Boric fertilizer water dispersing granule and preparing method thereof

A technology of dispersing granules and fertilizer and water, which is applied in the direction of fertilizer form, fertilization device, fertilizer mixture, etc., can solve the problems of increasing the cost of farmers' use, high requirements for raw materials, complex processes, etc., and achieve broad market application prospects, obvious performance, and complete dissolution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

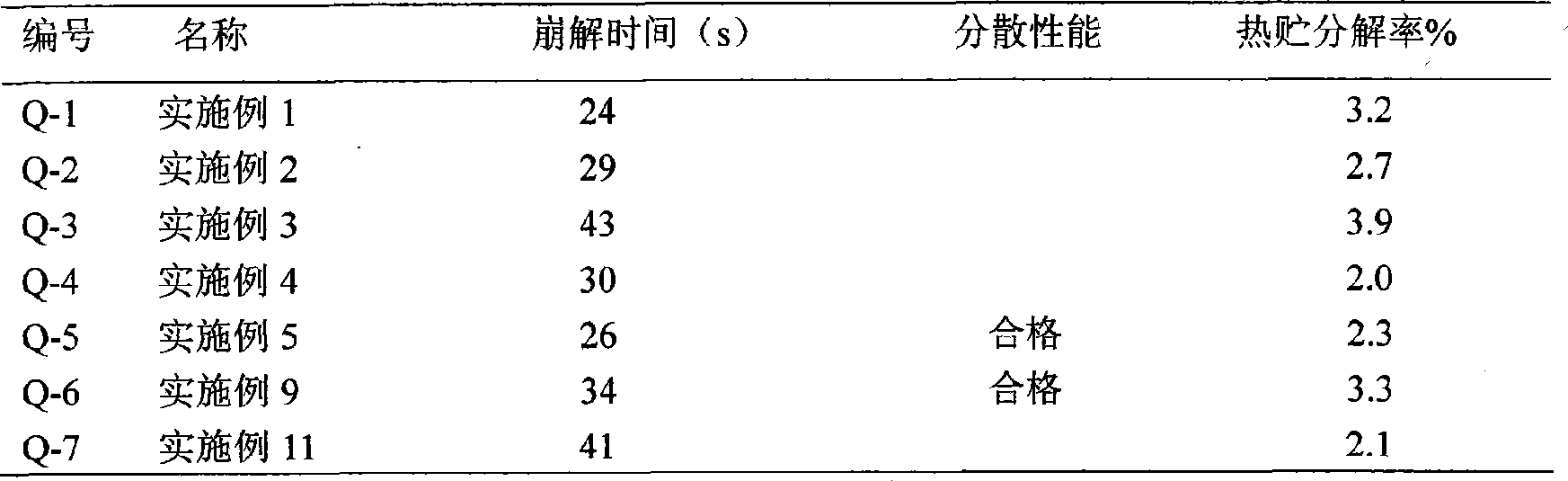

Examples

Embodiment 1

[0067] Weigh the raw materials of each component according to the following ratio

[0068] 70 parts of boric acid

[0069] Succinic acid half ester sulfonate fatty acid amide 15 parts

[0070] Sodium dodecylbenzenesulfonate 10 parts

[0071] White carbon black 5 parts

[0072] The above components are mixed, pulverized to prepare mother powder, mixed evenly with an appropriate amount of alcohol solution, then extruded and granulated, dried, analyzed and tested for storage to obtain boric acid water-dispersible granules.

Embodiment 2

[0074] Weigh the raw materials of each component according to the following ratio

[0075] Sodium tetraborate decahydrate 60 parts

[0076] Calcium carbonate 6 parts

[0077] Succinic acid half ester sulfonate fatty acid amide 15 parts

[0078] Fatty alcohol polyoxyethylene ether 13 parts

[0079] Carboxymethylcellulose 6 parts

[0080] The above components are mixed, pulverized to prepare mother powder, mixed evenly with an appropriate amount of alcohol solution, then extruded and granulated, dried, analyzed and checked for storage to obtain sodium tetraborate decahydrate (borax) water-dispersible granules.

Embodiment 3

[0082] Weigh the raw materials of each component according to the following ratio

[0083] Sodium tetraborate pentahydrate 80 parts

[0084] Low-substituted hydroxypropyl cellulose 11 parts

[0085] Alkylphenol polyoxyethylene ether succinate sulfonate 9 parts

[0086] The above components are mixed, pulverized to prepare mother powder, mixed evenly with an appropriate amount of alcohol solution, then extruded and granulated, dried, analyzed and tested for storage to obtain sodium tetraborate pentahydrate water-dispersible granules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube height | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com