Preparation of magnesium boride doped superconduction material

A superconducting material, magnesium diboride technology, applied in the field of preparation of doped magnesium diboride superconducting materials, can solve the problem that the doped nano-carbon powder cannot be uniformly dispersed, affecting the overall performance of the superconducting block, carbon high material prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of embodiment of the present invention is, a kind of preparation method of magnesium diboride superconducting material, and its concrete practice is:

[0026] Weigh magnesium powder and boron powder by molar ratio 1:2; Then weigh the dopant by the mass ratio 1:0.05 of the total mass of magnesium powder and boron powder and dopant, dopant is sorbic acid; Direct magnesium Powder, boron powder and dopant powder are uniformly mixed to form a mixed powder; the mixed powder is pressed into a tablet, and then sintered under the protection of an argon atmosphere at a sintering temperature of 800°C and kept for 1 hour to obtain magnesium diboride superconducting bulk.

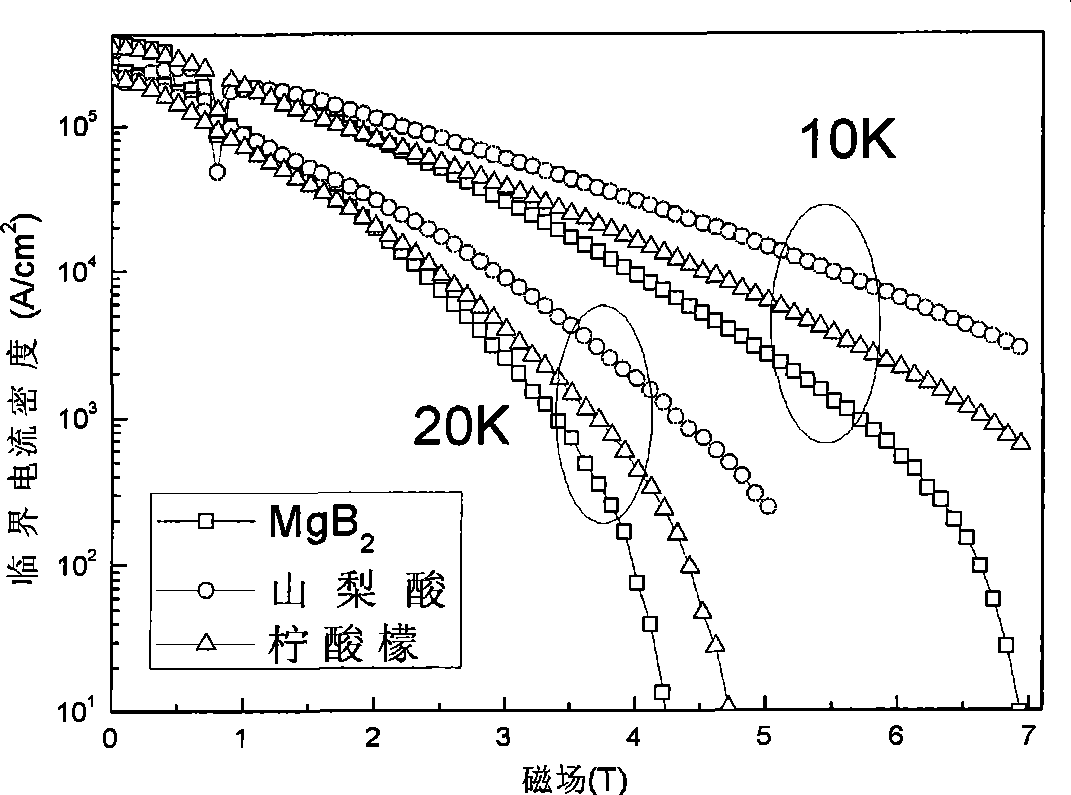

[0027] figure 1 The criticality of the magnesium diboride superconducting bulk material prepared for Example 1 of the present invention and the citric acid-doped magnesium diboride bulk material and undoped magnesium diboride superconducting bulk material prepared under the same conditions Current densit...

Embodiment 2

[0029] The invention discloses a method for preparing a magnesium diboride superconducting material. The specific method is: weighing Mg powder and B powder according to a molar ratio of 1:2.1. Then weigh the dopant sorbic acid powder according to the mass ratio of the total mass of Mg powder and B powder to the dopant is 1:0.1. Dissolve sorbic acid powder in acetone to form a solution, then ultrasonically disperse and mix this solution with weighed B powder to obtain a uniform suspension, vacuum dry to obtain a mixed powder, and then mix it with weighed Mg powder to form a mixed powder and compress the mixed powder into tablets. Sintering the pressed tablet in an argon atmosphere, the sintering temperature is 1000° C., the holding time is 0.5 hour, and it is rapidly cooled to room temperature to obtain a doped magnesium diboride superconducting bulk material.

[0030] figure 2 The critical current density curve of the magnesium diboride superconducting bulk material prepar...

Embodiment 3

[0032] A preparation method of a magnesium diboride superconducting material, the specific method is: weighing Mg powder and B powder according to a molar ratio of 1:2. Then weigh the dopant calcium sorbate powder according to the mass ratio of the total mass of Mg powder and B powder mass to the dopant is 1:0.05. Mix the three powders evenly, press the mixed powder into tablets, and sinter the tablets in an argon atmosphere at a sintering temperature of 700°C. After 5 hours of heat preservation, cool to room temperature with the furnace to prepare doped magnesium diboride. superconducting bulk.

[0033] image 3 The criticality of the magnesium diboride superconducting bulk material prepared for Example 3 of the present invention and the citric acid-doped magnesium diboride bulk material and undoped magnesium diboride superconducting bulk material prepared under the same conditions Current density curve. It can be seen from the figure that when the temperature is 20K and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical current density | aaaaa | aaaaa |

| Critical current density | aaaaa | aaaaa |

| Critical current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com