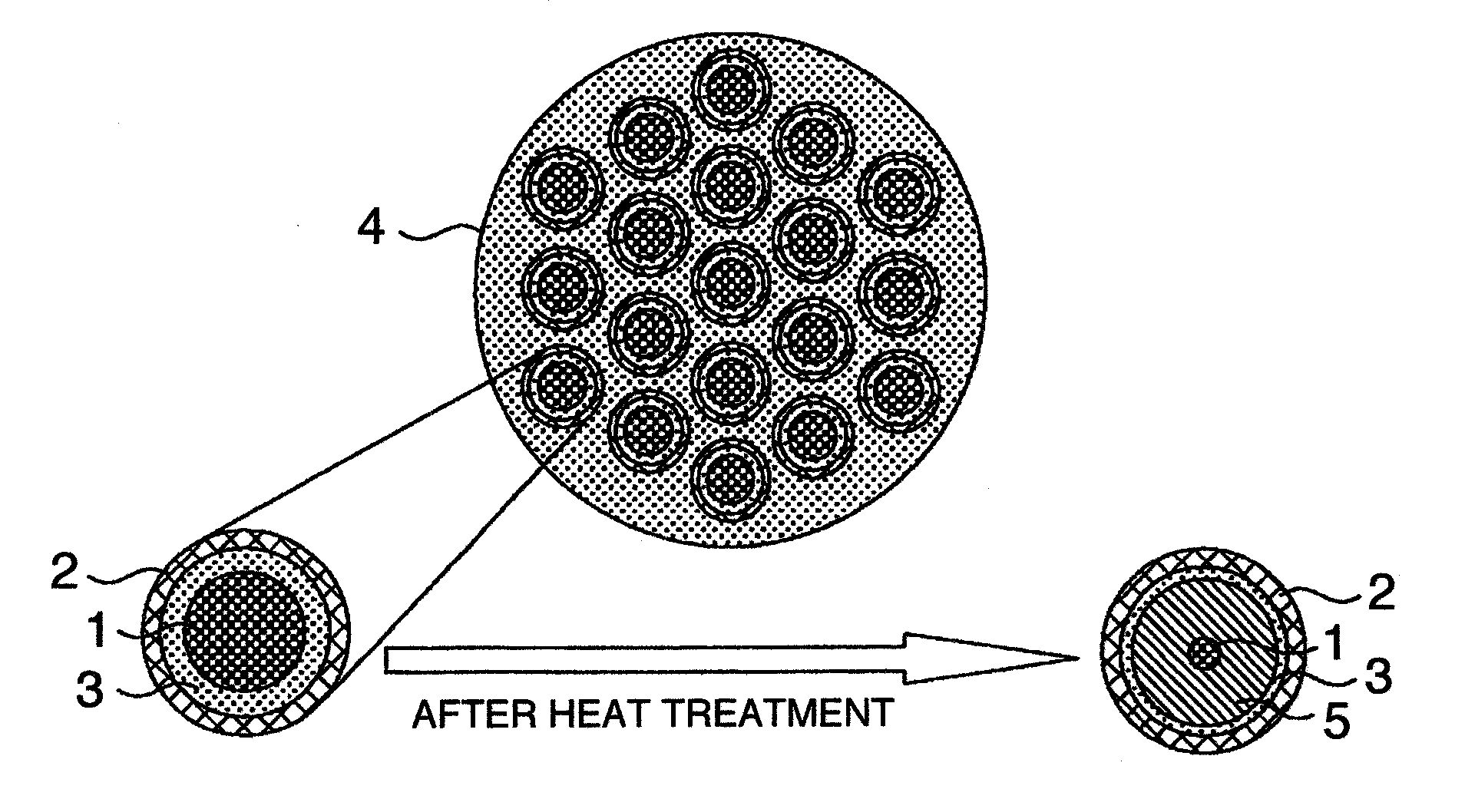

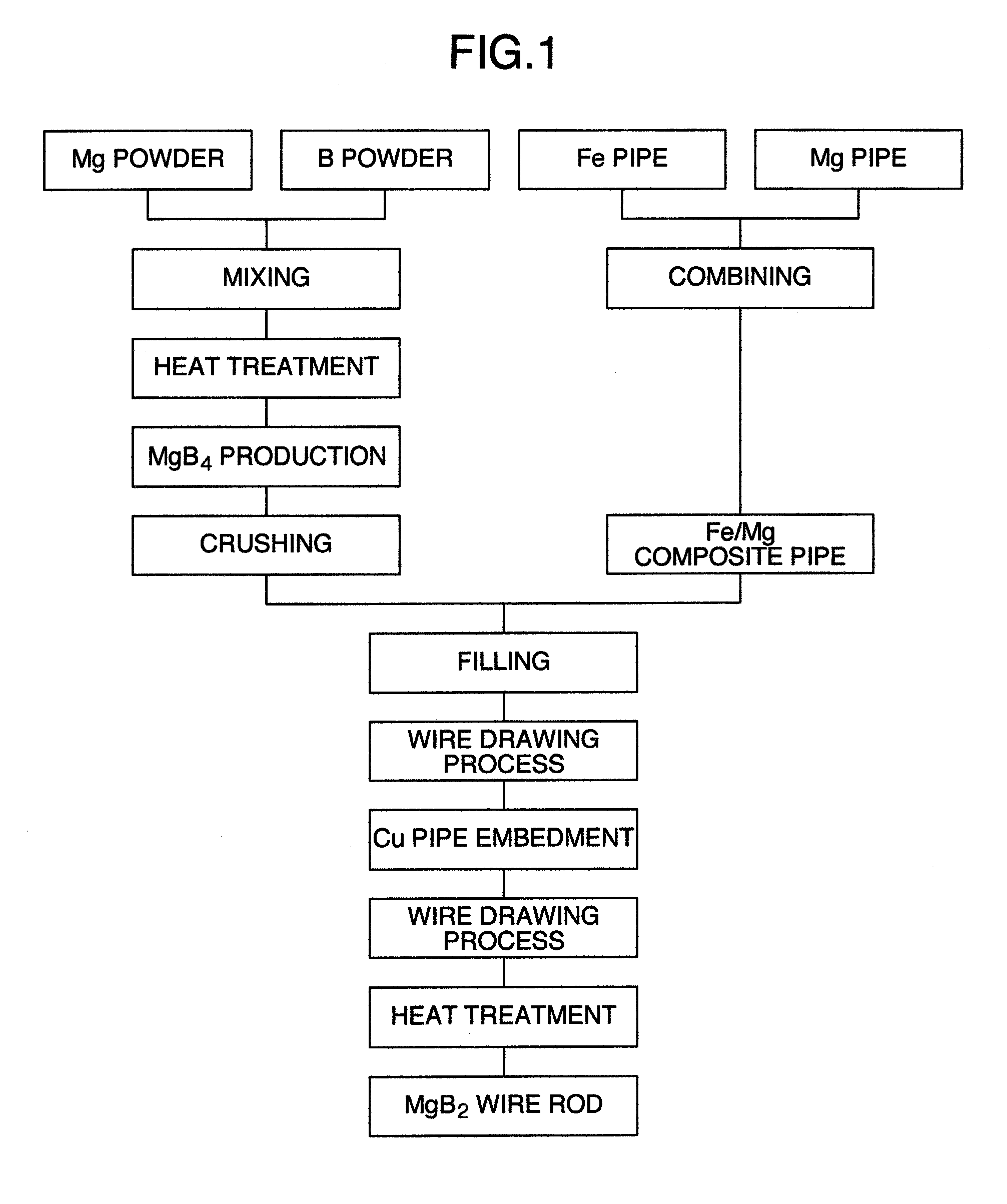

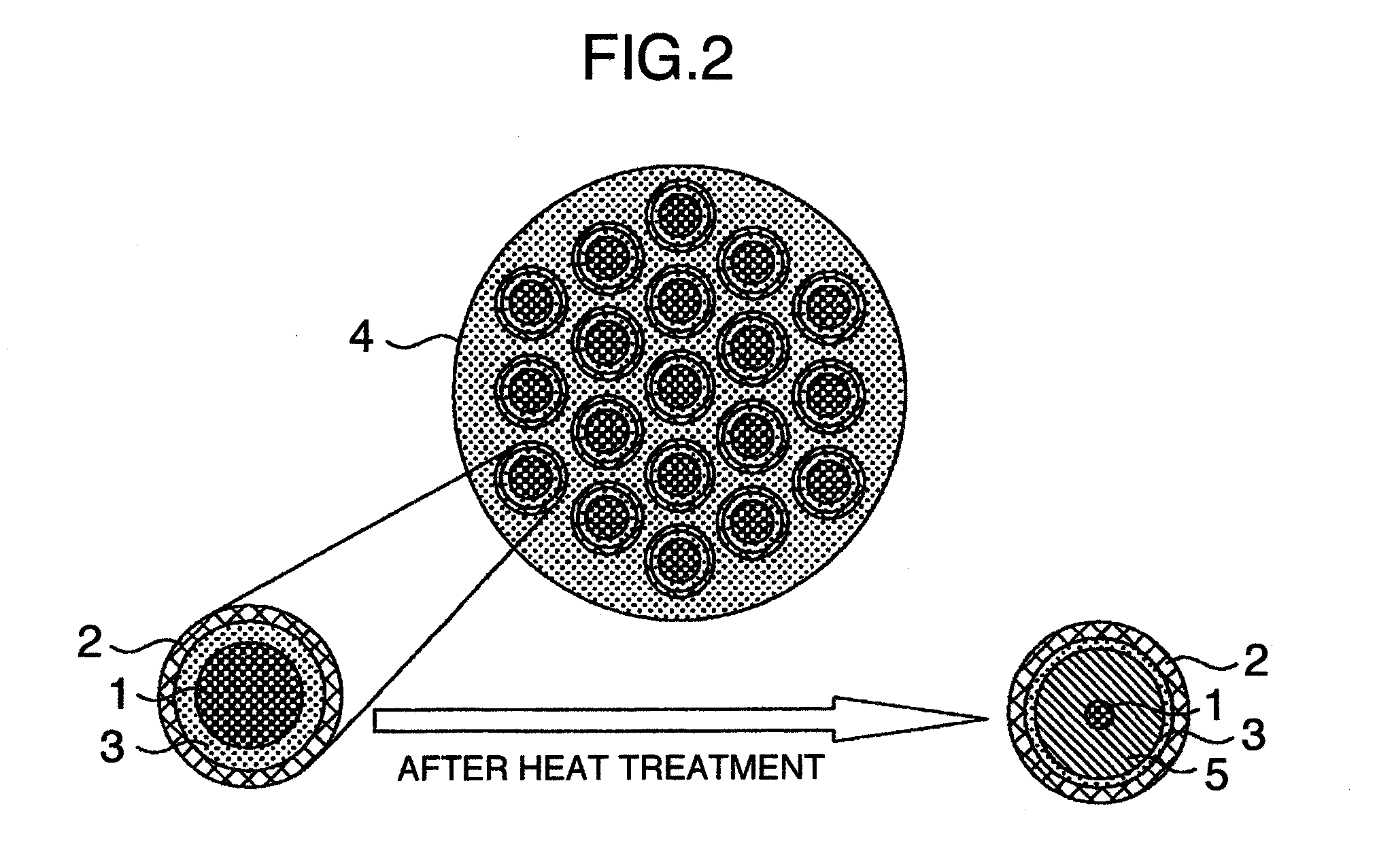

MgB2 SUPERCONDUCTIVE WIRE

The invention provides a MgB2 superconductive wire which is long and has a high critical current density. The invention provides a manufacturing method of a superconductive wire in which a magnesium or a magnesium alloy is reacted with a magnesium boride expressed by MgBx (x=4, 7, 12) by carrying out a heat treatment. A superconductive wire is characterized by the magnesium boride expressed by the MgBx (x=4, 7, 12) is included in a part.

Owner:HITACHI LTD

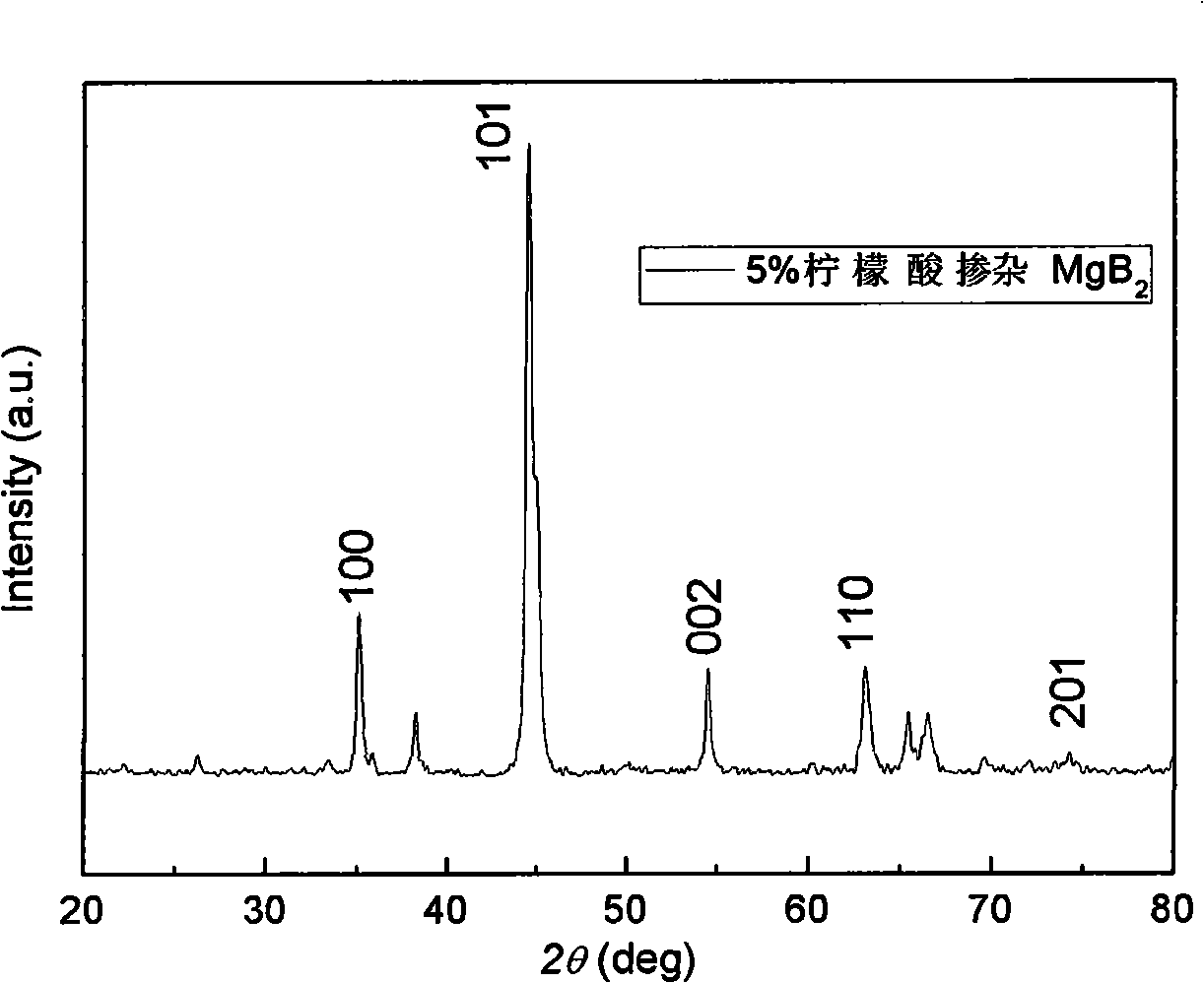

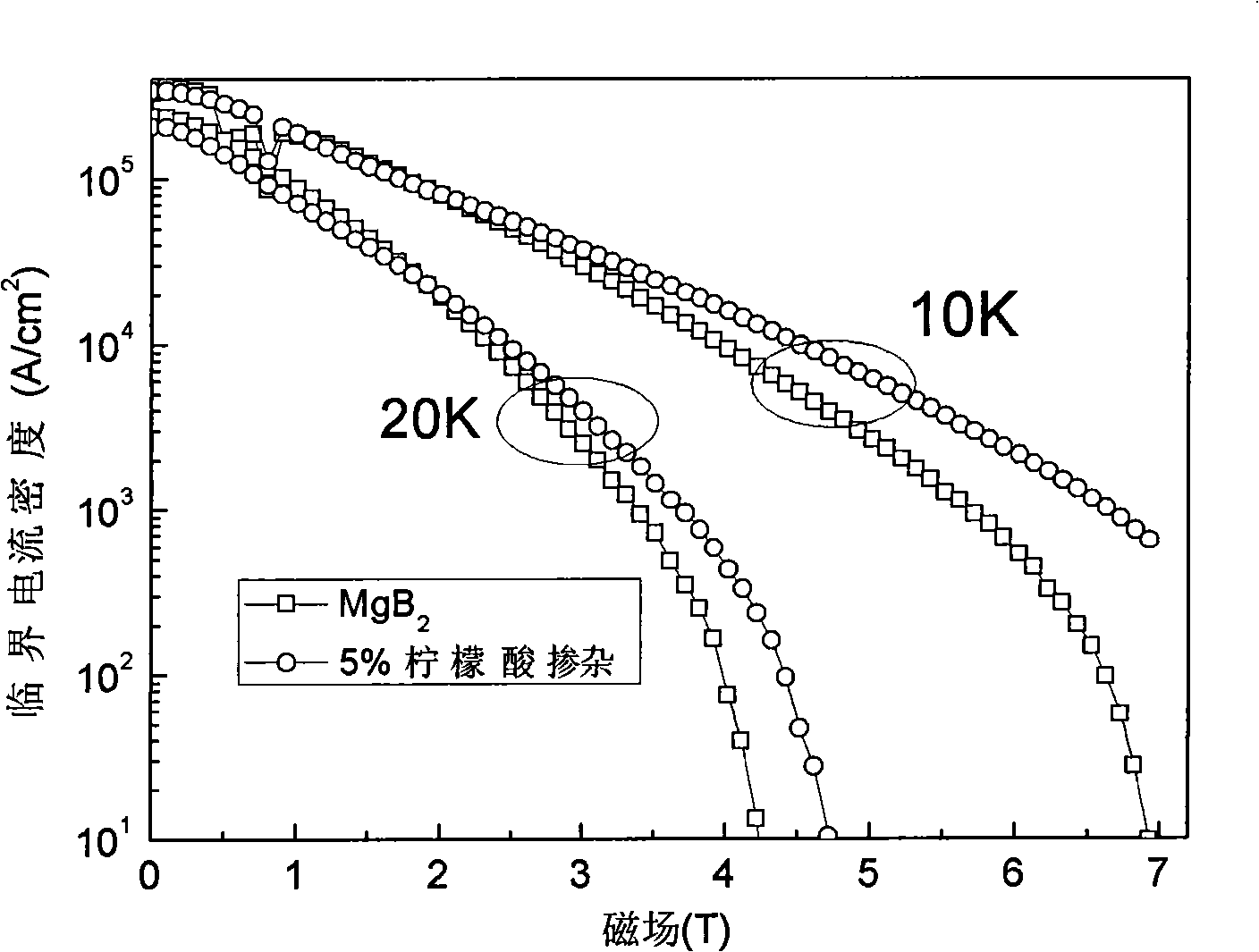

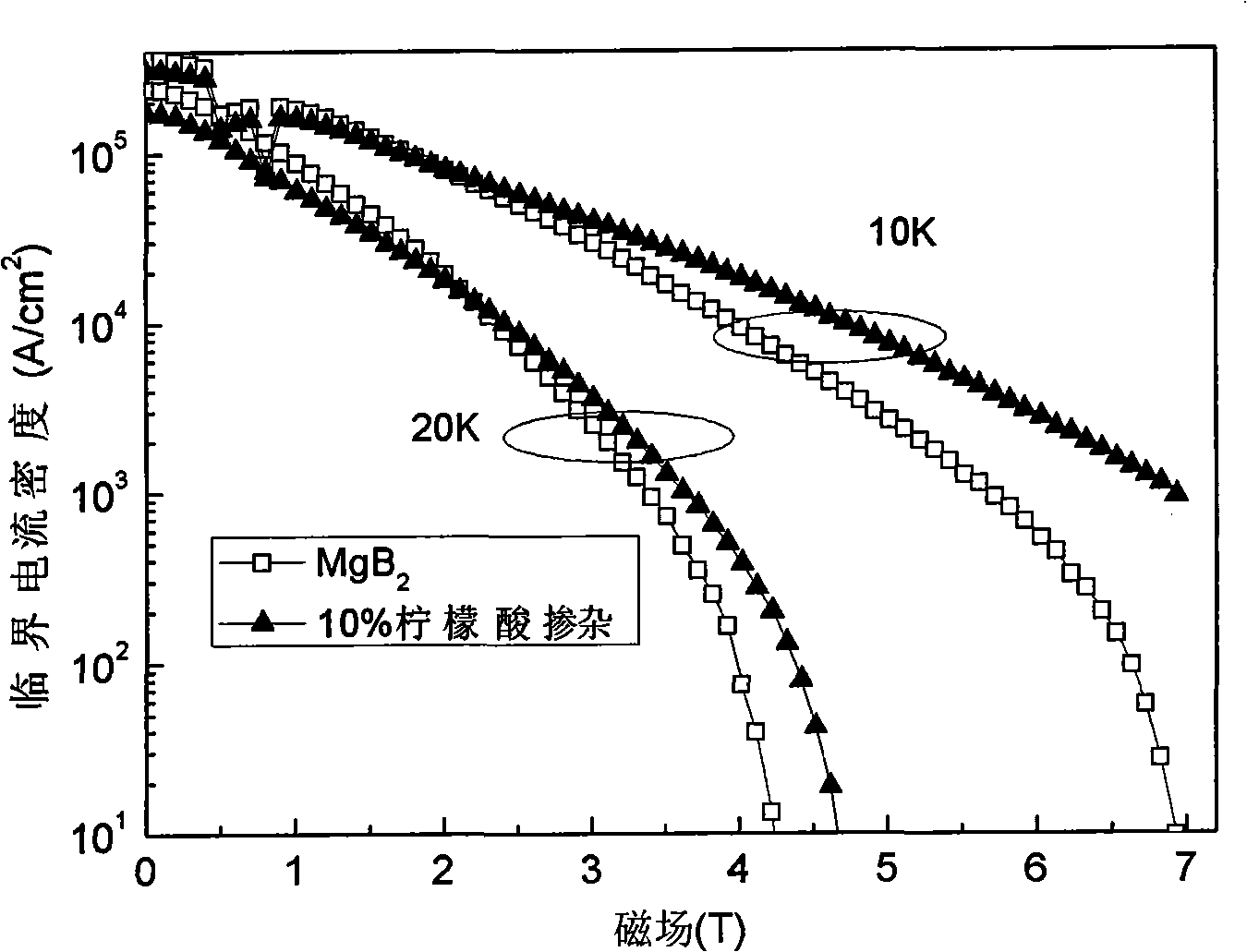

Method for preparing magnesium diboride superconductive material

InactiveCN101279741AEvenly dopedIncrease the upper critical fieldSuperconductors/hyperconductorsMetal boridesMass ratioArgon atmosphere

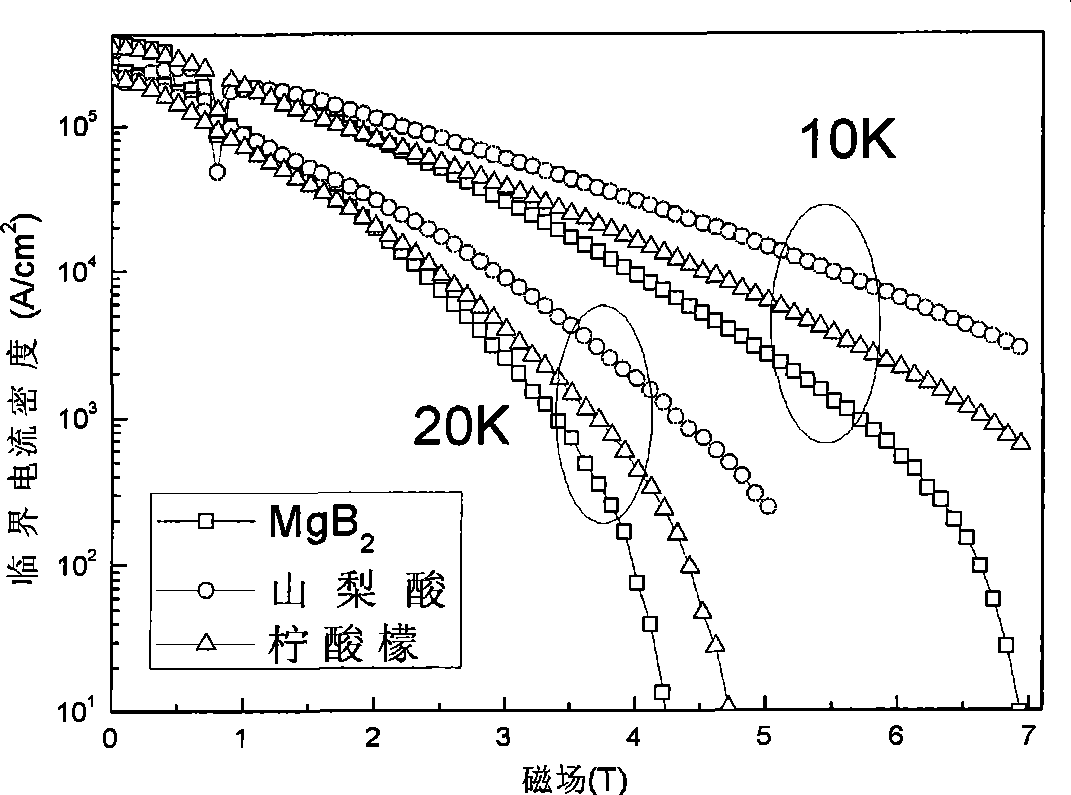

The invention relates to a method for preparing magnesium boride superconducting material. The method for preparing the magnesium boride superconducting material is that magnesium powder and boron powder are respectively weighted according to 1:0.7-2.5 of molar ratio; adulterant which is one of citric acid and citrate is weighted according to 1:0.01-1 of mass ratio between the total mass of the magnesium powder and the boron powder and the mass of the adulterant is weighted; the magnesium powder, the boron powder and the adulterant are evenly mixed into mixing powder, then sintered under the protection of argon atmosphere at the temperature of 600-1200 DEG C and the product is obtained after the heat is preserved for 0.5-12 hours. The method has short preparation time, low reaction temperature, high efficiency and low cost and is especially suitable for industrial production; the critical current density of the magnesium boride superconducting material prepared by the method is increased remarkably and is especially very high in highfield, thereby being good for the application in highfield and having strong practicability.

Owner:SOUTHWEST JIAOTONG UNIV

Preparation of magnesium boride doped superconduction material

InactiveCN101462881ALow reaction temperatureShorten the timeSuperconductors/hyperconductorsSuperconductor devicesDopantArgon atmosphere

A preparation method of a magnesium diboride-doped superconducting material comprises the following steps: respectively weighing magnesium powder and boron powder based on a mol ratio of 1:0.7-2.5; weighing a dopant based on the ratio of the total mass of the magnesium powder and the boron powder to the mass of the dopant of 1:0.01-1, wherein, the dopant is one of sorbic acid or sorbate; evenly mixing the magnesium powder, the boron powder and the dopant powder to obtain mixed powder; and sintering the mixed powder under the protection of argon atmosphere at the sintering temperature of 600 DEG C-1200 DEG C, and keeping the temperature for 0.5-12 hours, thus obtaining the superconducting material. The method has the advantages of short preparation time, low reaction temperature, high efficiency and low cost, and is especially suitable for industrialized production. The magnesium diboride superconducting material obtained by the method has obviously increased critical current density especially very high critical current density in a high magnetic field, which is beneficial to the application of the superconducting material to the high magnetic field; and the superconducting material has strong practicability.

Owner:SOUTHWEST JIAOTONG UNIV

Method for preparing magnesium diboride superconductive wire and strip

InactiveCN101279740AImprove compactnessFirmly connectedSuperconductors/hyperconductorsMetal boridesHigh magnesiumDiboride

The invention relates to a method for preparing a magnesium boride superconducting line and belt material. The preparation method is that a. preparation of precursor powder: high magnesium diboride MgBx powder is taken as the precursor powder, wherein, x is more than or equal to 4 and less than or equal to 12; or magnesium powder and amorphism boron powder are mixed according to 1:3-20 of stoichiometric ratio between magnesium and boron to form the precursor powder; b. putting into a magnesium pipe: the precursor powder is put into a magnesium pipe, compacted and sealed; c. putting into a canning pipe: the magnesium pipe is put into a metal canning pipe and is sealed after the metal canning pipe is fully filled with metal powder as a barrier layer; or the magnesium pipe is first put into a barrier layer metal pipe and then is put into the metal canning pipe and the metal canning pipe is sealed; d. moulding treatment: the metal canning pipe is produced into line and belt material; e. heat treatment: the metal canning pipe is put into a pipe typed furnace and under the protection of argon, the temperature is raised to 700-1200 DEG C by the speed of 1-10 DEG C / minute, preserved for 1-30 hours and then cooled to room temperature. The MgB2 superconducting line and belt material prepared by the method has high compactability, good grain connectivity and even cross section.

Owner:SOUTHWEST JIAOTONG UNIV

Method for manufacturing magnesium boride superconductive belt material

InactiveCN102034575AImprove compactnessIncrease the critical current densitySuperconductors/hyperconductorsSuperconductor devicesDiamond-like carbonArgon atmosphere

The invention provides a method for manufacturing a magnesium boride superconductive belt material. The method comprises the following steps: A, uniformly distributing amorphous boron on a conductive substrate by adopting a coating method to form an amorphous boron layer with thickness of between 0.1 and 2.0mm; B, covering a magnesium or magnesium alloy flake with thickness of between 0.1 and 2.0mm on the boron layer, and rolling to form a magnesium-boron-substrate combination; C, putting the combination in the step B in a thermal treatment furnace, under the protection of argon atmosphere, heating to the temperature of between 550 and 800 DEG C, preserving the temperature for 0.1 to 3 hours, and cooling; D, coating metal, metallic oxide, silicon carbide or diamond like carbon film on the combination which is treated in the step C to serve as a protective layer to form a composite body; and E, cutting the composite body in the step D into long belts. The MgB2 superconductive belt prepared by the method has the advantages of good compactness and grain connection, high critical current density, uniform current density distribution and high fatigue life, and is suitable for commercial application. The method is simple, and is suitable for industrial production.

Owner:SOUTHWEST JIAOTONG UNIV

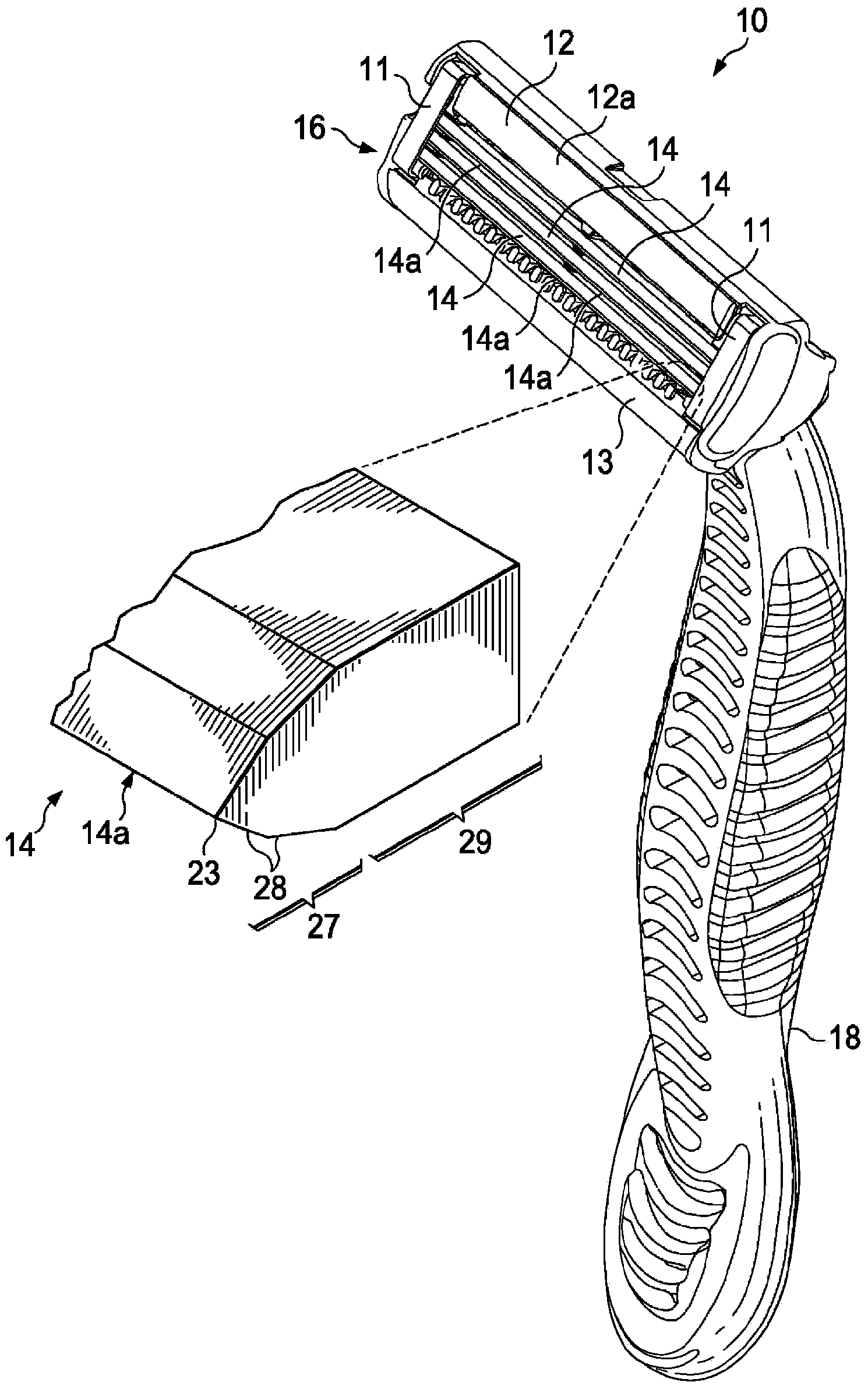

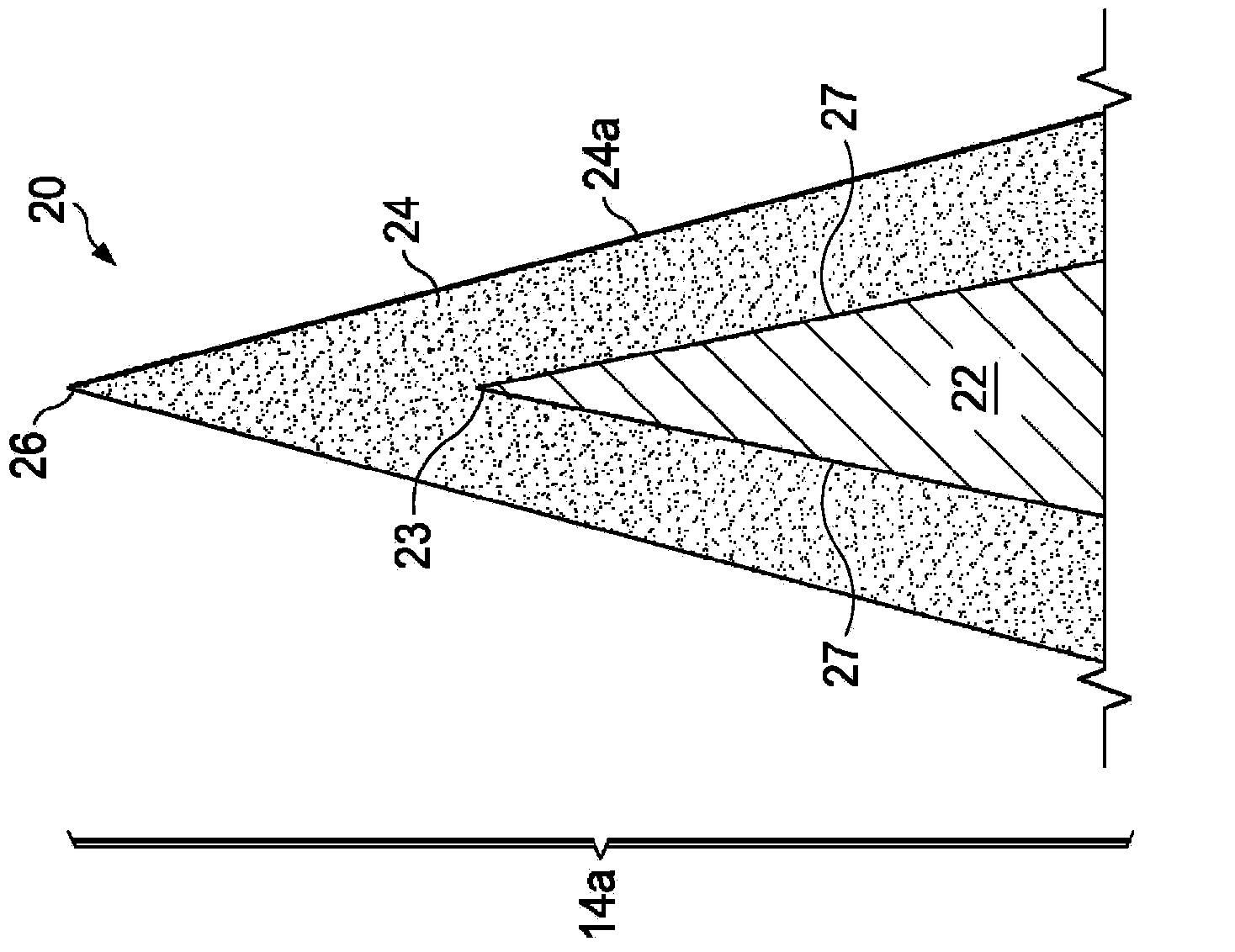

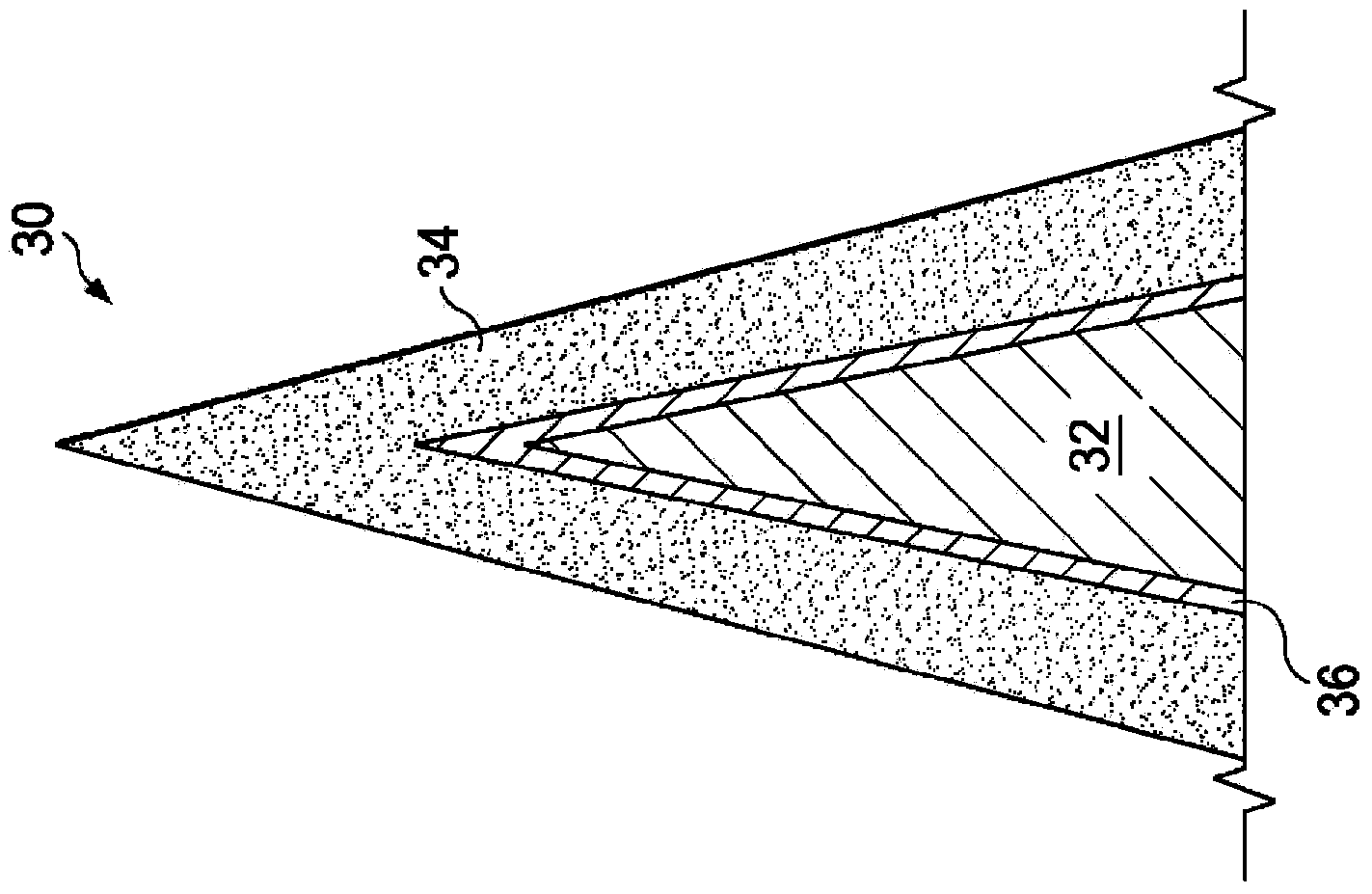

Razor blades with aluminum magnesium boride (AlMgB14)-based coatings

This invention relates to a novel application of hard, low friction aluminum magnesium boride (AlMgB14, also known as BAM) based ceramic coatings to surfaces of razor components and in particular to blade edges of razor blades. On razor blade edges, these coatings may elevate blade performance, while also simplifying the manufacturing process.

Owner:THE GILLETTE CO

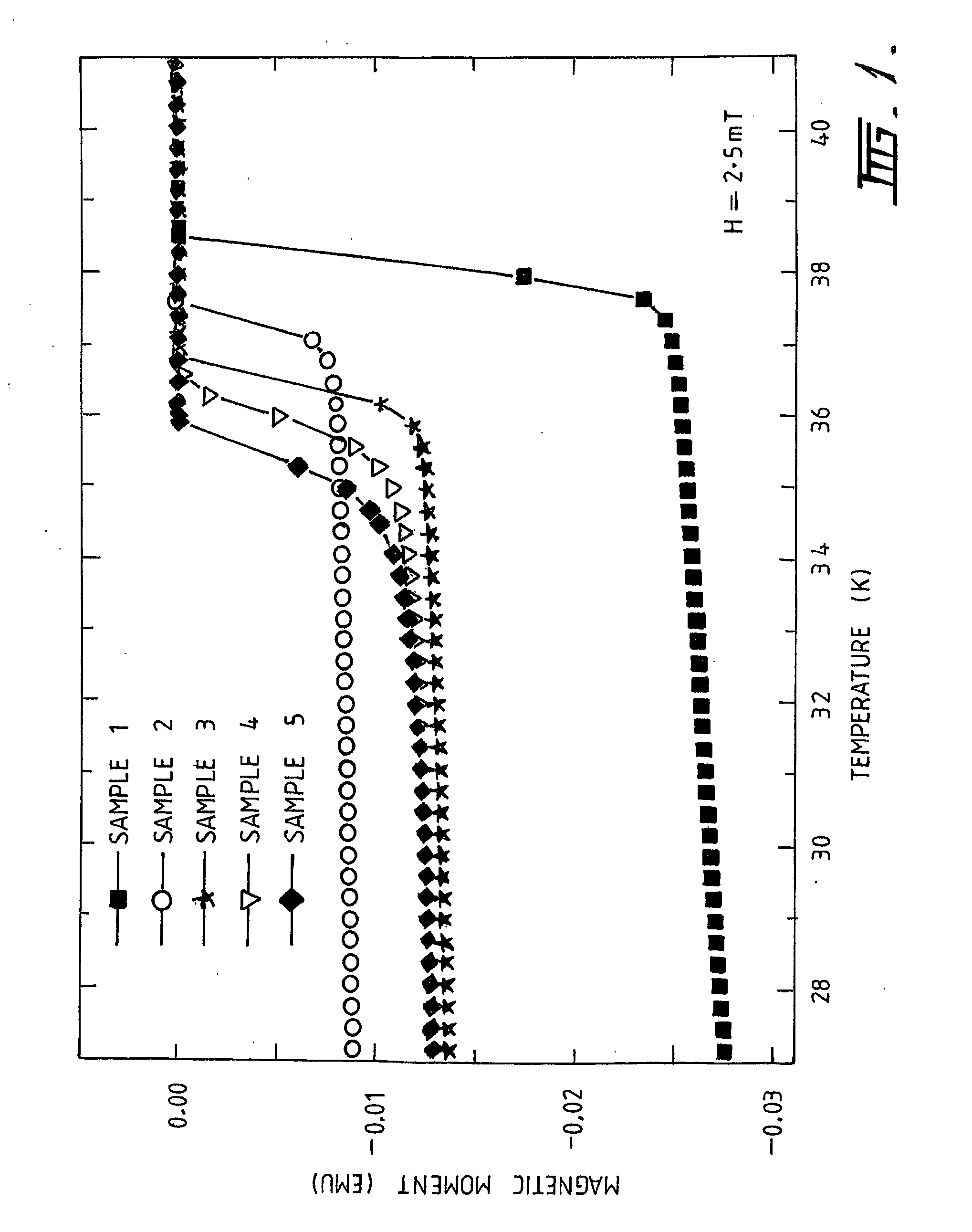

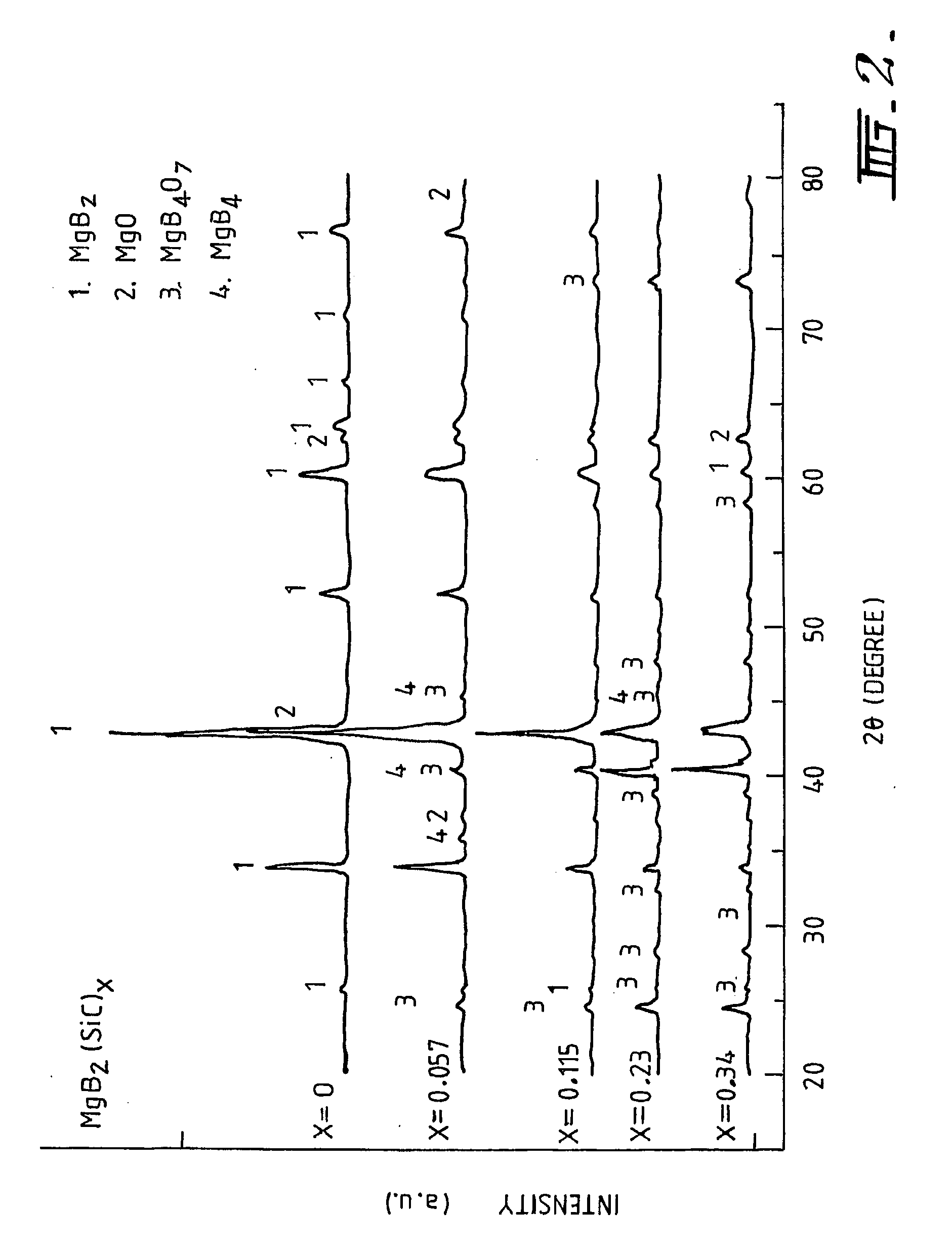

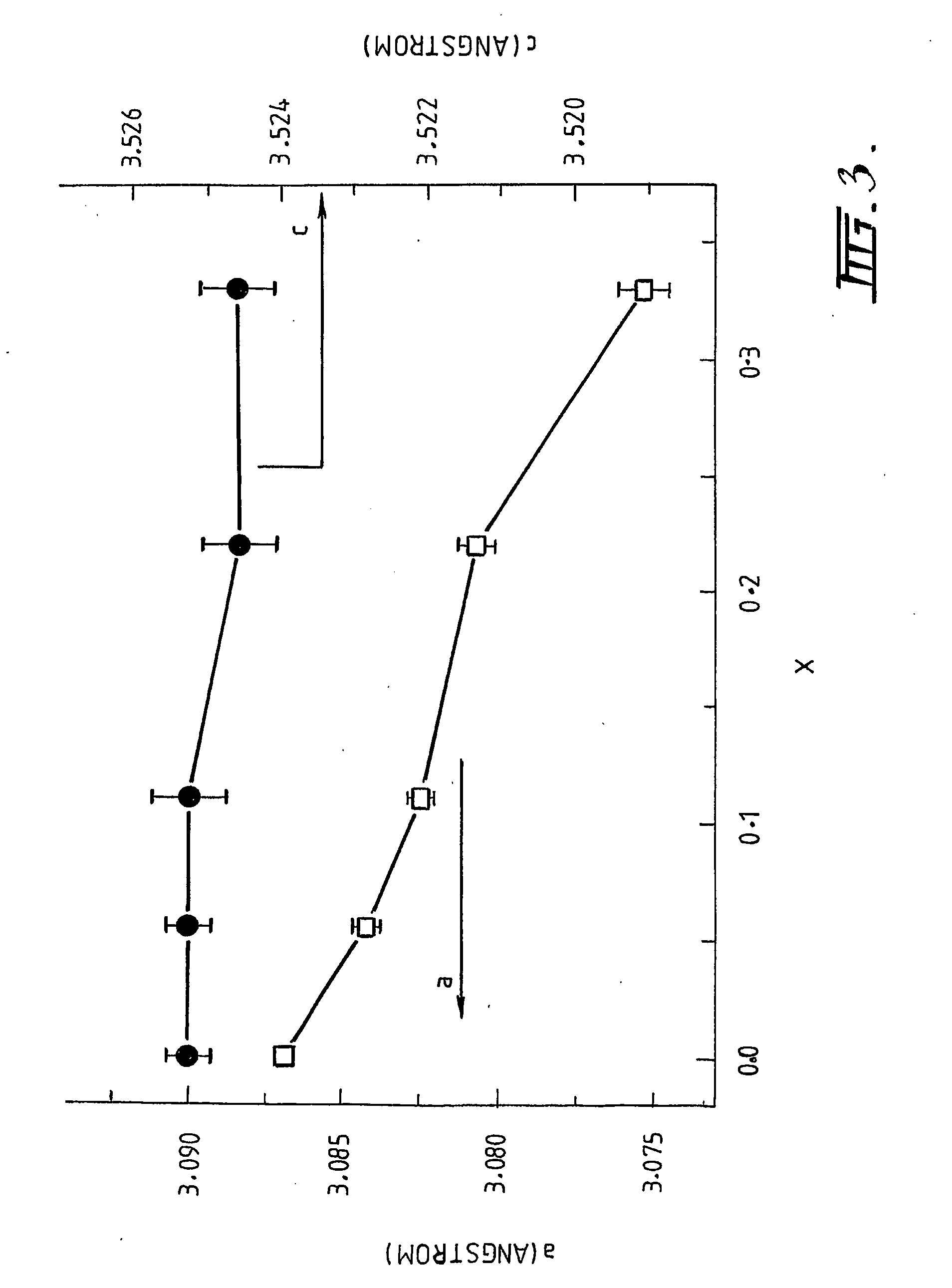

Method of synthesis of a superconducting material

A method of synthesizing a superconducting material, comprising mixing starting materials comprising magnesium, boron, silicon and carbon; heating the mixture of starting materials to a temperature in the range between 650° C. and 2000° C. to produce a material comprising magnesium boride doped with silicon carbide; and cooling the resulting material to a temperature below the critical temperature of the material to render the material capable of superconducting.

Owner:UNIV OF WOLLONGONG

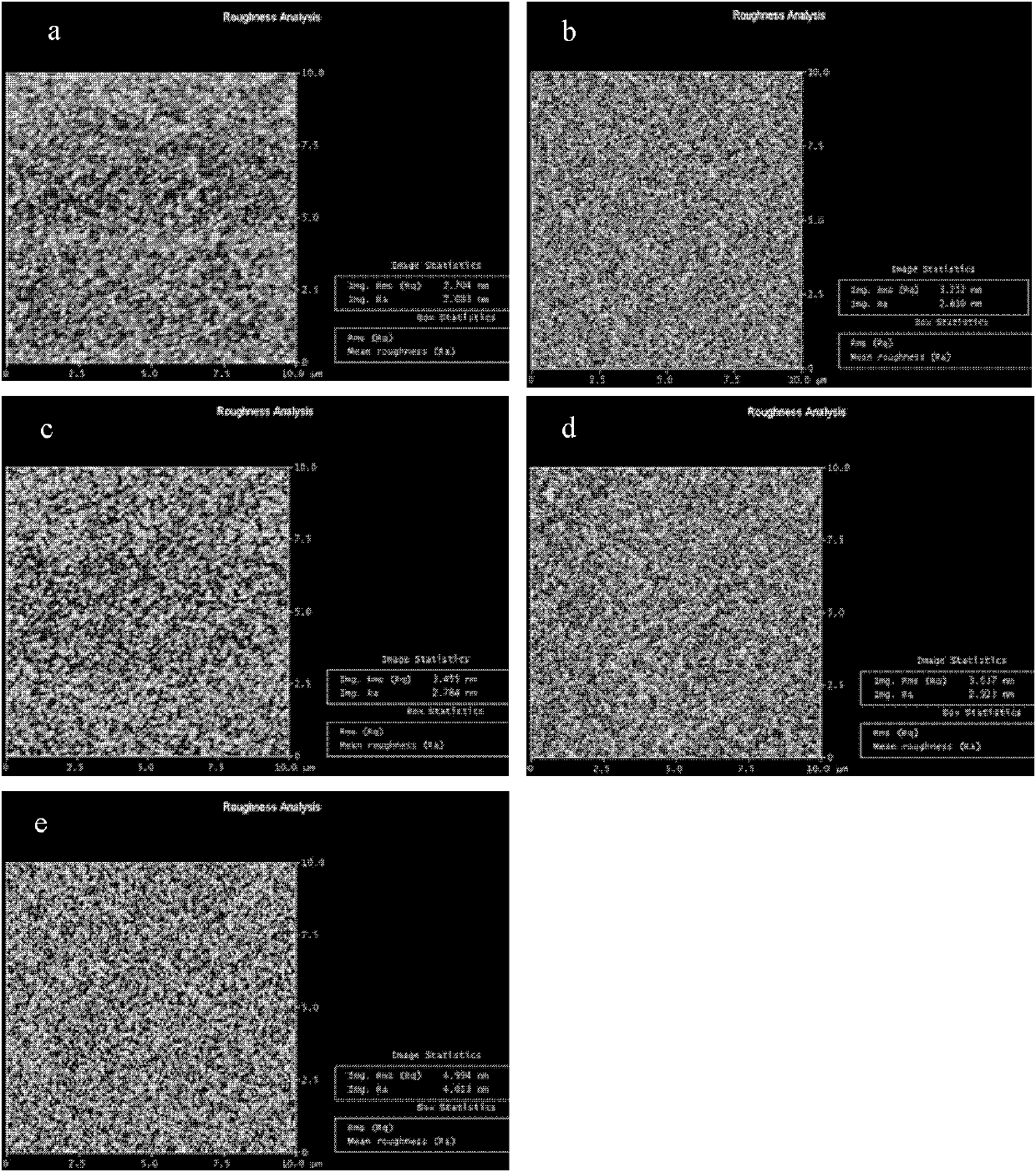

Method for preparing magnesium diboride superconducting thin film by electron beam annealing

InactiveCN102214786BReduce volatilityShort annealing timeSuperconductor device manufacture/treatmentChemical reactionMagnesium diboride

A method for preparing a magnesium diboride superconducting film by electron beam annealing. The method uses an electron beam to anneal a magnesium diboride precursor film in a vacuum, and the magnesium and boron elements in the precursor film are eliminated within an annealing time of the order of seconds. A chemical reaction occurs ultimately producing a magnesium diboride superconducting film. During annealing, the electron beam parameters and annealing time are determined according to different precursor film thickness and annealing temperature requirements. The annealing of films with different thicknesses can be completed by precisely controlling the electron beam energy and dose. The magnesium diboride superconducting film prepared by the invention has stable performance, smooth surface, and a transition temperature higher than 35K. It has the advantages of uniform annealing, high efficiency, simple operation, etc., and can be used for the preparation of various functional films.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Magnesium doping of boron nitride nanotubes

ActiveUS9059361B1Less susceptibility to stressImprove thermal conductivityMaterial nanotechnologySuperconductor detailsYarnHigh-temperature superconductivity

A method to fabricate boron nitride nanotubes incorporating magnesium diboride in their structure. In a first embodiment, magnesium wire is introduced into a reaction feed bundle during a BNNT fabrication process. In a second embodiment, magnesium in powder form is mixed into a nitrogen gas flow during the BNNT fabrication process. MgB2 yarn may be used for superconducting applications and, in that capacity, has considerably less susceptibility to stress and has considerably better thermal conductivity than these conventional materials when compared to both conventional low and high temperature superconducting materials.

Owner:JEFFERSON SCI ASSOCS LLC

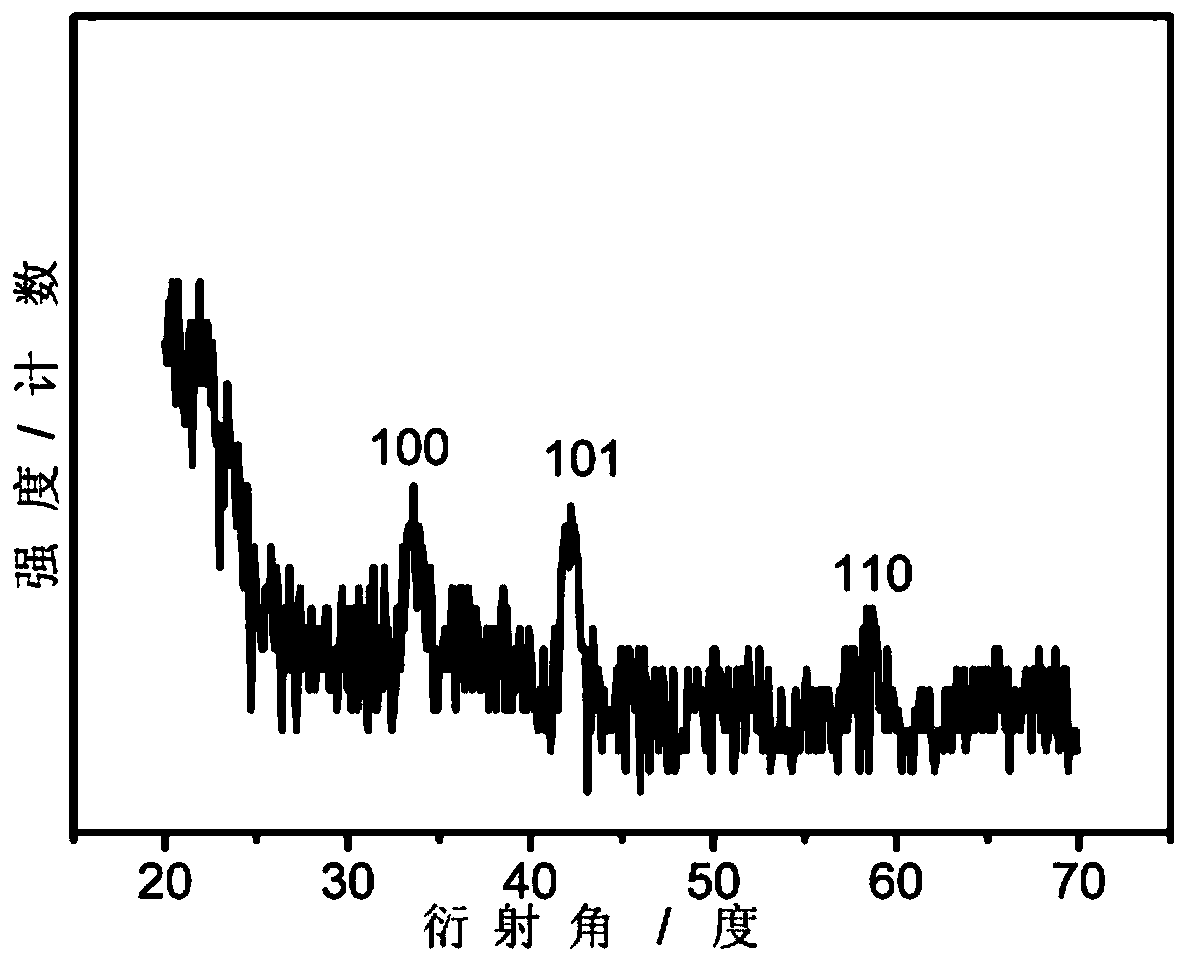

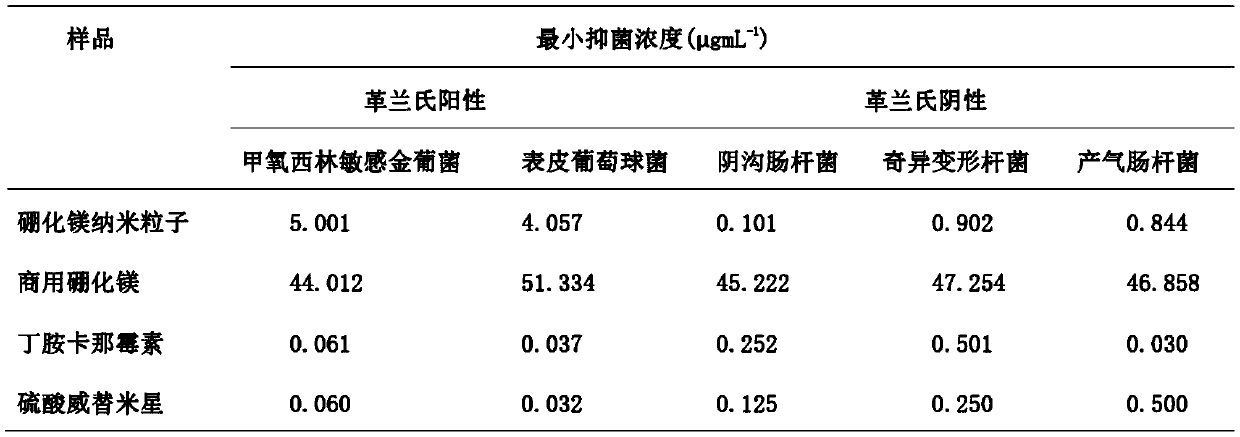

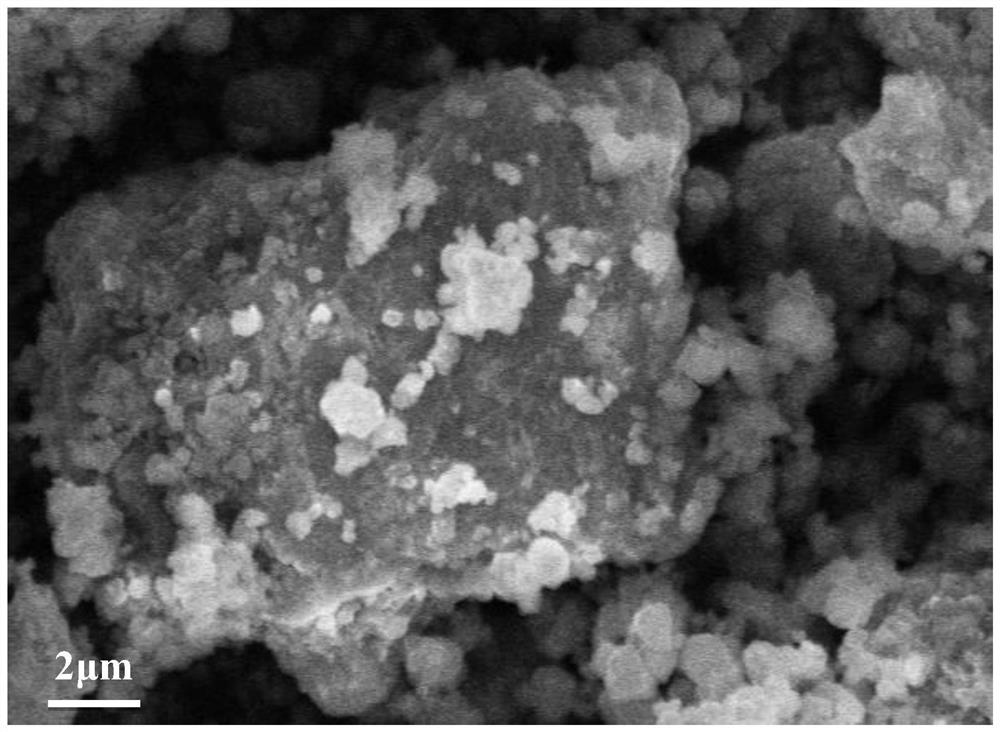

Preparation method of magnesium boride nanoparticles

InactiveCN110844917AEnterobacter cloacae activityHigh activityAntibacterial agentsInorganic boron active ingredientsDiseaseUpper urinary tract infection

The invention discloses a preparation method of magnesium boride nanoparticles. According to liquid phase plasma technology, the magnesium boride nanoparticles are synthesized by reducing MgCl2 with borane in triethylphenylammonium bis (trifluoromethanesulfonyl) imine ionic liquid at room temperature. Compared with commercial magnesium boride, the prepared magnesium boride nanoparticles are largerin specific surface area and stronger in antibacterial effect. Compared with amikacin and vertilmicin sulfate, the magnesium boride nanoparticles prepared by the invention show stronger antibacterialactivity on enterobacter cloacae. Through the excellent antibacterial property of the enterobacter cloacae, the wide application of magnesium boride in the clinical treatment fields of hospital infected bacterial infectious diseases, such as skin soft tissue infection, urinary tract infection, respiratory tract infection and septicemia is expected to expand.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

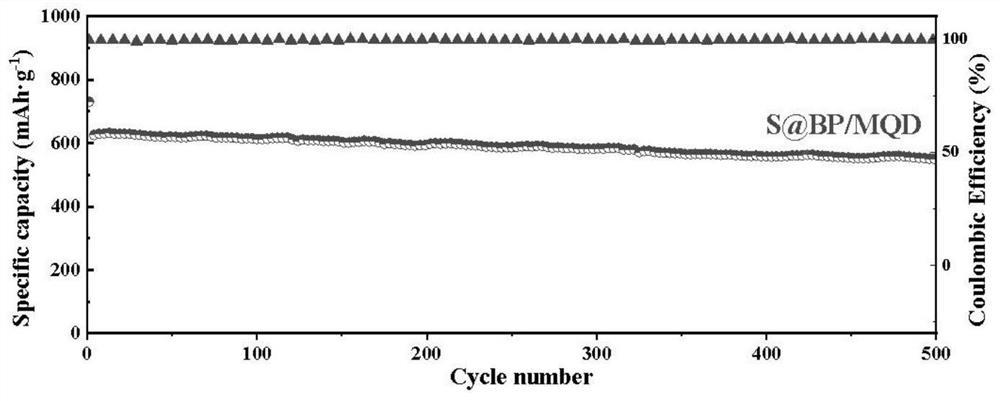

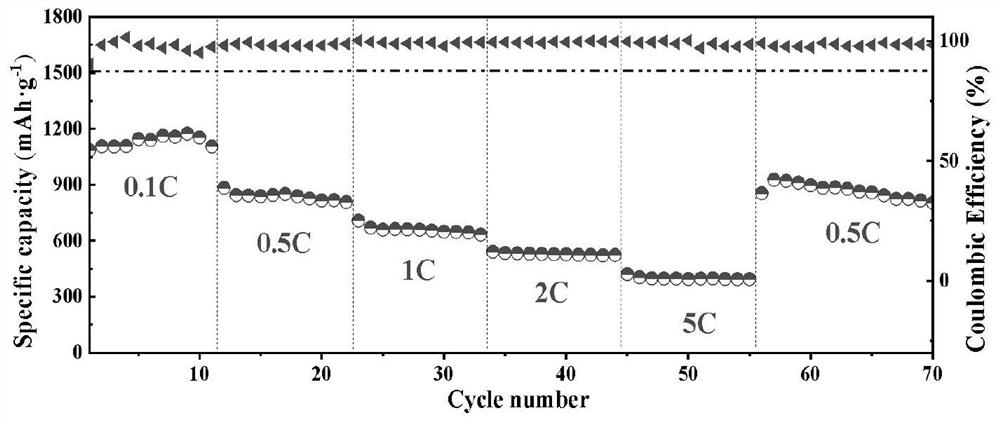

Preparation method and application of lithium-sulfur battery positive electrode material

The invention discloses a preparation method of a positive electrode material of a lithium-sulfur battery. The preparation method comprises the following steps: obtaining BP (at) MQD by using an in-situ vapor deposition method; and compounding elemental sulfur with the BP (at) MQD. The preparation method comprises the following steps: fully mixing red phosphorus powder and magnesium boride powder according to a certain proportion by using a beaker, and sintering in a muffle furnace; and removing non-fixed-state boron oxide in the product by a centrifugal washing method to obtain the required host material. The magnesium oxide quantum dots in the host material have strong polarity and can capture long-chain polysulfide and reduce the shuttle effect; the BP (at) MQD heterojunction can improve the electron transfer rate and accelerate the reaction kinetics. According to the invention, elemental sulfur is used as a positive electrode active material, BP-coated MQD is used as a host material of sulfur, and compared with other lithium-sulfur battery positive electrode materials, the cycle stability and rate capability of the battery are optimized. The preparation method is simple in process, low in equipment requirement, excellent in performance and suitable for large-scale commercial battery production.

Owner:BEIJING INFORMATION SCI & TECH UNIV

Process for preparing magnesium diboride superconductor

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

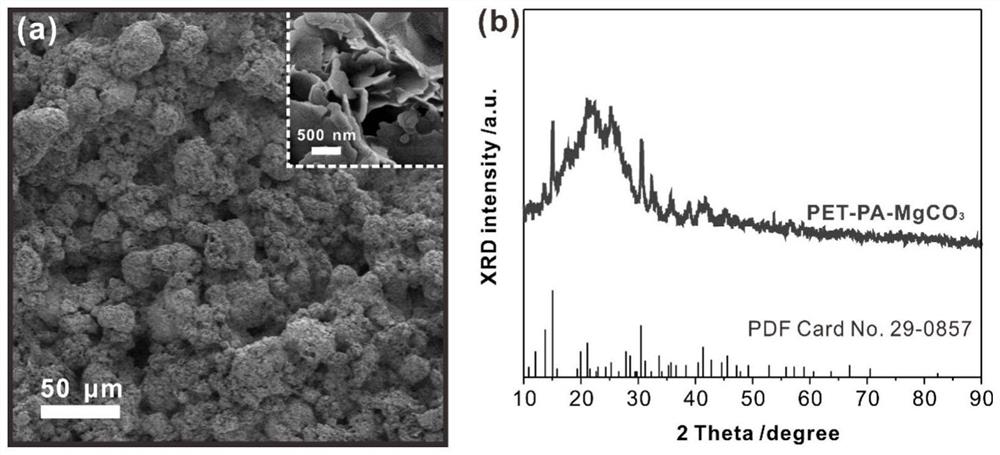

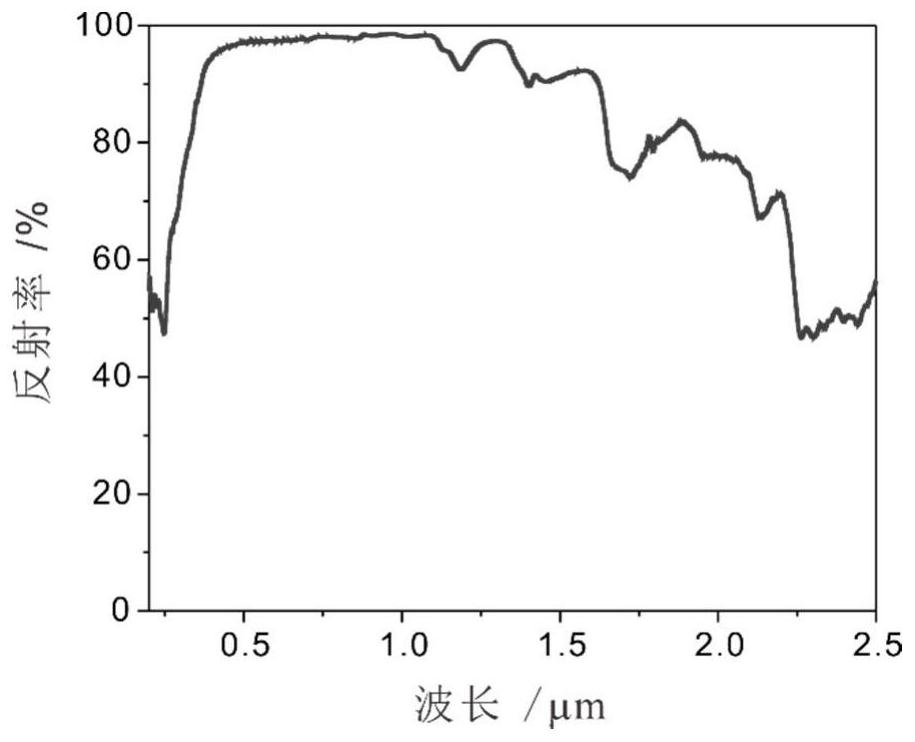

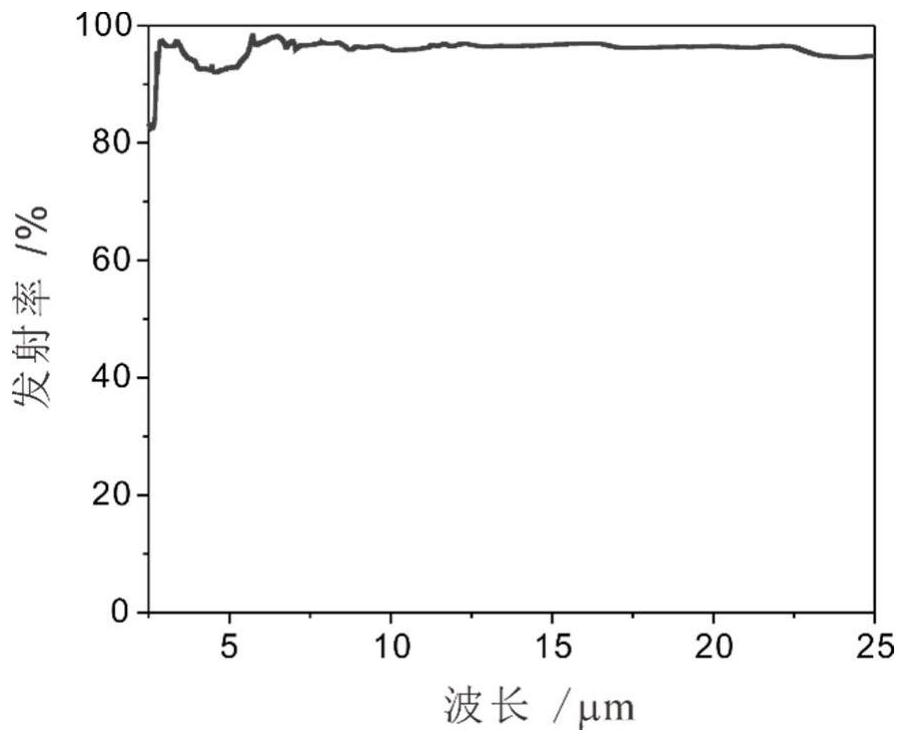

Textile with radiation refrigeration function and preparation method thereof

The invention relates to the field of functional textile materials, and discloses a textile with a radiation refrigeration function and a preparation method thereof. The textile comprises a fabric substrate, an organic coating adhesive attached to the surface of the fabric substrate and a radiation refrigeration functional material dispersed in the organic coating adhesive, the radiation refrigeration functional material at least comprises one or more of magnesium carbonate, magnesium hydroxide, magnesium boride, magnesium nitride and magnesium titanate. The radiation refrigeration material disclosed by the invention has excellent refrigeration performance, not only has relatively high emissivity in an atmospheric window wave band, but also has high reflectivity in a solar spectral region. Therefore, even in the daytime, temperature rise caused by the fact that a large amount of solar energy is absorbed is avoided.

Owner:ZHEJIANG SCI-TECH UNIV

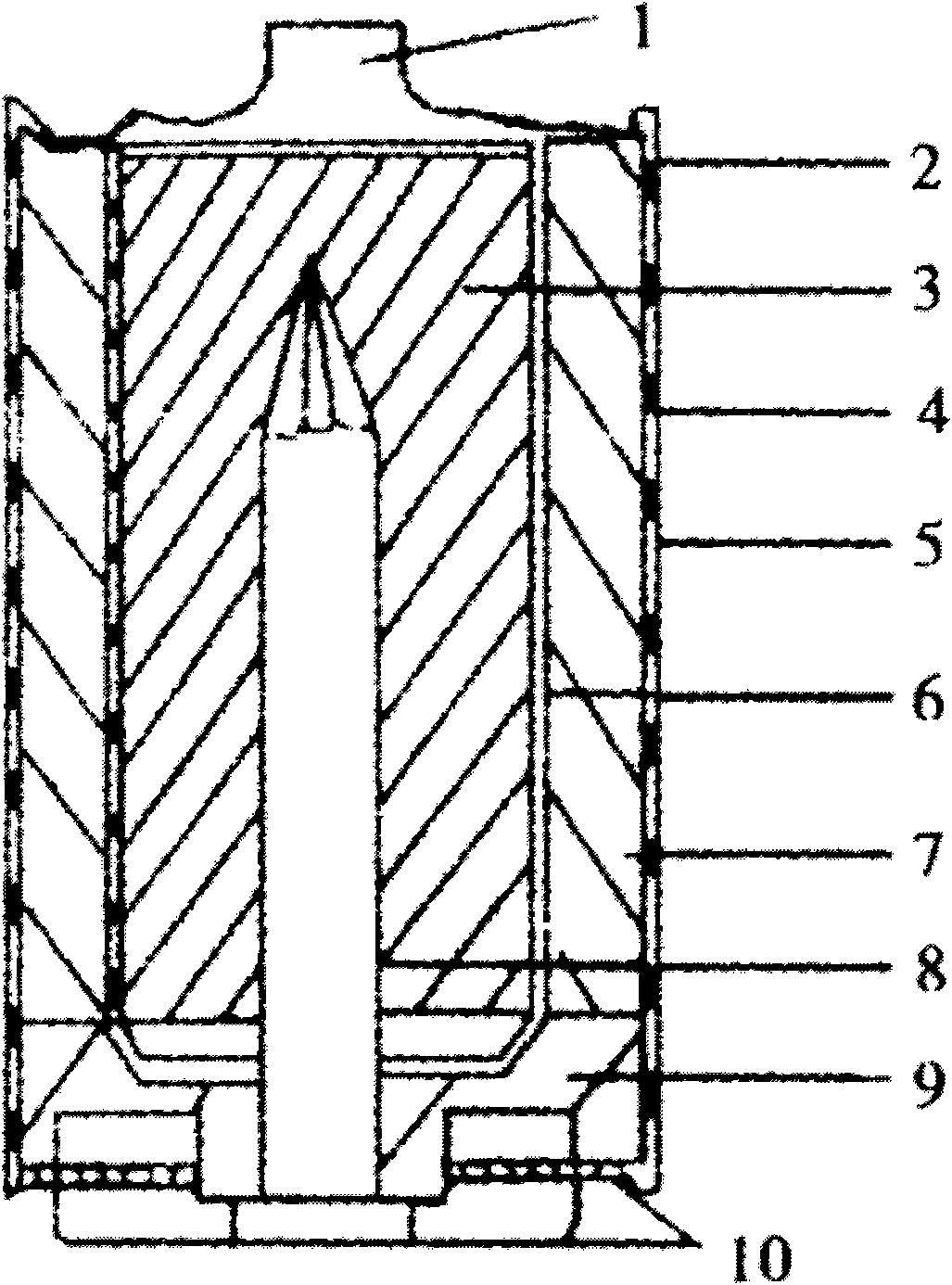

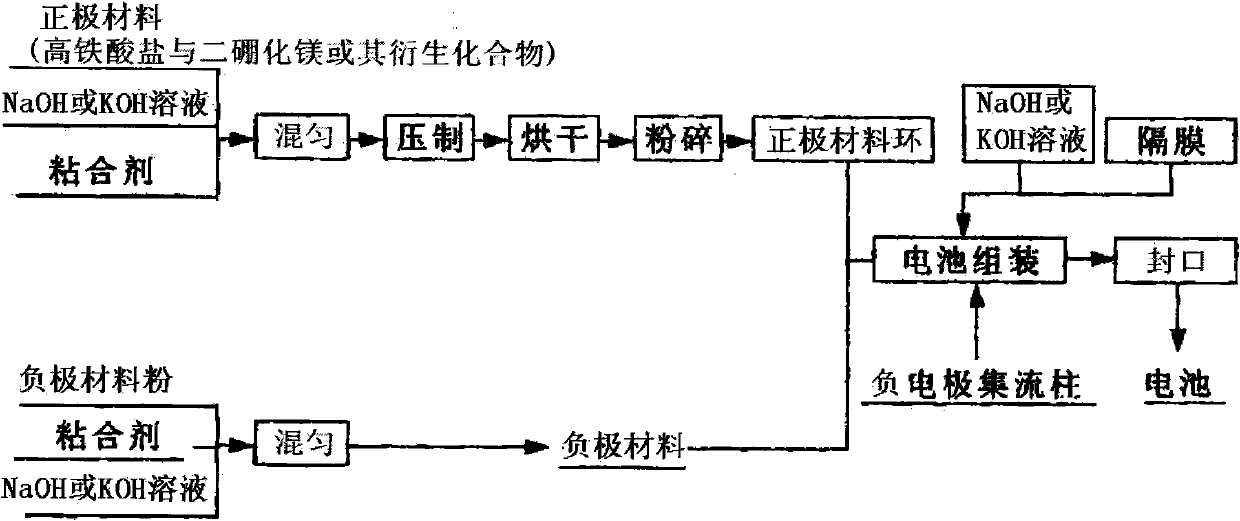

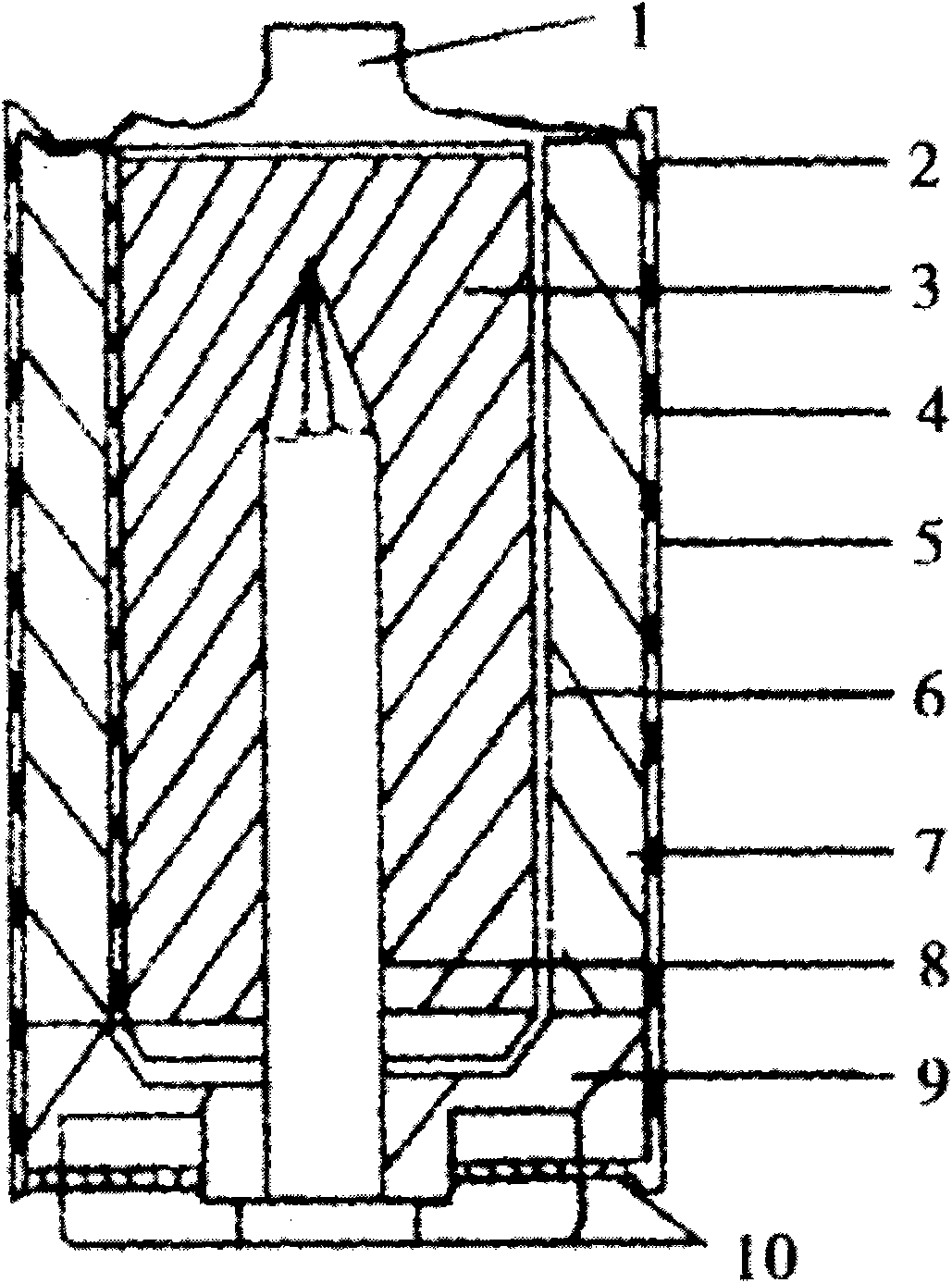

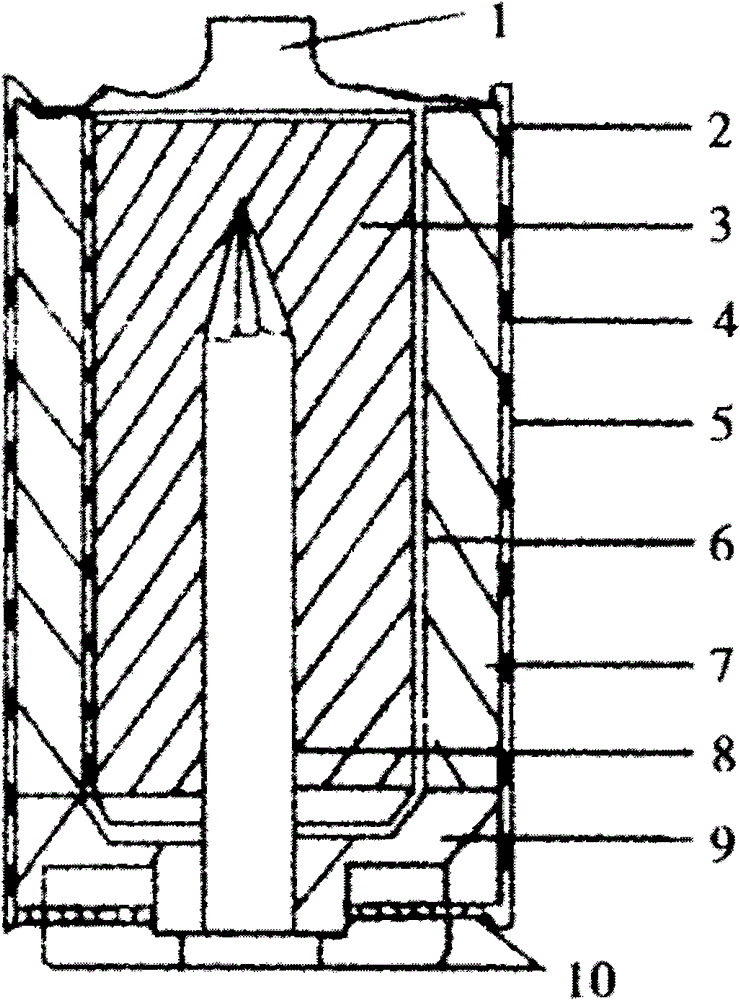

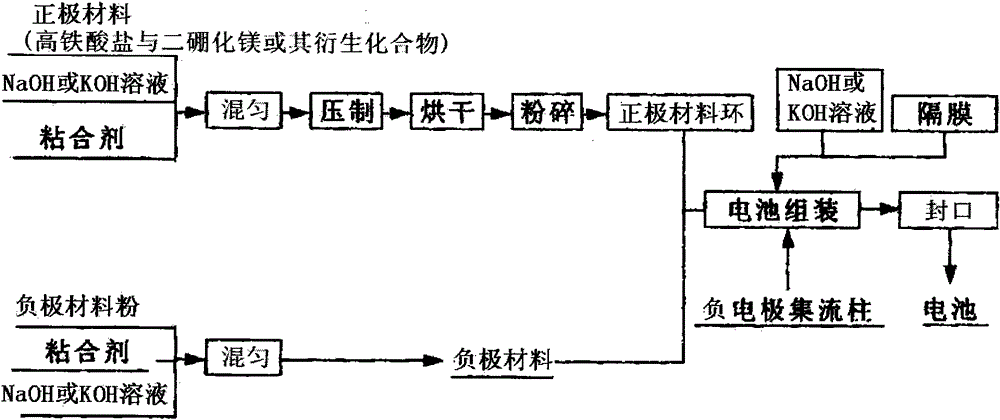

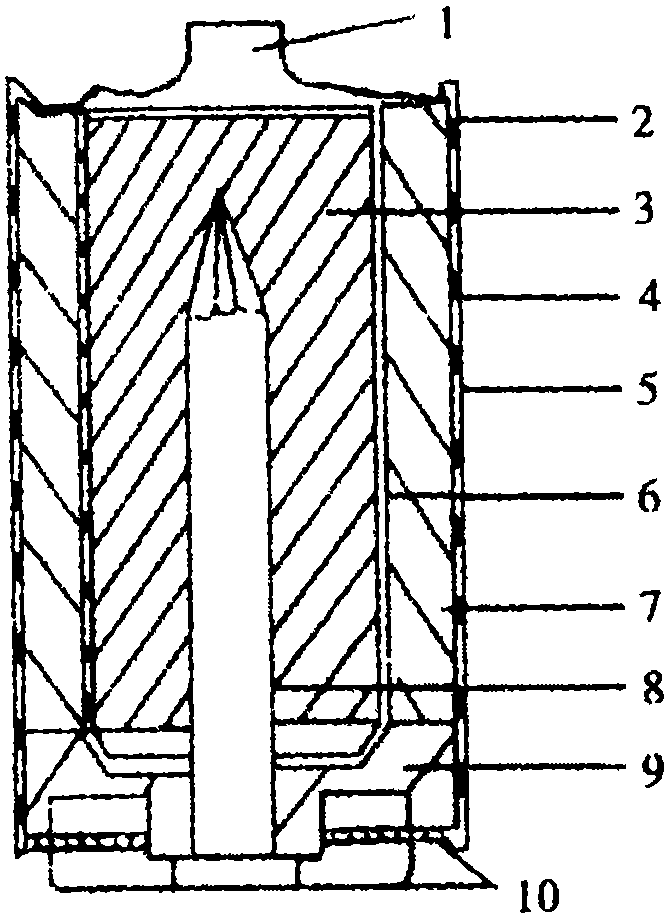

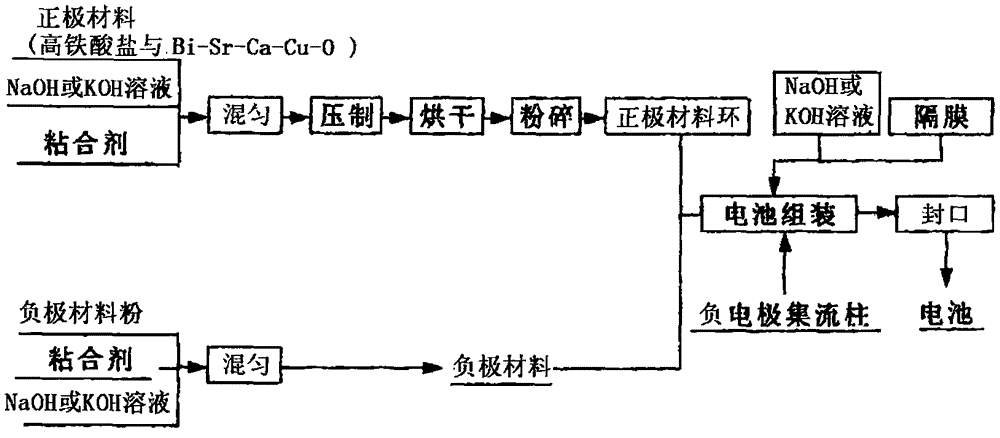

Aluminum super-iron alkaline battery

ActiveCN101997142ASmooth dischargeDischarge safetyAlkaline accumulatorsCell electrodesMagnesium diboridePhysical chemistry

The invention relates to an aluminum super-iron alkaline battery, which is provided according to the characteristic that an aqueous solution system of a chemical power source of an anode material of a super-iron battery can only be concentrated strong alkali aqueous solution. The battery comprises a shell, an anode, a cathode, alkaline electrolyte and a diaphragm which is arranged between the anode and the cathode, wherein a cathode material is aluminum, the anode material is ferrate, and the electrolyte is NaOH or KOH aqueous solution; the NaOH or KOH aqueous solution serving as the electrolyte accounts for 10 to 15 percent, and the anode material consisting of the ferrate, and magnesium boride or a derivative compound thereof accounts for 85 to 90 percent; the open circuit voltage of the battery is 1.6 to 1.65V and the working voltage is 1.2 to 1.5V which is 0.1 to 0.15V high than that of a primary battery in the prior art; and the battery discharges stably, is pollution-free and safe and has high performance, and over 85 percent of discharge time is in a period when the voltage is 1.2 to 1.5V.

Owner:桐乡乐维新材料有限公司

Al-Fe Alkaline Batteries

ActiveCN101997142BSmooth dischargeDischarge safetyAlkaline accumulatorsCell electrodesAqueous solutionPollution

The invention relates to an aluminum super-iron alkaline battery, which is provided according to the characteristic that an aqueous solution system of a chemical power source of an anode material of a super-iron battery can only be concentrated strong alkali aqueous solution. The battery comprises a shell, an anode, a cathode, alkaline electrolyte and a diaphragm which is arranged between the anode and the cathode, wherein a cathode material is aluminum, the anode material is ferrate, and the electrolyte is NaOH or KOH aqueous solution; the NaOH or KOH aqueous solution serving as the electrolyte accounts for 10 to 15 percent, and the anode material consisting of the ferrate, and magnesium boride or a derivative compound thereof accounts for 85 to 90 percent; the open circuit voltage of the battery is 1.6 to 1.65V and the working voltage is 1.2 to 1.5V which is 0.1 to 0.15V high than that of a primary battery in the prior art; and the battery discharges stably, is pollution-free and safe and has high performance, and over 85 percent of discharge time is in a period when the voltage is 1.2 to 1.5V.

Owner:TONGXIANG LEWEIXIN MATERIAL CO LTD

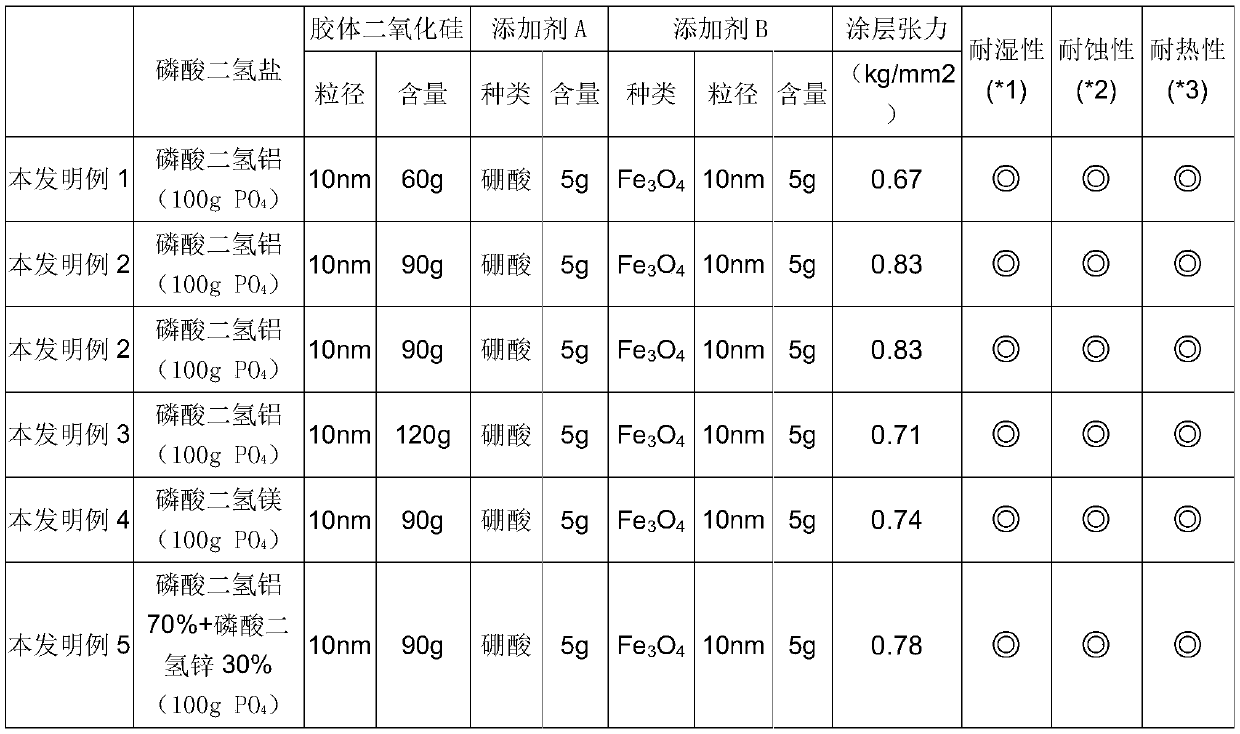

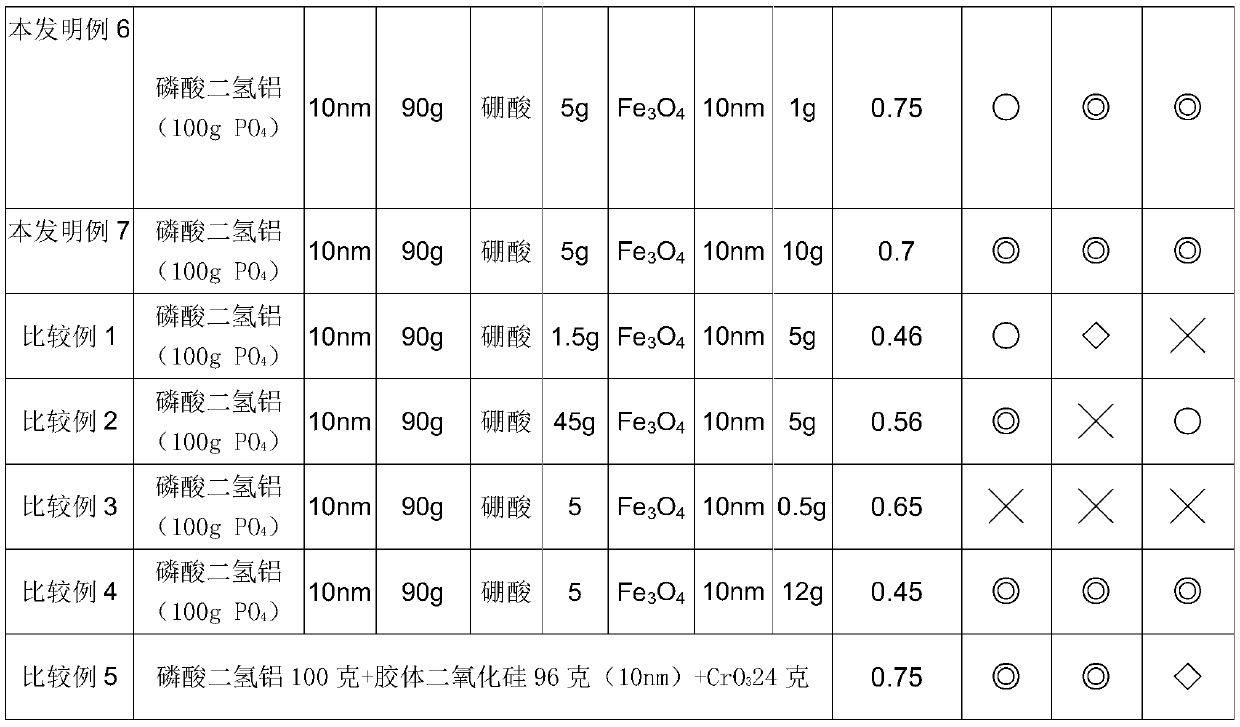

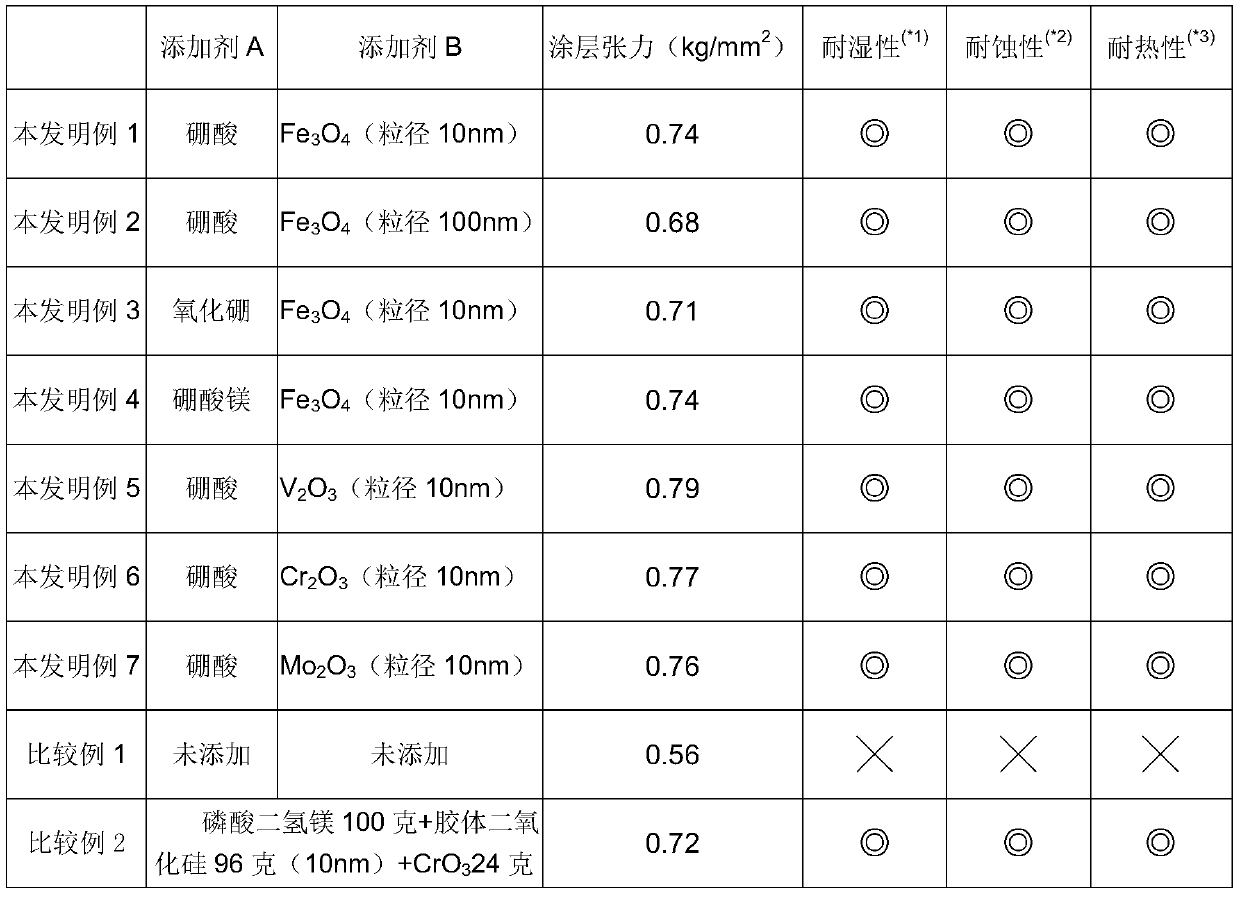

Hexavalent chromium free environmentally friendly type paint for steel plates and preparation method thereof

The invention discloses an environmentally friendly type paint for steel plates and a preparation method thereof. The paint is composed of following components: phosphate; colloidal silicon dioxide; at least one of Fe3O4, V2O3, Cr2O3, and Mo2O3; and at least one of boron oxide, boric acid, and magnesium borate. The preparation method comprises following steps: dispersing one or more of boron oxide, boric acid, and magnesium boride into silica sol; then adding one or more of Fe3O4, V2O3, Cr2O3, and Mo2O3 powder; carrying out mechanical dispersion or ultrasonic dispersion to form a stable mixedsolution; mixing the mixed solution with phosphate, and stirring to form the paint. The invention aims to provide a hexavalent chromium free paint, which can form a coating on the surface of directional electromagnetic steel; the environment pollution is prevented; and at the same time, shortages of a coating formed by a hexavalent chromium free phosphate-silica paint such as bad moisture-proof property, poor heatproof property, bad corrosion resistant property, weak tension force, and the like, can be overcome. The paint has good stability and an excellent coating property and can meet the requirements of massive production.

Owner:NANJING BAOCHUN NEW MATERIAL TECH CO LTD

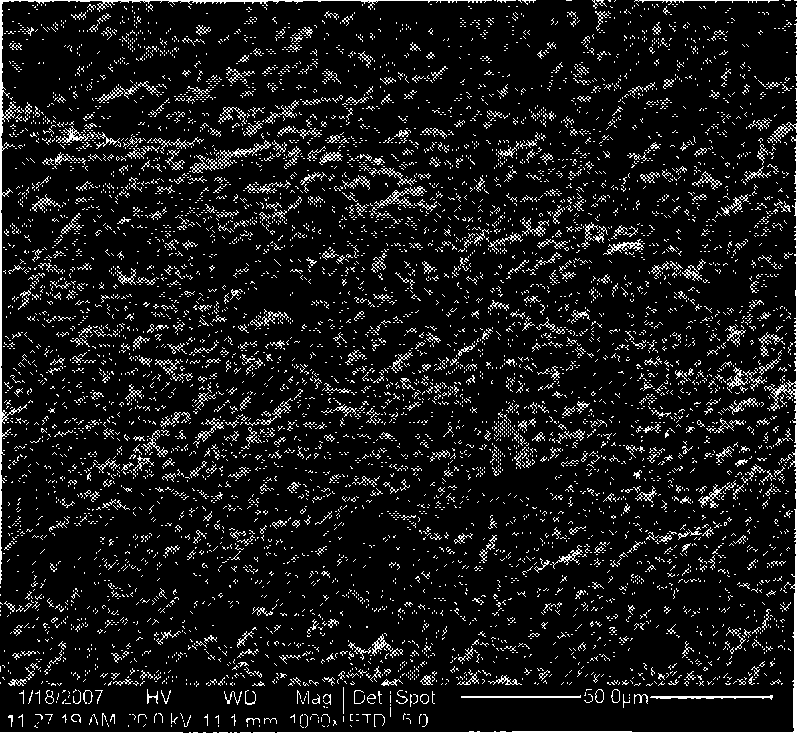

A nano-catalyzed metal-ceramic combined non-burning and non-immersing environment-friendly sliding plate and its preparation process

InactiveCN104341161BReduce energy consumptionIn line with the trend of energy saving and emission reductionAl powderFerrosilicon

The invention relates to a nano-scale catalytic metal-ceramic bonding firing-free bitumen-impregnation-free environment-friendly slide plate and a preparation method thereof. The invention relates to the firing-free bitumen-impregnation-free environment-friendly slide plate and the process thereof. The invention relates to the field of a refractory material. The material comprises the raw materials of 25-40% granular first-grade alumina, 15-25% of tabular corundum, 6-12% of mullite, 6-15% of silicon carbide fine powder, 0.5-1% of clay, 0.5-2% of magnesium boride, 6-10% of zircon sand, 2-5% of aluminum powder, 1-3% of carbon black, 0.5-1.5% of boron carbide, 3-10% of alumina micro-powder, 0.5-1.5% of aluminum fiber, 1-3% of nano-powder ferrosilicon, 1-3% of iron silicon nitride, and 4-6% of a composite resin binder. The process comprises the following steps: resin, polycarboxylic acid and nano-powder are mixed to prepare the composite resin binder; the granular materials are dry-mixed; premixed powder and the binder are added; and mix grinding, aging, molding, drying, strapping, grinding, shell-applying, and packaging are carried out. The process does not require a firing step, such that energy is saved; and bitumen impregnation is not required, such that pollution is avoided. When the slide plate is applied in a continuous-casting large ladle, the slide plate can be used for continuous sliding more than 4 times. The slide plate can also be used in converter slag stopping.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD +1

Method for manufacturing magnesium boride superconductive belt material

InactiveCN102034575BImprove compactnessIncrease the critical current densitySuperconductors/hyperconductorsSuperconductor devicesDiamond-like carbonArgon atmosphere

The invention provides a method for manufacturing a magnesium boride superconductive belt material. The method comprises the following steps: A, uniformly distributing amorphous boron on a conductive substrate by adopting a coating method to form an amorphous boron layer with thickness of between 0.1 and 2.0mm; B, covering a magnesium or magnesium alloy flake with thickness of between 0.1 and 2.0mm on the boron layer, and rolling to form a magnesium-boron-substrate combination; C, putting the combination in the step B in a thermal treatment furnace, under the protection of argon atmosphere, heating to the temperature of between 550 and 800 DEG C, preserving the temperature for 0.1 to 3 hours, and cooling; D, coating metal, metallic oxide, silicon carbide or diamond like carbon film on thecombination which is treated in the step C to serve as a protective layer to form a composite body; and E, cutting the composite body in the step D into long belts. The MgB2 superconductive belt prepared by the method has the advantages of good compactness and grain connection, high critical current density, uniform current density distribution and high fatigue life, and is suitable for commercial application. The method is simple, and is suitable for industrial production.

Owner:SOUTHWEST JIAOTONG UNIV

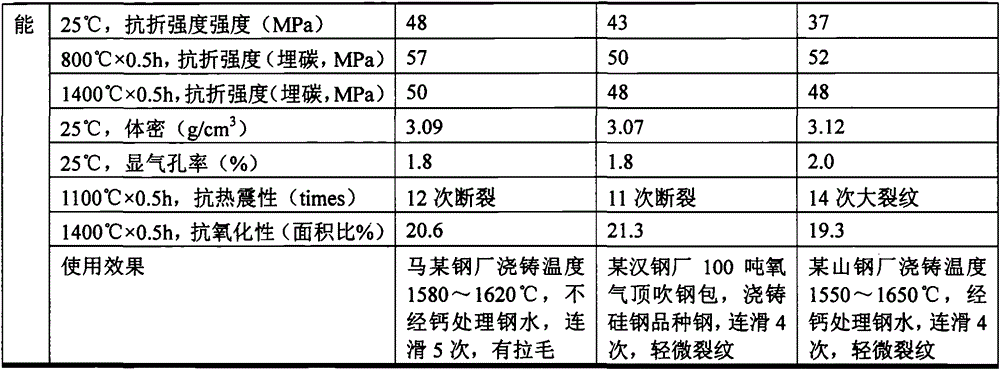

Controllable preparation method of porous silicon material by using reducing agent

PendingCN114044519ANarrow pore size distributionReduce production processHybrid capacitor electrodesCell electrodesElectrochemical responseNew energy

The invention relates to a controllable preparation method of a porous silicon material, which comprises the following steps: by taking silicon oxide SiOx as a main raw material and magnesium boride as a reducing agent, carrying out magnesiothermic reduction reaction to obtain a mixture of monatomic silicon, magnesium oxide and the like, and pickling to obtain the porous silicon material. The porous silicon material prepared by the preparation method disclosed by the invention retains typical morphological characteristics of an original material and shows a rich mesoporous structure. The unique adjustable porous structure not only can effectively relieve mechanical strain caused by volume change, but also is beneficial to improving transmission kinetics in an electrochemical reaction process. Meanwhile, the method has the advantages of being simple in preparation process, controllable in reaction, universal in strategy and the like. The micron / nano porous silicon material prepared by the method has potential application prospects in the field of new energy such as lithium ion batteries and the like.

Owner:SHANGHAI UNIV

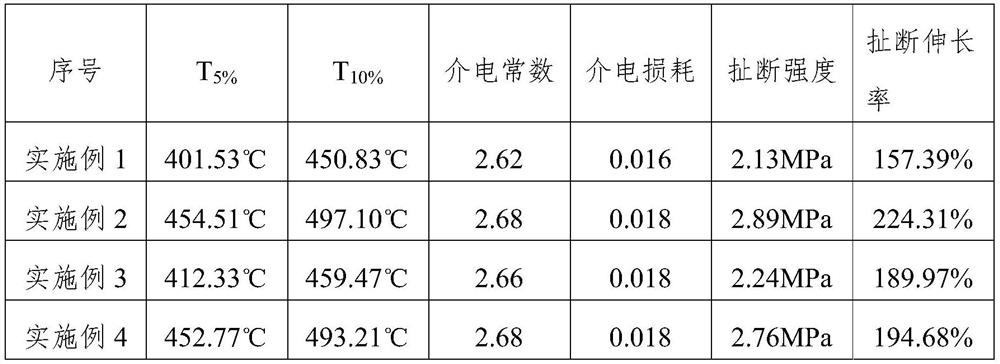

Modified organic silicon composite material as well as preparation method and application thereof

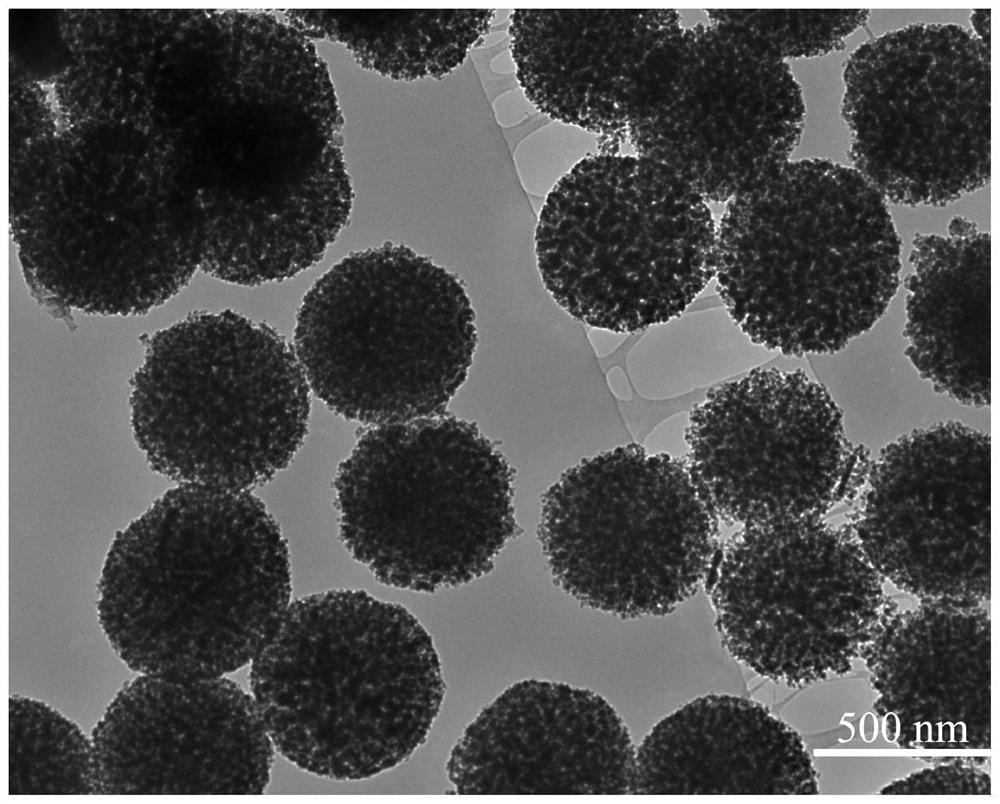

ActiveCN113583449AHigh temperature resistantLow dielectricNon-macromolecular adhesive additivesSilicic acidBoron nitride

The invention relates to the technical field of functional materials, and provides a modified organic silicon composite material and a preparation method and application thereof, the preparation method comprises the following steps: (1) activating boron oxide, boron powder and magnesium boride to obtain a precursor; (2) sintering the precursor obtained in the step (1) and ammonia gas to obtain a boron nitride nanotube crude product; (3) carrying out heat treatment on the boron nitride nanotube crude product obtained in the step (2) in an acid solution, and washing to obtain a pretreated boron nitride nanotube; (4) adding the pretreated boron nitride nanotube obtained in the step (3) into a cerous nitrate ethanol solution, and adjusting the pH value to obtain CeO2@BNNTs; and (5) mixing the CeO2@BNNTs obtained in the step (4) with phenyl siloxane rubber, fumed silica, dibutyltin dilaurate and tetraethoxysilane to obtain slurry, and curing the slurry to obtain the modified organic silicon composite material which has the properties of high temperature resistance, low dielectric and low loss.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Method for preparing magnesium diboride superconductive wire and strip

InactiveCN101279740BImprove compactnessFirmly connectedSuperconductors/hyperconductorsMetal boridesHigh magnesiumDiboride

The invention relates to a method for preparing a magnesium boride superconducting line and belt material. The preparation method is that a. preparation of precursor powder: high magnesium diboride MgBx powder is taken as the precursor powder, wherein, x is more than or equal to 4 and less than or equal to 12; or magnesium powder and amorphism boron powder are mixed according to 1:3-20 of stoichiometric ratio between magnesium and boron to form the precursor powder; b. putting into a magnesium pipe: the precursor powder is put into a magnesium pipe, compacted and sealed; c. putting into a canning pipe: the magnesium pipe is put into a metal canning pipe and is sealed after the metal canning pipe is fully filled with metal powder as a barrier layer; or the magnesium pipe is first put into a barrier layer metal pipe and then is put into the metal canning pipe and the metal canning pipe is sealed; d. moulding treatment: the metal canning pipe is produced into line and belt material; e. heat treatment: the metal canning pipe is put into a pipe typed furnace and under the protection of argon, the temperature is raised to 700-1200 DEG C by the speed of 1-10 DEG C / minute, preserved for 1-30 hours and then cooled to room temperature. The MgB2 superconducting line and belt material prepared by the method has high compactability, good grain connectivity and even cross section.

Owner:SOUTHWEST JIAOTONG UNIV

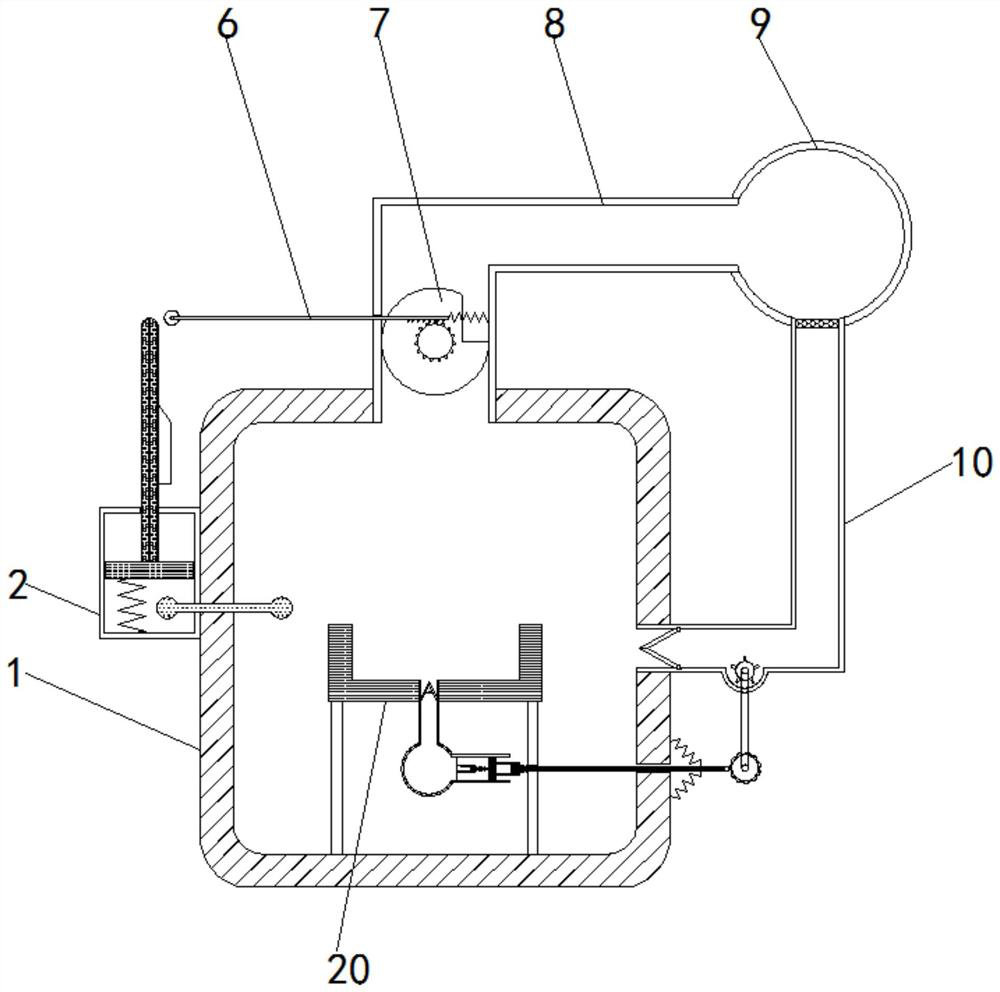

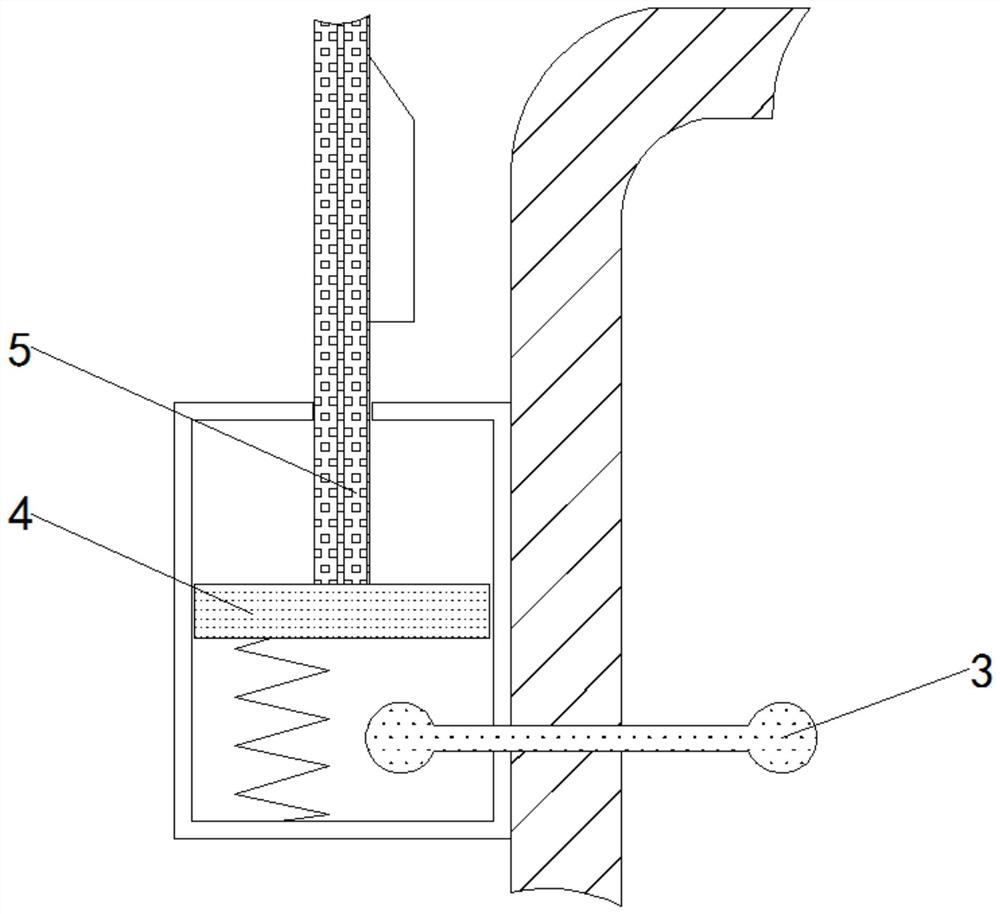

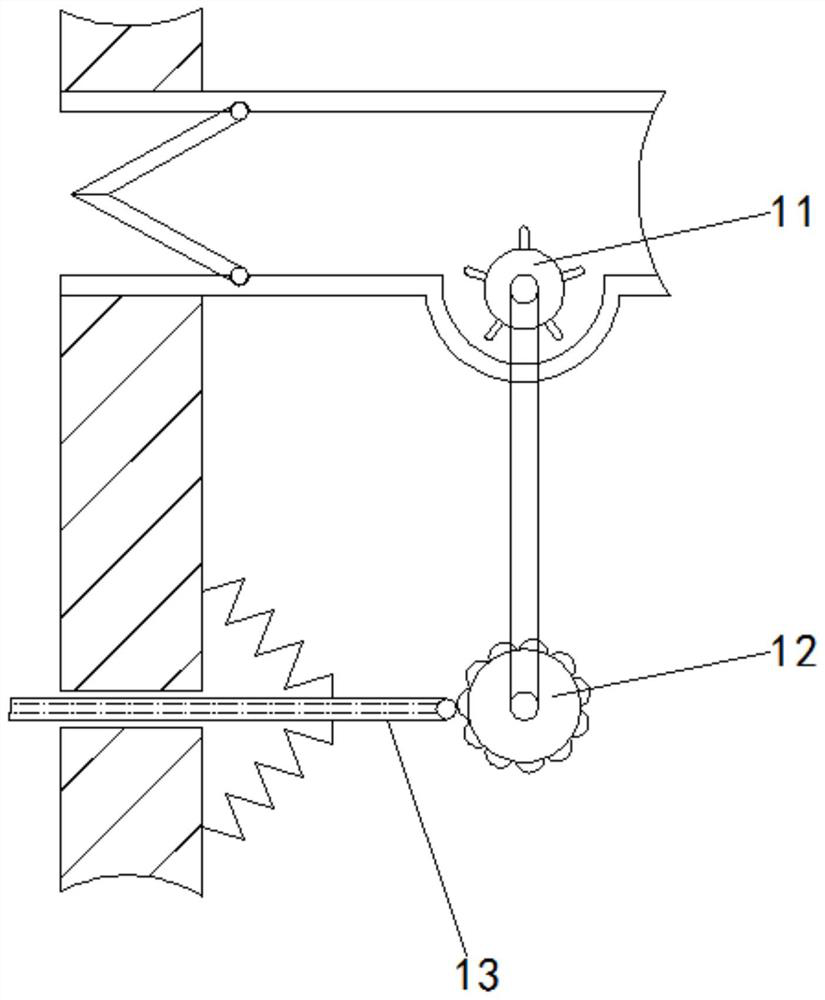

New material research magnesium diboride high-purity extraction equipment

InactiveCN112374507AIncrease temperatureConstant nitrogen contentMetal boridesMagnesium diborideMechanical engineering

The invention relates to the technical field of magnesium diboride, and discloses new material research magnesium diboride high-purity extraction equipment. The equipment comprises a vacuum box, a mercury box is fixedly connected to the left side of the vacuum box, a heat conduction rod is arranged on the right side of the mercury box in a penetrating mode, a mercury plate is slidably connected tothe interior of the mercury box, an extrusion rod is fixedly connected to the top of the mercury plate, an exhaust pipe is fixedly connected to the top of the vacuum box, a ventilation wheel is rotatably connected to the interior of the exhaust pipe, a limiting plate is connected to the side face of the limiting rod in a meshed mode, a guide pipe is connected to the side face of the extrusion plate in a meshed mode, and a magnesium powder box is fixedly connected to the left side of the guide pipe. According to the new material research magnesium diboride high-purity extraction equipment, through cooperative use of the mercury box and the exhaust pipe, the effects of preventing the gas formed by volatilization of magnesium powder from influencing the reaction of the magnesium powder and boron powder and preventing magnesium tetraboride from appearing in a product during preparation of magnesium diboride are achieved.

Owner:闫巍

Alkaline zinc-ferrate (VI) battery

ActiveCN105070909ASmooth dischargeNo pollution in the processCell electrodesElectricityAqueous solution

The invention discloses an alkaline super-iron zinc battery based on the characteristic that an aqueous solution system of a chemical power supply of an anode material of a super-iron battery only can be concentrated alkaline aqueous solution. The super-iron alkaline zinc battery comprises a shell, an anode, a cathode, alkaline electrolyte and a diaphragm positioned between the anode and the cathode, wherein the cathode material is a zinc cathode; the anode material is ferrate; the electrolyte is the aqueous solution of NaOH or KOH; the electrolyte content is 10 to 15 percent; and the anode consists of ferrate and magnesium borides or derivative compounds thereof, and the anode content is 85 to 90 percent. An open circuit of the battery has the voltage of 1.6 to 1.65V, and the working voltage of 1.2 to 1.5V which is 0.1 to 0.15V higher than that of a primary battery in the prior art, is stable discharge electricity, pollution-free, safe and high in performance, and discharges the electricity under 1.2 to 1.5V for over 85 percent of the total discharge time.

Owner:桐乡乐维新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com