Superconductive connecting device for the end pieces of two superconductors and method for the production thereof

A connection device and superconductor technology, applied in the direction of superconductor components, connection contact materials, etc., can solve the problems of increasing the difficulty of end pieces, unable to establish connection of end pieces, material fragmentation, etc., to achieve quality reduction, easy method, and resource requirements low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The same components are denoted by the same reference symbols in the various drawings.

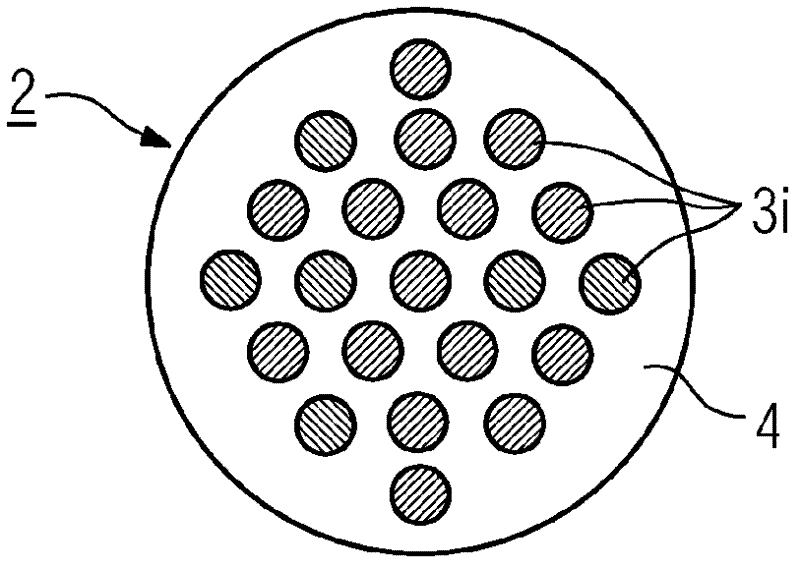

[0054] figure 1 The shown superconductors are based on known embodiments. In this case, both so-called monocore superconductors and multifilament superconductors as shown in the drawing can be involved. Such a superconductor 2 has a plurality of superconducting conductor cores or wires 3i embedded in a matrix 4, which consists of a normally conducting material. The conductor core 3i is made of MgB 2 Made of high temperature superconducting materials. Known materials used for the matrix are either elements (eg Cu, Ni, Ag, Fe, Wo, Al) or alloys, in particular alloys of these elements (eg CuNi, AgMg, CuSn, CuZn or NiCr).

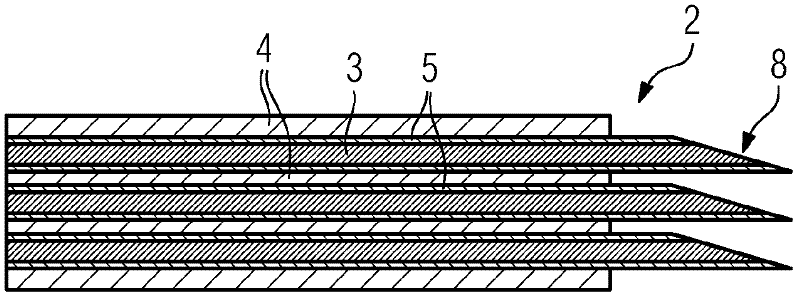

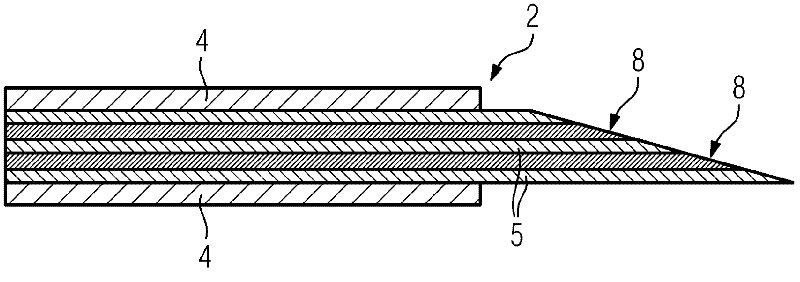

[0055] figure 2 A longitudinal cross-sectional view of a superconductor 2 used in the connection device of the present invention. Superconductor 2 can be employed with figure 1 The superconductor 2 shown is of similar design, or consists of a plurality of str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com