A nano-catalyzed metal-ceramic combined non-burning and non-immersing environment-friendly sliding plate and its preparation process

An environment-friendly, ceramic-bonded technology, which is applied in the field of high-temperature ceramics and refractory materials in the field of inorganic non-metallic materials, can solve the problems of low-temperature strength of non-burning slides, and achieve the goals of reducing sensitivity, excellent oxidation resistance, and saving energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

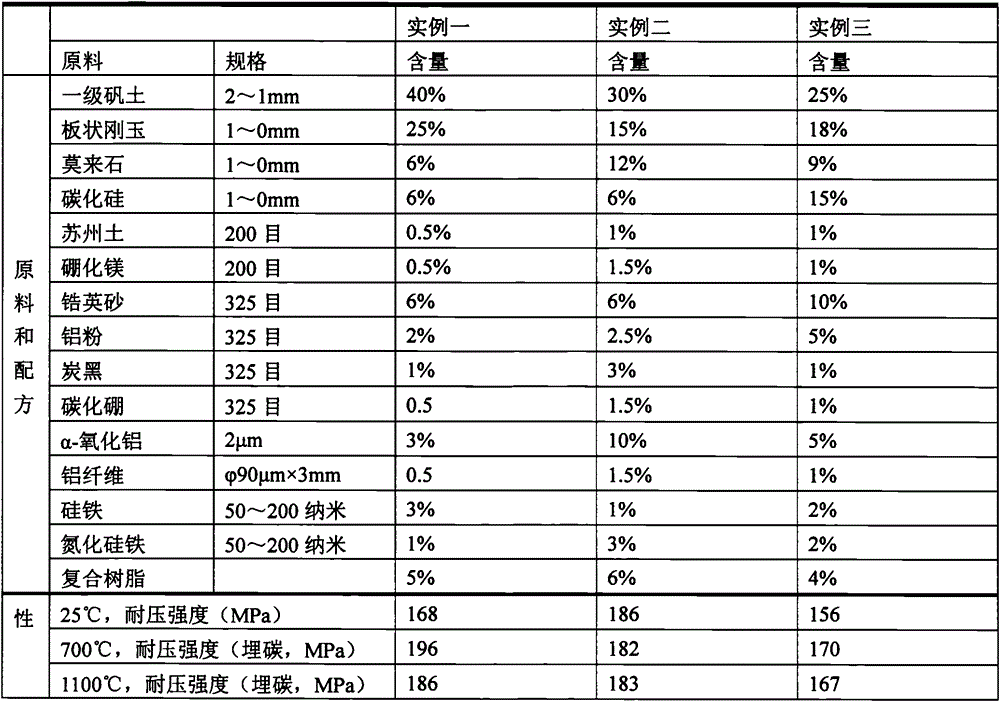

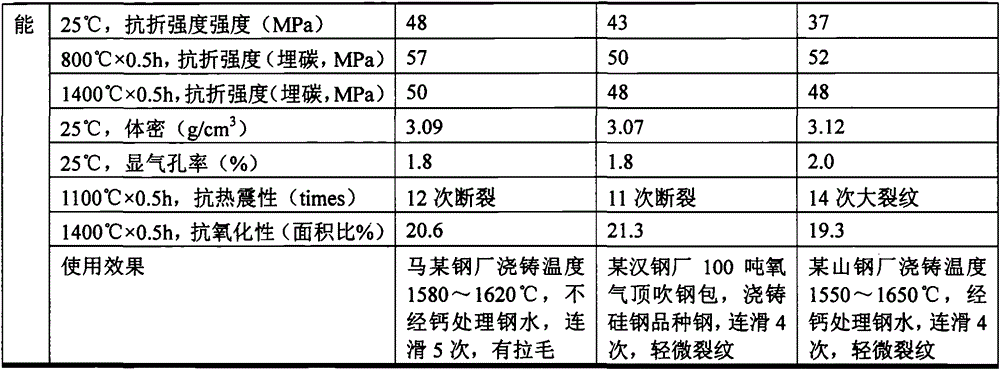

Embodiment 1

[0042] The skateboard is produced according to the following formula and process: (1) 200 mesh Suzhou soil 0.5%, magnesium boride 0.5%, 325 mesh zircon sand 6%, aluminum powder 2%, carbon black 1%, boron carbide 0.5%, 2μm α -Alumina powder at a ratio of 3%, the fine powder and micro powder are premixed vigorously for 20 minutes; (2) The resin is measured at a ratio of 5% of the composite resin, and the silicone resin and phenol resin are mixed at a ratio of 3:1. Add 3% of the total weight of the mixed liquid polycarboxylic acid dispersant to prepare the composite resin binder, then mix with 50 nanometers of catalyst ferrosilicon nanopowder 3% and ferrosilicon nitride nanopowder 1%, and disperse with ultrasonic for 20 minutes; (3 ) According to the ratio of 40% primary alumina with a particle size of 2~1mm, 25% of tabular corundum with a particle size of 1~0mm, 6% of mullite, 6% of silicon carbide, and 0.5% of aluminum fiber, dry blend for 3 minutes, add 1 % Composite resin bind...

Embodiment 2

[0048] The skateboard is produced according to the following formula and process: (1) 200 mesh Suzhou soil 1%, magnesium boride 1.5%, 325 mesh zircon sand 6%, aluminum powder 2.5%, carbon black 3%, boron carbide 1.5%, 2μm α -Premix the fine powder and the fine powder with a ratio of 10% of alumina powder for 15 minutes; (2) Measure the resin at the ratio of 6% of the composite resin, mix the silicone resin and phenolic resin at a ratio of 1:1, and Add 3% of the total weight of the mixed solution with polycarboxylic acid dispersant to prepare the composite resin binder, then mix with 200 nanometers of catalyst ferrosilicon nanopowder 2% and ferrosilicon nitride nanopowder 2%, and disperse with ultrasonic for 40 minutes; (3 ) According to the ratio of 25% primary alumina with a particle size of 2~1mm, 18% of tabular corundum with a particle size of 1~0mm, 9% of mullite, 15% of silicon carbide, and 1% of aluminum fiber, dry blend for 3 minutes, add 2 % Composite resin binder, then...

Embodiment 3

[0051] The skateboard is produced according to the following formula and process: (1) 200 mesh Suzhou soil 1%, magnesium boride 1%, 325 mesh zircon sand 10%, aluminum powder 5%, carbon black 1%, boron carbide 1%, 2μm α -Alumina powder at a ratio of 5%, the fine powder and micro powder are premixed vigorously for 20 minutes; (2) The resin is measured at a ratio of 4% of the composite resin, and the silicone resin and phenol resin are mixed at a ratio of 2:1. Add 2% of the total weight of the mixed solution with polycarboxylic acid dispersant to prepare the composite resin binder, then mix with 100 nanometers of catalyst ferrosilicon nanopowder 1% and ferrosilicon nitride nanopowder 3%, and disperse with ultrasonic for 30 minutes; (3 ) According to the ratio of 30% primary alumina with a particle size of 2~1mm, 15% of tabular corundum with a particle size of 1~0mm, 12% of mullite, 6% of silicon carbide, and 1.5% of aluminum fiber, dry blend for 2 minutes, add 3 % Composite resin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com