Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

163 results about "Magnesium diboride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

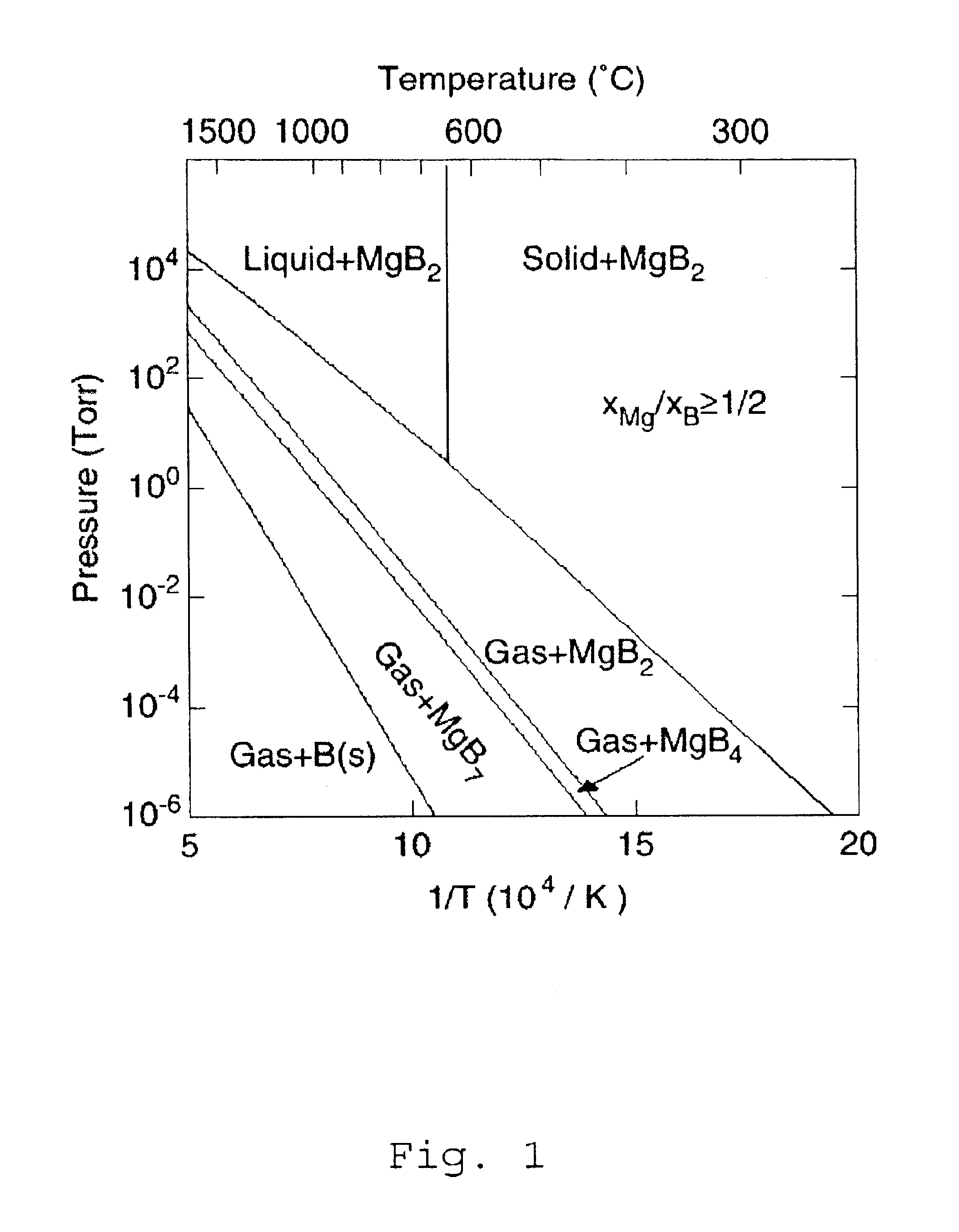

Magnesium diboride is the inorganic compound with the formula MgB₂. It is a dark gray, water-insoluble solid. The compound has attracted attention because it becomes superconducting at Tc = 39K. In terms of its composition, MgB₂ differs strikingly from most superconductors of comparable Tc, which feature transition metals.

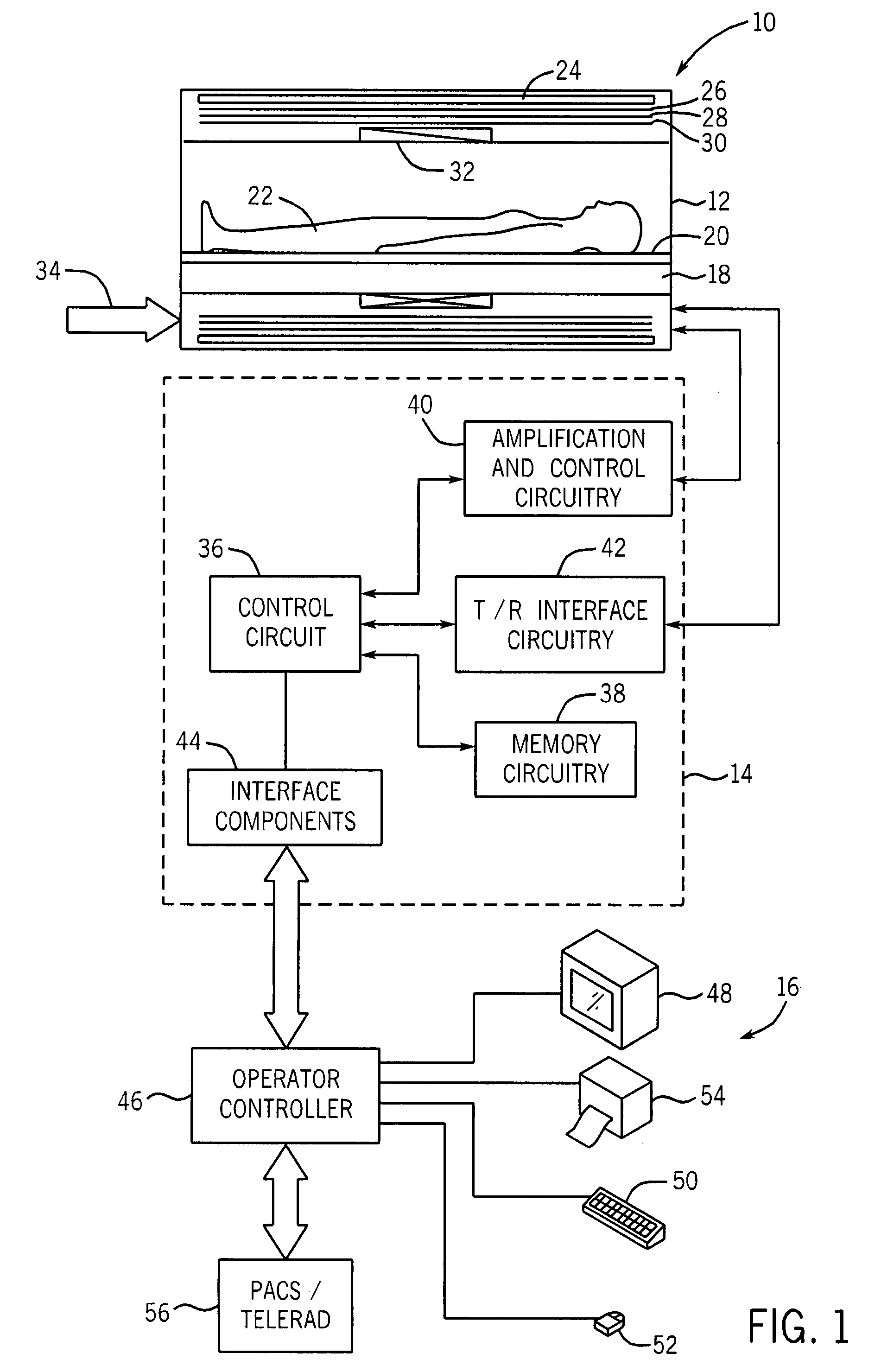

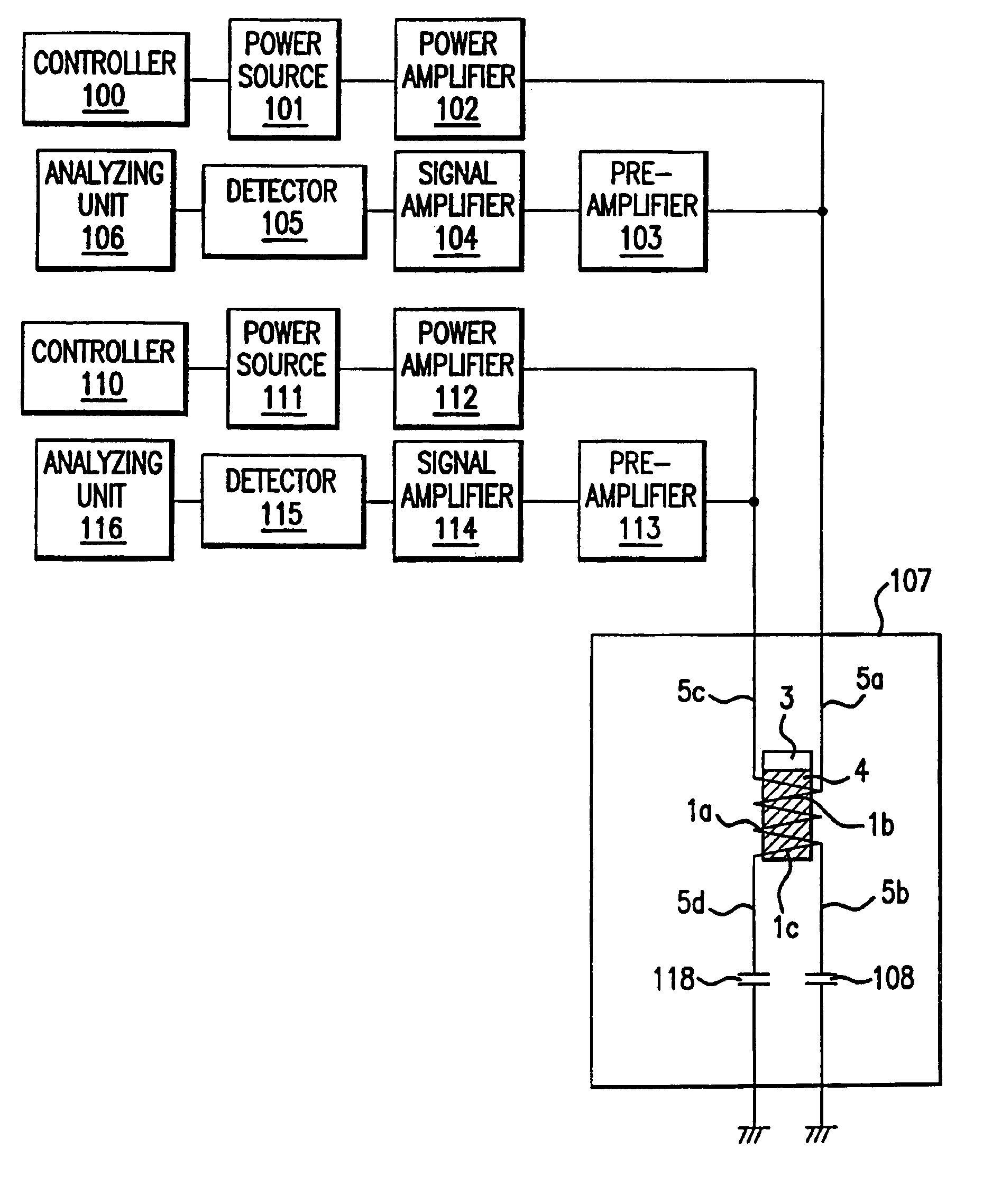

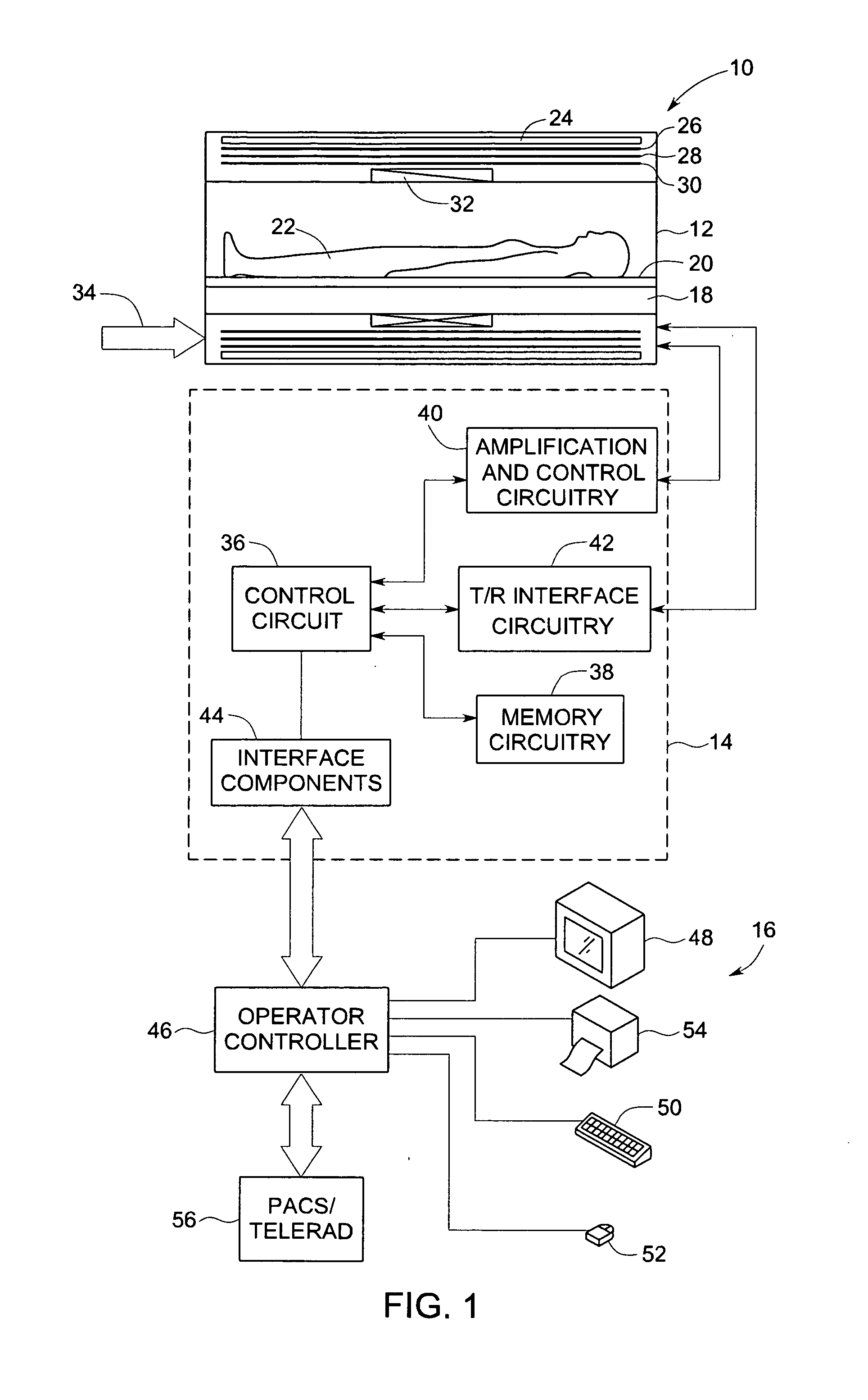

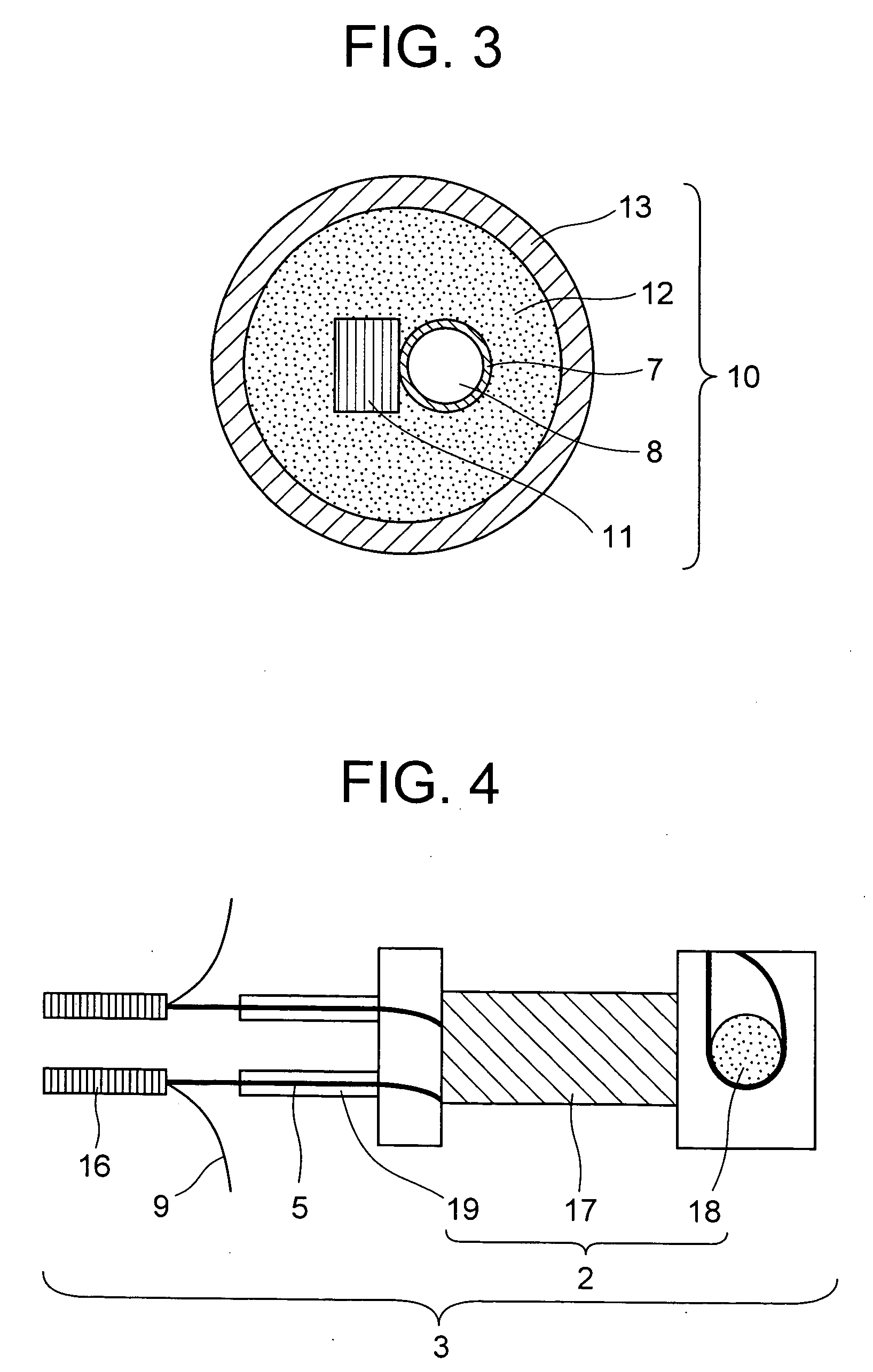

Nuclear magnetic resonance equipment

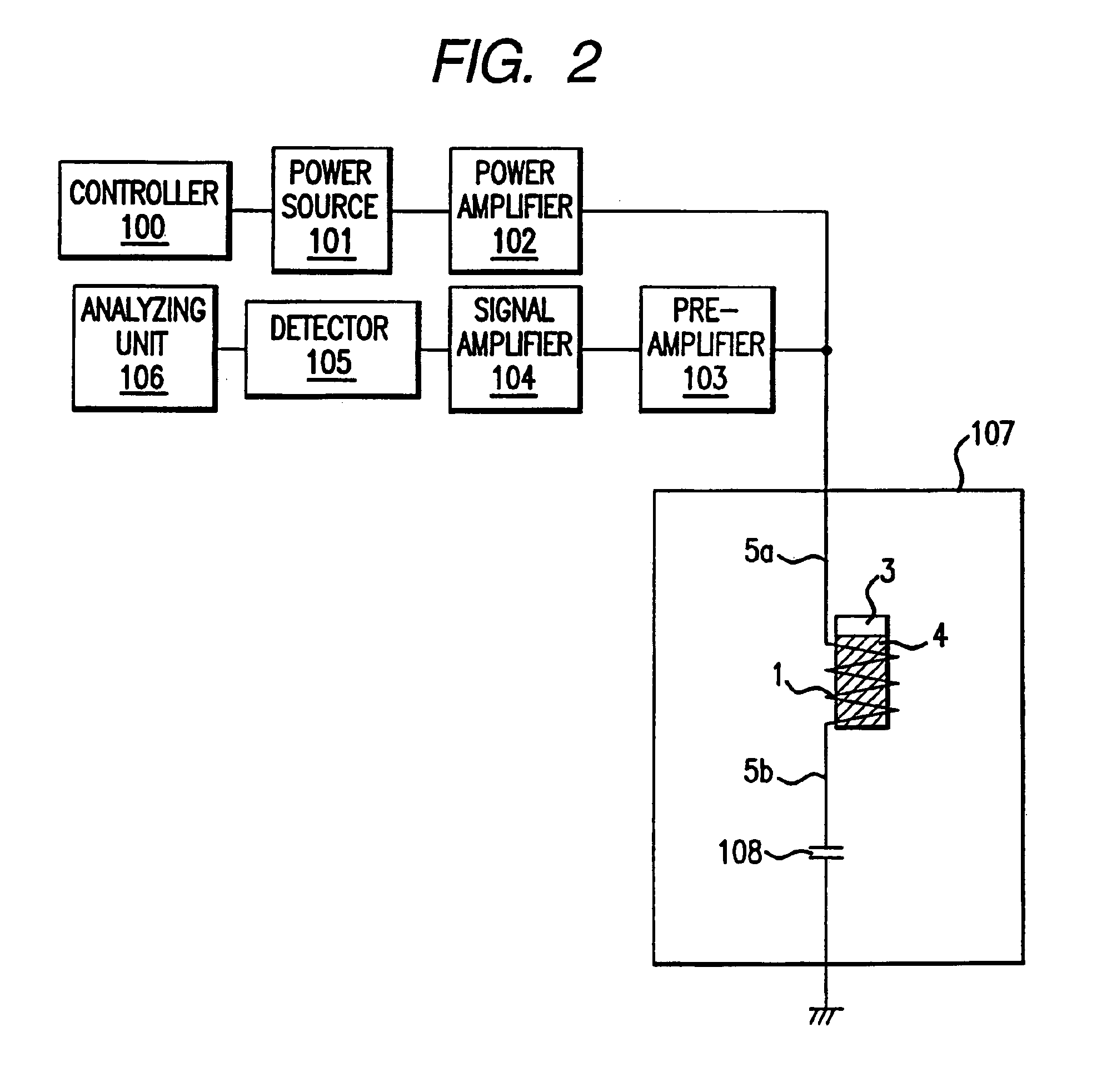

InactiveUS6958608B2High sensitivityElectric/magnetic detectionMeasurements using magnetic resonanceCapacitanceSpectroscopy

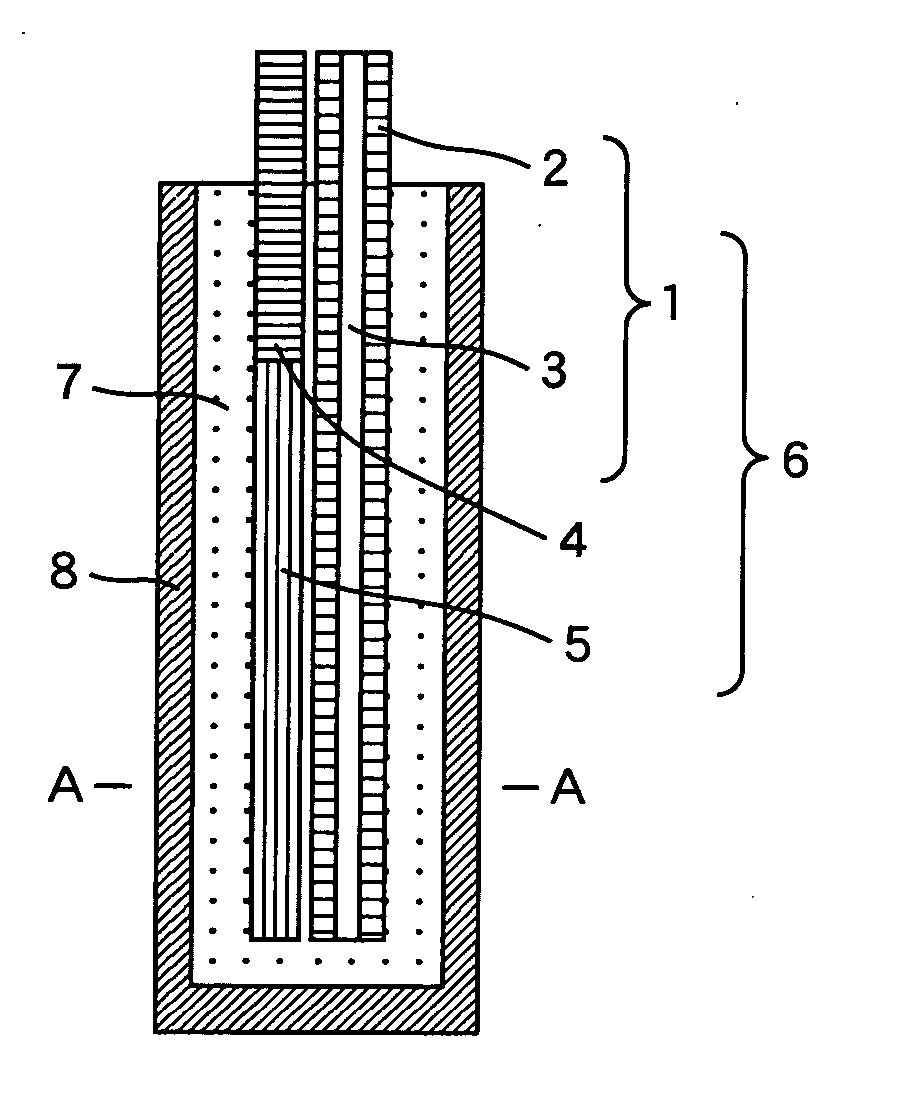

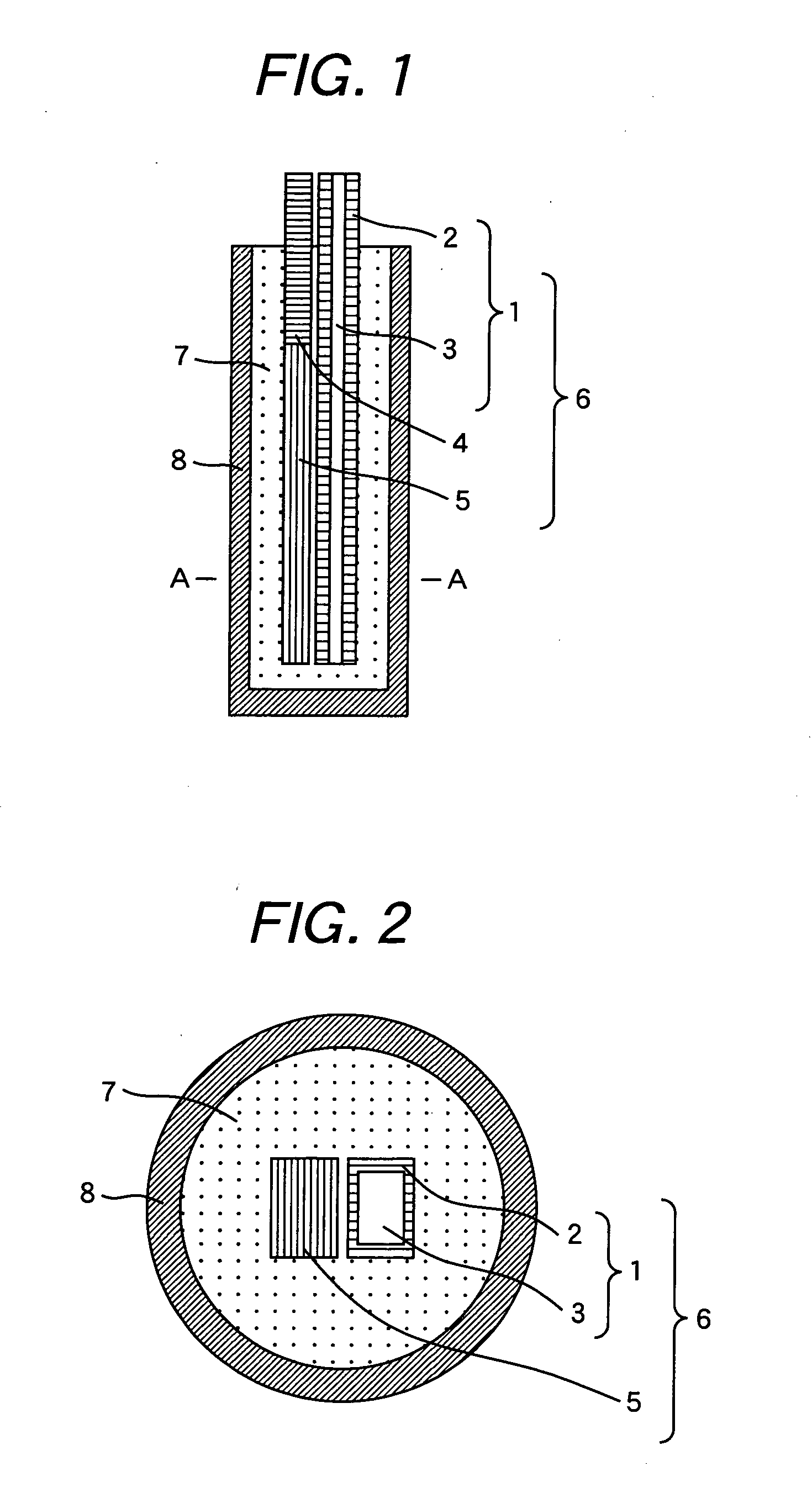

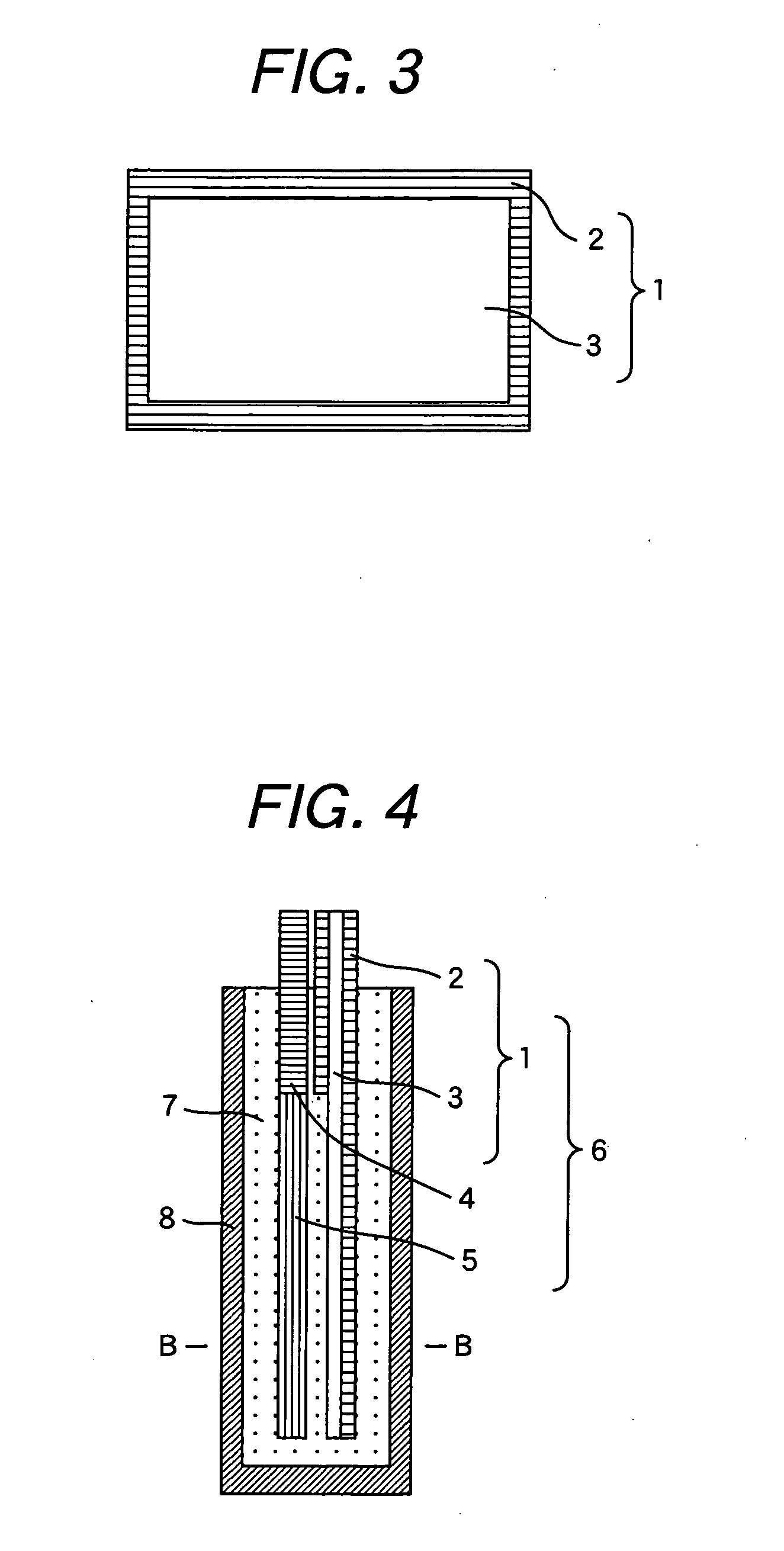

The invention provides nuclear magnetic resonance equipment realizing improved sensitivity of a probe for receiving a free induction decay (FID) signal in nuclear magnetic resonance (NMR) spectroscopy in a high frequency band of 600 MHz or higher. By manufacturing a solenoid coil of a higher filling factor by using a superconductor of extremely low resistance to high frequency current, sensitivity is increased. A superconducting thin film made of magnesium diboride (MgB2) formed on a donut plate-type substrate is disposed so that the film surface becomes parallel with the uniform magnetic field. The object is realized by a probe made by a solenoid coil formed by connecting a plurality of coil parts by capacitive coupling via a normal metal lead.

Owner:HITACHI LTD

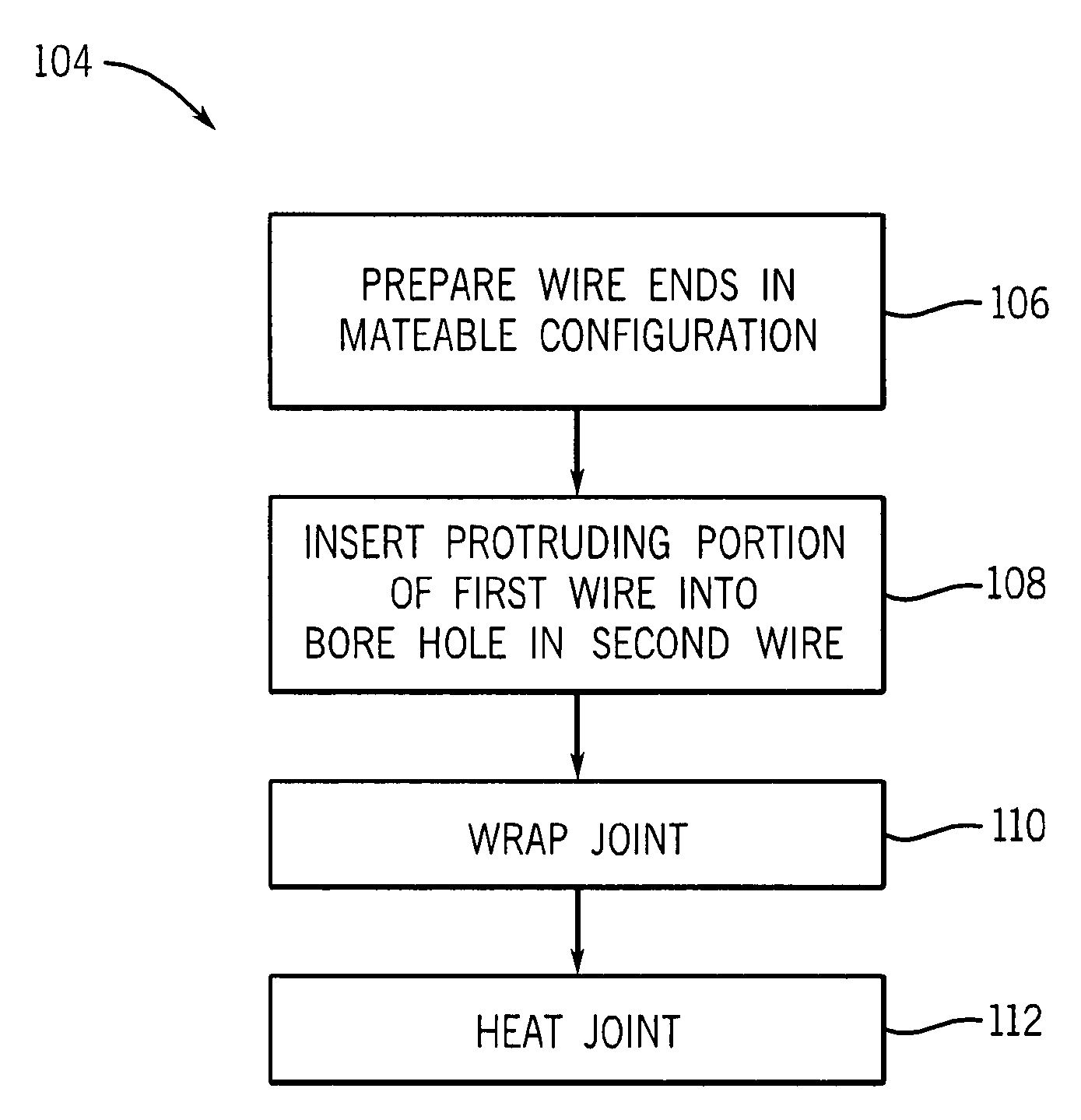

Low resistivity joints for joining wires and methods for making the same

InactiveUS20080236869A1Low resistivityLine/current collector detailsSuperconductors/hyperconductorsMagnesium diborideEngineering

Method for joining wires using low resistivity joints is provided. More specifically, methods of joining one or more wires having superconductive filaments, such as magnesium diboride filaments, are provided. The wires are joined by a low resistivity joint to form wires of a desired length for applications, such in medical imaging applications.

Owner:GENERAL ELECTRIC CO

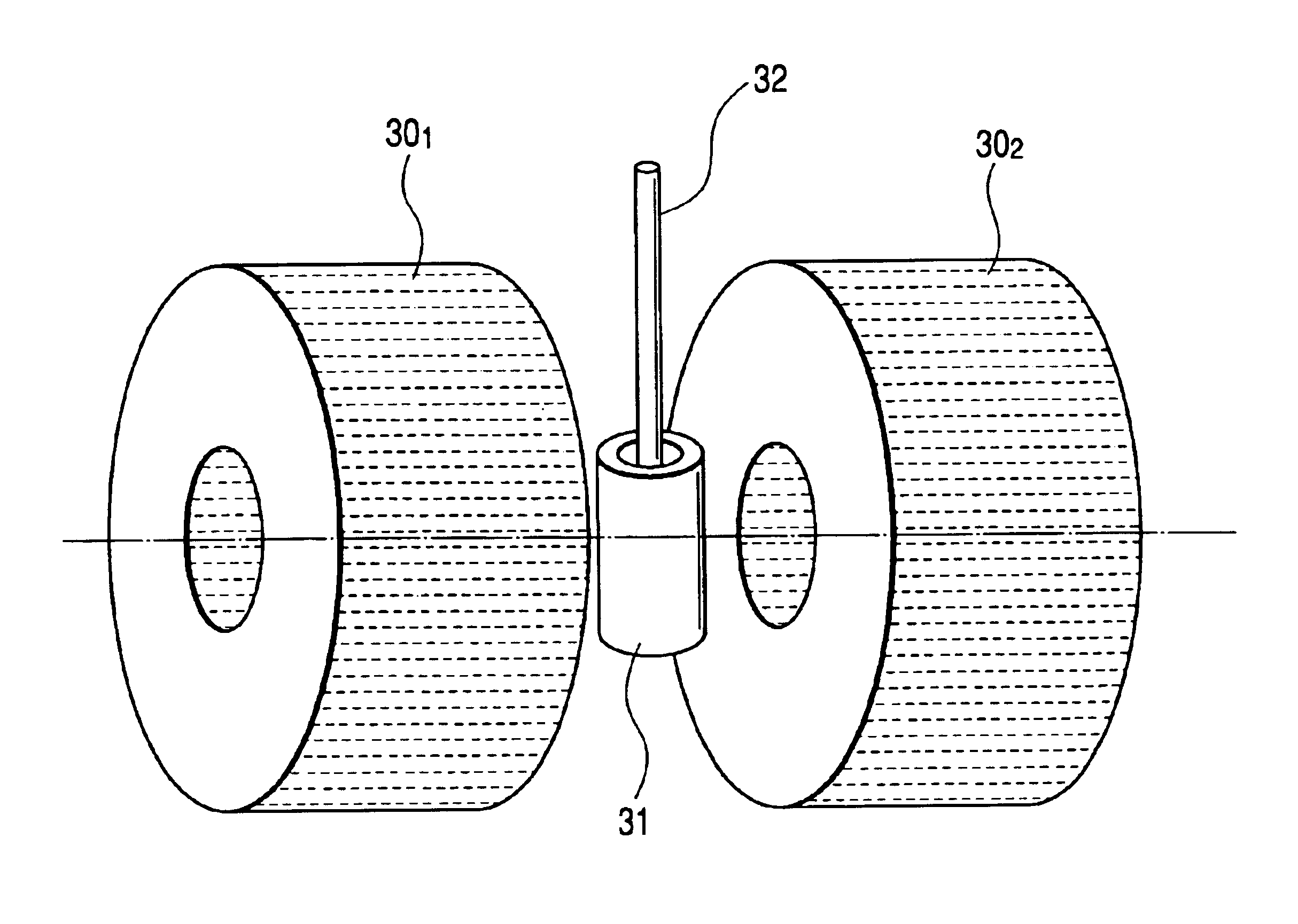

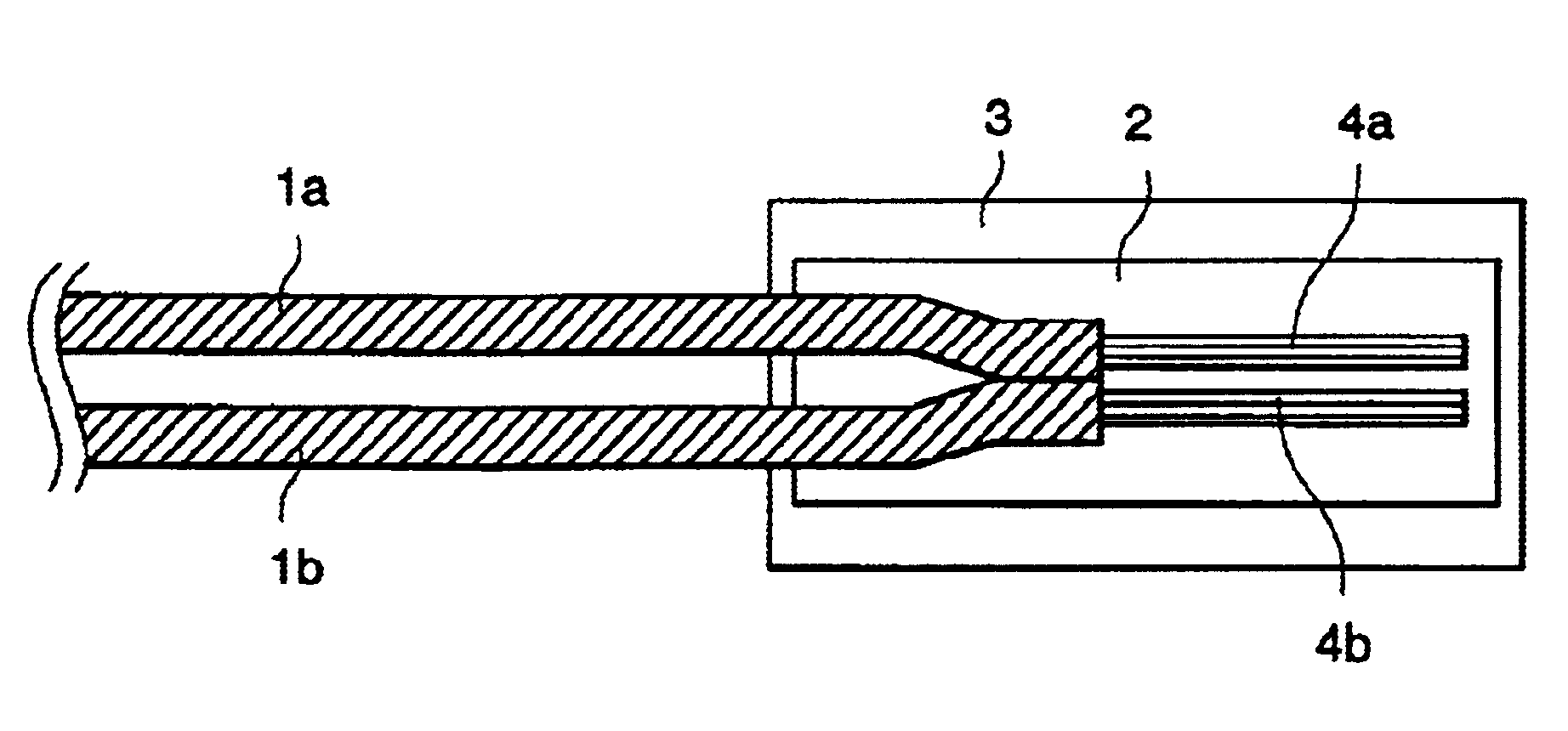

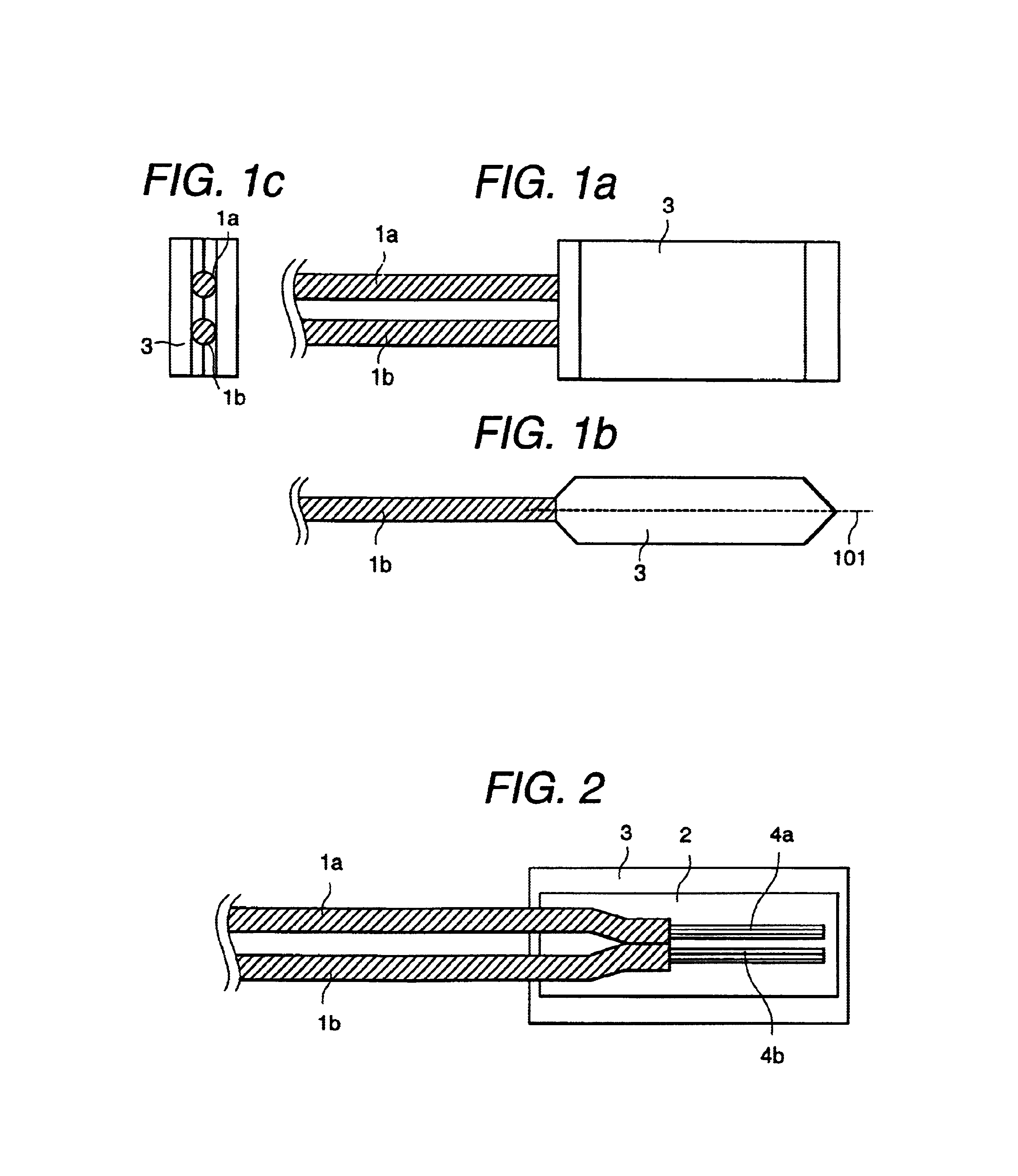

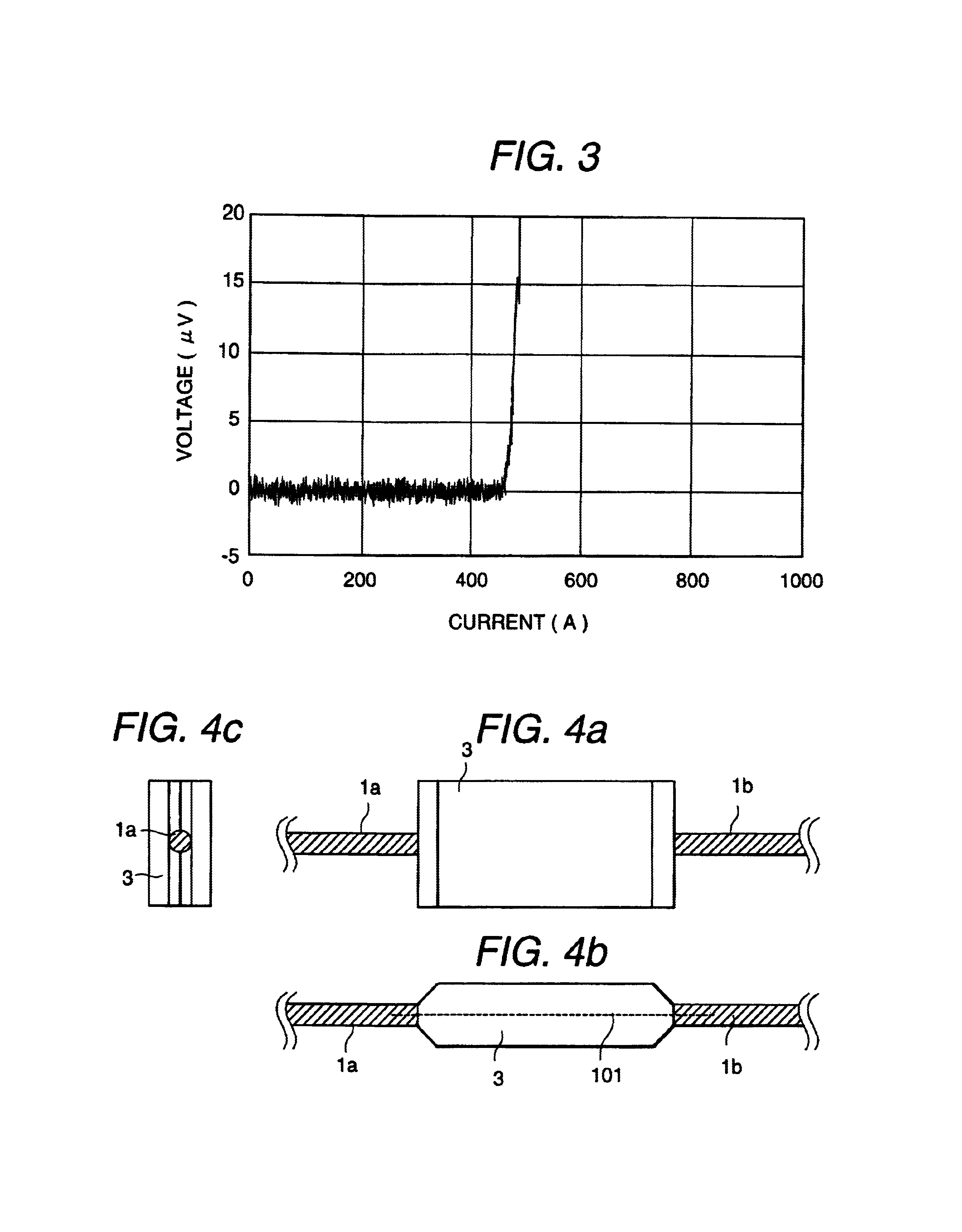

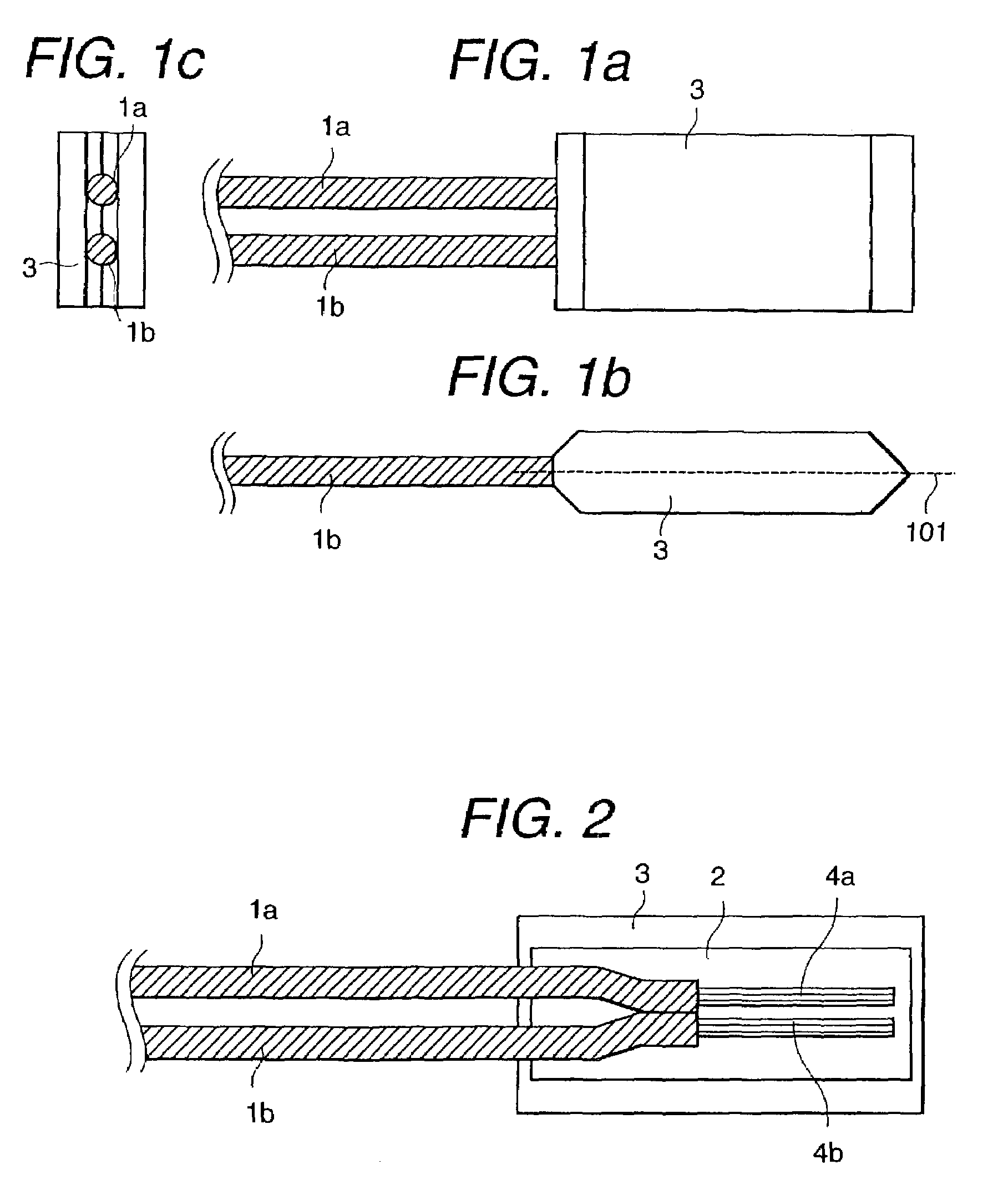

Superconductor connection structure

InactiveUS6921865B2Reduce power consumptionSimple connection structureSuperconductors/hyperconductorsSuperconductor detailsElectricityElectrical connection

Electrical connection of superconducting lines can be achieved by using a low-melting point metal, by mechanical contact of superconducting lines or by welding. According to these methods, however, critical current and critical magnetic field at the connection point are low, and stable connection in a superconducting state has been difficult. The present invention solves these problems and provides a structure and method for connecting superconducting lines. The present invention provides high-performance, high-stability connection of superconducting lines through magnesium diboride (MgB2) powder arranged between superconducting lines.

Owner:HITACHI LTD

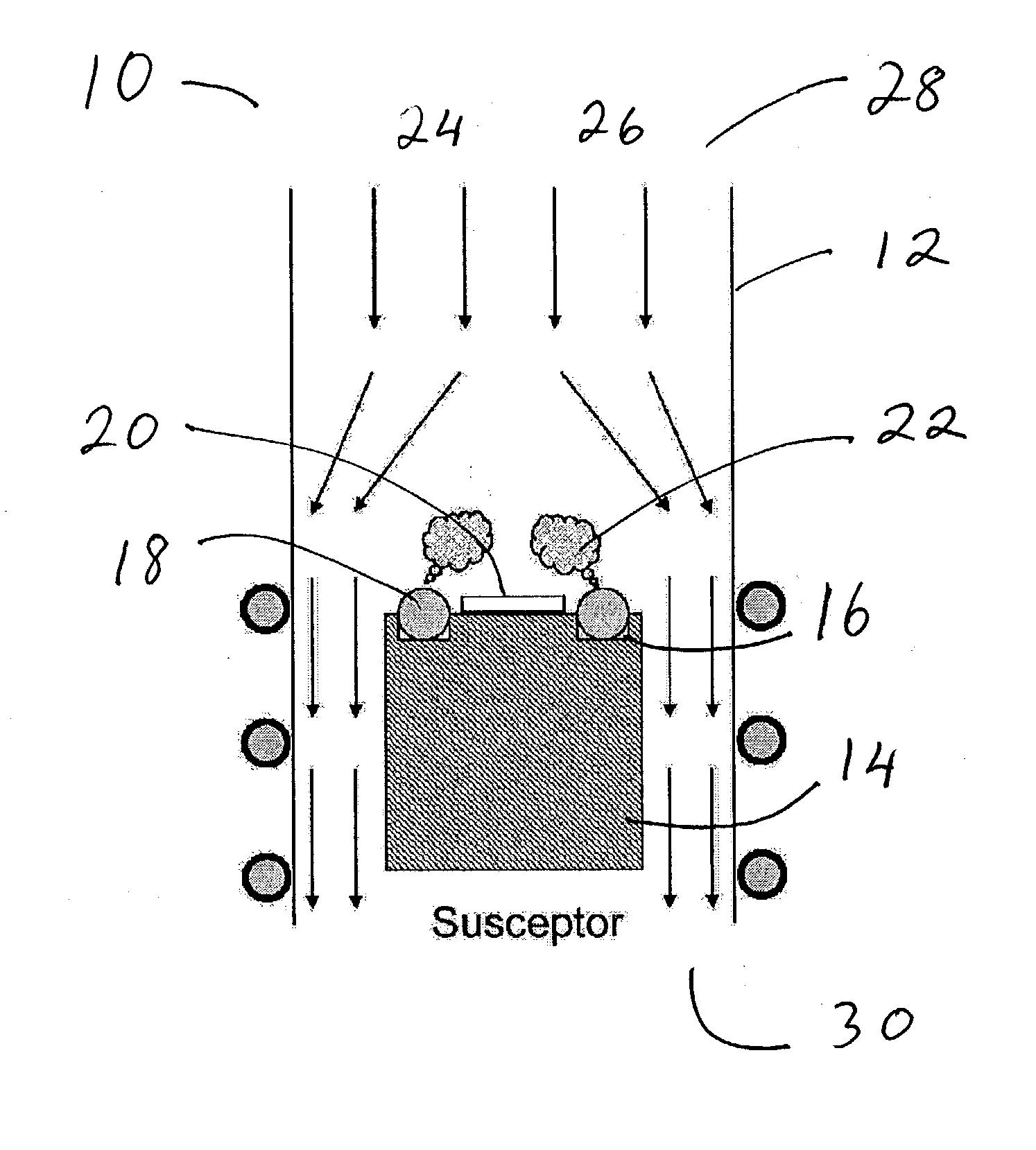

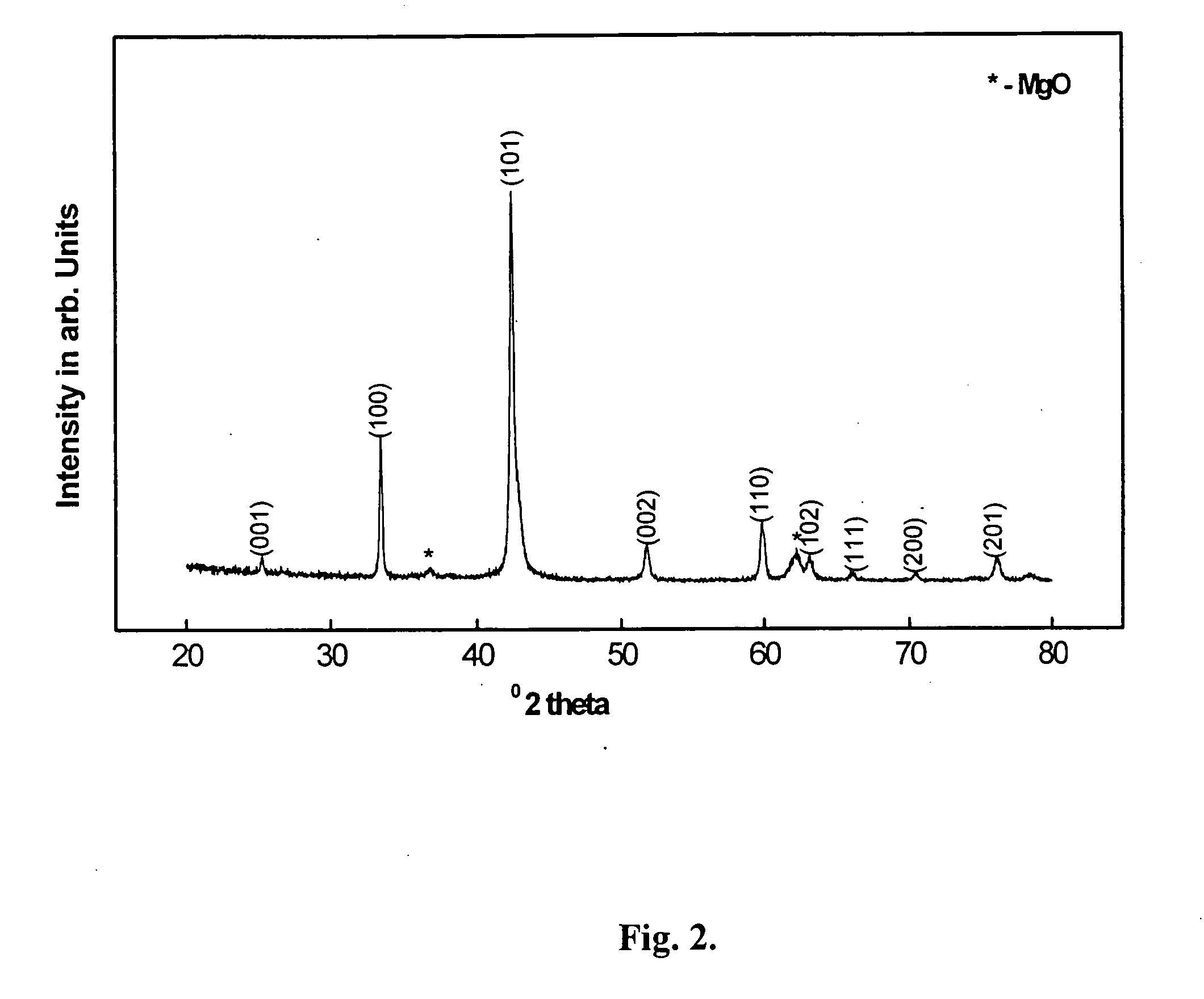

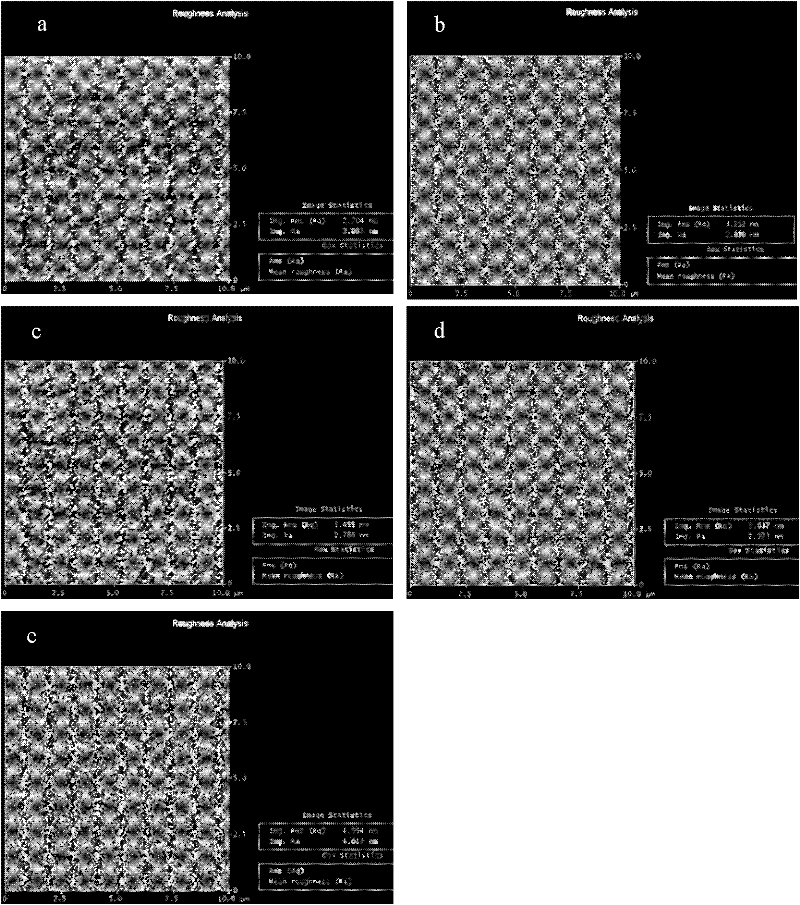

Method for producing boride thin films

InactiveUS6797341B2High purityReduce roughnessElectric discharge heatingVacuum evaporation coatingGas phaseBoron containing

Owner:PENN STATE RES FOUND

Method for producing doped, alloyed, and mixed-phase magnesium boride films

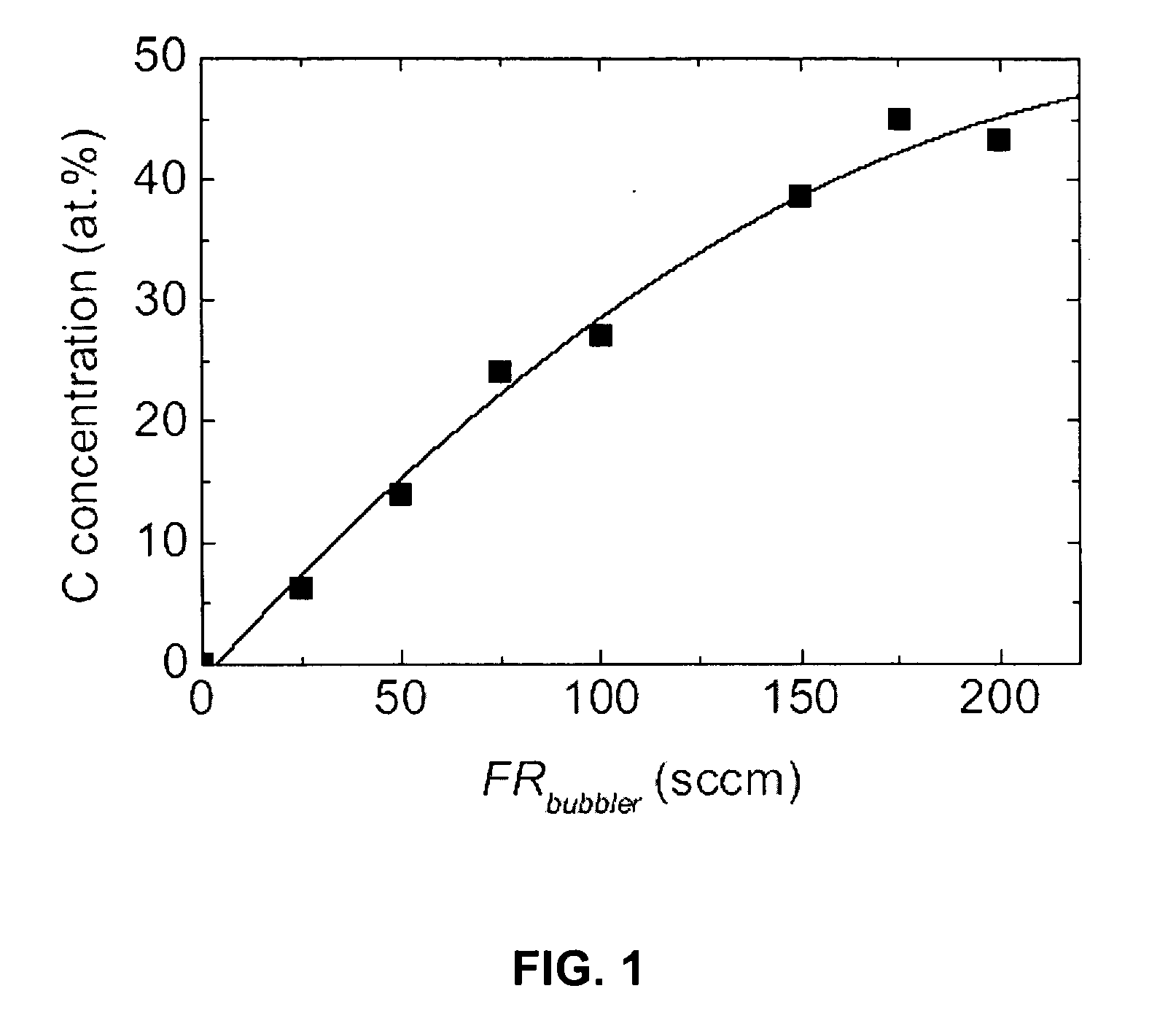

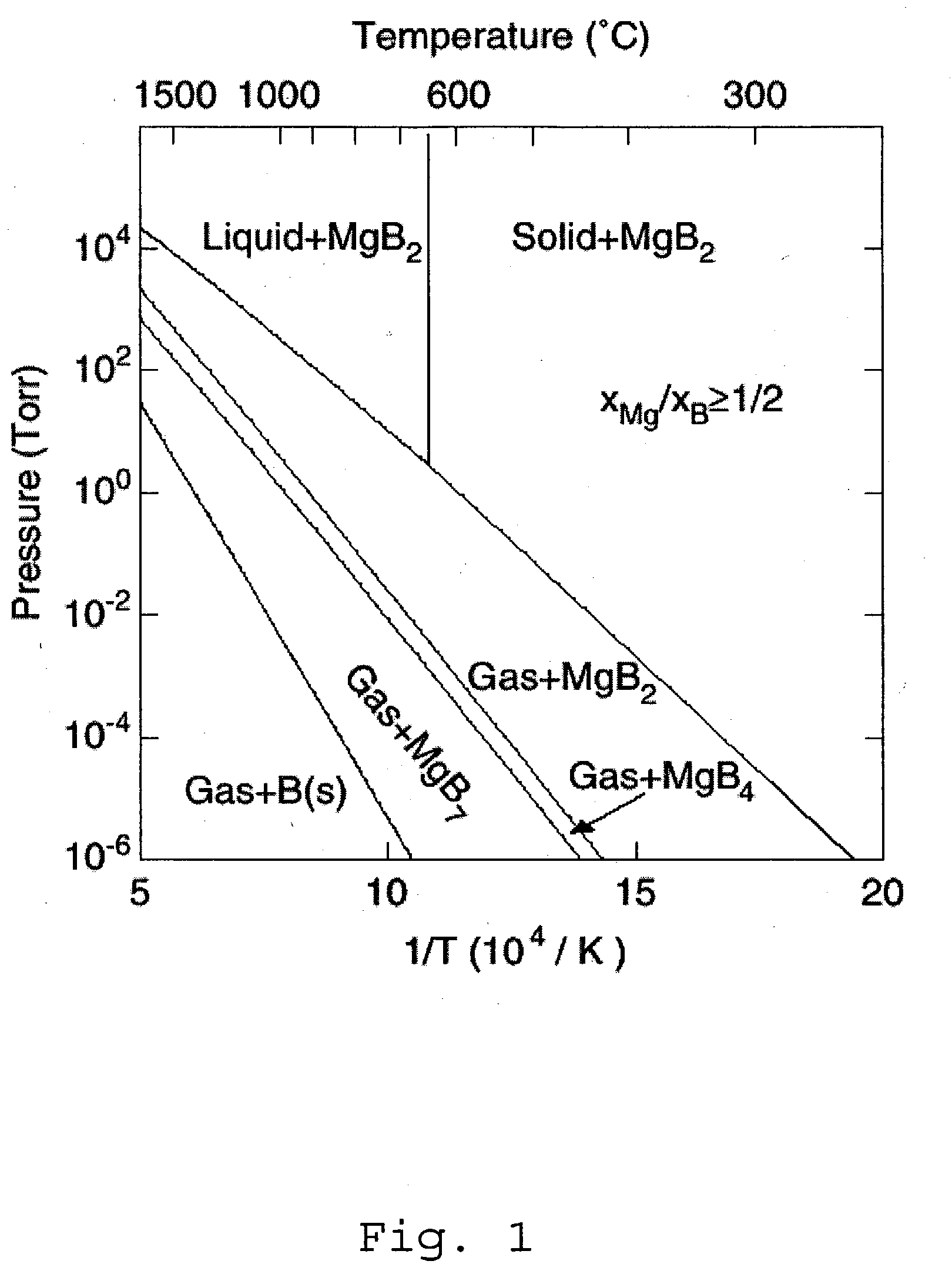

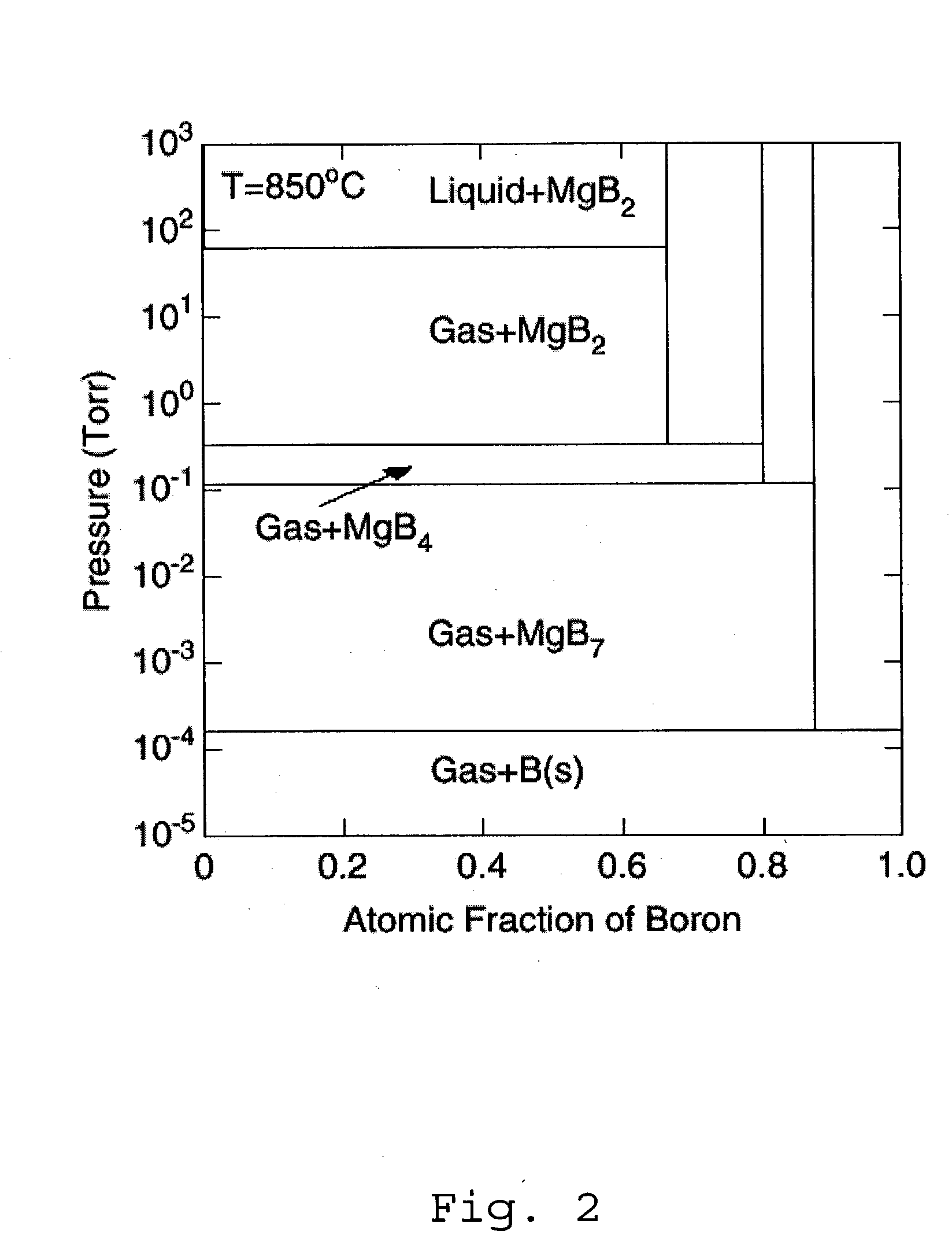

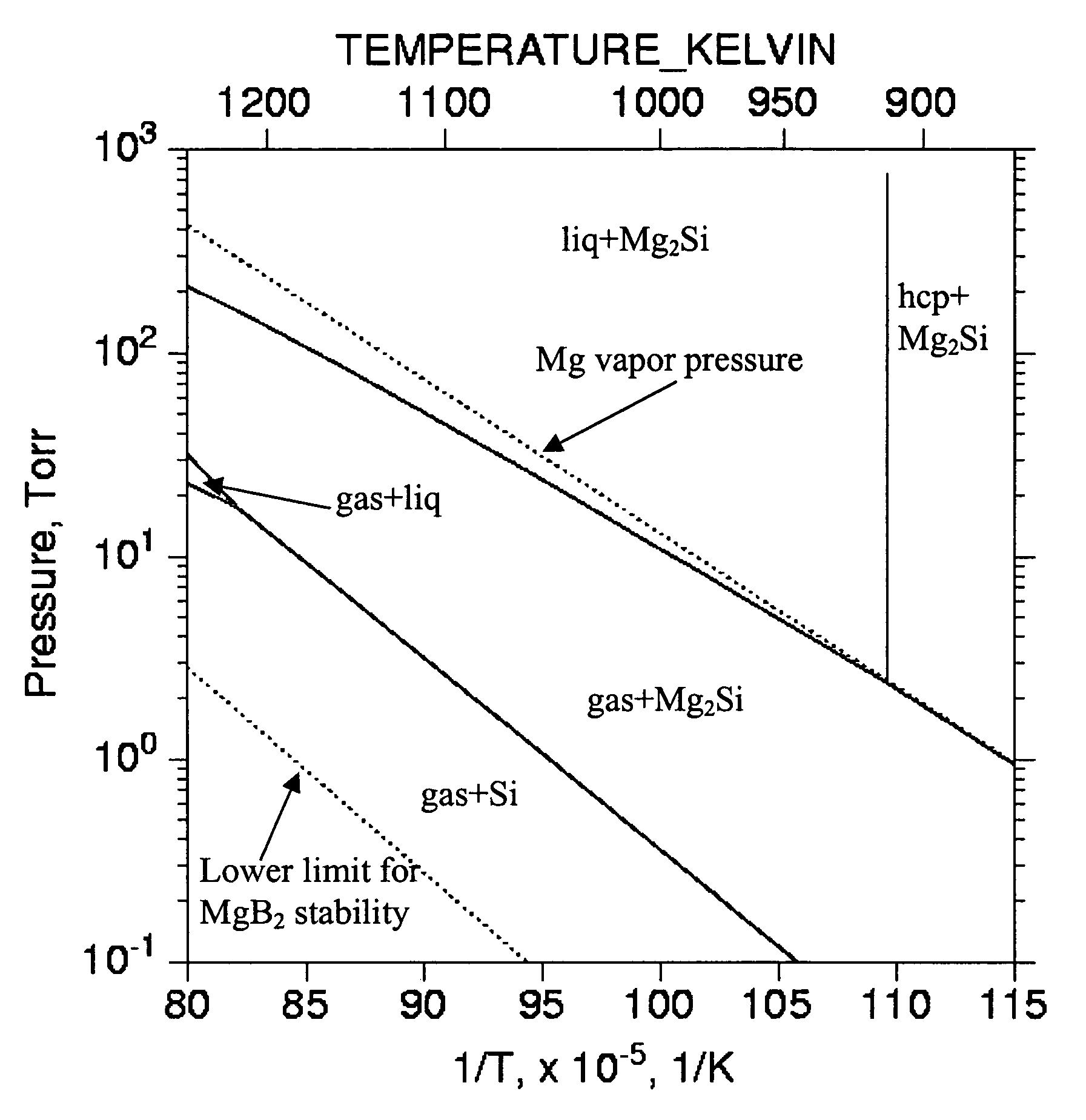

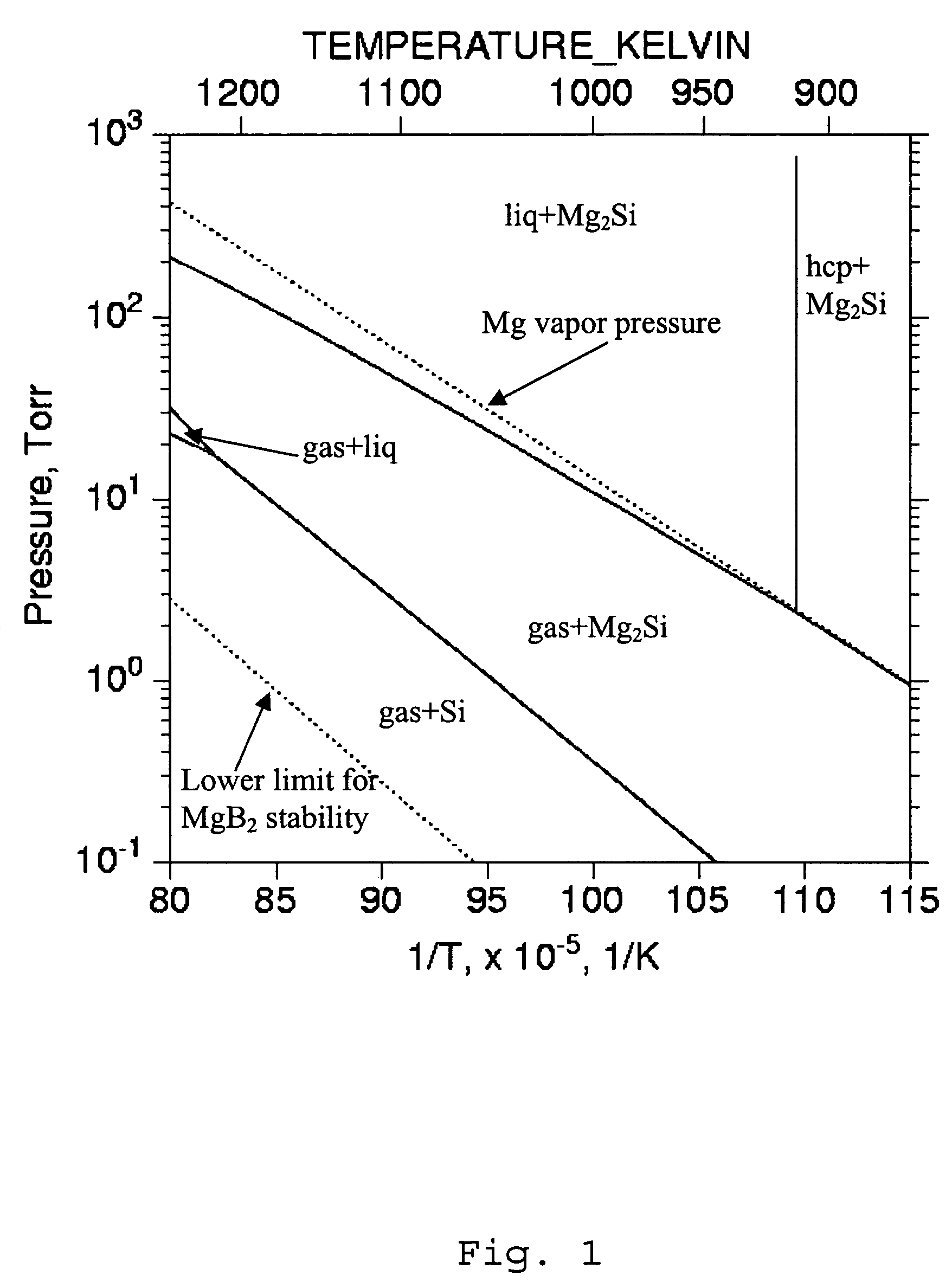

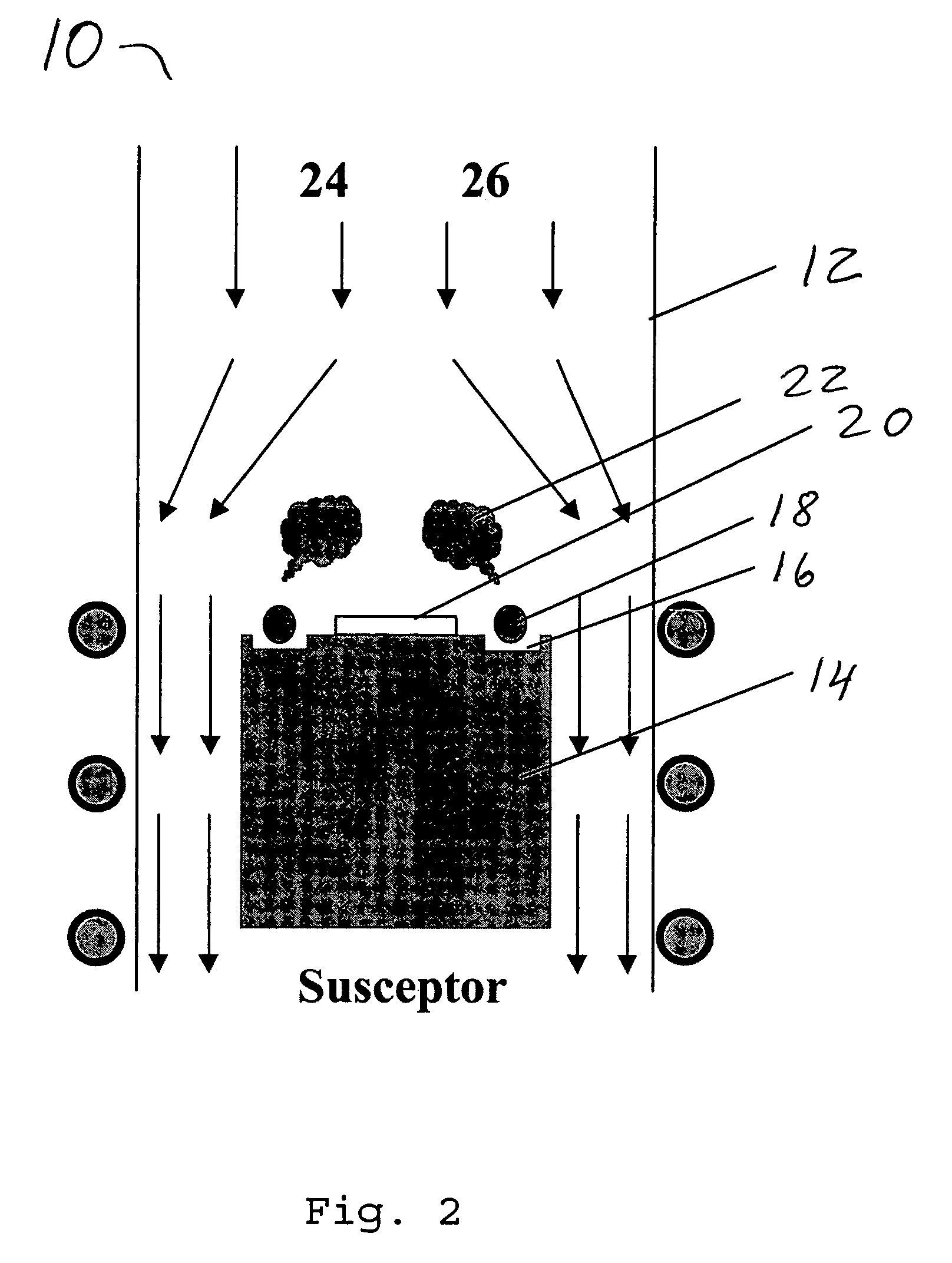

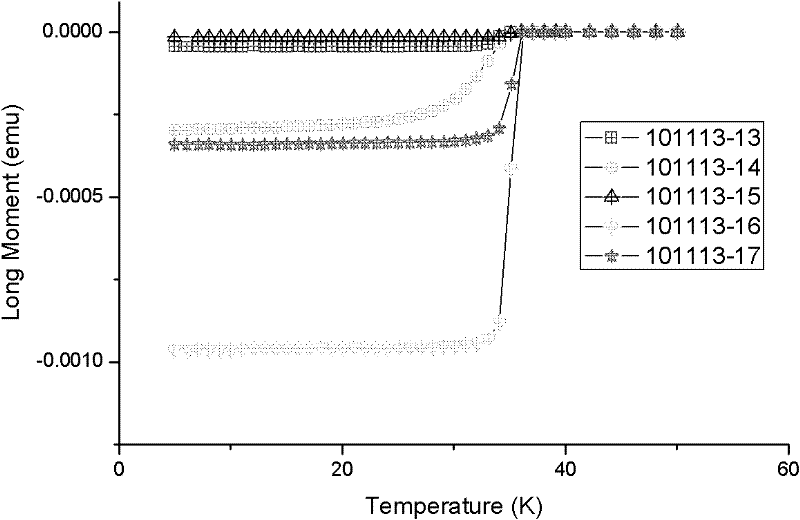

Conducting and superconducting doped, magnesium boride materials are formed by a process which combines physical vapor deposition with chemical vapor deposition by physically generating magnesium vapor in a deposition chamber and introducing a boron containing precursor and a dopant into the chamber which combines with the magnesium vapor to form the material. Embodiments include forming carbon-doped magnesium diboride film and powder with hybrid physical-chemical vapor deposition (HPCVD) by adding a carbon-containing metalorganic magnesium precursor, bis(methylcyclopentadienyl)magnesium, with a hydrogen carrier gas together with a borane precursor in a chamber having a source of magnesium vapor.

Owner:PENN STATE RES FOUND

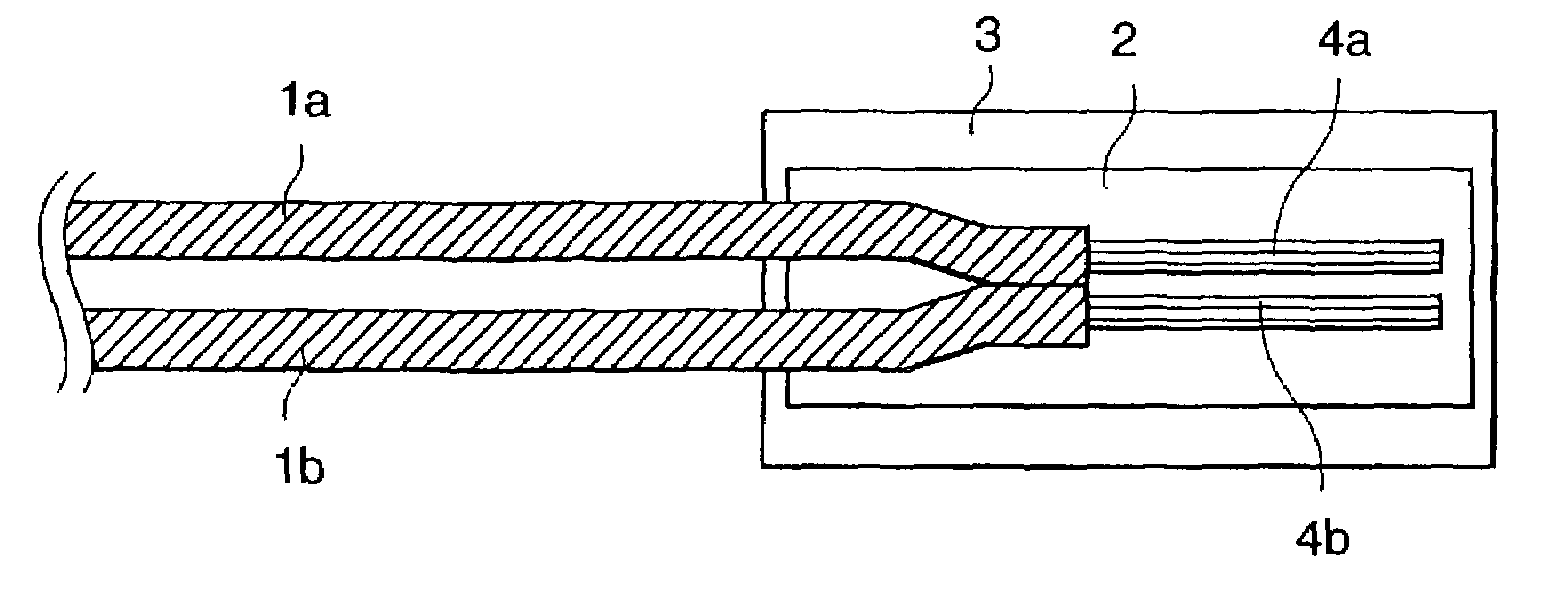

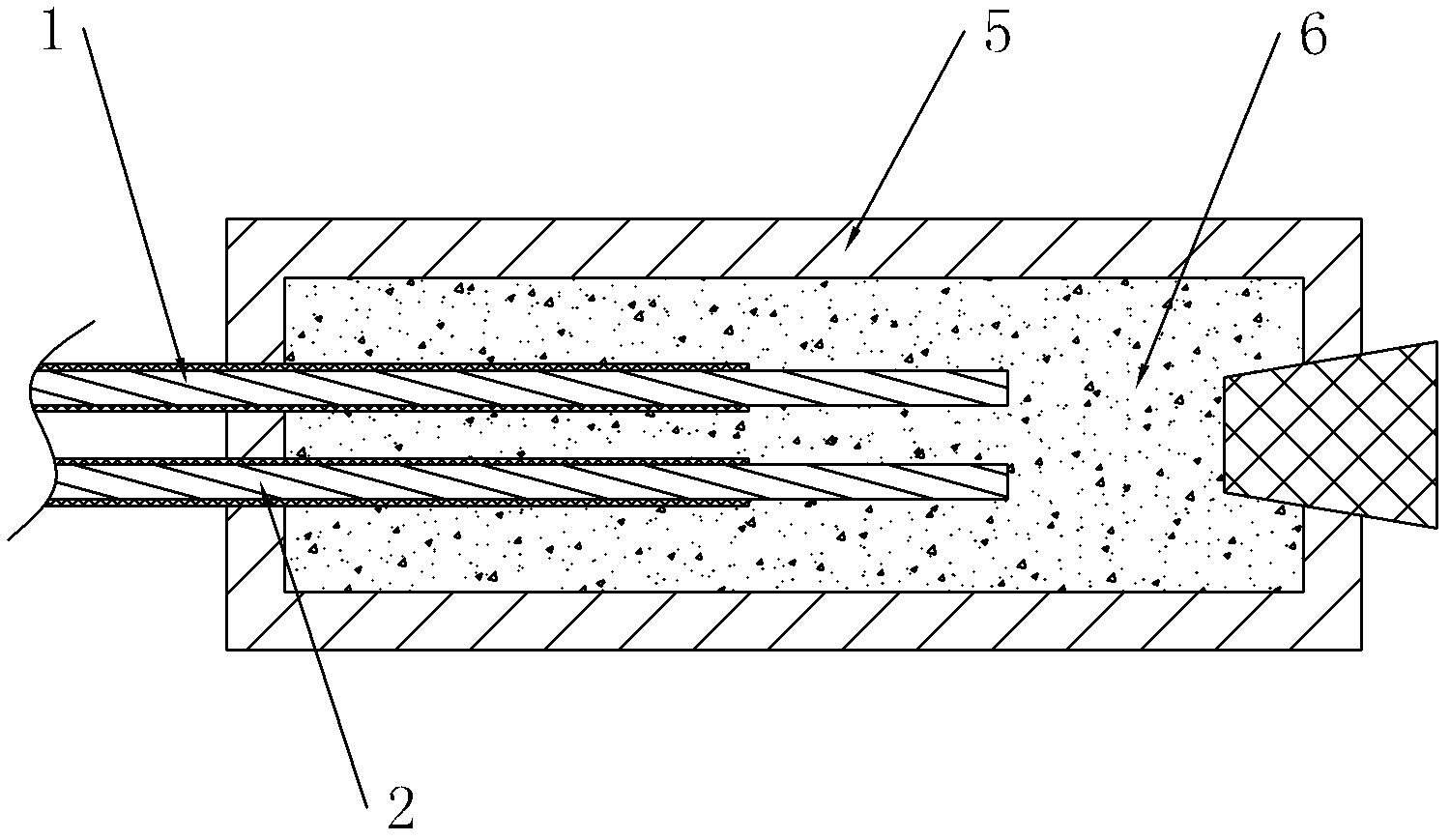

Connecting structure for magnesium diboride superconducting wire and a method of connecting the same

InactiveUS20060240991A1Excellent current conduction propertyImprove stabilitySuperconductor detailsSuperconductor device manufacture/treatmentMagnesium diborideMetal

A magnesium diboride superconducting wire has excellent conduction property and stability. The superconductive connection of the magnesium diboride superconducting wire covered with a superconducting coating layer and a same or different kind of another superconducting wire are connected in a metal tube filled with a solder by way of the superconductive coating layer.

Owner:HITACHI LTD

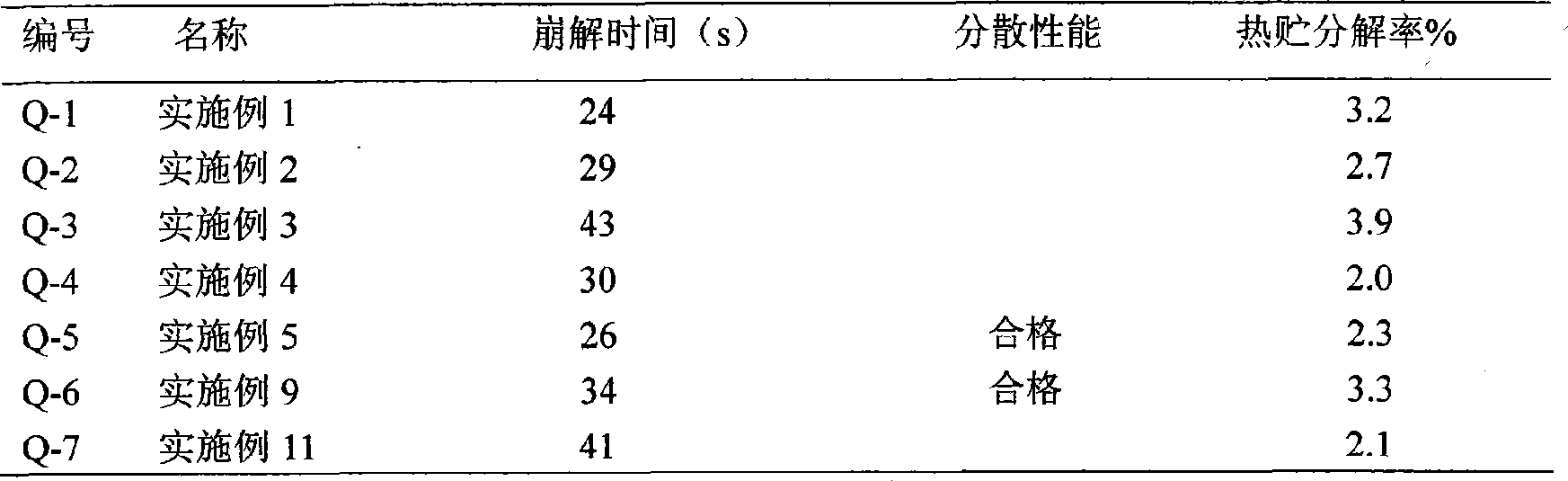

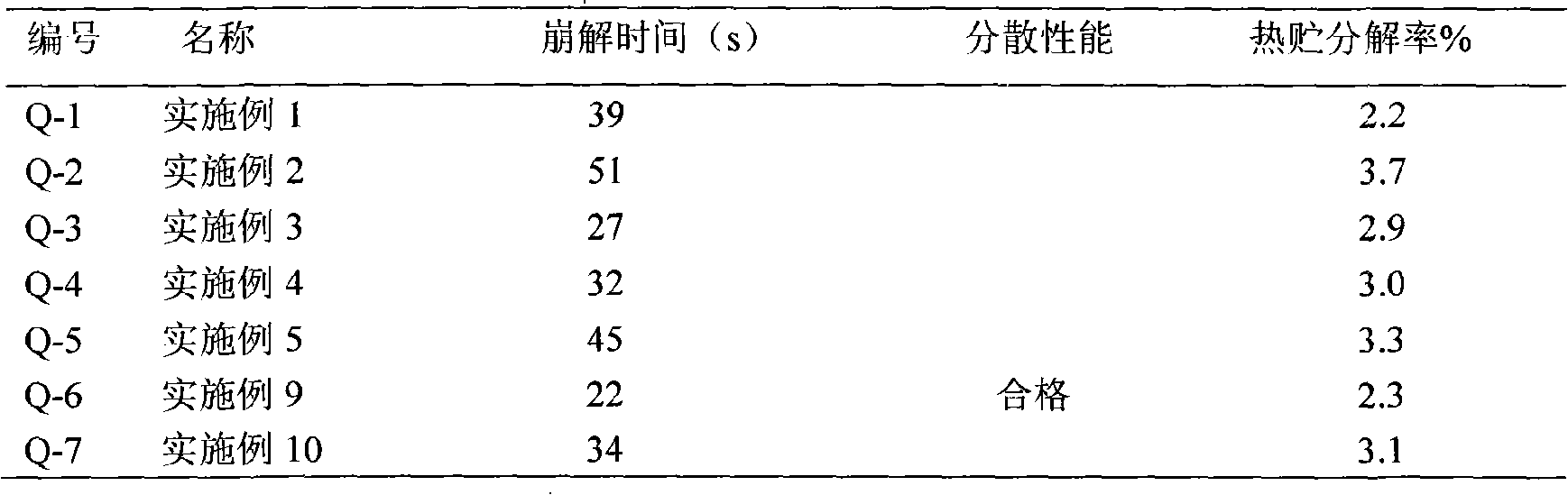

Boric fertilizer water dispersing granule and preparing method thereof

InactiveCN101531550AFast disintegrationDissolve (disperse) completelyFertiliser formsFertilizer mixturesMagnesium phosphatePotassium

The invention belongs to a new boric fertilizer, referring to a boric fertilizer water dispersing granule and preparing method thereof. The invention comprises one or more than one boric fertilizers and at least one surfactant; the materials are processed as the regular or irregular granules water dispersing granule; the weight part of the boric fertilizer is 5-95 parts; the rest is the assistant. The preferable solution of the invention is following: the boric fertilizer comprises one of the boric acid, boron oxide, boric acid ammonium, sodium tetraborate, calcium borate side, partial sodium borate, sodium borate tetrahydrate, magnesium diboride, sodium perborate, zinc borate, boric acid manganese, high-sodium borate, partial acid potassium, boron and magnesium fertilizer, boron and magnesium phosphate and boron mud or the mixture of the two or more than two of the above. The preparing method of the invention is scaling the prescription, mixing, crushing, and granule and drying to obtain the product. The boric fertilizer water dispersing granule of the invention has a fast disintegration, dissolving (dispersing) completely, not plugging the nozzle and the dropping pipe lines, no heating while using, easy to absorb moisture, packaging, storage and transportation, measurement, the use of low cost, widely used in food crops, cash crops, horticulture, lawns and urban greening; the market prospect is very broad.

Owner:SHENZHEN LANGTAI BIOTECH

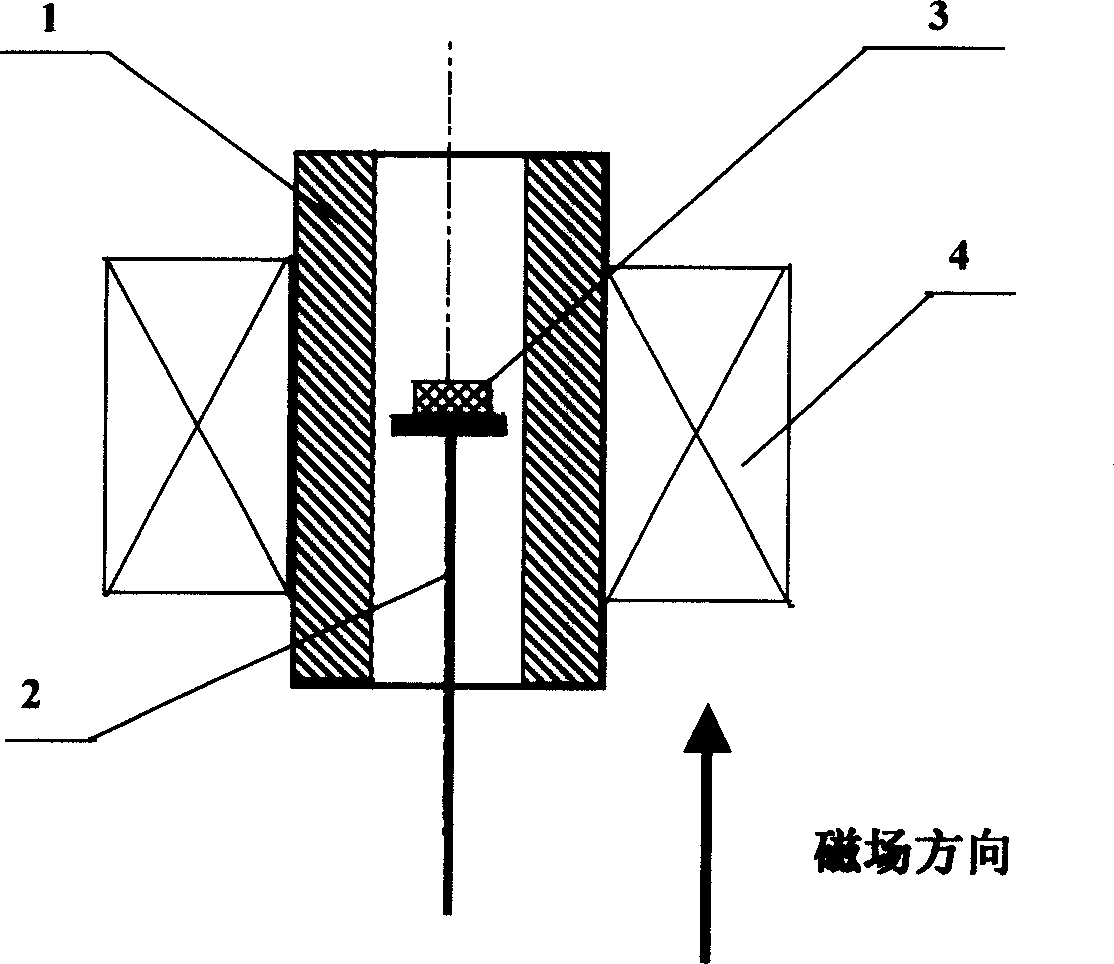

Process for preparing magnesium diboride superconductor

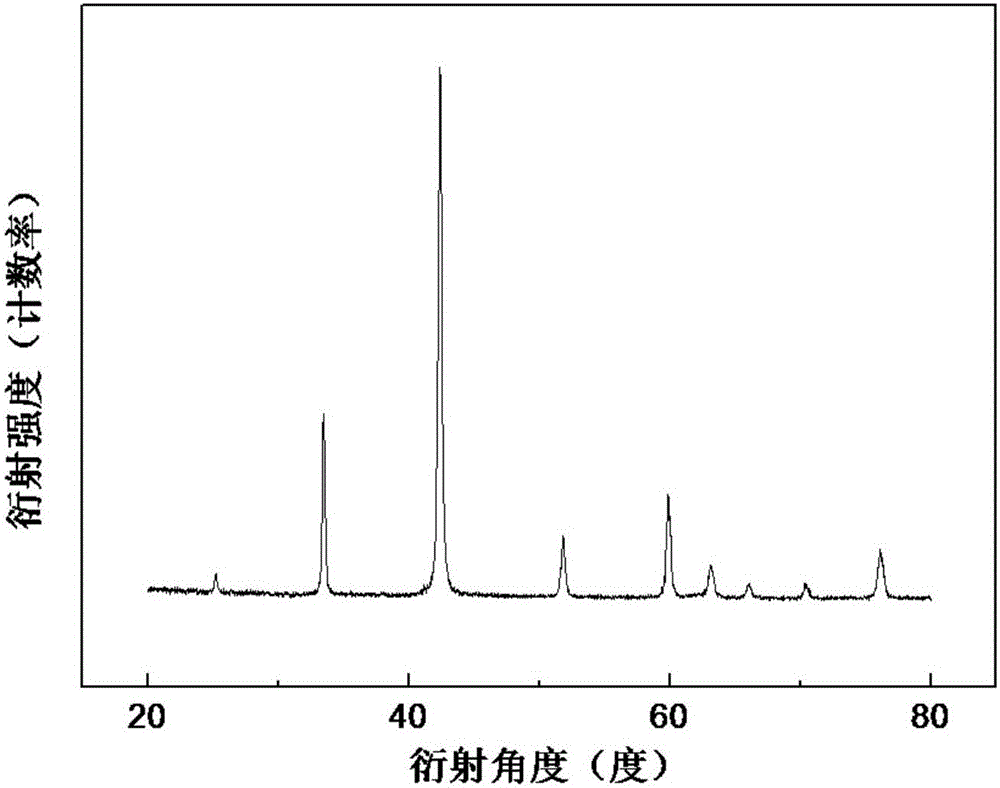

The preparation process of magnesium diboride superconductor features that magnesium diboride superconductor is prepared in strong magnetic field. Magnesium powder and boron powder in stoichiometric ratio are mixed homogeneously, the mixture is prepared into lump or belt sample, and the lump or belt sample is set heating furnace with Ar atmosphere and strong magnetic field and maintained at magnetic field of 0-30 tesla and temperature of 600-950 deg.c for 1-3 hr before the power source for the strong magnetic field and heating is turned off and the sample is cooled to room temperature inside the furnace. The present invention has effectively improved crystal grain connectivity and greatly raised clinical current structure of the magnesium diboride superconductor.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

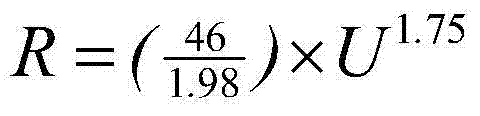

Method for preparing iron/copper compound coated magnesium diborate superconductive long wire

InactiveCN1945759AGuaranteed success rateGuaranteed thermal stabilitySuperconductors/hyperconductorsSuperconductor devicesMagnesium diborideThermal stability

This invention relates to a preparation method for an iron / copper compound packet wrapping MgB2 super-conduction long wires including: processing an iron tube and a copper tube of a certain specification, jacketing the iron tube into the copper tube, putting Mg powder, B powder and doped materials into a ball mill tank, then adding acetone reagent to dip the materials and mill the balls, vacuum-drying the ball-mill sample under ordinary temperature to get the material powder to be pressed to a cylinder with 10-600 MPa pressure and put into an iron tube, then to be pressed tightly and seal the port to get a compound packet wire in a certain diameter and length after swaging, rolling the hole and drawing, which is processed under 650-950deg.C for 0.5-5h to get a MgB2 super conduction wire with compound iron / copper.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

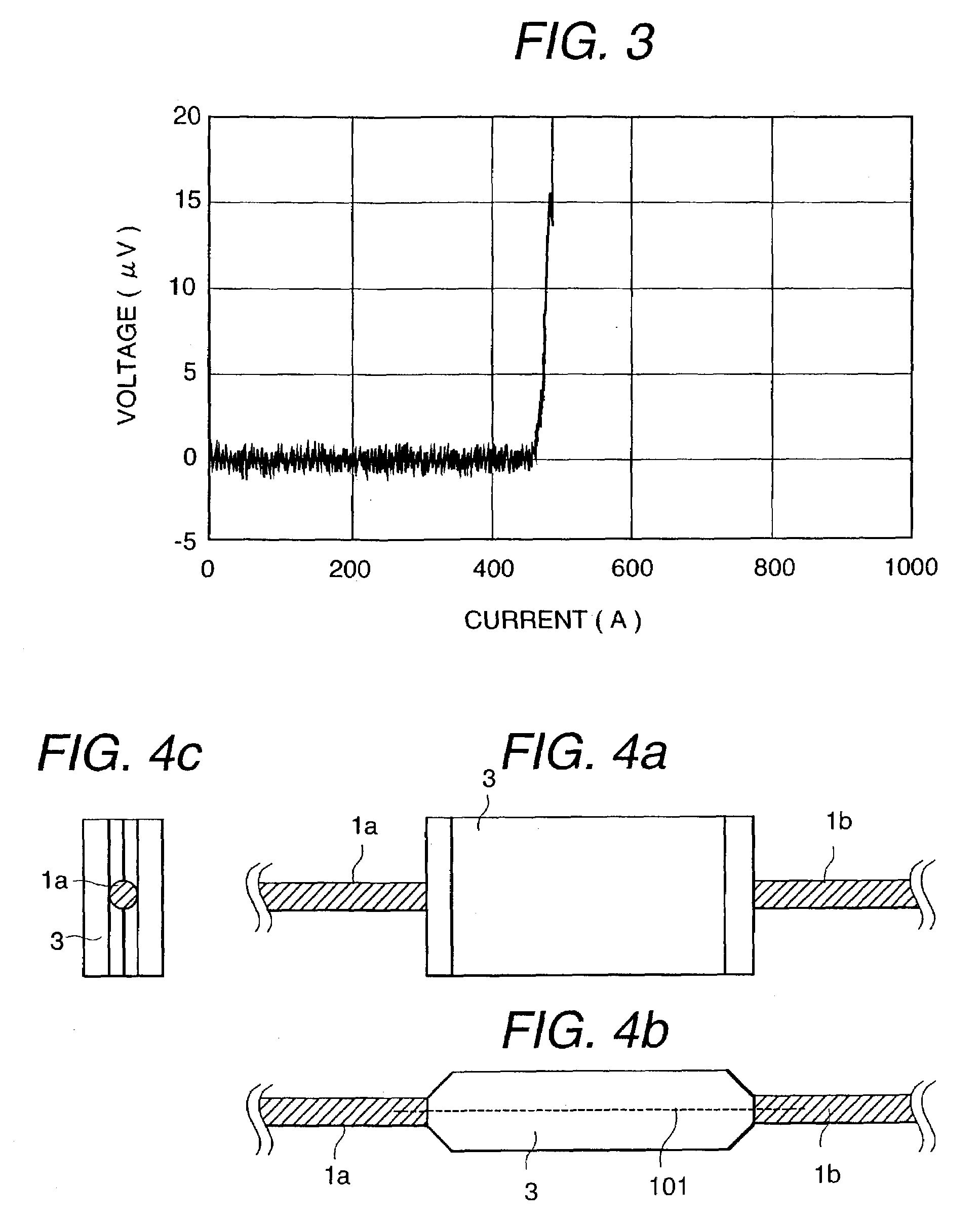

Probe for NMR apparatus using magnesium diboride

InactiveUS6967482B2Improved Q-factor and S/N ratioHigh frequency radio wavesSuperconducting magnets/coilsElectric/magnetic detectionNiobiumCobalt

To provide a probe coil for an NMR apparatus which can transmit and receive high frequency radio waves with improved Q-factor and S / N ratio. As a measure, the probe coil for an NMR apparatus is provided as of a solenoid type formed of magnesium diboride superconductor. As another measure, the probe coil for an NMR apparatus has a plurality of coils using magnesium diboride superconductors connected in series. As further another measure, there is used a magnesium diboride superconductor mixed with metal. As still further another measure, the probe coil for an NMR apparatus is formed by using a single metal selected from gold, silver, copper, aluminum, iron, platinum, palladium, nickel, stainless steel, chromium, magnesium, tantalum, niobium, titanium, zinc, beryllium, tungsten, or cobalt, or an alloy including a plurality thereof.

Owner:HITACHI LTD

Superconductor connection structure

InactiveUS7152302B2Increase freedomReduce connectionsSuperconductors/hyperconductorsSuperconductor detailsMagnesium diborideElectrical connection

A method of producing an electrical connection structure between at least two superconducting lines. The method comprises adding metal powder or alloy powder to a superconducting material comprising magnesium diboride, intervening the superconducting material between at least two superconducting lines, and heating said superconducting lines and said superconducting material to a temperature lower than the melting point of said superconducting material prior to the addition of said metal powder or alloy powder thereto, but higher than the melting point of said metal powder or alloy powder.

Owner:HITACHI LTD

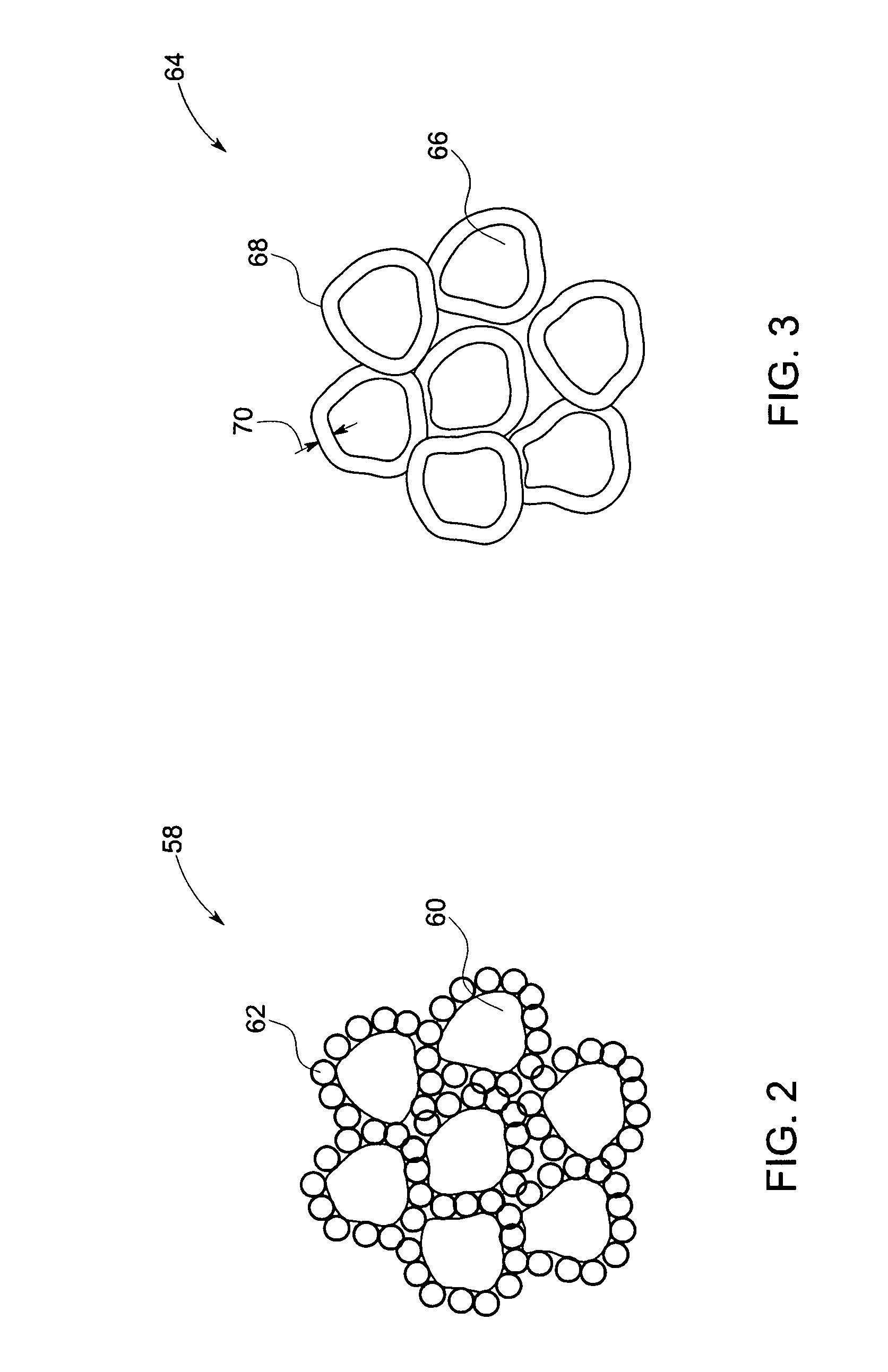

Method for preparing magnesium diboride superconducting wire with graphene coated boron powder

ActiveCN105931750ACombine tightly and evenlyInhibition of contractionSuperconductors/hyperconductorsSuperconductor devicesRoom temperatureMagnesium diboride

The invention discloses a method for preparing a magnesium diboride superconducting wire with graphene coated boron powder. The method comprises the steps of: 1, adding the spherical nano boron powder to graphene oxide solution, filtering after stirring uniformly to obtain filter residue and carrying out vacuum drying on the filter residue to obtain mixed powder; 2, carrying out heat treatment on the mixed powder to obtain the graphene coated boron powder; 3, after mixing the graphene coated boron powder with magnesium powder, grinding to obtain tubing precursor powder; 4, putting the tubing precursor powder into an Nb / Cu composite tube which is processed by acid pickling to obtain a tubing complex; 5, processing the tubing complex into a single-core wire; 6, processing into a multi-core wire by employing a bundle-drawing technology; and 7, carrying out phase-forming heat treatment, and cooling to room temperature with a furnace to obtain the magnesium diboride superconducting wire. According to the method disclosed by the invention, through adding the spherical boron powder to the graphene oxide solution, the single-layer graphene coated boron powder is realized; after the heat treatment, the graphene has no agglomeration and can be combined with the boron powder tightly and uniformly; and the phenomena of graphene contraction and nonuniformity in the traditional method are inhibited.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

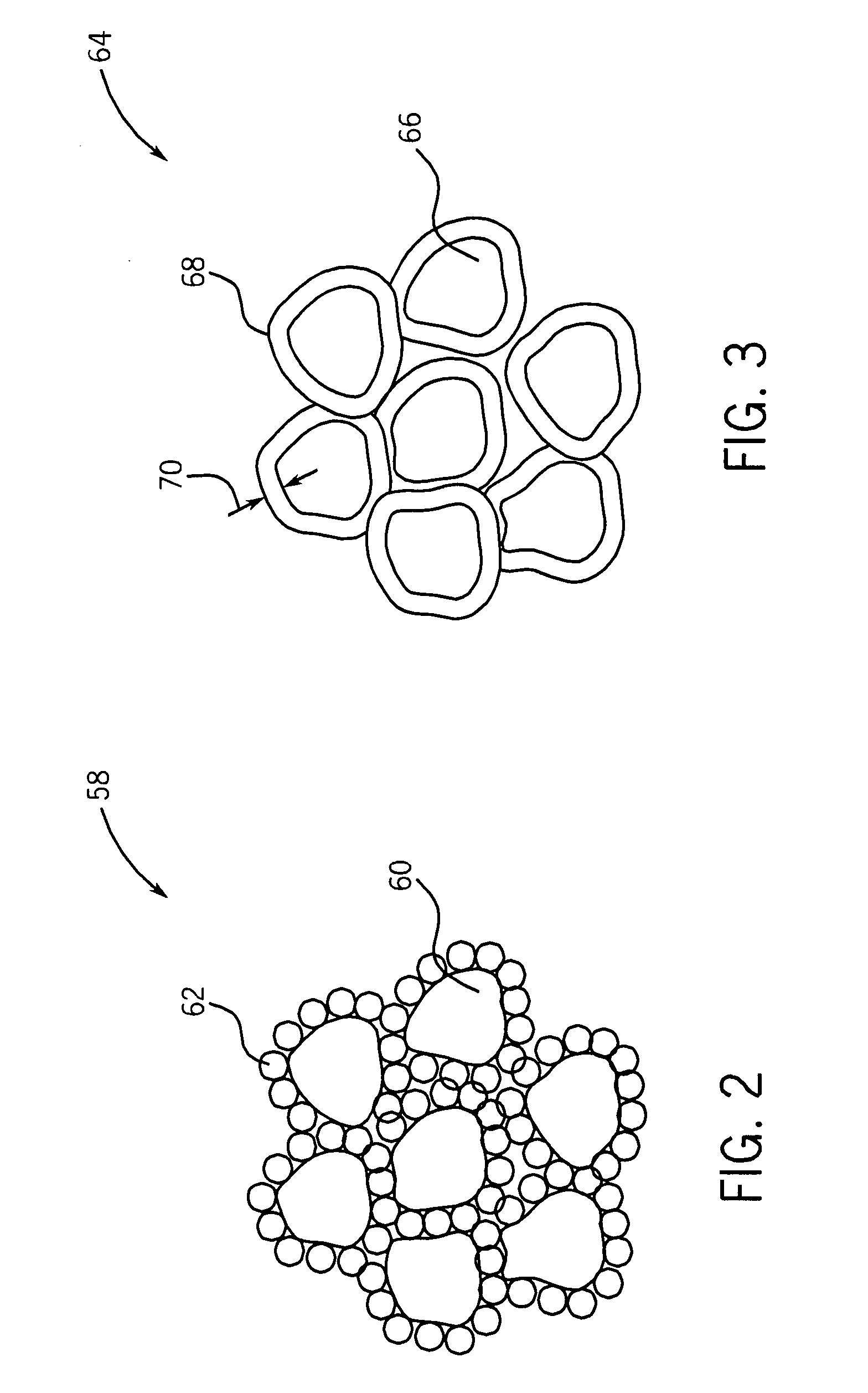

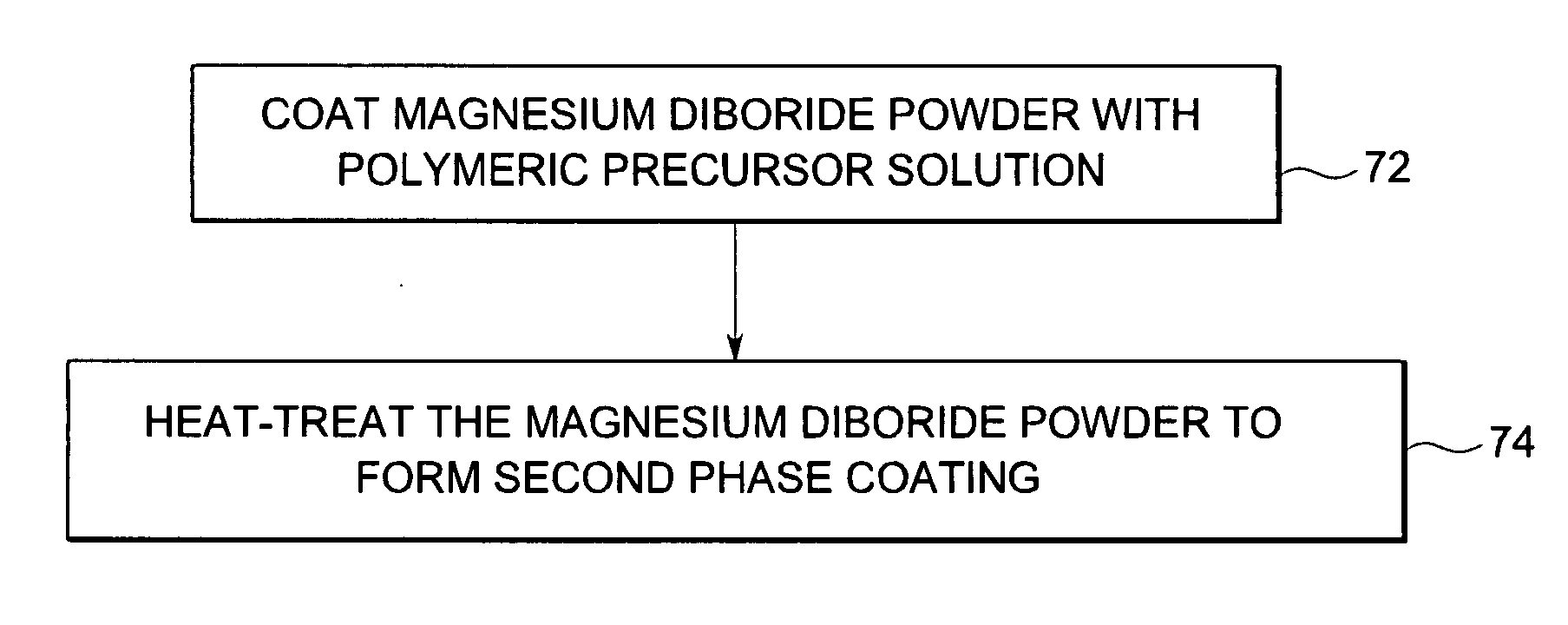

Doped magnesium diboride powders and methods for making the same

A method for making a doped magnesium diboride powder is provided. The method includes coating a polymeric precursor on at least one of a plurality of particles of a first phase, where the first phase includes a magnesium diboride powder, where the polymeric precursor includes chemical elements yielding a second phase. The second phase includes one or more of a boride, a nitride, a carbide, an oxide, an oxy-boride, an oxy-nitride, an oxy-carbide, or combinations thereof. The method further includes forming a second phase coating onto at least one of the plurality of particles of the magnesium diboride powder.

Owner:GENERAL ELECTRIC CO

Method for producing boride thin films

InactiveUS20030219911A1High purityReduce roughnessPolycrystalline material growthVacuum evaporation coatingGas phaseMagnesium diboride

Thin films of conducting and superconducting materials are formed by a process which combines physical vapor deposition with chemical vapor deposition. Embodiments include forming boride films, such as magnesium diboride, in high purity with superconducting properties on substrates typically used in the semiconductor industry by physically generating magnesium vapor in a deposition chamber and introducing a boron containing precursor into the chamber which combines with the magnesium vapor to form a thin boride film on the substrate.

Owner:PENN STATE RES FOUND

Boron fertilizer effervescence granule and method of producing the same

InactiveCN101550040AFast disintegrationImprove solubilityFertilizer mixturesMagnesium phosphateManganese

The invention relates to a boron fertilizer effervescence granule and method of producing the same, pertaining to a novel boron fertilizer. The boron fertilizer effervescence granule includes one or more boron fertilizer and one or more compounds contacted with water to generate gas, wherein, the weight part scope of the boron fertilizer is from 61 to 95. The preferred scheme of the invention is that the boron fertilizer includes one of boric acid, boron oxide, ammonium pentaborate, sodium tetraborate, calcium metaborate, sodium metaborate, tetrahydate octa sodium borate, magnesium diboride, sodium perborate, zinc borate, manganese borate, sodium perborate, potassium metaborate, boron magnesium fertilizer, boron and magnesium phosphate, and boron mud, or a mixture of two or more of the above. The preparation method of the invention includes: weighing the formulation material, mixing, grinding, granulating, and drying to obtain. The inventive boron fertilizer effervescence granule has a fast disintegrating velocity in the water; completely dissolving(dispersing); non-clogging of nozzle and drip irrigation pipeline; no need of heating when in use; no absorption of moisture; low packaging, storage and transportation, measurement and use cost; wide application in food crops, cash crops, horticulture, lawns and urban greening; and very broad market prospect.

Owner:SHENZHEN LANGTAI BIOTECH

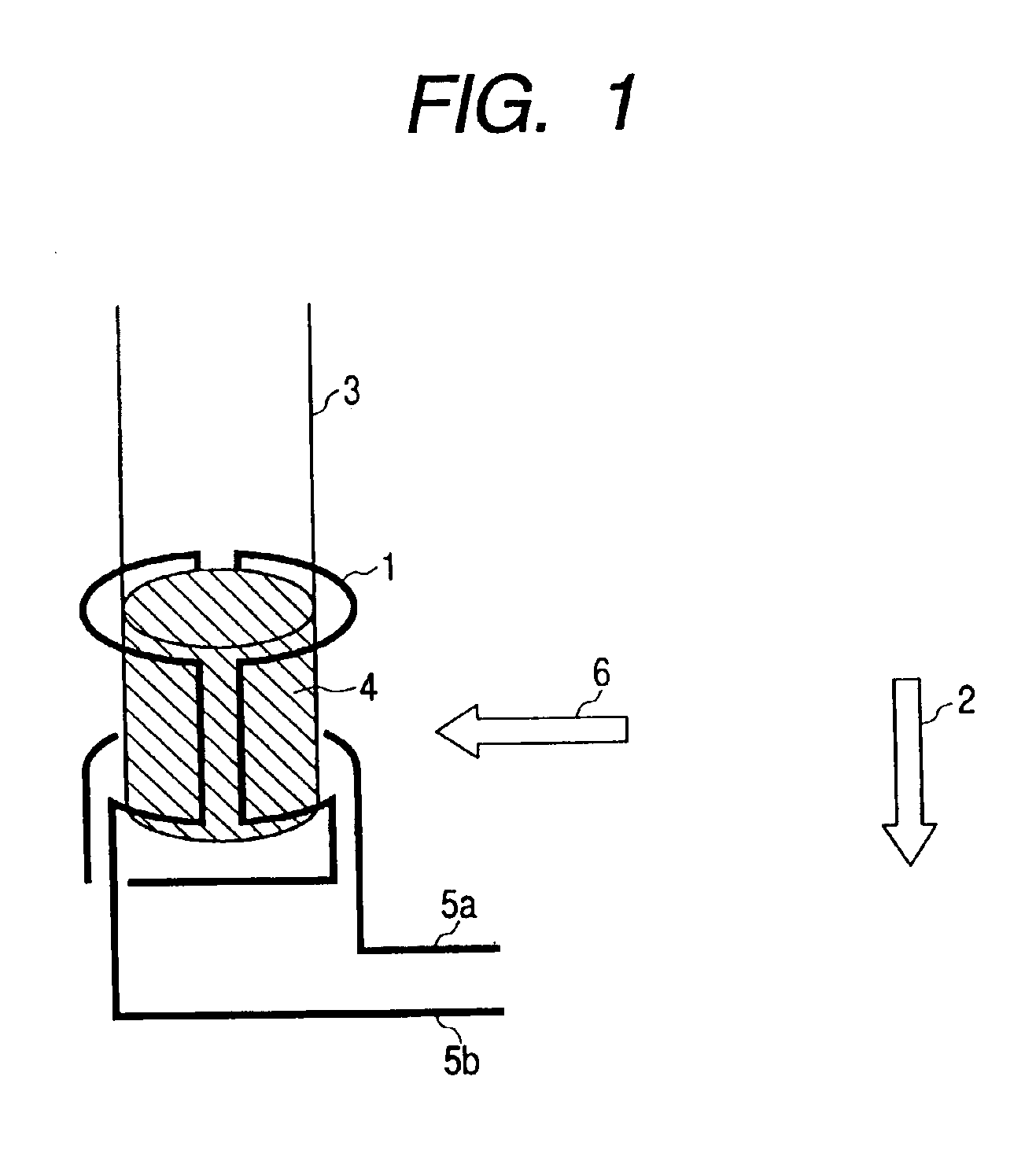

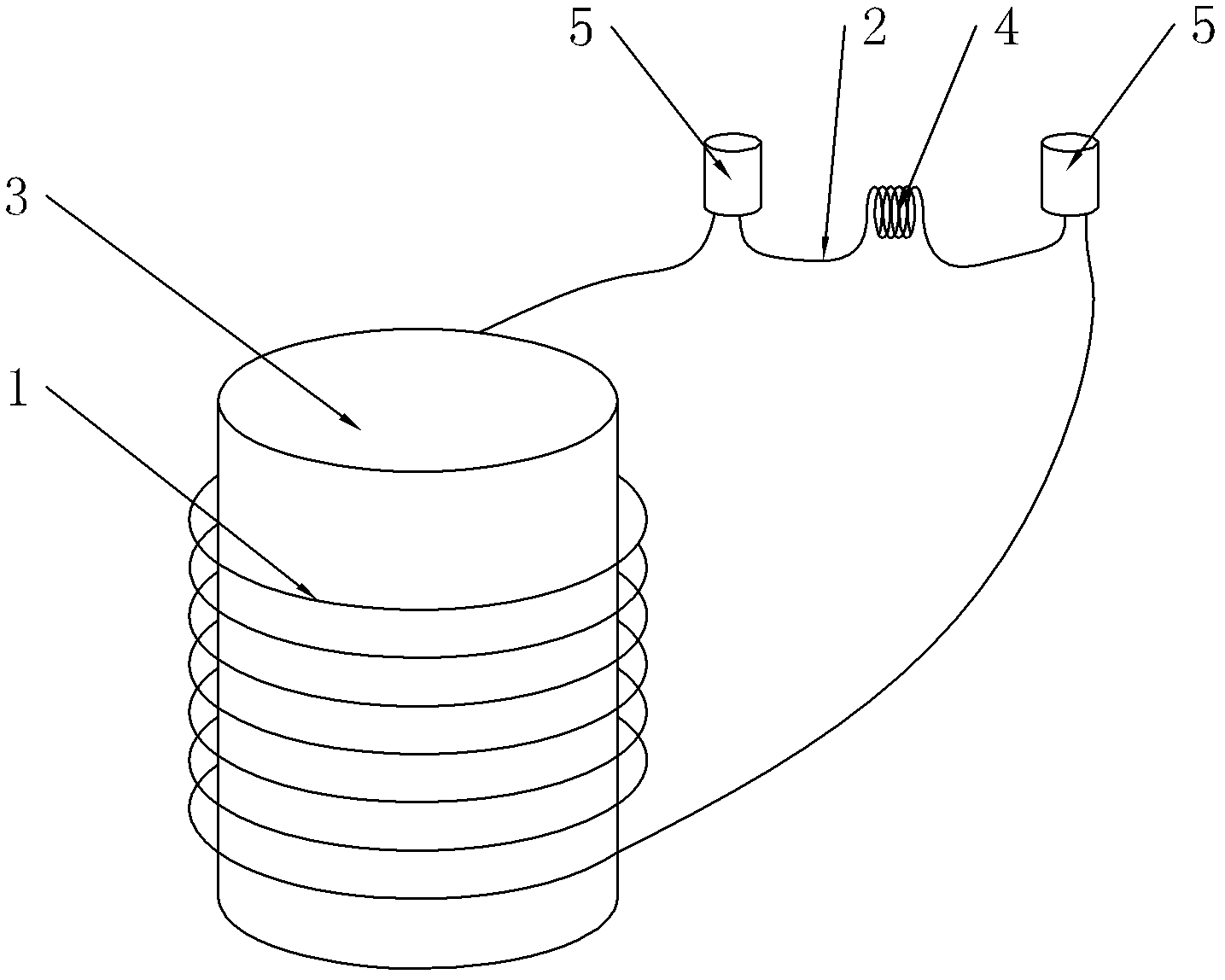

Method for manufacturing closed loop superconducting coil by using magnesium diboride and closed loop superconducting coil

ActiveCN102623167ADoes not consume energyLow superconducting critical transition temperatureSuperconducting magnets/coilsCoils manufactureBobbinClosed loop

The invention discloses a method for manufacturing a closed loop superconducting coil by using a magnesium diboride superconducting wire. The method comprises the following steps of: 1, winding an unsintered magnesium diboride superconducting wire on a bobbin by using a solenoid magnet winding method; 2, correspondingly arranging the two ends of the coil superconducting wire and the two ends of a switch superconducting wire in superconducting joints respectively, filling unsintered magnesium diboride powder into the superconducting joints, compacting the unsintered magnesium diboride powder, sealing the superconducting joints, and connecting the coil superconducting wire and the switch superconducting wire end to end to form the closed loop superconducting coil; 3, arranging the closed loop superconducting coil in a vacuum furnace and a furnace filled with a protective gas for sintering; and 4, slowly cooling the closed loop superconducting coil, and taking the cooled closed loop superconducting coil out. The invention also discloses the closed loop superconducting coil manufactured by the method. The closed loop superconducting coil can run without resistance at the temperature of about 20K, and required running temperature can be maintained only by using a low-cost cooler, so that use of high-cost liquid helium can be avoided, and the maintenance operation for a magnet is greatly simplified.

Owner:NINGBO JANSEN NMR TECH CO LTD

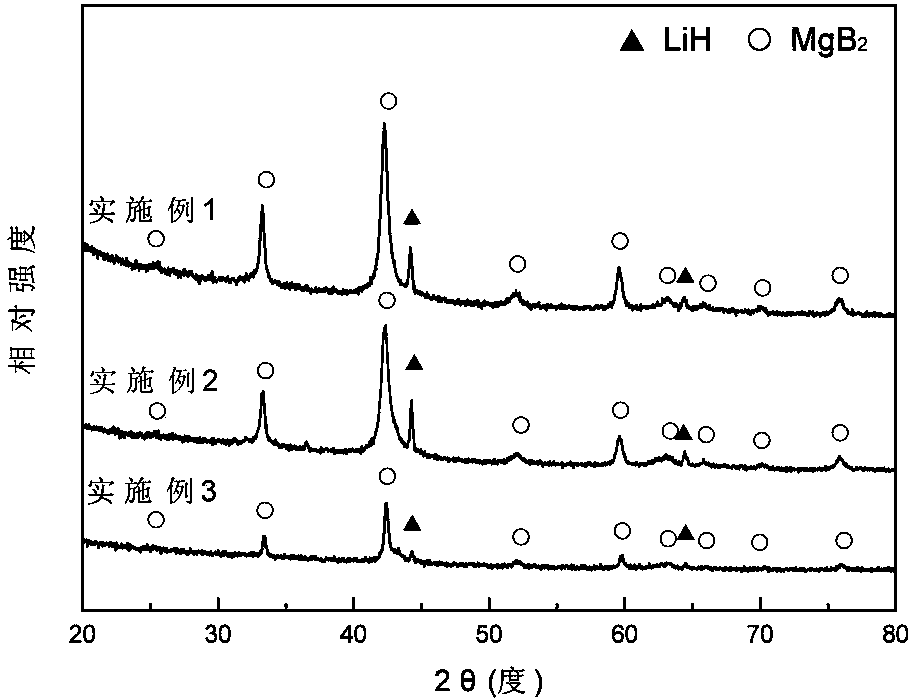

Method for synthesizing lithium borohydride

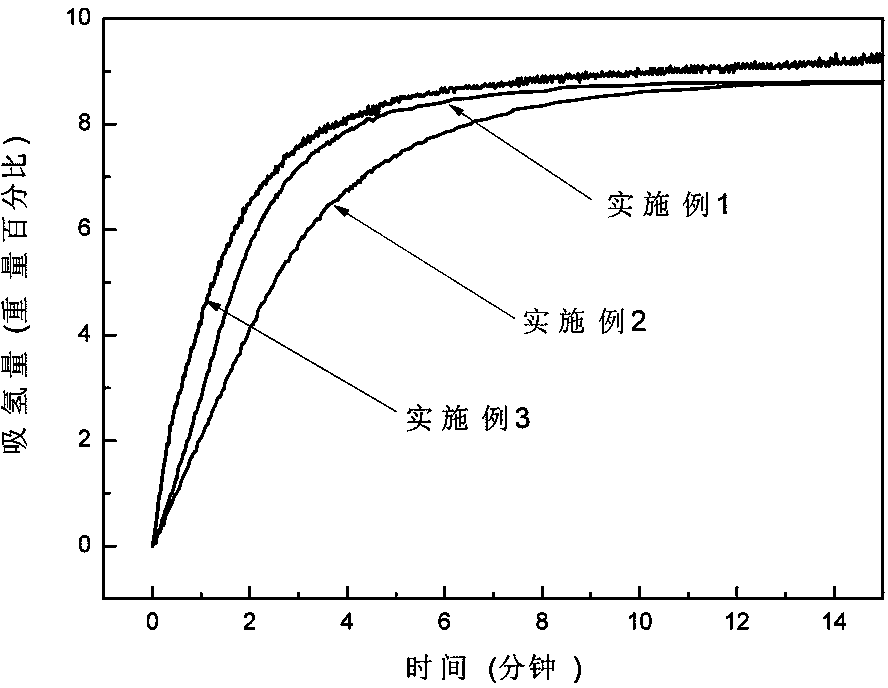

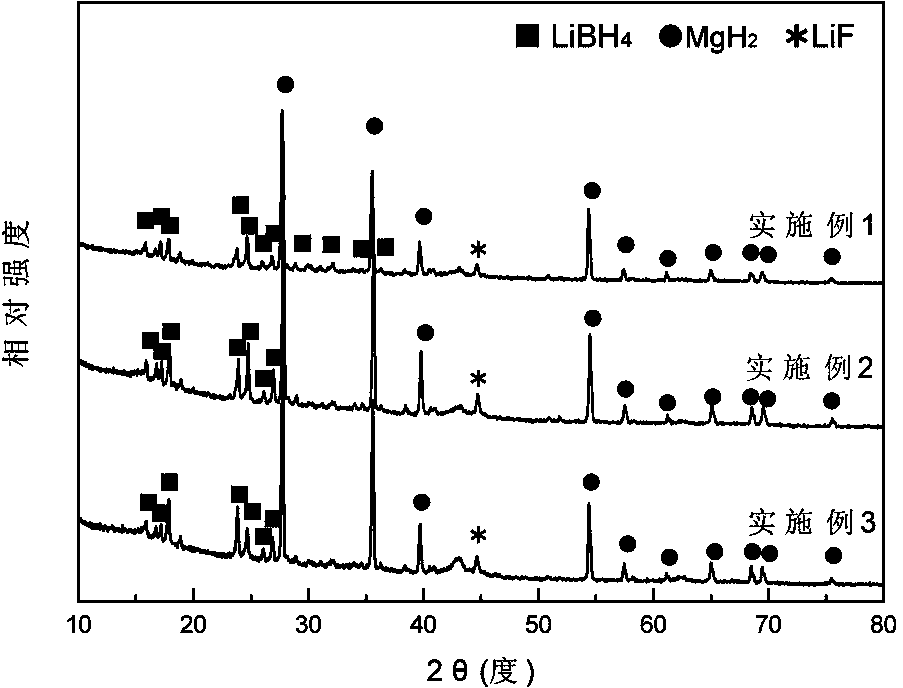

ActiveCN103922285ASimple reaction conditionsShort reaction timeMonoborane/diborane hydridesMagnesium diborideHydrogen absorption

The invention discloses a method for synthesizing lithium borohydride. The method aims at solving the problems that an existing method for preparing lithium borohydride is complex in technology, strict in synthesis condition and the like. The method comprises the following steps that in a protective atmosphere, after lithium hydride, magnesium diboride and a catalyst are mixed according to a ratio, ball-milling treatment is conducted, and a product is obtained after ball-milling treatment; a hydrogen absorption reaction is conducted on the product which is obtained after ball-milling treatment, so that a mixture of the lithium borohydride and magnesium hydride is obtained and is recorded as a reaction product; the magnesium hydride and the lithium borohydride in the reaction product are separated, so that the lithium borohydride is obtained. The method overcomes the shortages that a traditional method for preparing the lithium borohydride is complex in technology and strict in synthesis condition and the purity of the product is low and the like. The method is simple, gentle in reaction condition and short in reaction time. Synthesized LiBH4 is high in yield and purity. Meanwhile, through the method, the production period of the LiBH4 can be shortened, the production cost is reduced, the lithium borohydride can be produced in a large scale industrially, and application of the lithium borohydride is facilitated.

Owner:SICHUAN INST OF MATERIALS & TECH

Preparation method for graphene-loaded multielement-doped magnesium diboride superconducting bulk material

ActiveCN106205861AImprove performanceEvenly distributedSuperconductors/hyperconductorsSuperconductor devicesDopantTitanium ethoxide

The invention discloses a preparation method for a graphene-loaded multielement-doped magnesium diboride superconducting bulk material. The preparation method comprises the steps of 1, dropwise adding ethyl silicate and titanium ethoxide into a graphene oxide solution, and stirring uniformly to obtain a mixture material; 2, performing a hydrothermal reaction, filtering and washing and then carrying out vacuum drying to obtain graphene-loaded multielement mixture powder; 3, performing heat treatment to obtain graphene-loaded multielement-doped powder; 4, mixing boron powder and magnesium powder and grinding, then adding the mixture powder to the graphene-loaded multielement-doped powder, uniformly grinding and pressing and shaping to obtain a bulk material; and 5, performing sintering on the bulk material under protection of an inert atmosphere, and performing furnace cooling to the room temperature to obtain the graphene-loaded multielement-doped magnesium diboride superconducting bulk material. The preparation method is simple; the prepared multielement dopant is uniform in dispersion, free of agglomeration, high in activity and can rapidly enter magnesium diboride lattices, thereby reducing the phase-forming temperature of the doped magnesium diboride; and in addition, the prepared magnesium diboride bulk material has excellent performance.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

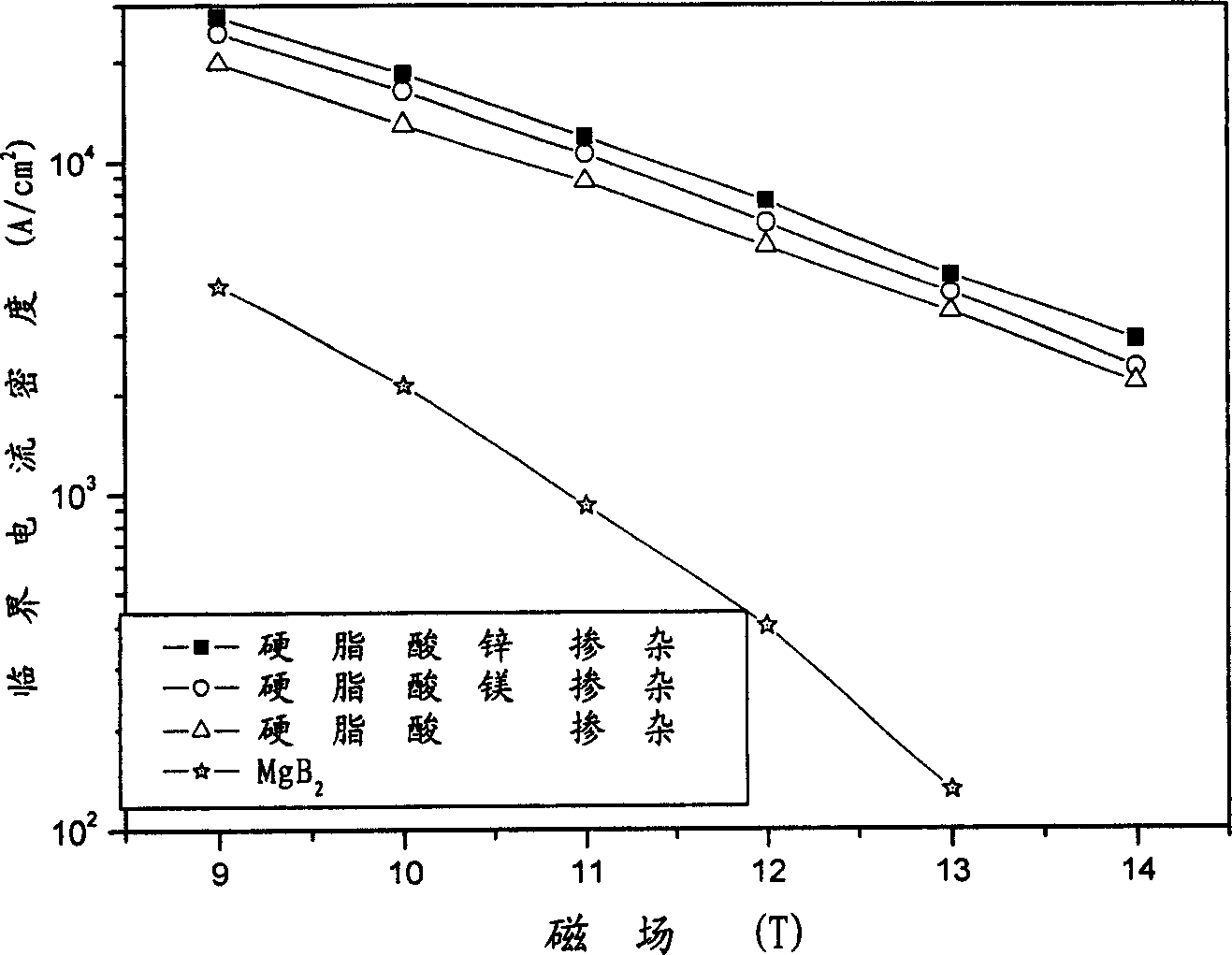

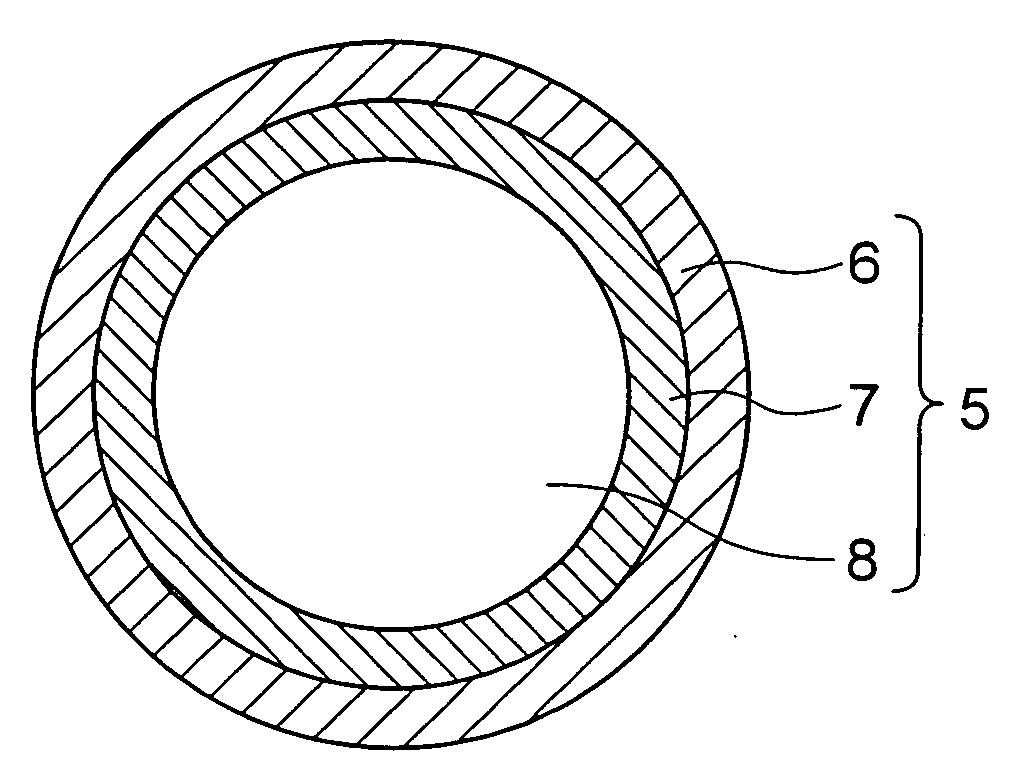

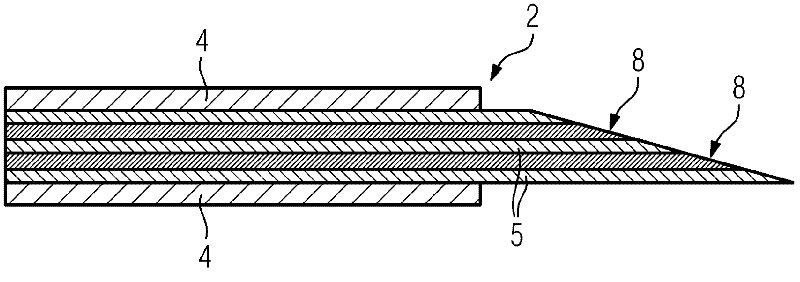

Magnesium diboride superconducting wire and method for manufacturing same

InactiveUS20120004110A1Improve superconductivitySuperconductors/hyperconductorsMagnetsMagnesium diborideFatty acid

It is an objective of the present invention to provide a method for manufacturing long lengths of MgB2 superconducting wire having excellent superconducting properties and an MgB2 superconducting wire manufactured thereby. There is provided a method for manufacturing a magnesium diboride superconducting wire, comprising the successive steps of: filling a metallic tube with a raw material powder; and subjecting the tube to wiredrawing processing, in which a fatty acid metal salt or a mixture of the fatty acid metal salt and a fatty acid is added to the raw material powder.

Owner:HITACHI LTD

Magnesium diboride super conductive material and its preparing method

InactiveCN1988058AEnhanced pinningGrain refinementSuperconductors/hyperconductorsSuperconductor detailsMass ratioMagnesium diboride

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Heat treatment method for iron base MgB2 superconductor wire and belt

InactiveCN1865457AIncrease the critical current densitySuperconductors/hyperconductorsFurnace typesMagnesium diborideJoule

The invention discloses a heat disposal method of iron-base magnesium diboride superconductive wire, which is characterized by the following: disposing the core superconductive material through joule heat of current flow; blending magnesite powder and boron powder evenly according to chemical gauge rate; filling the mixture in the iron pipe after grinding; producing iron-base leptctene and fasciola material with magnesite powder and boron powder in the middle through rotating, drawing and rolling; connecting two ends of leptctene or fasciola with blaster fuse in the Ar quartz tube; controlling the heating speed at 45-900 deg.c per min and heat disposal temperature at 600-900 deg.c; keeping temperature for 10-60 min; cooling at 30-300 deg.c per min to approach indoor temperature. The invention can improve the heating and cooling speed in the heat disposal course, which increases the marginal current density value of magnesium diboride superconductive wire.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

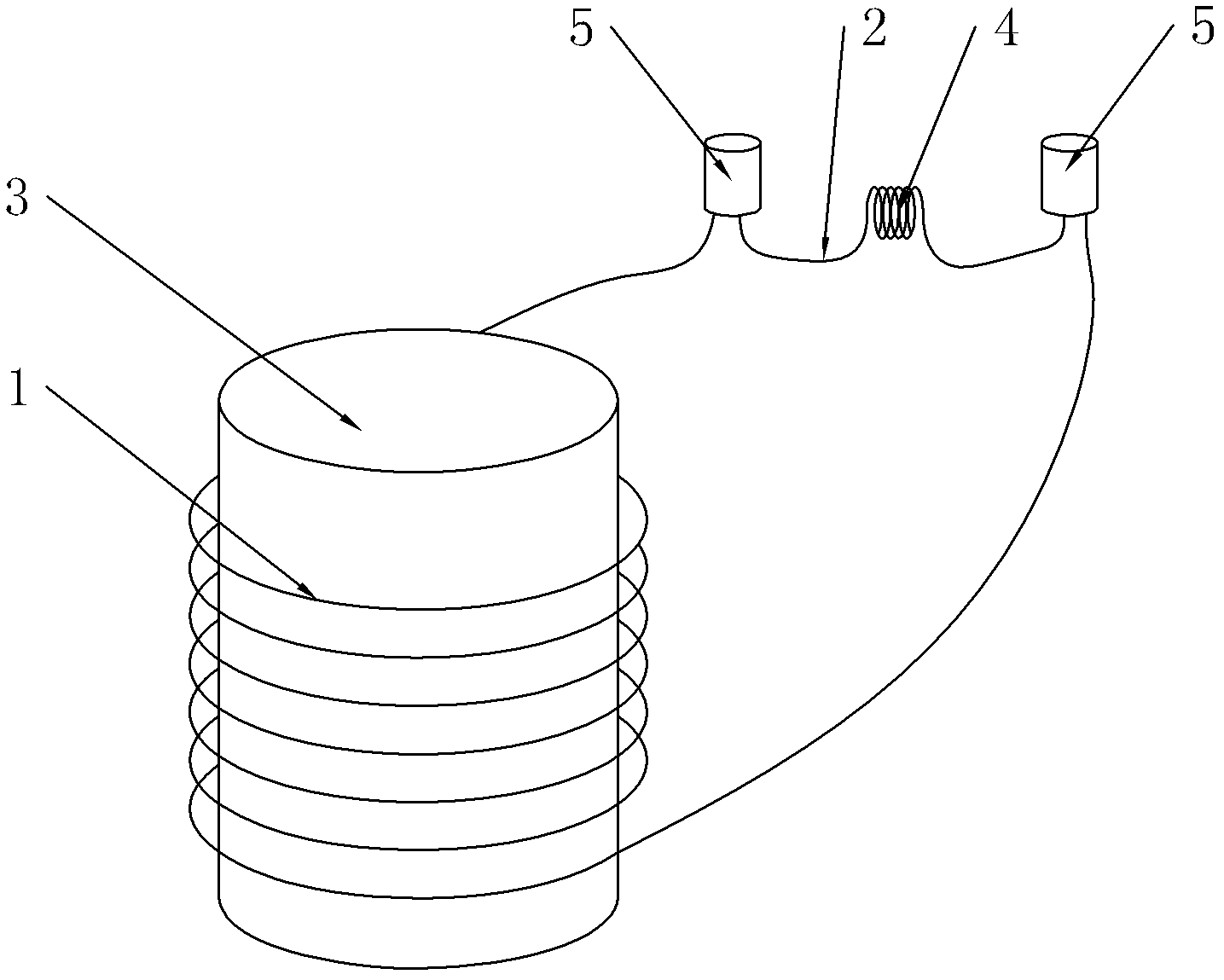

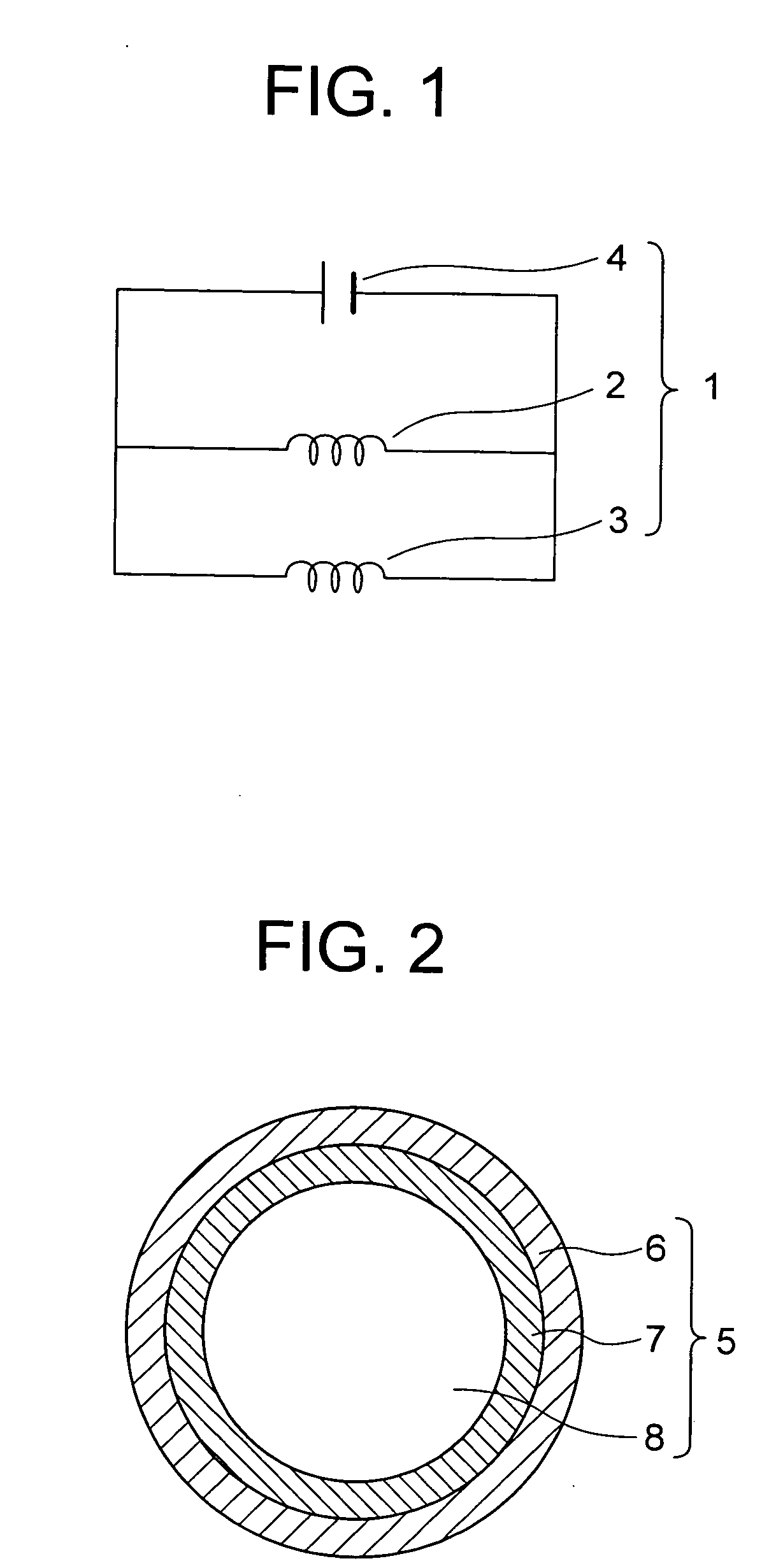

Permanent current switch

InactiveUS20070194870A1Improve reliabilityHigh temperature marginMagnetsMagnetic materialsHigh resistanceMagnesium diboride

There is disclosed a permanent current switch which has a high temperature margin and which is thermally stable and which securely performs a switching operation between a superconducting state and a normal conducting state. The permanent current switch of the present invention has a coiled superconducting wire and a heater wire which switches the superconducting wire between the superconducting state and the normal conducting state, the superconducting wire is a magnesium diboride superconducting wire having a high-resistance metal on an outer side and a magnesium diboride superconducting portion on an inner side and prepared by forming a superconducting metal on a layer between the high-resistance metal and the magnesium diboride superconducting portion, and the permanent current switch further comprises a superconductive connecting section superconductively connected to a lead wire guided from the superconducting wire and a superconducting wire for a wiring line.

Owner:HITACHI LTD

Method for preparing magnesium diboride superconductive material

InactiveCN101279741AEvenly dopedIncrease the upper critical fieldSuperconductors/hyperconductorsMetal boridesMass ratioArgon atmosphere

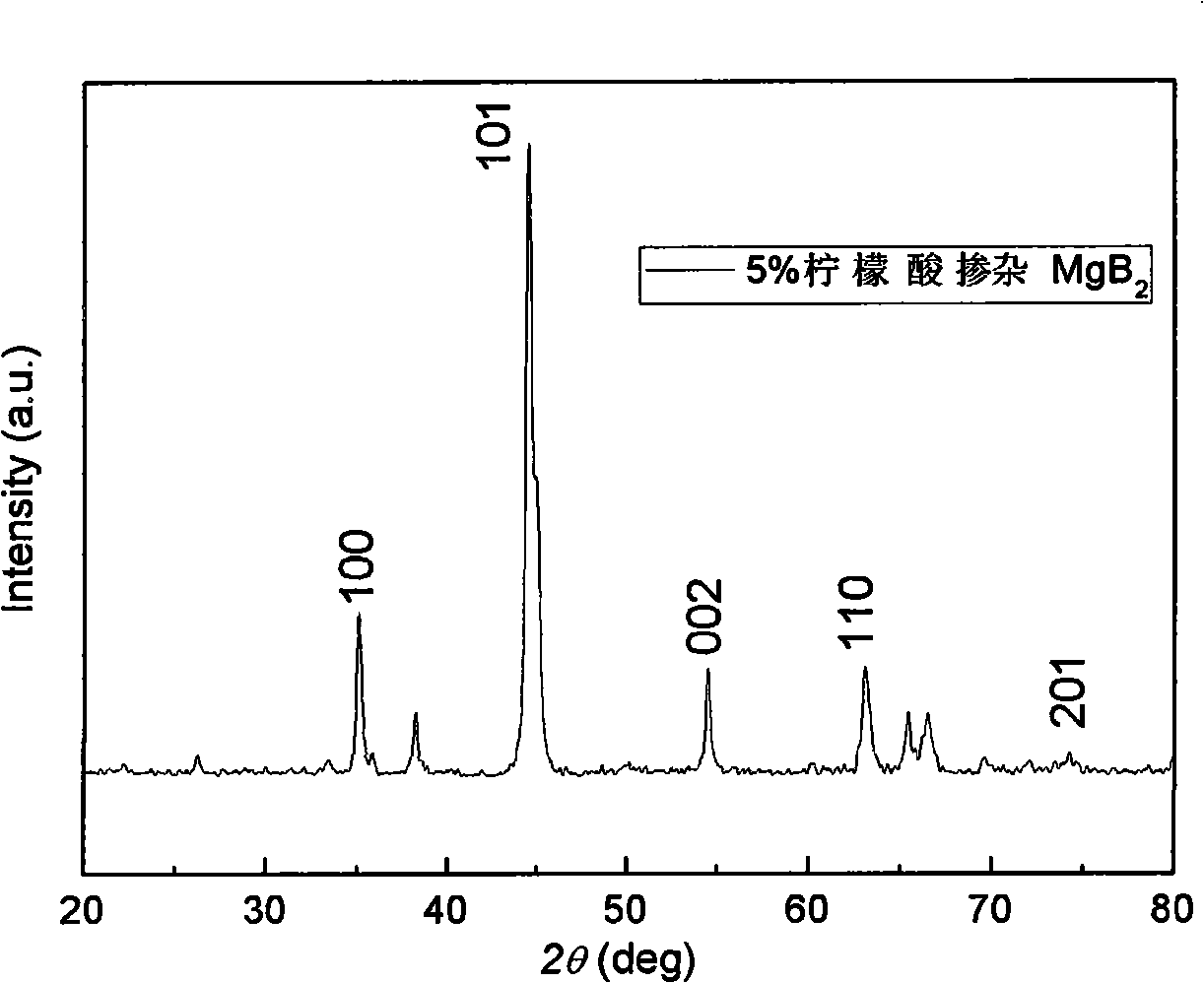

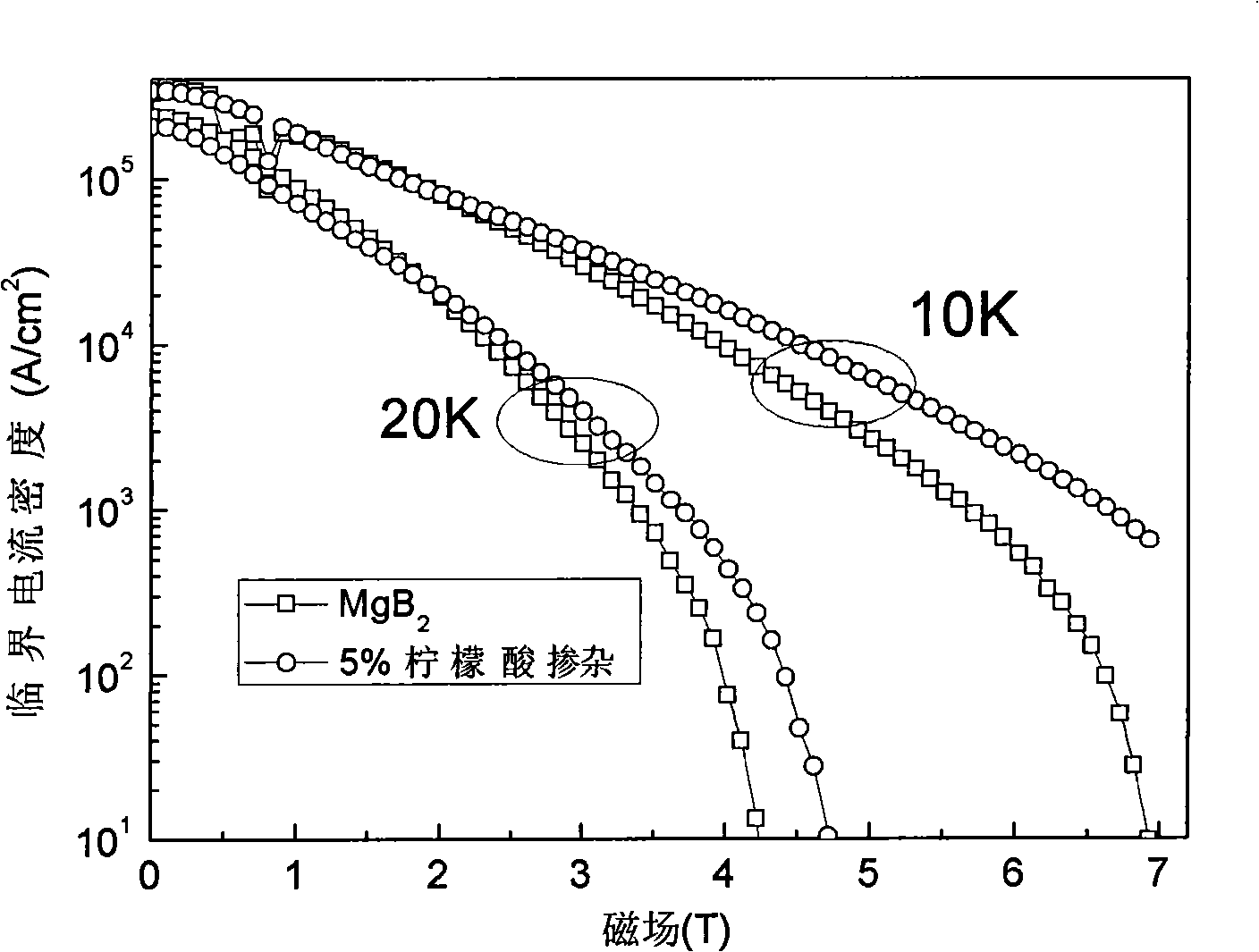

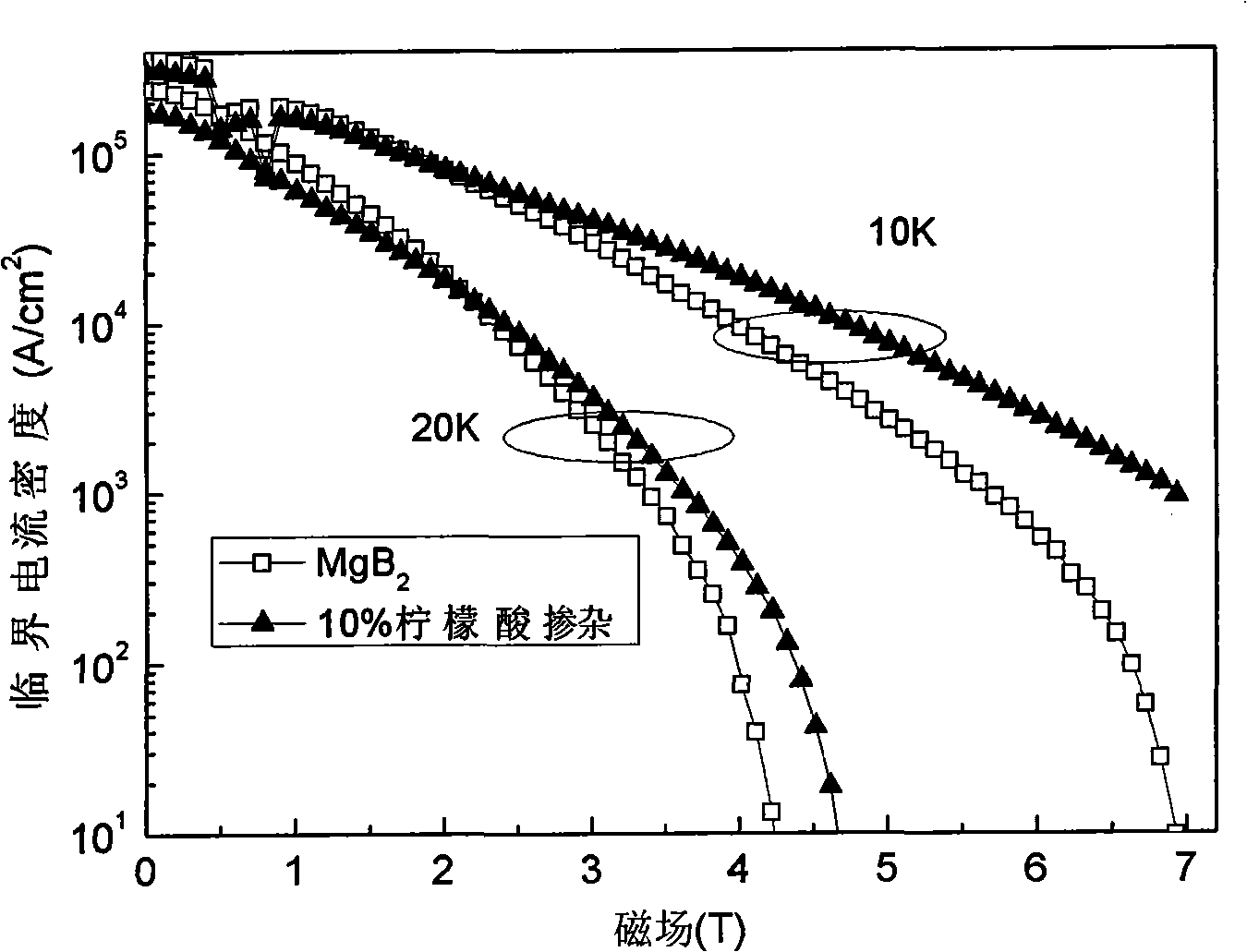

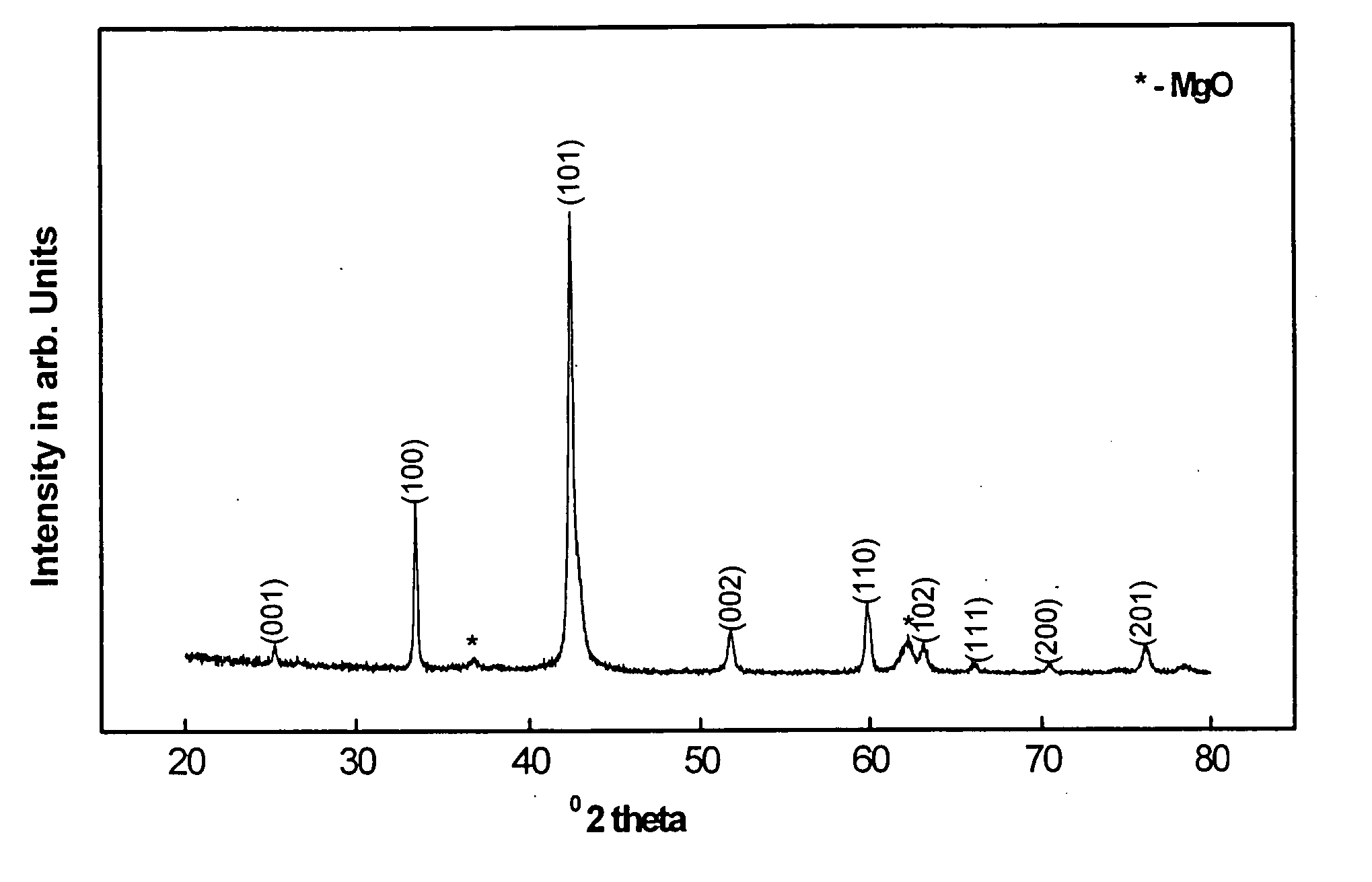

The invention relates to a method for preparing magnesium boride superconducting material. The method for preparing the magnesium boride superconducting material is that magnesium powder and boron powder are respectively weighted according to 1:0.7-2.5 of molar ratio; adulterant which is one of citric acid and citrate is weighted according to 1:0.01-1 of mass ratio between the total mass of the magnesium powder and the boron powder and the mass of the adulterant is weighted; the magnesium powder, the boron powder and the adulterant are evenly mixed into mixing powder, then sintered under the protection of argon atmosphere at the temperature of 600-1200 DEG C and the product is obtained after the heat is preserved for 0.5-12 hours. The method has short preparation time, low reaction temperature, high efficiency and low cost and is especially suitable for industrial production; the critical current density of the magnesium boride superconducting material prepared by the method is increased remarkably and is especially very high in highfield, thereby being good for the application in highfield and having strong practicability.

Owner:SOUTHWEST JIAOTONG UNIV

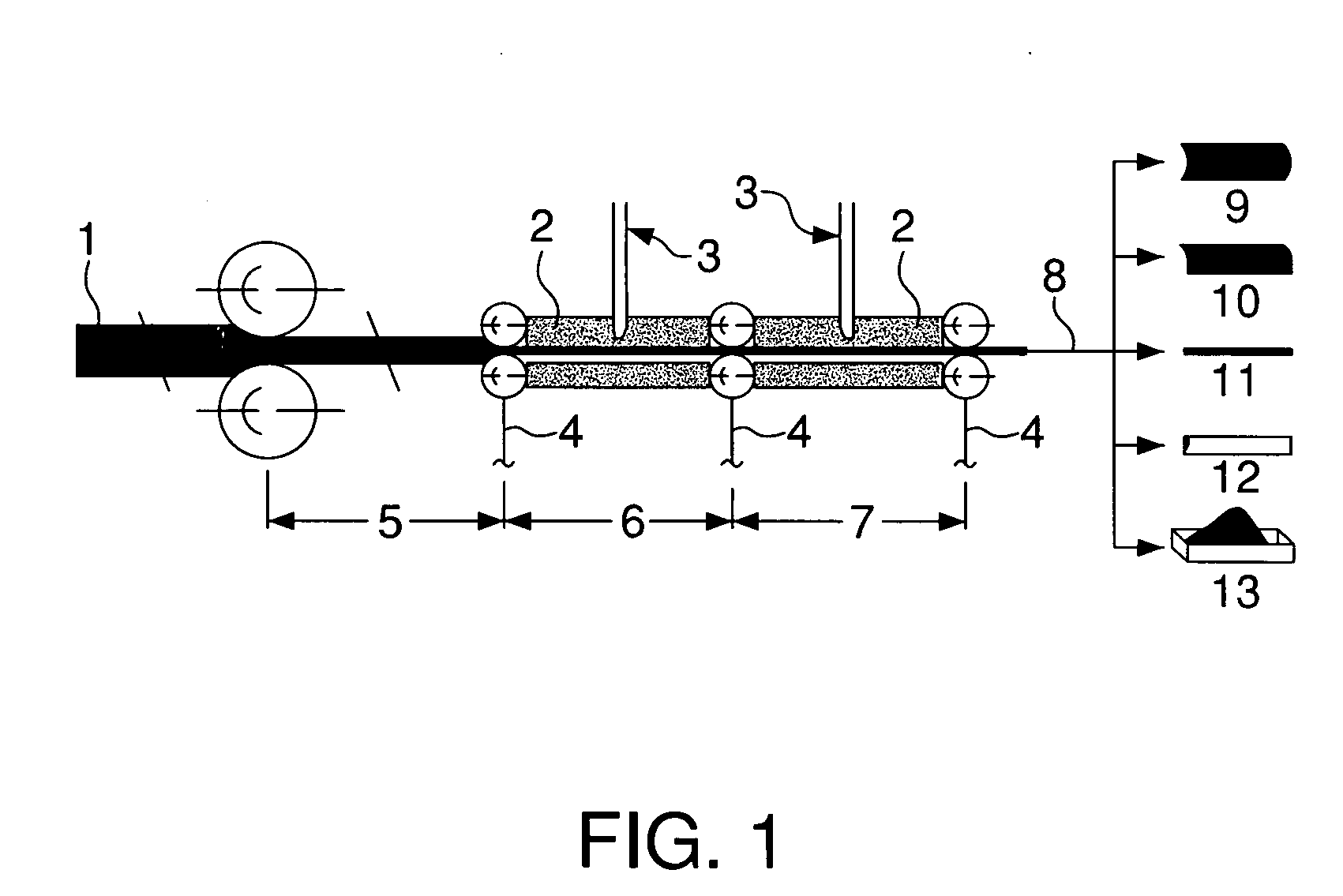

Process for the continuous production of magnesium diboride based superconductors

InactiveUS20070123427A1Energy efficient and simplifiedQuality improvementSuperconductors/hyperconductorsSuperconductor device manufacture/treatmentState of artMagnesium diboride

The present invention provides a simple, energy efficient and cost effective process for continuous production of high quality MgB2 based superconducting wires, tapes, bulk bodies and powders with better phase purity, microstructure and superconducting properties by introducing some innovative steps namely processing the reactants in evacuated and sealed metal tubes by electrical self-heating cum hot rolling followed by annealing under electrical self-heating, thereby overcoming various deficiencies and shortcomings associated with the prior art.

Owner:COUNCIL OF SCI & IND RES

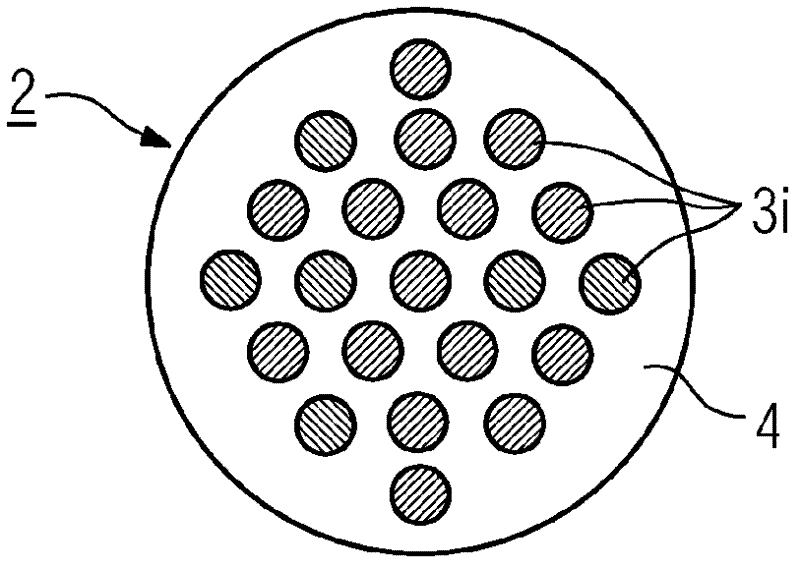

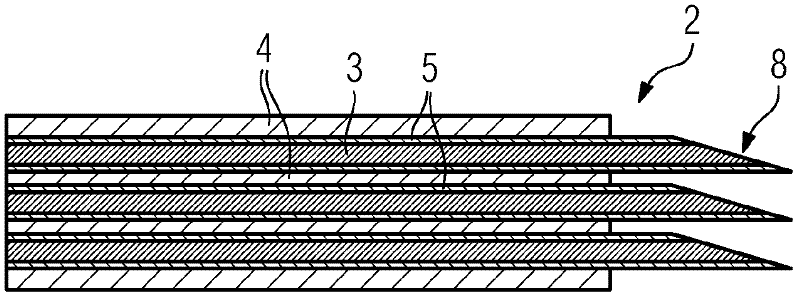

Superconductive connecting device for the end pieces of two superconductors and method for the production thereof

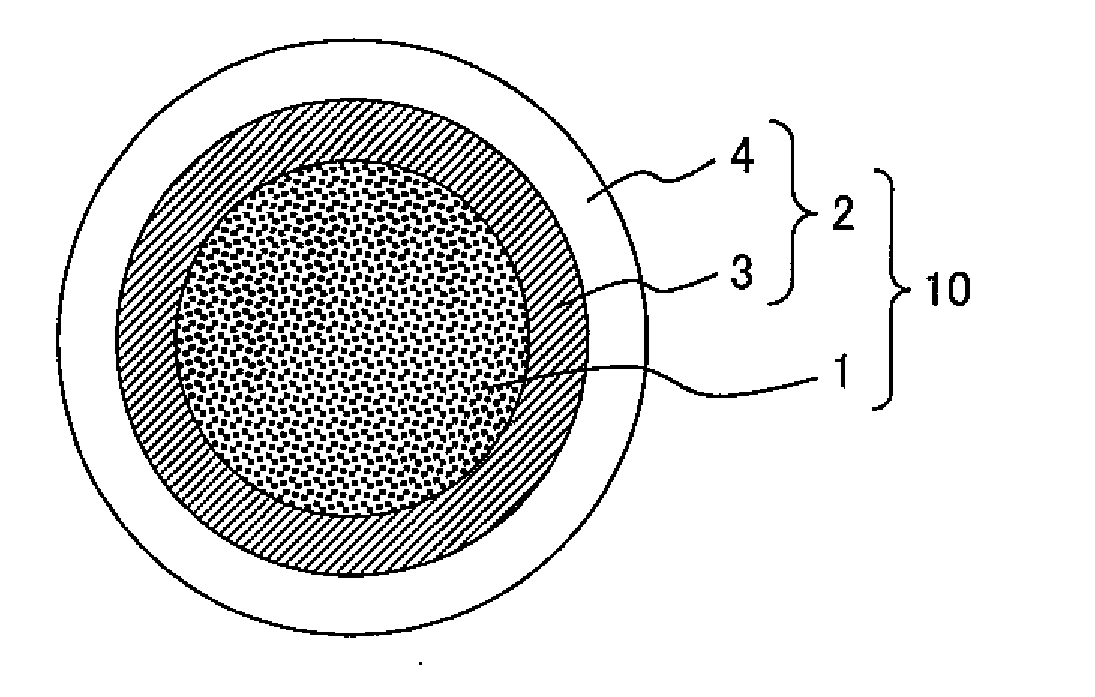

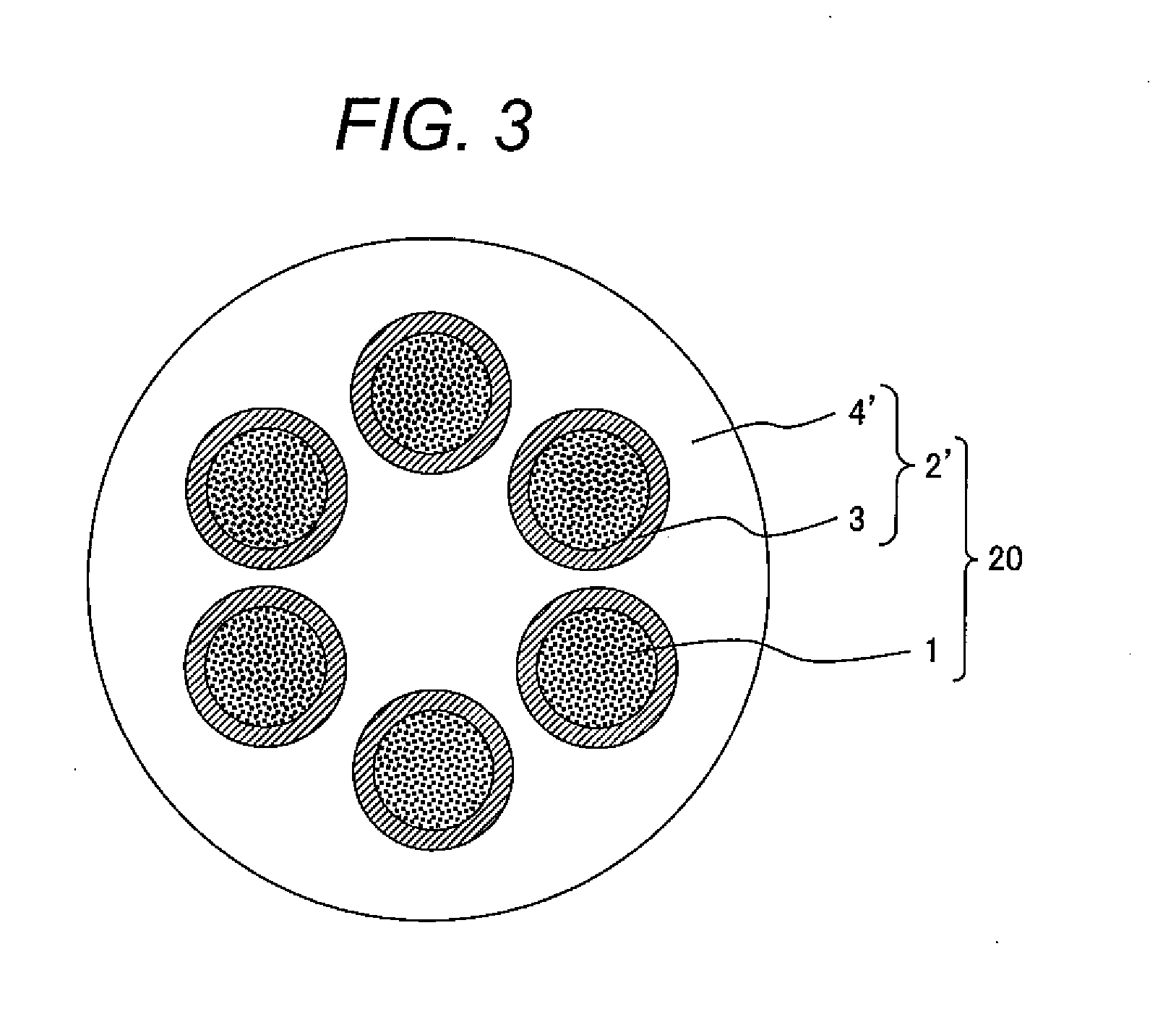

InactiveCN102449848AImprove current carrying capacityAvoid enteringConnection contact member materialMagnesium diborideConductive materials

The superconductive connecting device (10) is used to contact the end pieces (12, 22a) of two superconductors (12, 22), each of which has at least one conductor lead (3i, 13, 23) that is made of a superconductive MgB2 material and embedded in a matrix (4) made of a normally conductive material, the conductor lead being directly sheathed with a barrier material (5). In a connecting region (8), the conductor leads (3i, 13, 23) of the end pieces (12a, 2a), which are at least partially stripped of the matrix material (4) and the barrier material (5), are arranged inside a sleeve (6) or bushing (9), and a magnesium diboride (MgB2) material is additionally present as a superconductive contacting material (7) which is located at least in some partial regions between the conductor leads (3i, 13, 23). For establishing the connection (10), the cross-section of the sleeve (6) or bushing (9) filled in this way is reduced.

Owner:SIEMENS HEALTHINEERS LTD

High performance Fe/Cu wrapping structure magnesium diboride multiple core superconductive wire preparation method

InactiveCN101150004AGuaranteed thermal stabilityHigh critical current density valueSuperconductors/hyperconductorsSuperconductor devicesMagnesium diborideNon doped

This invention relates to a preparation method for MgB2 multi-core super-conductive wires with Fe / Cu jacket structure including the following steps: putting Mg and B powder in the mol ratio of 1 : 2 and Mg, B powder and doped material in the mol ratio of 1 : 2 : 0.5 into a Fe / Cu composite pipe to be pressed and sealed to get a single-core lead with Fe / Cu composite jacket after swaging, pass rolling and drawing, then a processed hardened layer of the single-core structure is eliminated and aligned to assemble the doped and non-doped single-core wires tightly in a seamless Cu pipe to be swaged and drawn to a MgB2 wire of multi-core Fe / Cu jacket structure to be processed for 0.5-5h under 650-950deg.C to become a MgB2 multi-core superconductive wire in the high performance Fe / Cu jacket.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Substrate and method for the formation of continuous magnesium diboride and doped magnesium diboride wires

InactiveUS20050127353A1Improve mechanical propertiesEasy to useLiquid surface applicatorsSemiconductor/solid-state device manufacturingGas phaseMagnesium diboride

Owner:IOWA STATE UNIV RES FOUND +1

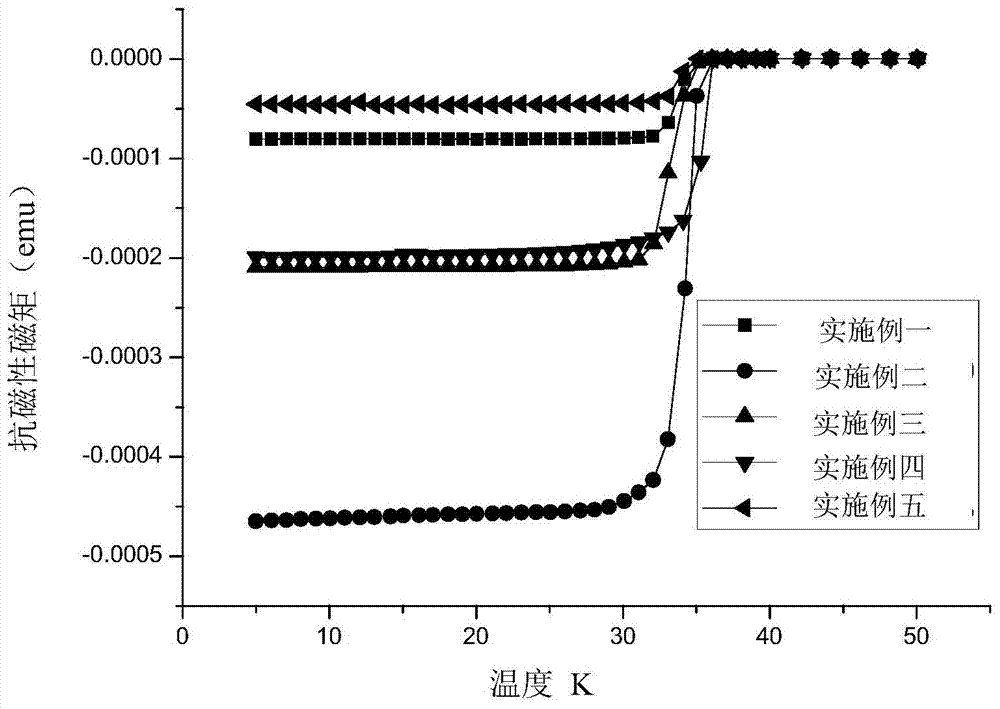

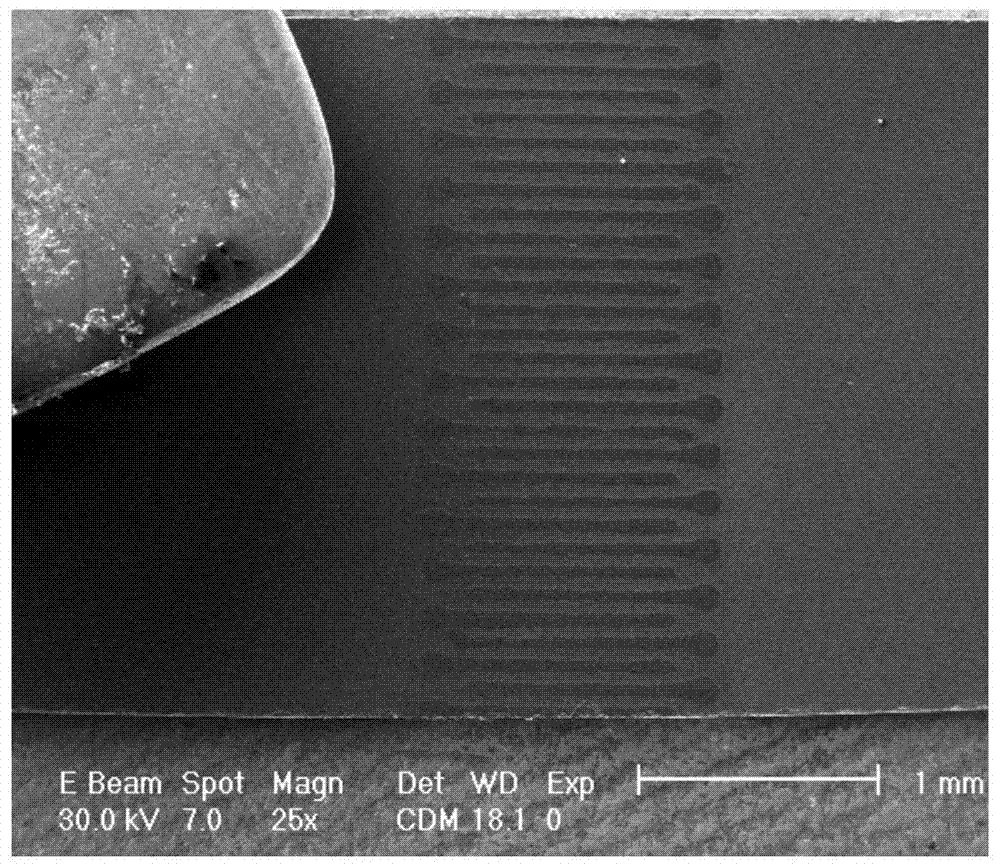

Method for manufacturing magnesium diboride superconducting thin film micro-structure through annealing

InactiveCN103500793AAvoid contactDoes not lead to deterioration of superconducting propertiesSuperconductor device manufacture/treatmentMicro structureChemical reaction

The invention discloses a method for manufacturing a magnesium diboride superconducting thin film micro-structure through annealing. According to the method, electron beams are used for annealing a magnesium diboride precursor film with micro-structure patterns in a vacuum. The magnesium diboride precursor film with the micro-structure patterns is an Mg / B multi-layer film manufactured with a film masking method. Elementary substances of magnesium and boron in the precursor film undergo a chemical reaction in annealing time of a second order of magnitude, and finally, the magnesium diboride superconducting thin film micro-structure with the conversion temperature higher than 35K is generated.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Boride thin films on silicon

InactiveUS7090889B2Minimize formationPromote formationSuperconductors/hyperconductorsVacuum evaporation coatingBorideGas phase

Boride thin films of conducting and superconducting materials are formed on silicon by a process which combines physical vapor deposition with chemical vapor deposition. Embodiments include forming boride films, such as magnesium diboride, on silicon substrates by physically generating magnesium vapor in a deposition chamber and introducing a boron containing precursor into the chamber which combines with the magnesium vapor to form a thin boride film on the silicon substrates.

Owner:PENN STATE RES FOUND

Method for preparing magnesium diboride superconducting thin film by electron beam annealing

InactiveCN102214786AAchieve preparationReduce volatilitySuperconductor device manufacture/treatmentChemical reactionMagnesium diboride

The invention relates to a method for preparing a magnesium diboride superconducting thin film by electron beam annealing. The method is characterized by annealing a magnesium diboride forerunner film in vacuum by adopting an electron beam, enabling a magnesium and boron simple substance in the forerunner film in the annealing time of the order of magnitude of seconds to perform chemical reaction, and generating the magnesium diboride superconducting thin film finally; and determining electron beam parameters and annealing time according to different thicknesses of the forerunner film and annealing temperatures in annealing, and finishing the annealing of thin films of different thicknesses through controlling energy and dosage of the electron beam accurately. The magnesium diboride superconducting thin film prepared by using the method in the invention has the advantages of stable performances, flat surface, higher transformation temperature than 35k, uniform annealing, and the method for preparing the film has high efficiency, and is simple in operation and the like, and can be used for the preparation of a plurality of functional thin films.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com