Method for preparing magnesium diboride superconducting wire with graphene coated boron powder

A technology of graphene coating and magnesium diboride, which is applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the problem of reducing the connectivity between grains, reducing the reactivity of boron powder, Uneven distribution of doping sources and other issues, to achieve the effect of improving magnetic flux pinning force, avoiding oxidation, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

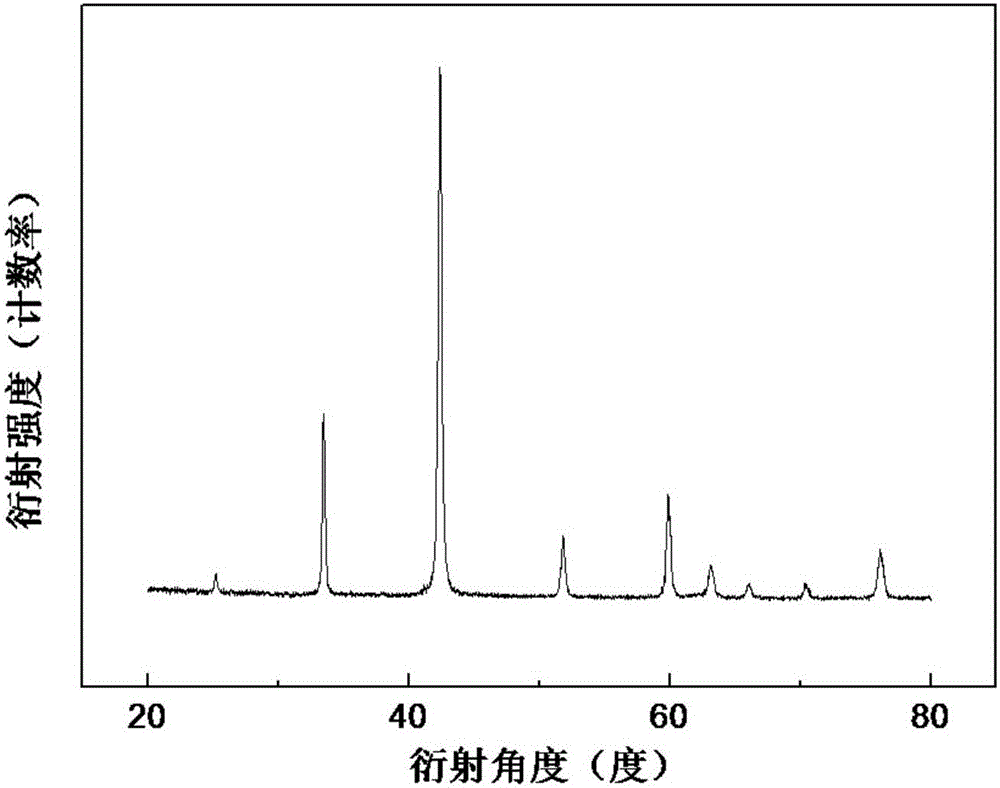

Image

Examples

Embodiment 1

[0028] In this embodiment, the method for preparing a magnesium diboride superconducting wire by using graphene-coated boron powder specifically includes the following steps:

[0029] Step 1, place graphene oxide in ethanol, and ultrasonically disperse to obtain a graphene oxide solution with a concentration of 0.1 mg / mL; then add spherical nano-boron powder to the graphene oxide solution, stir evenly, and filter to obtain a filter residue. The filter residue was vacuum-dried to obtain a mixed powder; the quality of the spherical nano-boron powder was 100 times that of graphene oxide; the power of the ultrasonic dispersion was 150W, and the ultrasonic dispersion time was 30 minutes;

[0030] Step 2, heat-treat the mixed powder described in step 1 in a reducing atmosphere to obtain graphene-coated boron powder; the reducing atmosphere is a mixed gas of argon and hydrogen, and the volume percentage of hydrogen in the mixed gas is The content is 8%; the temperature of the heat tr...

Embodiment 2

[0038] In this embodiment, the method for preparing a magnesium diboride superconducting wire by using graphene-coated boron powder specifically includes the following steps:

[0039]Step 1, place graphene oxide in ethanol, ultrasonically disperse to obtain a graphene oxide solution with a concentration of 5 mg / mL; then add spherical nano-boron powder to the graphene oxide solution, stir evenly, and filter to obtain a filter residue. Vacuum drying to obtain a mixed powder; the quality of the spherical nano-boron powder is 20 times that of graphene oxide; the power of the ultrasonic dispersion is 5000W, and the ultrasonic dispersion time is 60min;

[0040] Step 2, heat-treat the mixed powder described in step 1 in a reducing atmosphere to obtain graphene-coated boron powder; the reducing atmosphere is a mixed gas of argon and hydrogen, and the volume percentage of hydrogen in the mixed gas is The content is 2%; the temperature of the heat treatment is 400°C, the heating rate is...

Embodiment 3

[0048] In this embodiment, the method for preparing a magnesium diboride superconducting wire by using graphene-coated boron powder specifically includes the following steps:

[0049] Step 1, place graphene oxide in ethanol, ultrasonically disperse to obtain a graphene oxide solution with a concentration of 2 mg / mL; then add spherical nano-boron powder to the graphene oxide solution, stir evenly, and filter to obtain a filter residue. Vacuum drying to obtain a mixed powder; the quality of the spherical nano-boron powder is 30 times that of graphene oxide; the power of the ultrasonic dispersion is 3000W, and the ultrasonic dispersion time is 45min;

[0050] Step 2, heat-treat the mixed powder described in step 1 in a reducing atmosphere to obtain graphene-coated boron powder; the reducing atmosphere is a mixed gas of argon and hydrogen, and the volume percentage of hydrogen in the mixed gas is The content is 5%; the temperature of the heat treatment is 800°C, the heating rate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com