Method for preparing high critical current density yttrium barium copper oxide superconducting film

A yttrium barium copper oxide, superconducting thin film technology, applied in the usage of superconducting elements, superconducting devices, superconducting/high conducting conductors and other directions, can solve the problems of reducing the critical current density of thin films, etc. Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

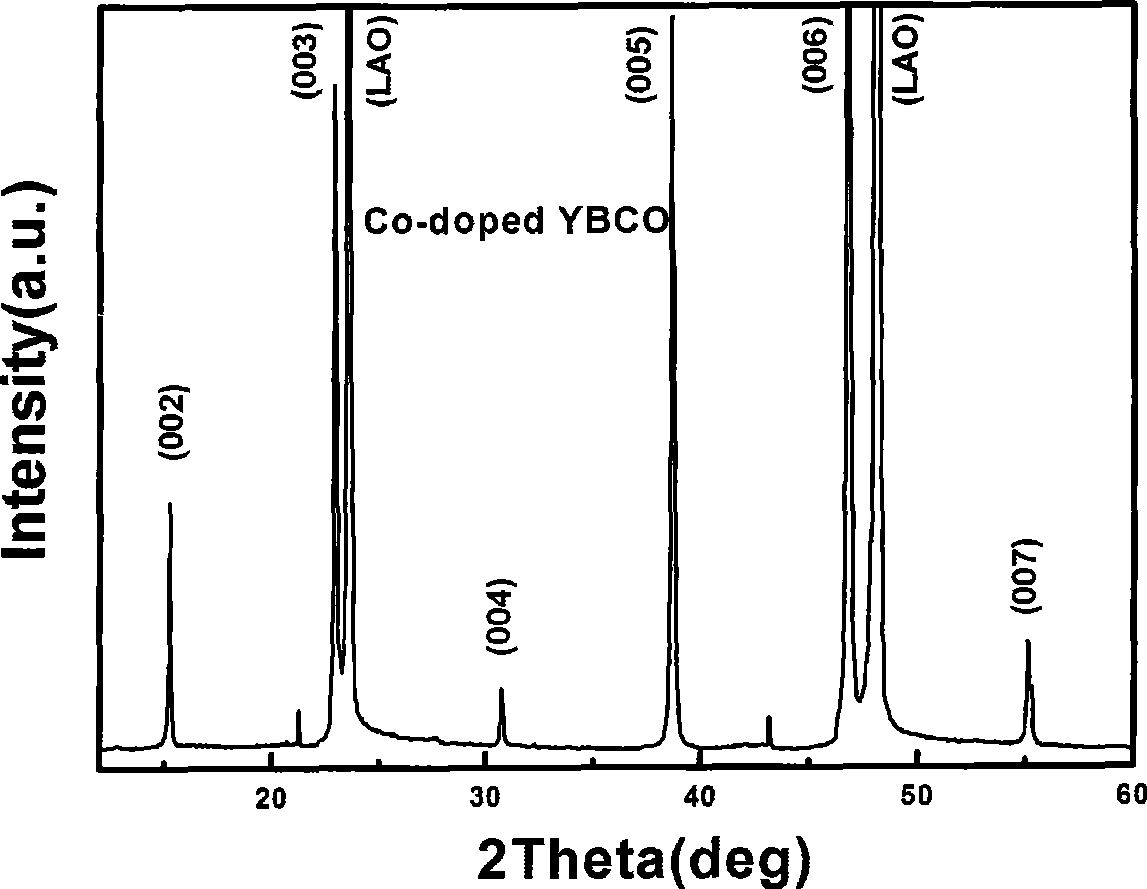

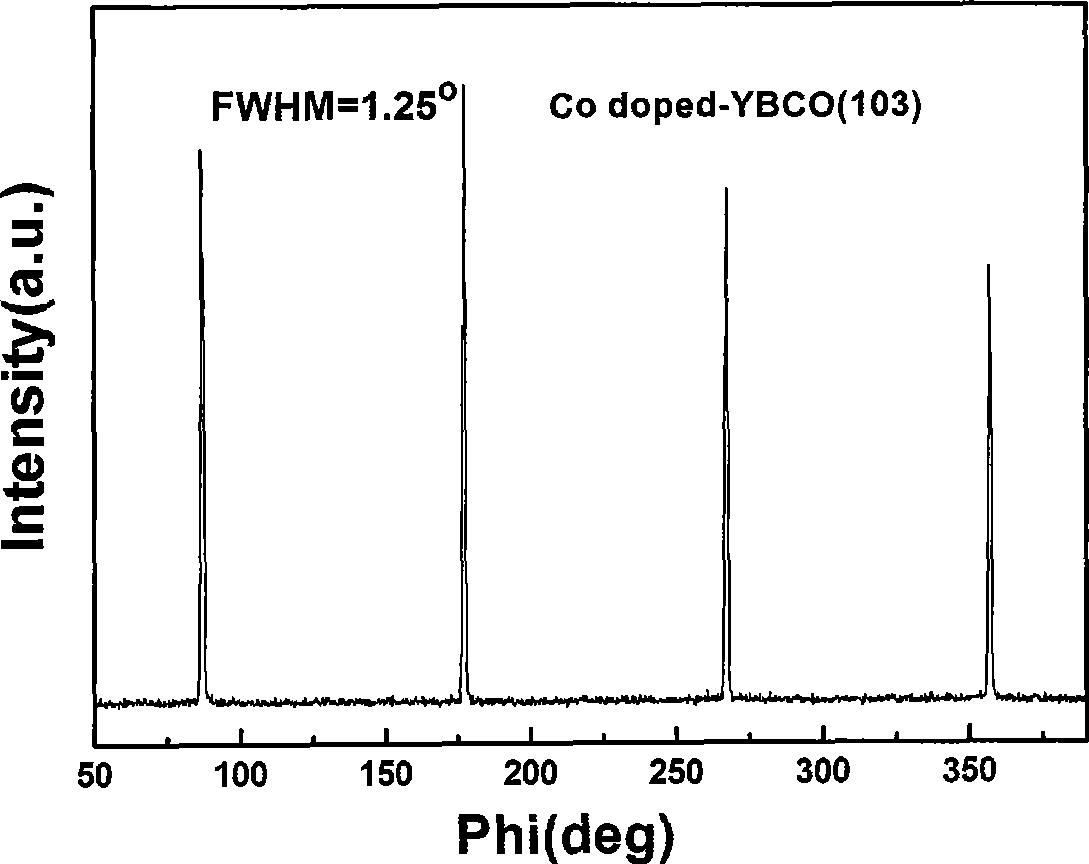

[0036] A specific embodiment of the present invention is: a method for preparing a high critical current density yttrium-barium-copper-oxygen superconducting thin film, and its specific method is:

[0037] a. Preparation of precursor solution: Dissolve yttrium acetate, barium acetate, copper acetate and cobalt acetate in propionic acid according to the stoichiometric ratio of yttrium: barium: copper: cobalt 1:2:2.999:0.001 to obtain a precursor solution. The impurity element in this example is cobalt, and the acetate of the impurity element is cobalt acetate.

[0038] b. Preparation of coating colloid: In the precursor solution of step a, add polymer material polyvinyl butyral (PVB), the mass ratio of the added polymer material to the precursor solution is 4:100, fully stir to obtain the coating layer colloid;

[0039] c. Coating and drying: apply the coating colloid prepared in step b on the substrate, form a thin film on the substrate, and dry at a temperature range of 150°...

Embodiment 2

[0046] The preparation method of this example is as follows:

[0047] A, preparation of precursor solution: yttrium acetate, barium acetate, copper acetate and zinc acetate are dissolved in propionic acid in the ratio of yttrium: barium: copper: zinc stoichiometric ratio 1:2:2.999:0.001, to obtain precursor solution;

[0048] b. Preparation of coating colloid: In the precursor solution of step a, add polymer material polyvinyl butyral (PVB), the mass ratio of the added polymer material to the precursor solution is 4:100, fully stir to obtain the coating layer colloid;

[0049] c. Coating and drying: apply the coating colloid prepared in step b on the substrate, form a thin film on the substrate, and dry at a temperature range of 100°C for 15 minutes;

[0050] d. Thermal decomposition treatment and phase forming heat treatment: the substrate with film obtained in step C is subjected to thermal decomposition treatment and then phase forming heat treatment is carried out. Its s...

Embodiment 3

[0055] The specific approach in this example is:

[0056] A, preparation of precursor solution: yttrium acetate, barium acetate, copper acetate and iron acetate are dissolved in propionic acid in the ratio of yttrium: barium: copper: iron stoichiometric ratio 1:2:2.999:0.001, obtain precursor solution;

[0057] b. Preparation of coating colloid: In the precursor solution of step a, add polymer material polyvinyl butyral (PVB), the mass ratio of the added polymer material to the precursor solution is 4:100, fully stir to obtain the coating colloid;

[0058] c. Coating and drying: apply the coating colloid prepared in step b on the substrate, form a thin film on the substrate, and dry at a temperature range of 160°C for 8 minutes;

[0059] d. Thermal decomposition treatment and phase forming heat treatment: the substrate with film obtained in step C is subjected to thermal decomposition treatment and then phase forming heat treatment is carried out. Its specific operation is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com