Controllable preparation method of porous silicon material by using reducing agent

A technology of porous silicon and reducing agent, applied in chemical instruments and methods, silicon compounds, hybrid/electric double layer capacitor manufacturing, etc., can solve the problems of increasing costs and achieve the effect of reducing the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In this embodiment, a reducing agent can controlly prepare porous silicon material, and the steps are as follows:

[0043](1) Commercial micro-SiO and MgB with a particle size of 1-2 μm 2 Mix evenly, SiO and MgB in the mixture 2 The mass ratio is 1:1;

[0044] (2) Heat the mixture prepared in the step (1) to 800°C in an inert atmosphere of nitrogen or argon, and keep it at a constant temperature for 6h to perform a reduction reaction; then cool to room temperature under an inert atmosphere to obtain a solid product ;

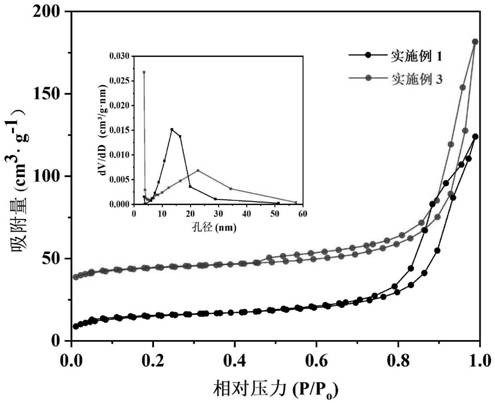

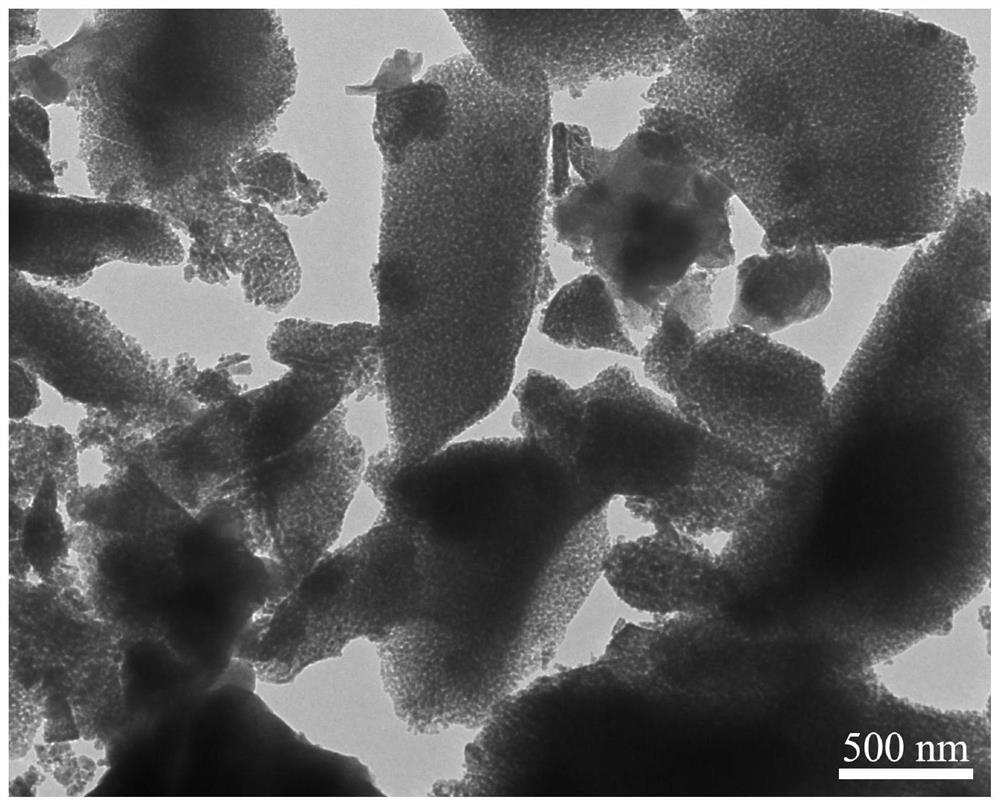

[0045] (3) Etching the solid product obtained in the step (2) with dilute hydrochloric acid with a concentration of 20% by mass for 12 hours, then repeatedly washing with deionized water, and then drying to obtain a porous silicon material. Its morphology is as figure 1 shown.

Embodiment 2

[0047] This embodiment is basically the same as Embodiment 1, and the special features are:

[0048] In this embodiment, a reducing agent can controlly prepare porous silicon material, and the steps are as follows:

[0049] (1) Commercial micro-SiO and MgB with a particle size of 1-2 μm 2 Mix evenly, SiO and MgB in the mixture 2 The mass ratio is 2:1;

[0050] (2) Heat the mixture prepared in the step (1) to 900°C in an inert atmosphere of nitrogen or argon, and keep it at a constant temperature for 6h to perform a reduction reaction; then cool to room temperature under an inert atmosphere to obtain a solid product ;

[0051] (3) Etching the solid product obtained in the step (2) with dilute hydrochloric acid with a concentration of 20% by mass for 12 hours, then repeatedly washing with deionized water, and then drying to obtain a porous silicon material. Due to the insufficient amount of magnesium boride, in this embodiment only the outer layer has a porous structure, and...

Embodiment 3

[0053] This embodiment is basically the same as the previous embodiment, and the special features are:

[0054] In this embodiment, a reducing agent can controlly prepare porous silicon material, and the steps are as follows:

[0055] (1) Nano-SiO with a particle size of 200-500nm 2 with MgB 2 Evenly mixed, SiO in the mixture 2 with MgB 2 The mass ratio is 2:3;

[0056] (2) Heat the mixture prepared in the step (1) to 800°C in an inert atmosphere of nitrogen or argon, and keep it at a constant temperature for 6h to perform a reduction reaction; then cool to room temperature under an inert atmosphere to obtain a solid product ;

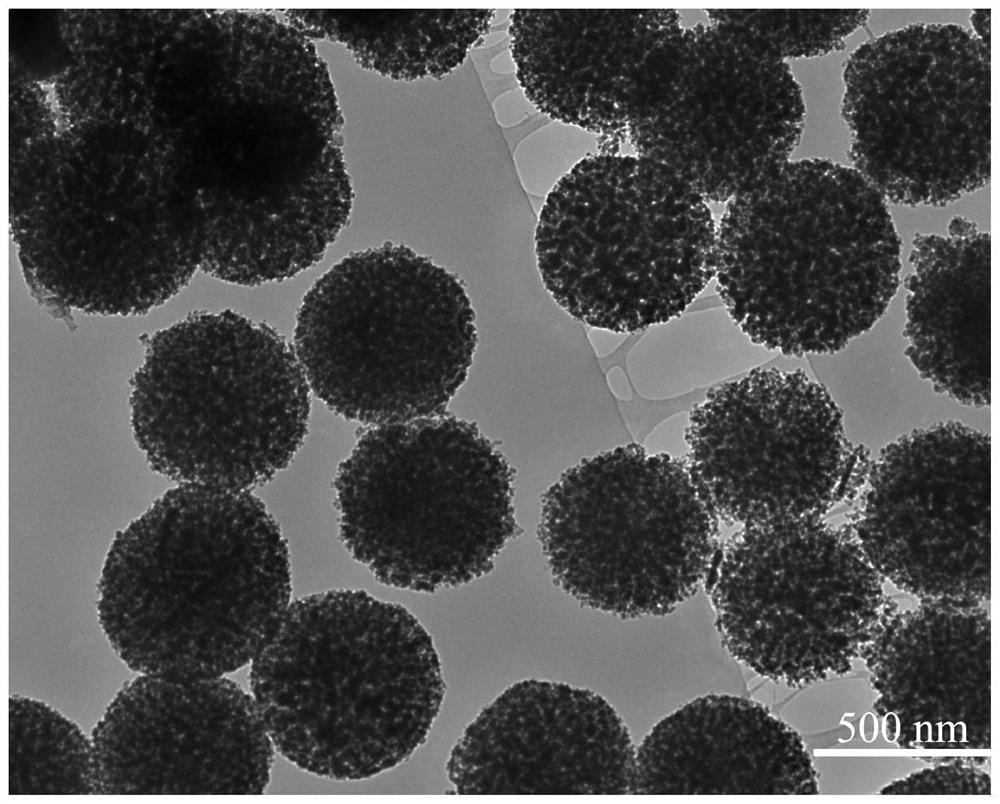

[0057] (3) Etching the solid product obtained in the step (2) with dilute hydrochloric acid with a concentration of 20% by mass for 12 hours, then repeatedly washing with deionized water, and then drying to obtain a porous silicon material. Its morphology is as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com