Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79results about How to "Short annealing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

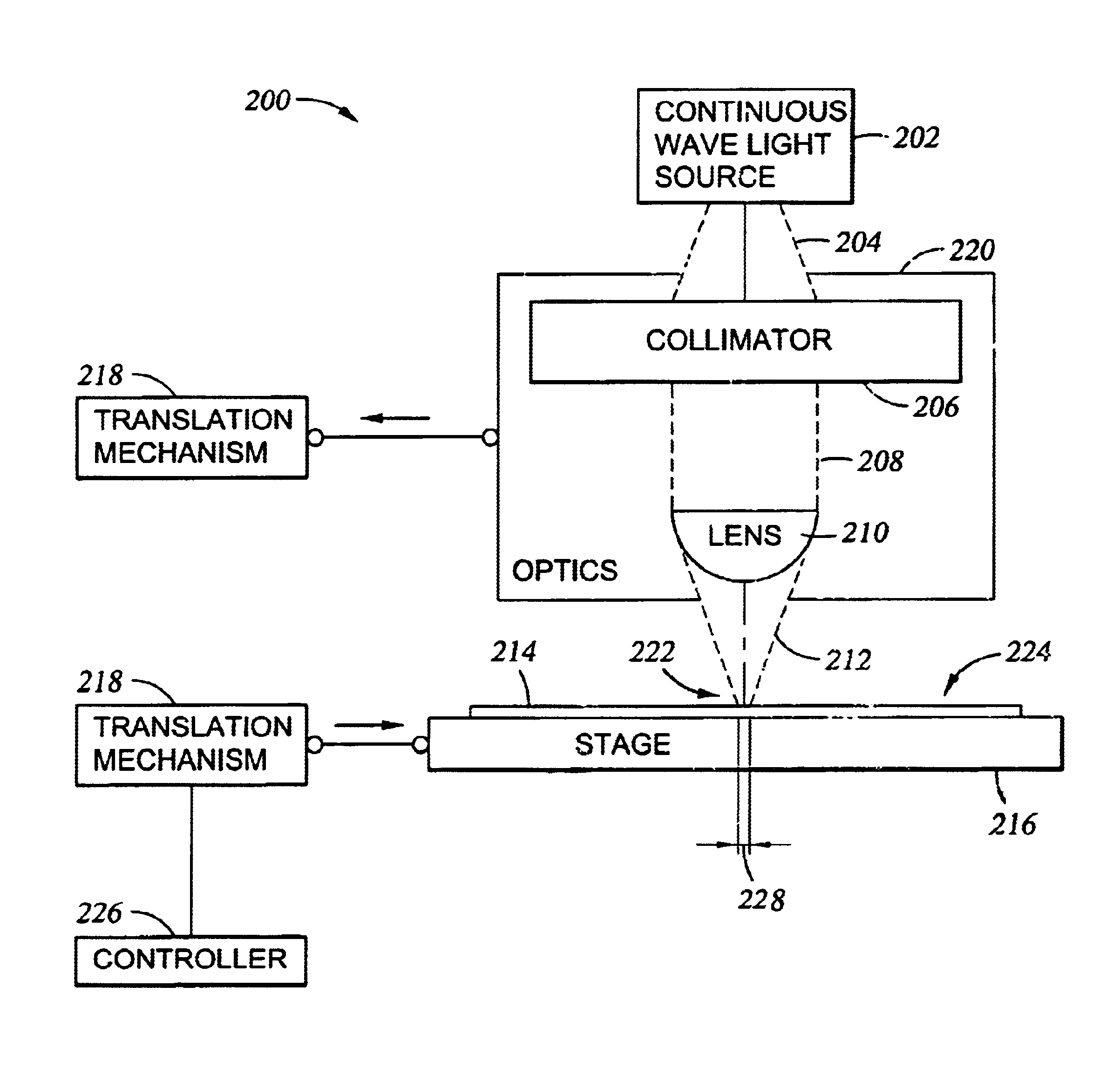

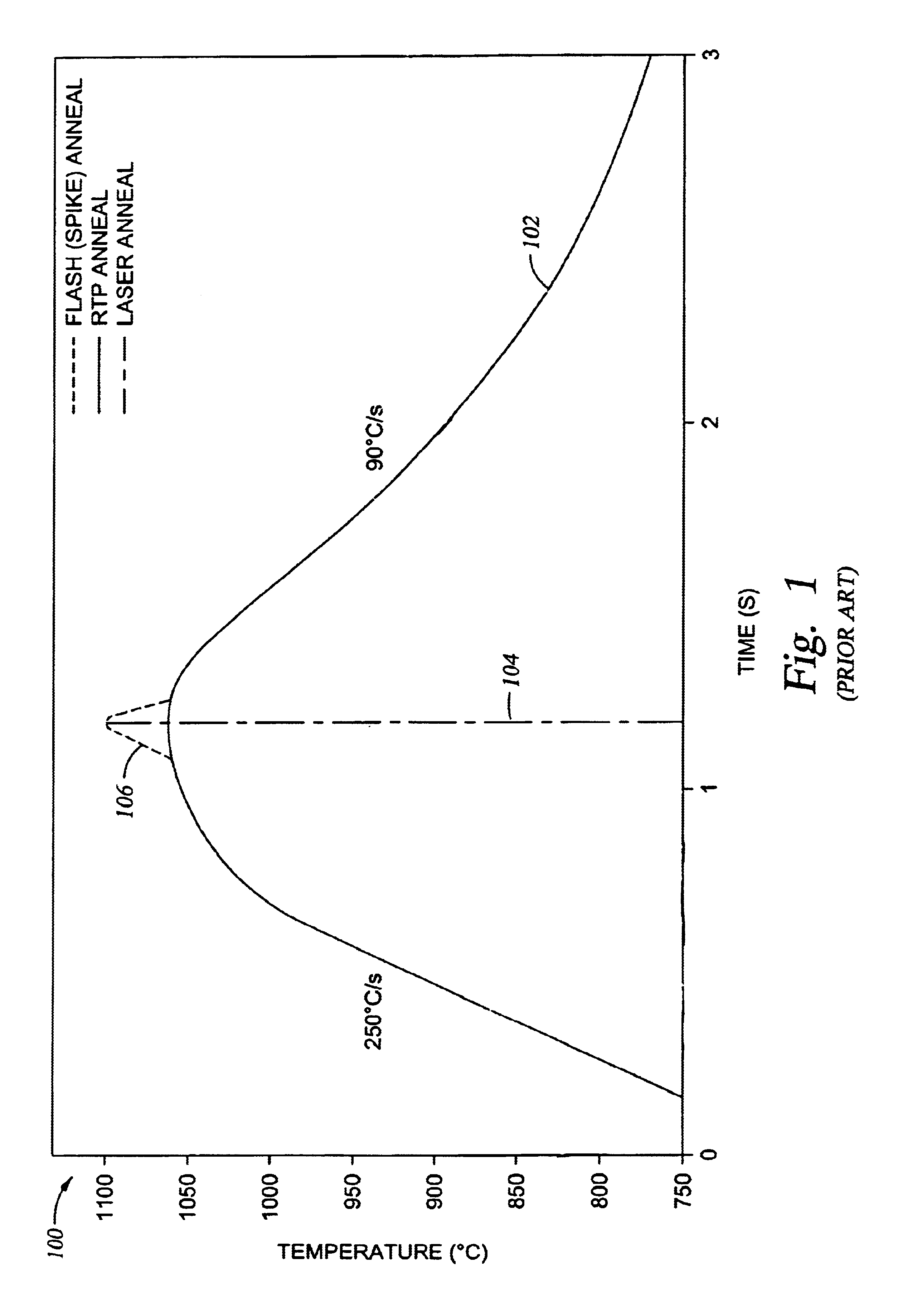

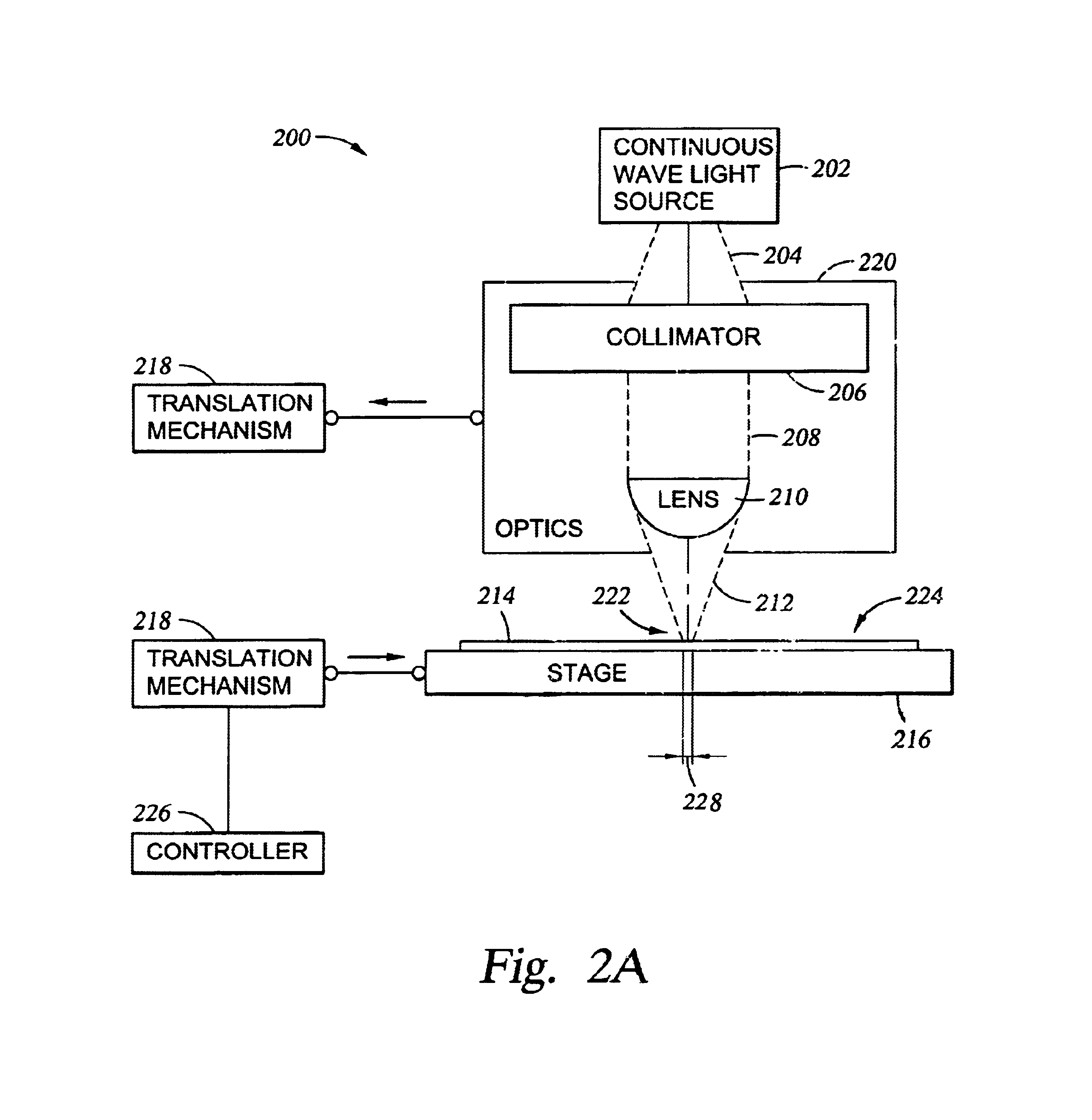

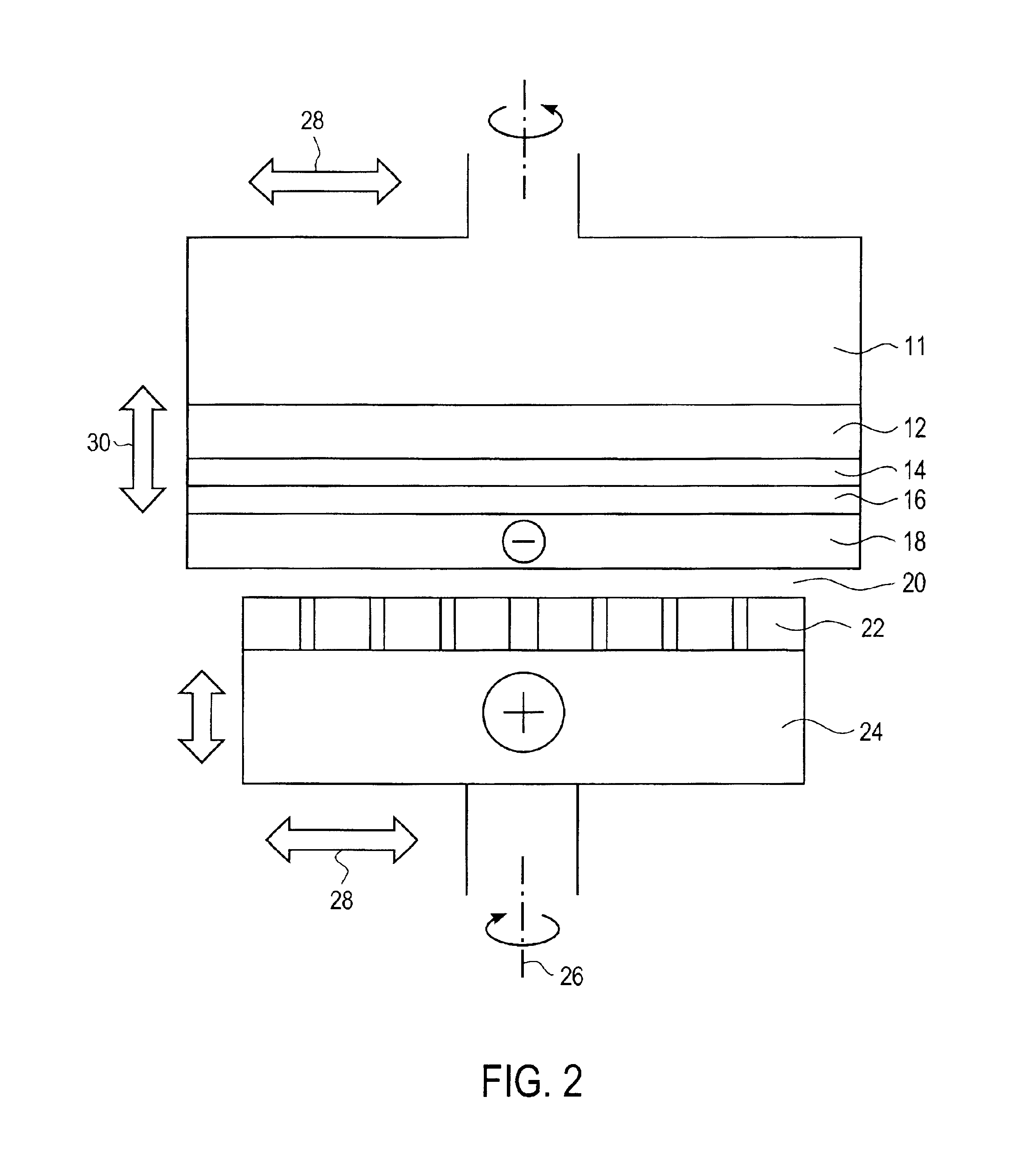

Thermal flux processing by scanning

InactiveUS7005601B2Easy to controlShort annealing timeSemiconductor/solid-state device manufacturingSolid state diffusion coatingHeat fluxContinuous wave

The thermal flux processing device includes a continuous wave electromagnetic radiation source, a stage, optics, and a translation mechanism. The continuous wave electromagnetic radiation source is preferably a diode / s. The stage is configured to receive a semiconductor substrate thereon. The optics are preferably disposed between the continuous wave electromagnetic radiation source and the stage. Also, the optics are configured to focus continuous wave electromagnetic radiation from the continuous wave electromagnetic radiation source into a line of continuous wave electromagnetic radiation on an upper surface of the semiconductor substrate. A length of the line of continuous wave electromagnetic radiation extends across an entire width of the semiconductor substrate. The translation mechanism is configured to translate the stage and the line of continuous wave electromagnetic radiation relative to one another, and preferably includes a chuck for securely grasping the substrate. A method for thermally processing a semiconductor substrate is also provided.

Owner:APPLIED MATERIALS INC

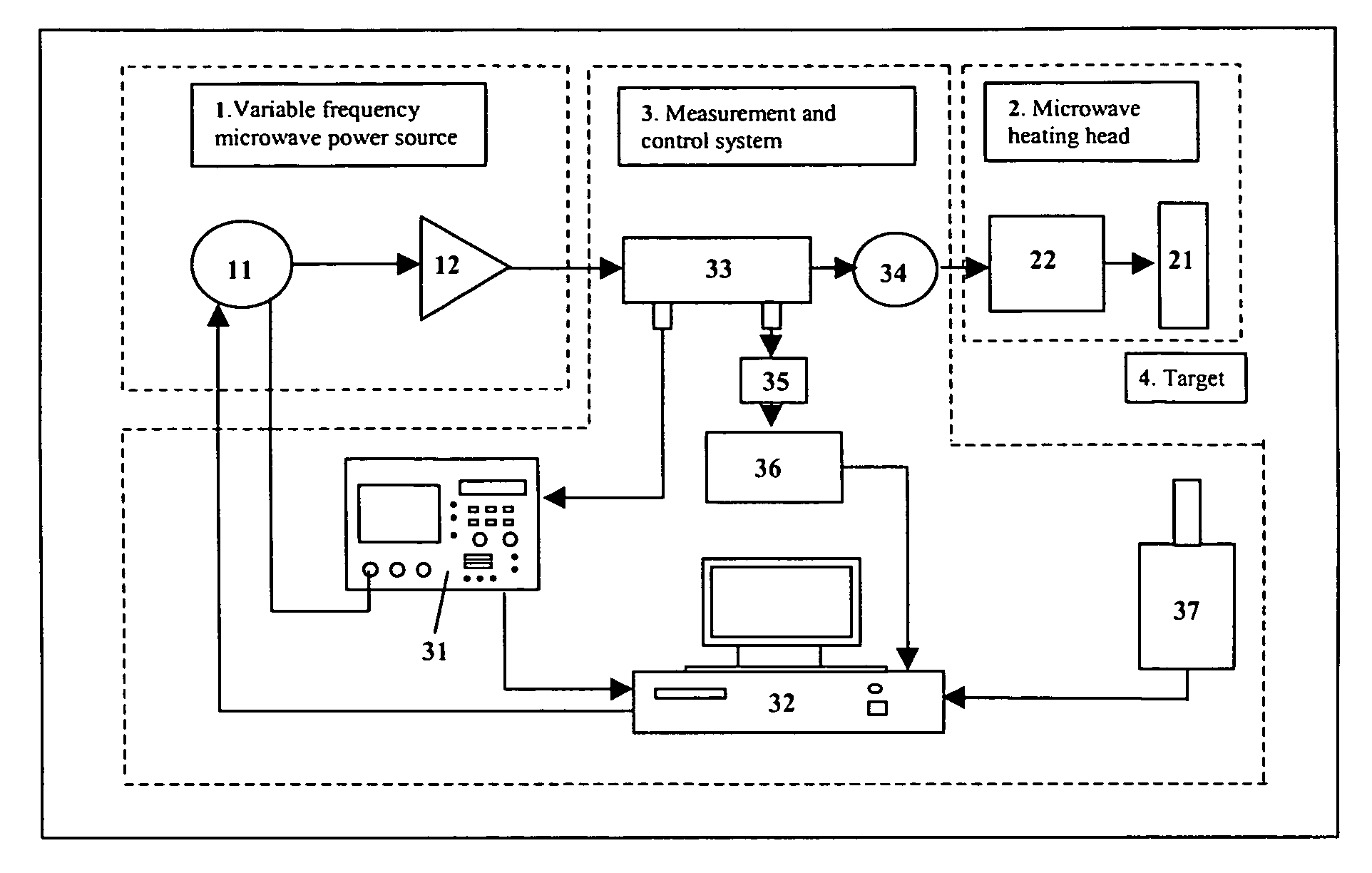

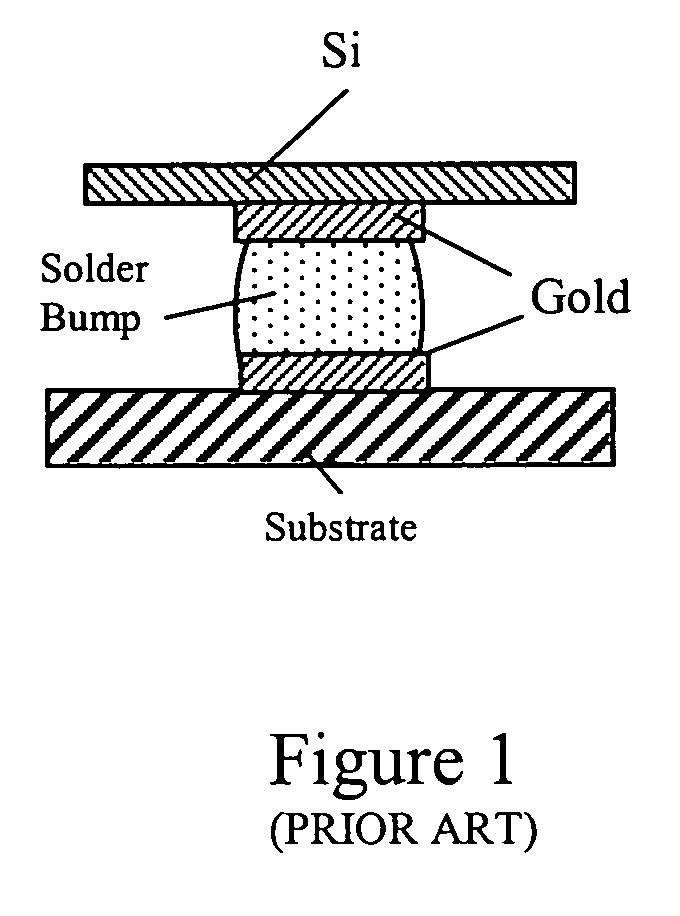

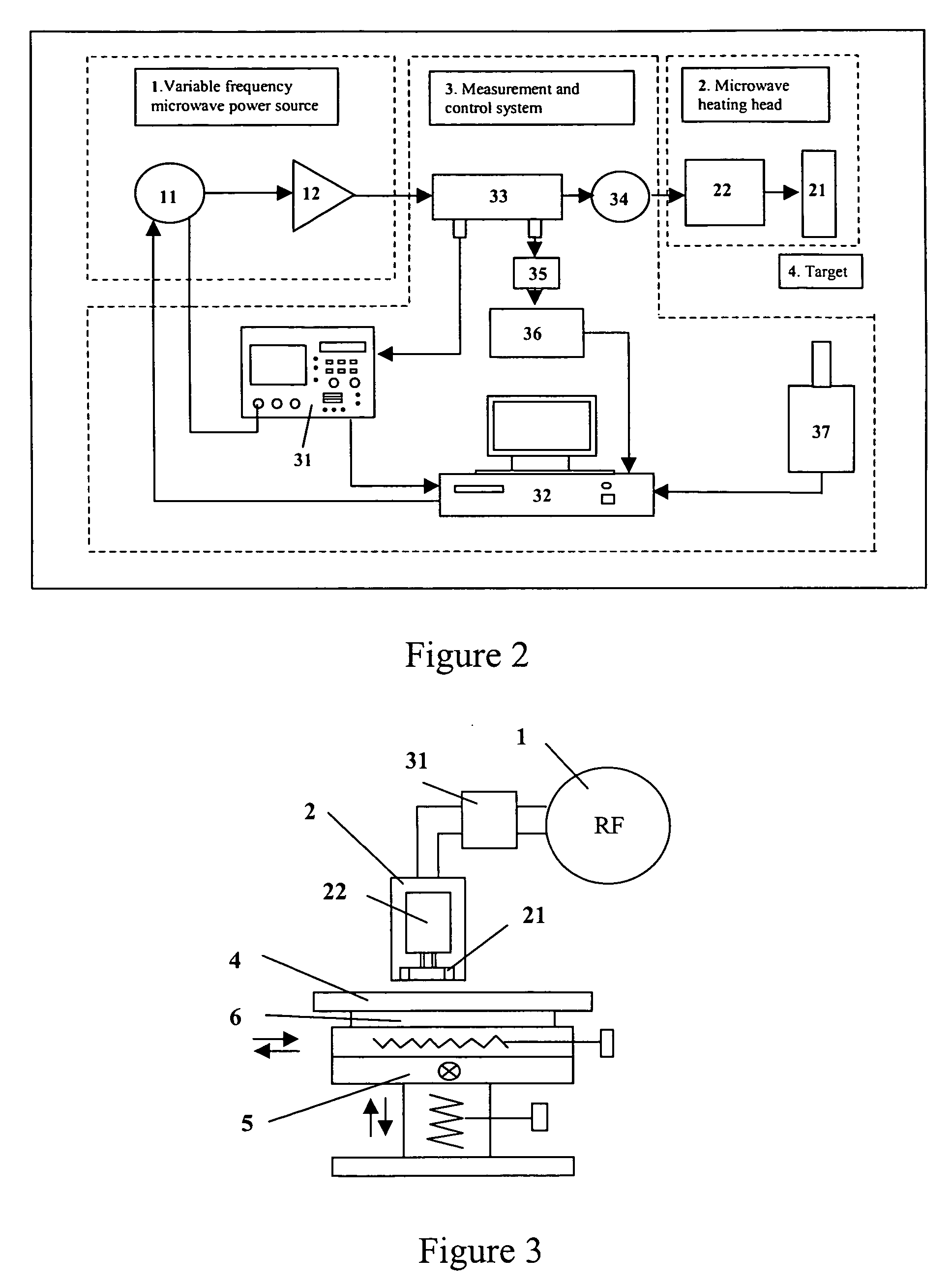

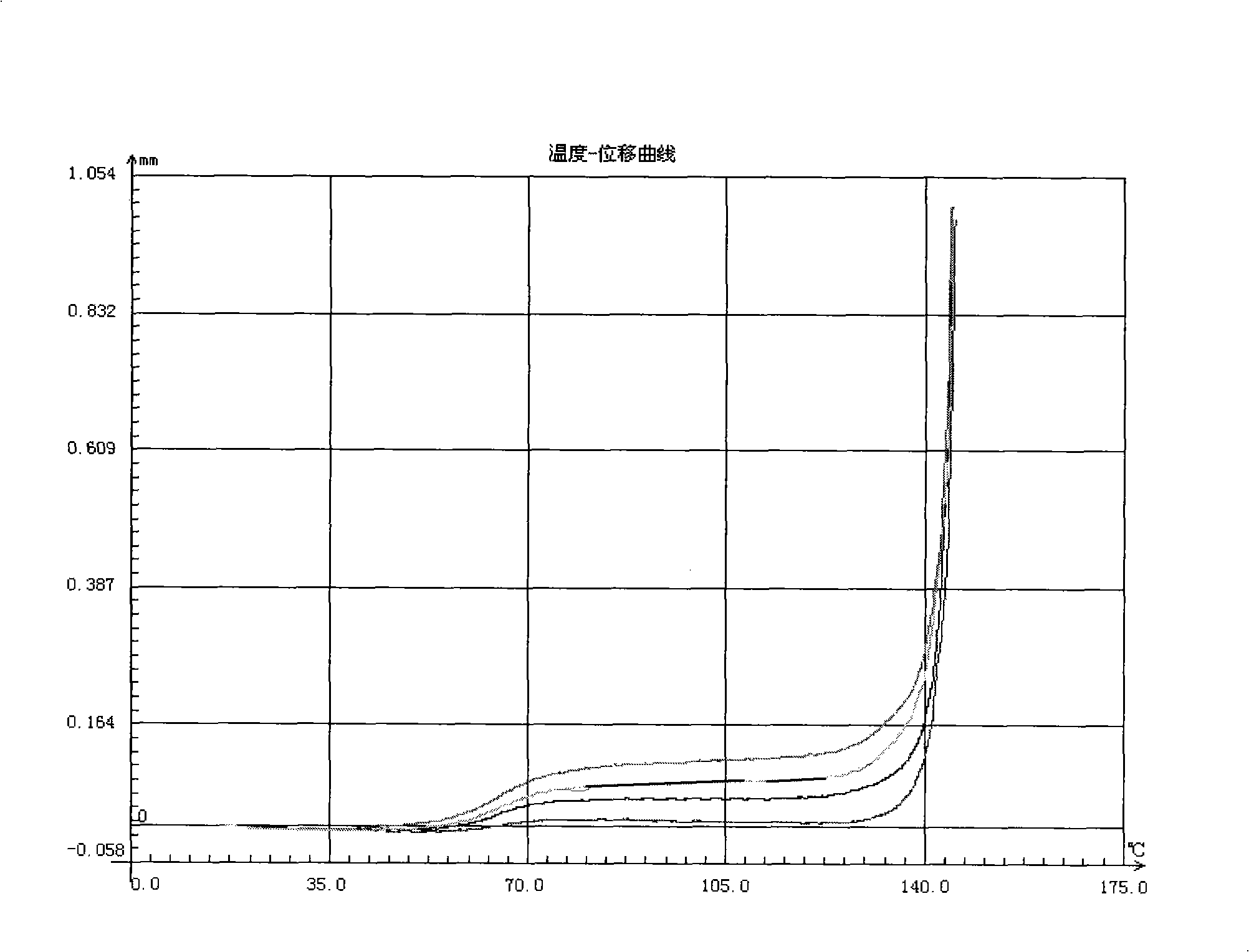

Method and apparatus for rapid thermal processing and bonding of materials using RF and microwaves

ActiveUS20070108195A1Heating fastMicrowave heating is fastSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceInterconnection density

A method and apparatus for rapid and selective heating of materials using variable frequency RF and microwaves. The apparatus uses variable frequency solid state electronics as a microwave power source, a novel microwave heating head to couple microwave energy to the target materials and a match-up network to tune the frequency and impedance match between the microwave source and the load. An electronic and computer measurement and control system is employed to monitor and control the microwave heating process. The method teaches the use of inductive microwave coupling for thin conductive materials such as metal film and impurity doped silicon wafers. The method also teaches the use of capacitive microwave coupling for dielectric material such as glass and ceramics. The method further teaches the use of rapid and selective heating of heterostructure for bonding and sealing of mems and integrated circuits. The method and apparatus can provide ultra-high heating speed along with ultra-high heating temperatures for rapid thermal processing of semiconductors and other materials. It also allows the use of bonding materials with high melting temperature for strong bonding and sealing of mems and IC devices. The apparatus further provides for high interconnection density of integrated circuits as connections are made without the use of solder bumps.

Owner:TIAN YONGLAI +1

High thermotolerance polylactic acid composite material filled by french chalk and method for preparing same

InactiveCN101333331AImprove mechanical propertiesImprove heat resistanceHeat resistanceMechanical property

The invention relates to polylactic acid composite material which takes heat resistant talcum powder as filler and a preparation method thereof. The polylactic acid composite material contains(based on weight portion) 59-98 portions of semi-crystalline poly-L-lactic acid, 1-40 portions of modified talcum powder, 0.1-1.0 portions of heat stabilizer, 0.2-1.5 portions of talcum powder surface passivator and 0.05-1.0poritons of lubricant. The polylactic acid composite material is prepared through the following steps: firstly, preparing modified talcum powder; then batching according to the composition of the polylactic acid composite material, stirring and mixing to be even, putting the mixture into a kneader, and melting and blending under 160-200DEG C; hot press molding under 10-20MPa and finally annealing under 100-120 DEG C. The composite material is applicable in automobile and house appliance fields. The polylactic acid composite material can not only be biologically degraded but also has excellent mechanical property and heat resistance. The filler adopted by the invention is low in cost, simple in preparation process and short in process period and can be realized in large-scale industrial production.

Owner:SHANGHAI UNIV

Method and apparatus for depositing and controlling the texture of a thin film

InactiveUS6837979B2Accelerate grain recoveryPromote growthCellsSemiconductor/solid-state device detailsConductive materialsElectroplating

The present invention provides a method and apparatus for plating a conductive material to a substrate and also modifying the physical properties of a conductive film while the substrate is being plated. The present invention further provides a method and apparatus that plates a conductive material on a workpiece surface in a “proximity” plating manner while a pad type material or other fixed feature is making contact with the workpiece surface in a “cold worked” manner. In this manner, energy stored in the cold worked regions of the plated layer is used to accelerate and enhance micro-structural recovery and growth. Thus, large grain size is obtained in the plated material at a lower annealing temperature and a shorter annealing time.

Owner:NOVELLUS SYSTEMS

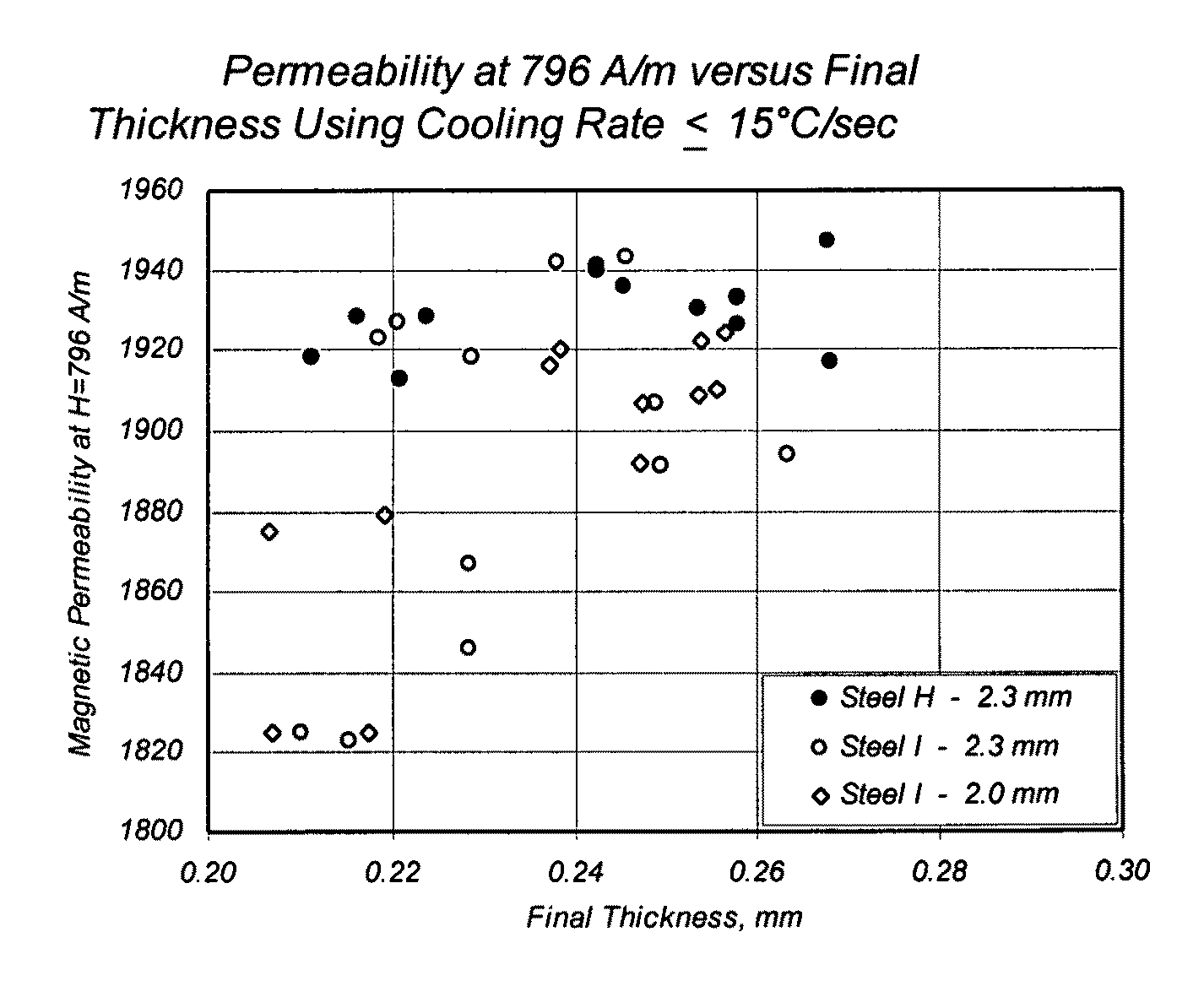

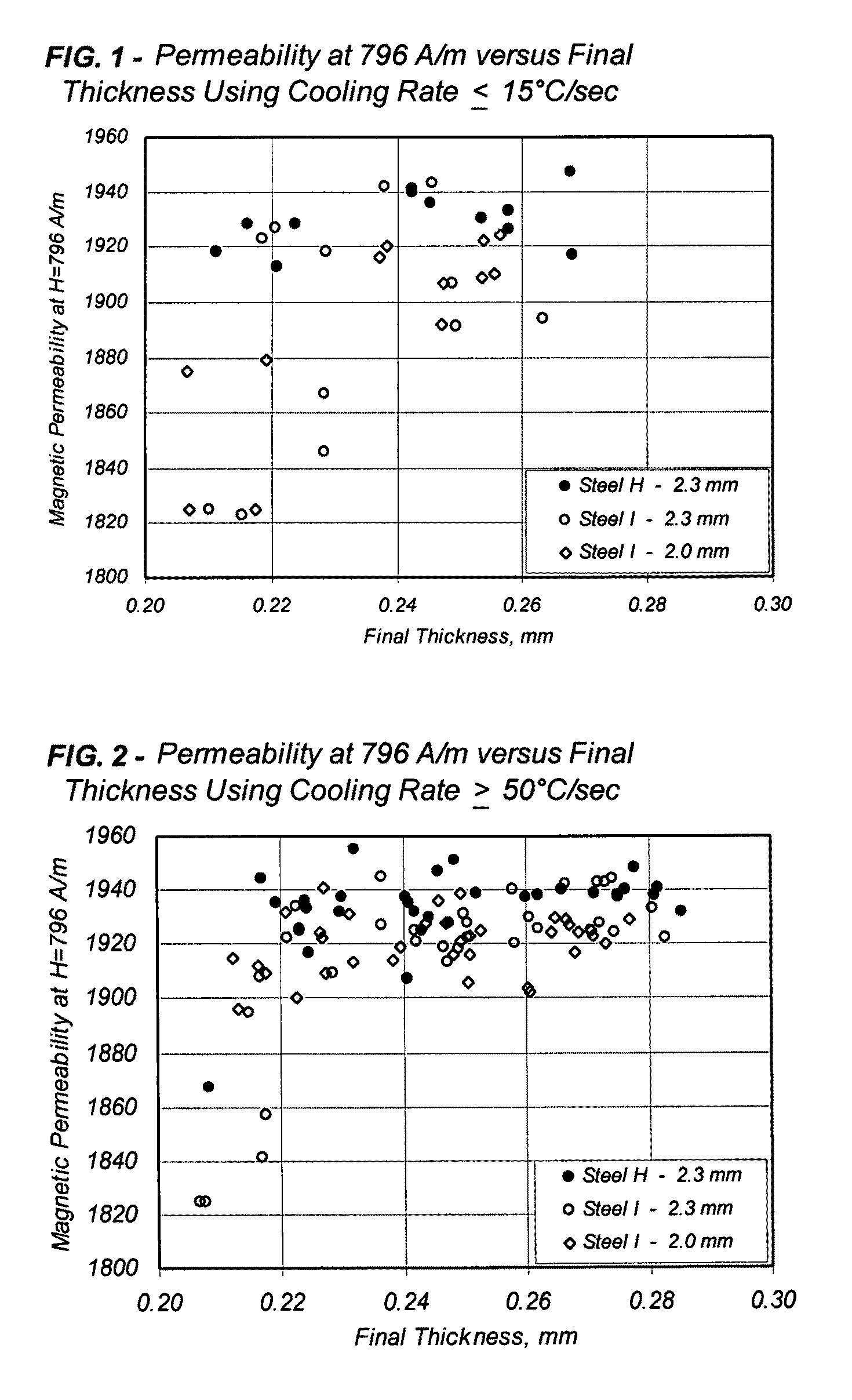

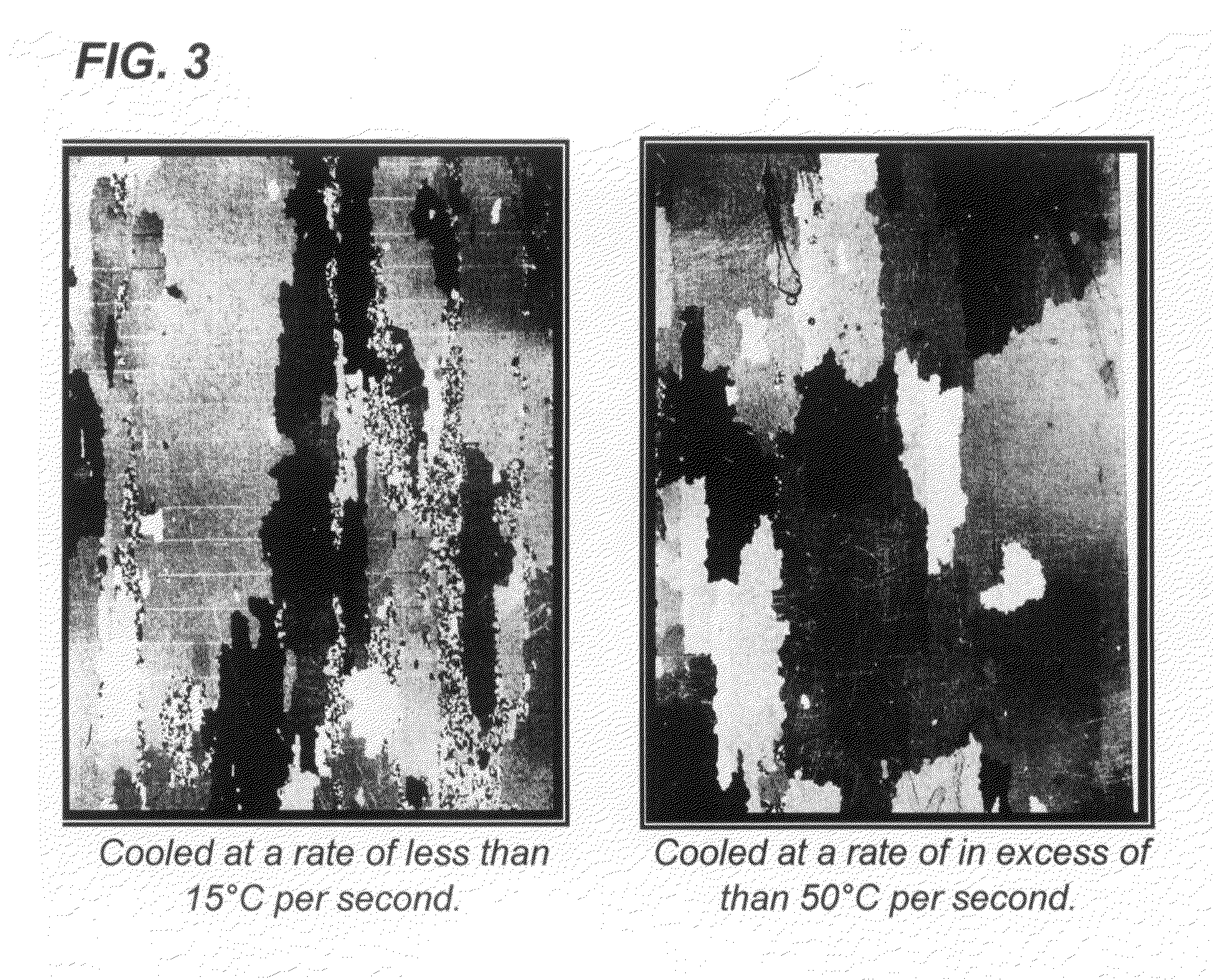

High permeability grain oriented electrical steel

InactiveUS7887645B1Improve permeabilityImprove magnetic propertiesInorganic material magnetismManganeseLayer thickness

The present invention provides a method of producing a high permeability grain oriented electrical steel having excellent mechanical and magnetic properties. A hot band having a thickness of about 1.5 to about 4.0 mm has a chemistry comprising about 2.5 to about 4.5% silicon, about 0.1 to about 1.2% chromium, about 0.02 to about 0.08% carbon, about 0.01 to about 0.05% aluminum, up to about 0.1% sulfur, up to about 0.14% selenium, about 0.03 to about 0.15% manganese, up to about 0.2% tin, up to about 1% copper, and balance being essentially iron and residual elements, all percentages by weight. The band has a volume resistivity of at least about 45 μΩ-cm, an austenite volume fraction (γ1150° C.) of at least 20% and the strip has an isomorphic layer thickness of at least about 2% of the total thickness on at least one surface of the hot processed band. The band is rapidly cooled after the anneal prior to cold rolling at a rate of at least 30° C. / second from 875-950° C. to a temperature below 400° C. The band is cold reduced in one or more stages with a final reduction of at least 80%, annealed, decarburized and coated with an annealing separator on at least one side. A final annealing provides stable secondary grain growth and a permeability measured at 796 A / m of at least 1840.

Owner:AK STEEL PROPERTIES

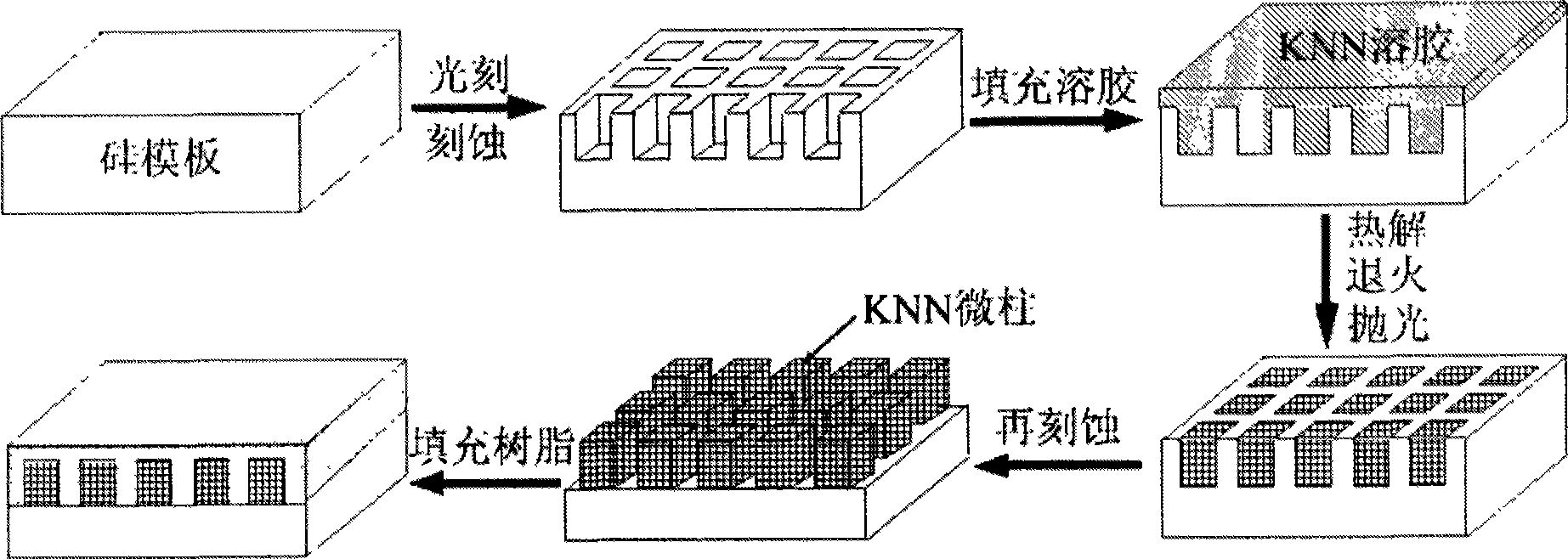

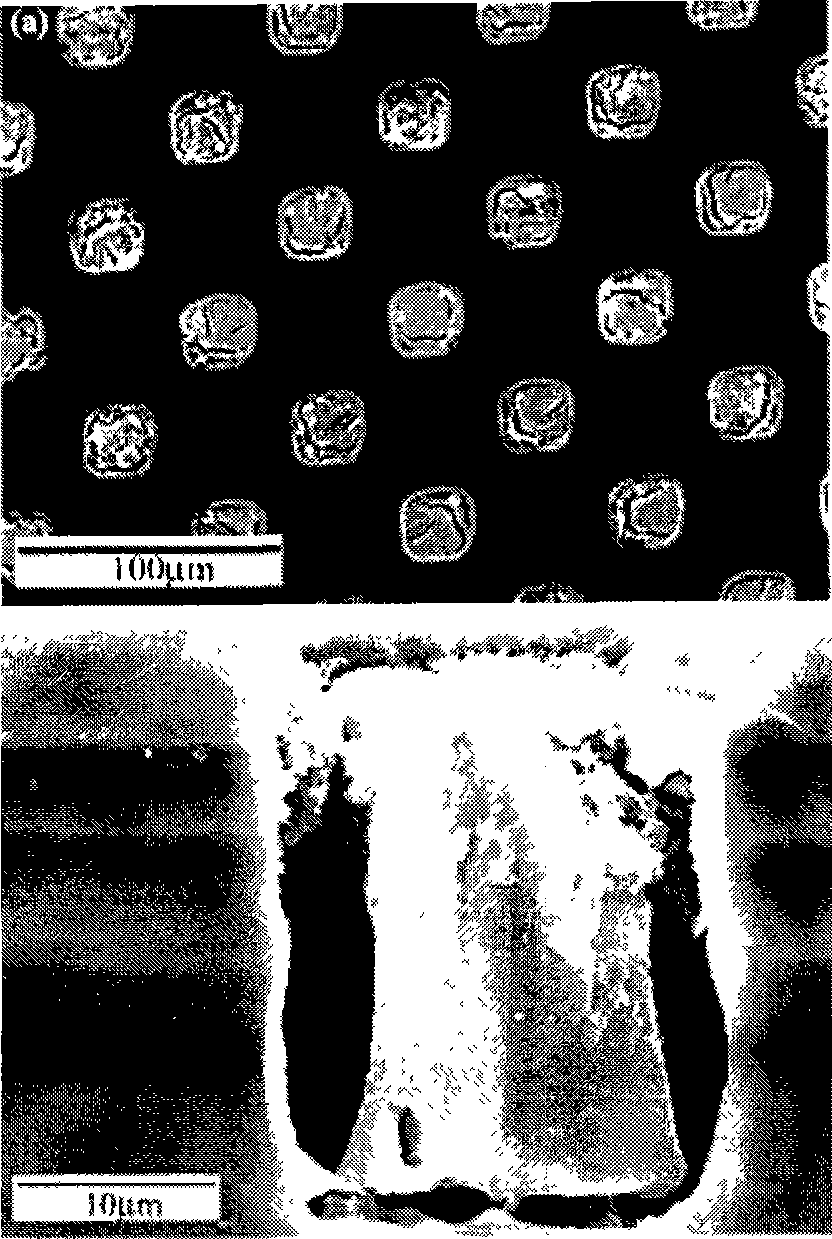

Microfine piezoelectric ceramics array structure composite material and preparation thereof

The invention discloses a hyperfine piezoelectric ceramic array structure composite material and a preparation method, belonging to the field of functional ceramics material and the preparation technology thereof. The preparation technique comprises: a metal alkoxide reflux method is adopted to prepare sol precursor, silicon micromachining technology is used for preparing a silicon template; then, piezoelectric ceramic microcolumn array which has the length and the width being 5-100 microns, the hole height being 1-500 microns and the spacing being 10-200 microns is prepared by sol padding template technique and the subsequent pyrogenation and annealing processing process; finally, the microcolumn array is compounded with polymer to obtain 1-3 type piezoelectric ceramic / polymer composite material. Compared with the traditional mechanical cutting technique, the invention can prepare the ceramic microcolumn with smaller size and better array period, and the minimum column width can reach 7mum, thereby being suitable for a micro electrical / mechanic system (MEMS); compared with the array preparation techniques such as heat pressing, laser cutting and the like, the invention has simple equipment condition and is easy to realize.

Owner:TSINGHUA UNIV

Annealing process for growing large-size sapphire crystal by kyropoulos method

InactiveCN103540998AReduce dislocation densityReduce internal stressPolycrystalline material growthAfter-treatment detailsThermal insulationSingle crystal

The invention relates to an annealing process for growing a large-size sapphire crystal by a kyropoulos method. After a large-size sapphire crystal grows by a kyropoulos method, the vacuum degree in a single crystal furnace is maintained, the heater power is gradually reduced, and the cooling is performed in five stages until the heater power is zero; through staged thermal insulation annealing, the dislocation density of large-size sapphire can be effectively reduced, internal stress of the crystal is eliminated, and the quality and the utilization rate of the crystal are improved; the annealing time is short, the energy consumption is reduced, and the growth period of the large-size sapphire crystal is shortened; moreover, the sapphire crystal is rotated in a thermal insulation stage so that the sapphire crystal annealing is uniform and the influence of non-uniform temperature field in annealing is eliminated.

Owner:江西东海蓝玉光电科技有限公司

Method for producing lead belt of battery plate

InactiveCN102925834ASimple preparation processLow annealing temperatureLead-acid accumulator electrodesHeat conservationThermal treatment

The invention relates to a method for producing a lead belt of a battery plate. The technical scheme is that lead alloy for manufacturing the lead belt of the storage plate is performed with melting, continuous casting and rolling, and the thickness of a finished product of the lead belt of the battery plate is 0.4-1.2mm; and rolling reduction rate of pre-rolling pass of the finished product of the lead belt of the battery plate and rolling pass of the finished product of the lead belt of the battery plate is 22-44%. Thermal treatment is respectively performed before and after the rolling pass of the finished product of the lead belt of the battery plate, the thermal treatment temperature is 240-290 DEG C, and the heat preservation time is 8-356 seconds. The chemical components of the lead alloy for producing the lead belt of the battery plate contain: 0.04-0.1wt% of Ca, 0.9-1.8wt% of Sn, 0.01-0.03wt% of Al and the balance of Pb. The method for producing the lead belt of the battery plate has the advantages of being simple in production process, and the prepared lead belt of the battery plate is strong in corrosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

Sapphire crystal annealing process

InactiveCN103014874AShort annealing timeLow energy consumptionAfter-treatment detailsPass rateSapphire

The invention discloses a sapphire crystal annealing process. The sapphire crystal annealing process comprises the steps of: cooling at a high temperature stage, cooling at an intermediate temperature stage and cooling at a low temperature stage, wherein inert gases are used for cooling and protection during cooling at the low temperature stage. The sapphire crystal annealing process has the advantages that the annealing time is short by saving about 50 percent of time compared with the traditional melting processes, the energy consumption is low by reducing 10 percent of energy consumption compared with the traditional annealing processes; the production efficiency is improved, and cooling is uniform and fast to avoid stress cracking of sapphire crystal; and the product quality and the pass rate are improved.

Owner:焦作市光源晶电科技有限公司

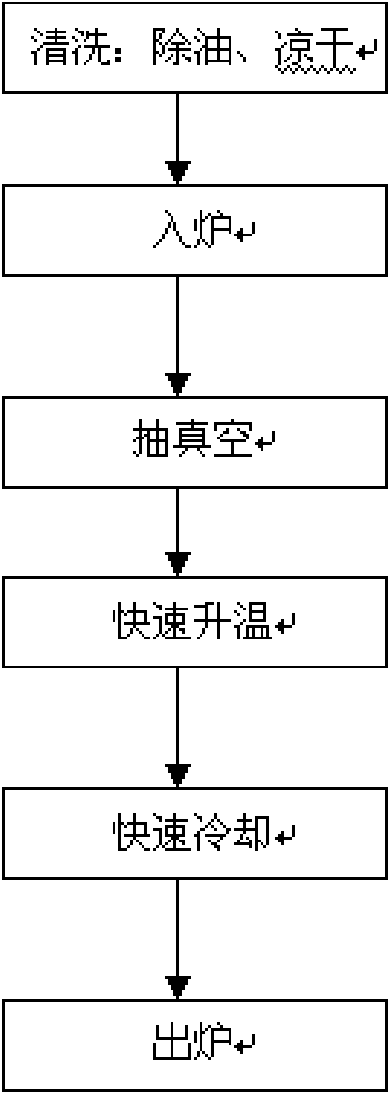

Vacuum annealing method for tantalum tube

InactiveCN101603164AGood organization and performanceFine and uniform grainFurnace typesHeat treatment furnacesAir dryingEnergy consumption

The invention relates to a rapid vacuum annealing method for a tantalum tube, which comprises the steps of: washing and air-drying the tantalum tube; placing the washed tantalum tube into a heat-resistant casing, and axially sending the washed tantalum tube and the heat-resistant casing to a vacuum induction annealing furnace together; adopting a three-stage vacuum system to work, and ensuring that the three-stage vacuum system pumps until the vacuum degree is 10Pa; ensuring that the inside of the vacuum induction annealing furnace is in a high vacuum state; and annealing the tantalum tube in the vacuum induction annealing furnace, namely finishing the temperature increase by heating and quick cooling in the furnace. The annealing by the method has the advantages of quick temperature increase of the tantalum tube, good product structure and performance of the tantalum tube, good mass conformance of the tantalum tube, low energy consumption, low operation cost, low investment on annealing equipment, and simple disassembly and maintenance. The method does not perform heat preservation for a long time and has low power consumption. The admissible stress of the tantalum tube is improved by 60 percent or so compared with the prior vacuum annealing furnace after the annealing is performed by the method; and under the same service strength, the method can save about 40 percent of tantalum materials and has remarkable economic benefit.

Owner:长沙南方钽铌有限责任公司

Nickel silicide layer forming method and semiconductor device forming method

ActiveCN103014656ALower resistanceIncrease contentSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenSemiconductor

The invention discloses a nickel silicide layer forming method and a semiconductor device forming method, wherein the nickel silicide layer forming method comprises the following steps of: providing a substrate, and forming a dinickel silicide layer on the surface of the substrate; forming a hydrogen ion containing silicon nitride layer on the surface of the dinickel silicide layer; and carrying out secondary annealing treatment on the dinickel silicide layer so as to form a nickel silicide layer. Before the step of carrying out secondary annealing treatment on the dinickel silicide layer so as to form a nickel silicide layer, a hydrogen ion containing silicon nitride layer is formed on the surface of the dinickel silicide layer, and in the process of carrying out secondary annealing treatment, hydrogen ions in the silicon nitride layer are diffused into the dinickel silicide layer, so that the finally formed nickel silicide layer internally contains hydrogen ions, therefore, the resistance of the nickel silicide layer can be effectively decreased, and the RC delay of a circuit can be reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP

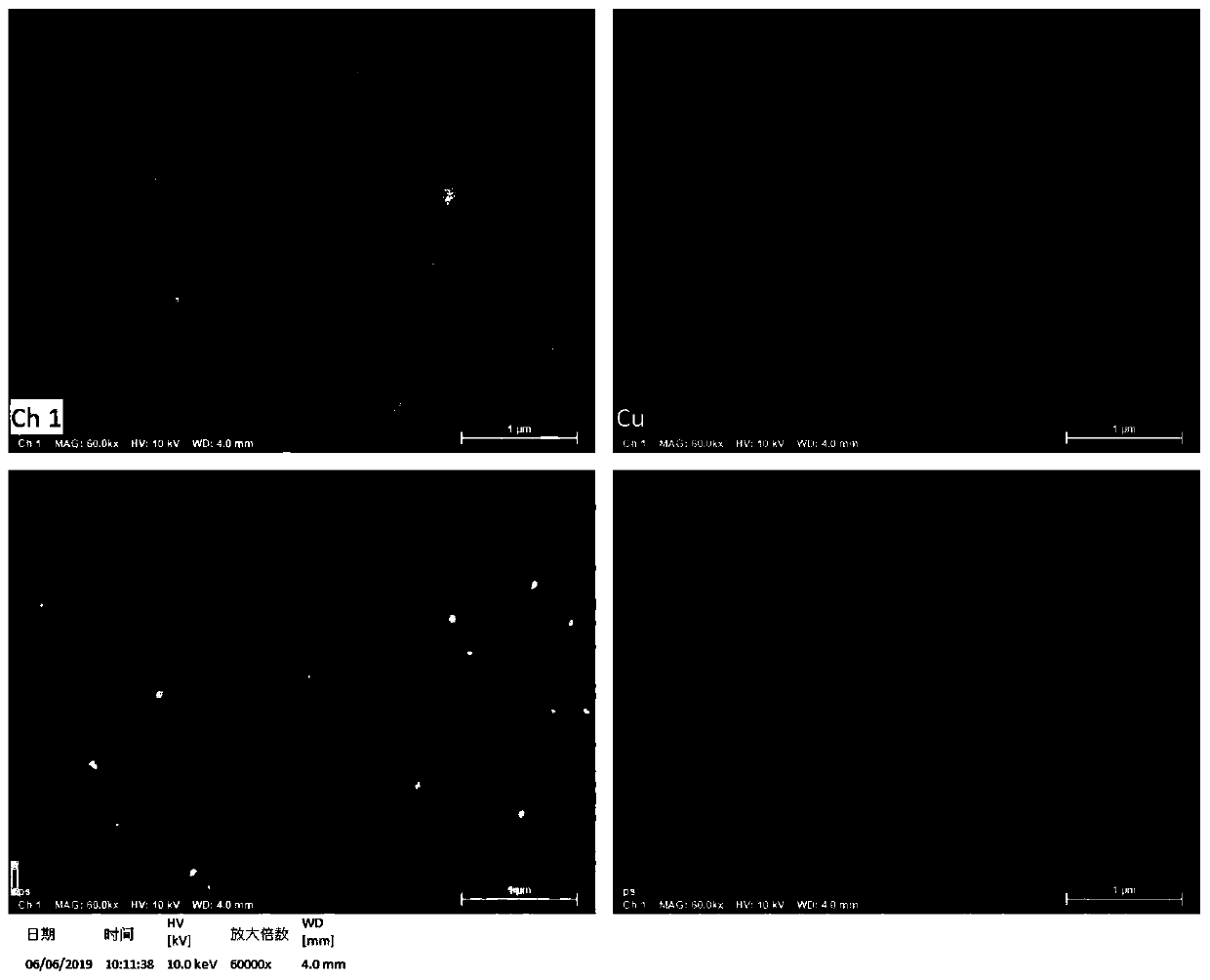

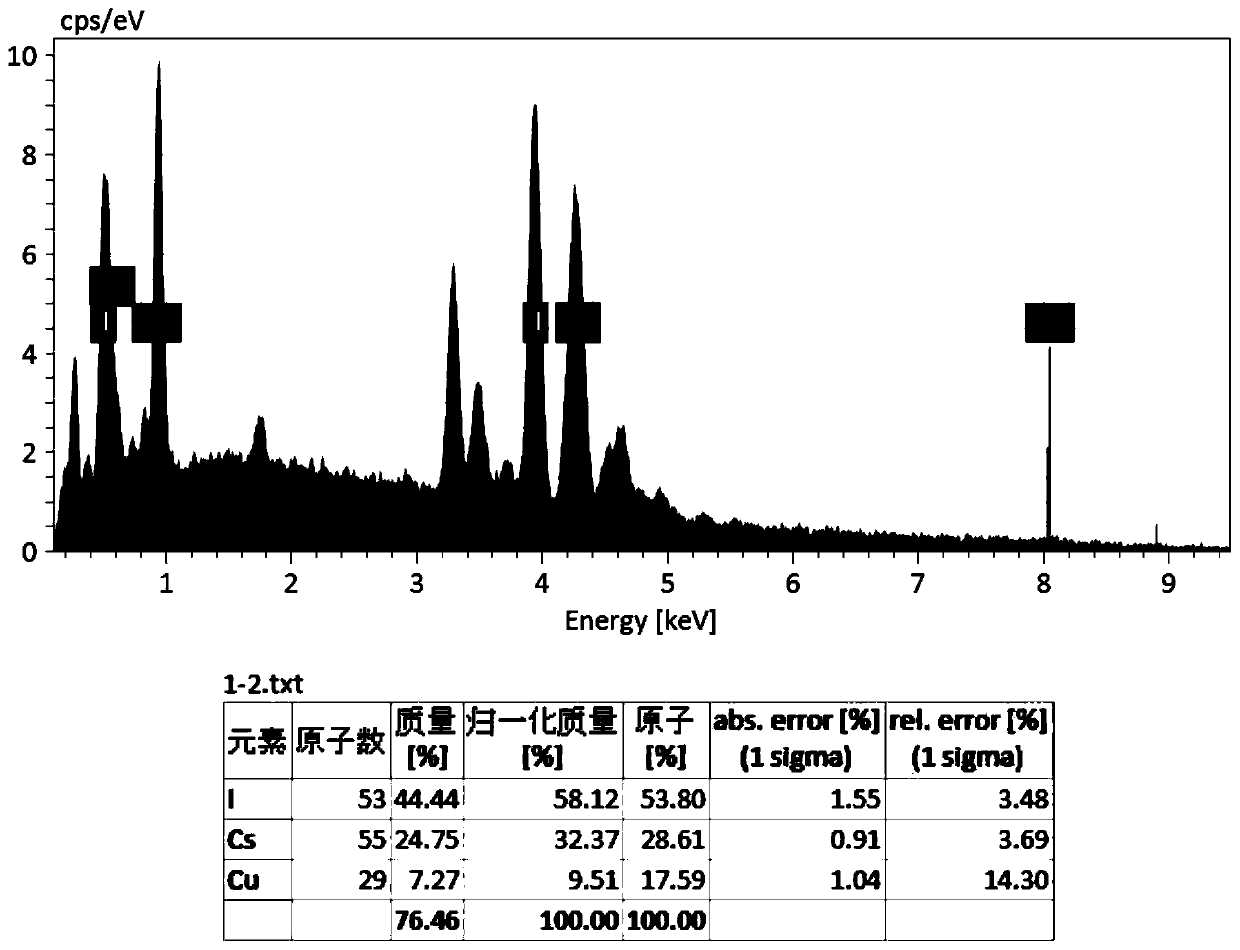

Cs3Cu2I5 ultraviolet detector and film preparation method thereof

ActiveCN110611014AAid in evaporationTiled evenlyFinal product manufactureSemiconductor devicesQuantum efficiencyUltraviolet detectors

The invention discloses a Cs3Cu2I5 ultraviolet detector and a film preparation method. A Cs3Cu2I5 precursor solution is applied to ITO glass by means of differential spin coating, and an anti-solventis added dropwise in the last 5 seconds of spin coating, and the differential speed is low first and then high. According to the film preparation technology, the annealing time needed is short, the annealing temperature is low, the film prepared is uniform and compact, the transmittance is high, the fluorescence quantum efficiency is high and reaches 76.1%, the film is kept stable in the air, andthe luminous efficiency is still kept at 76% after the film is stored in the air for 2 months.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

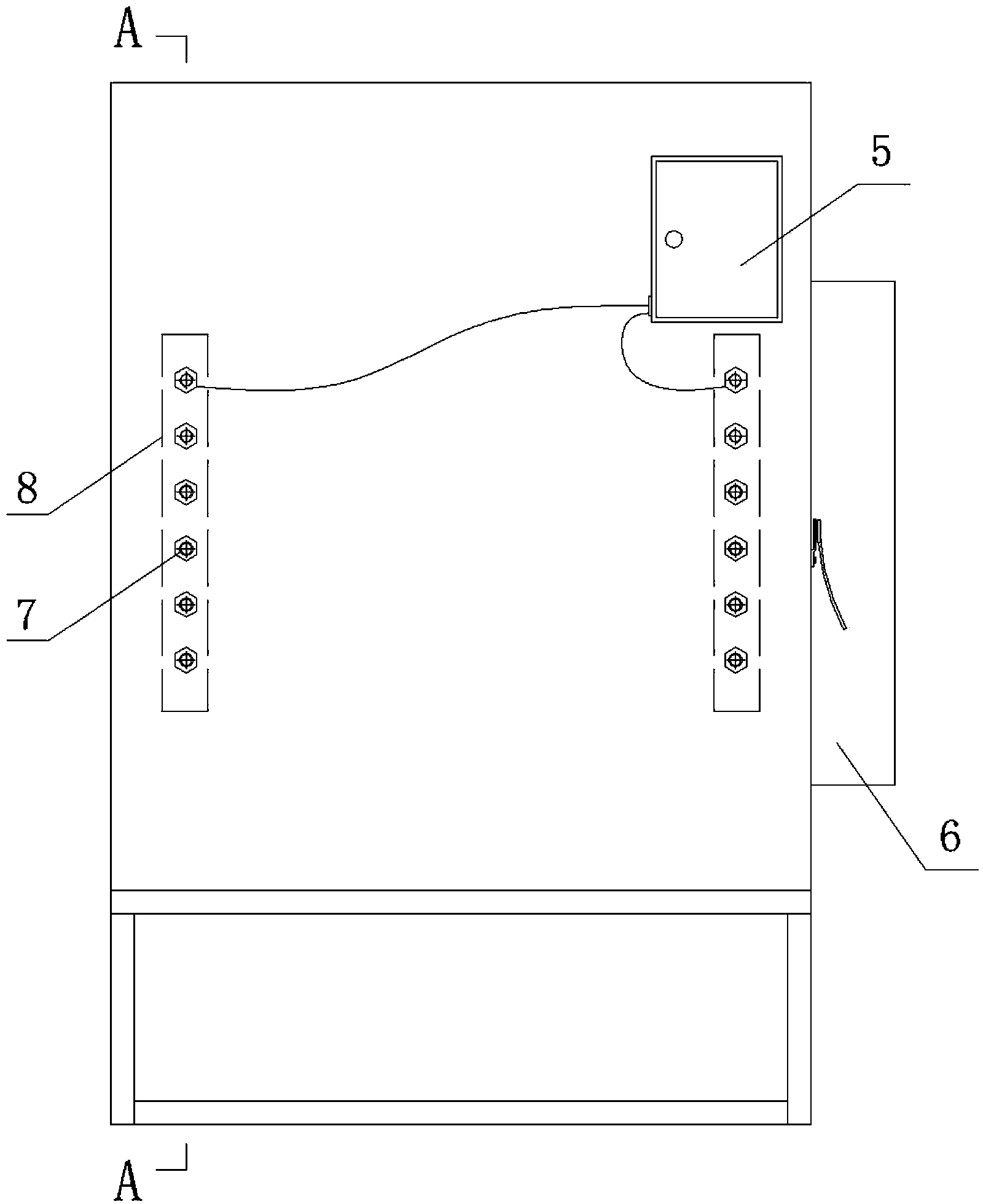

High-frequency induction annealing device and technology for regulation and control of copper-clad aluminum composite flat bus

ActiveCN103695609AControl thicknessImprove performanceIncreasing energy efficiencyFurnace typesHeating timeAluminum composites

The invention discloses a high-frequency induction annealing device and technology for regulation and control of a copper-clad aluminum composite flat bus. The high-frequency induction annealing device mainly comprises a guide roller, a driving device, a ceramic tube, temperature measuring device, an induction heating device, and an air blast cooling device. The high-frequency induction annealing device is characterized in that an induction heating power supply adopts high-frequency induction heating to improve the heating rate, shorten the heating time and control the interface layer thickness; an induction heating coil is designed to be flat similar to the cross-sectional shape of the copper-clad aluminum flat bus, so that in induction heating, the temperature distribution at different parts of the copper-clad aluminum flat bus is uniform, the heating time can be shortened, and the interface layer thickness is controlled; as the ceramic tube with a certain length is arranged, the temperature is uniform in heating, and the copper cladding layer and the aluminum core can be recrystallized synchronously; the annealed flat bus temperature can be quickly reduced to below 150 DEG C through a forced air cooling section, so that the thickness-increasing of the aluminum-copper interface is avoided; the aluminum-copper interface layer thickness is controlled within 2-3 microns.

Owner:UNIV OF SCI & TECH BEIJING

Cold-rolled steel plate for structure with yield strength of 240 MPa level and preparation method

The invention discloses a cold-rolled steel plate for a structure with yield strength of 240 MPa level and a preparation method. The steel plate is prepared from the following chemical components in percentage by mass: 0.15 to 0.18% of C, 0.40 to 0.60% of Mn, less than or equal to 0.05% of Si, less than or equal to 0.02% of P, less than or equal to 0.01% of S, 0.02 to 0.06% of Als, and the balanceof Fe and other inevitable impurities. The cold-rolled steel plate has the advantages that the steel plate adopts a carbon-manganese component design, has yield strength of 240 to 340 MPa after beingannealed and flattened, has tensile strength of 390 to 480 MPa, and has specific elongation greater than or equal to 29%.

Owner:ZHANGJIAGANG YANGTZE RIVER COLD ROLLED PLATE CO LTD +2

Preparing process of titanium strip coil used for high-end anode

InactiveCN110814079AUniform temperatureImprove performance uniformityMetal rolling arrangementsEtchingSurface oxidation

The embodiment of the invention provides a preparing process of a titanium strip coil used for a high-end anode. The preparing process comprises two rolling processes, the size and the uniformity of grains of a finished product are controlled conveniently, surface defects of the produced titanium coil are less, compared with first rolling process rolling, namely a hot rolling coil is directly rolled to the thickness of a second-thickness cold rolling coil, the pausing does not occur in the middle, and if continuous annealing and surface treatment are carried out firstly, and then second rolling process rolling is carried out, the surface defects of the finally obtained finished product are more. After the finished product is annealed, then flatten treatment is conducted, and then an oxidelayer on the surface of the titanium coil is uniformly crushed, so that a more consistent condition is provided for the etching of the subsequent titanium coil, the etching effect can be improved, thesurface color of an etched titanium plate is consistent, and finally, the titanium plate coating is better facilitated.

Owner:湖南湘投金天钛金属股份有限公司

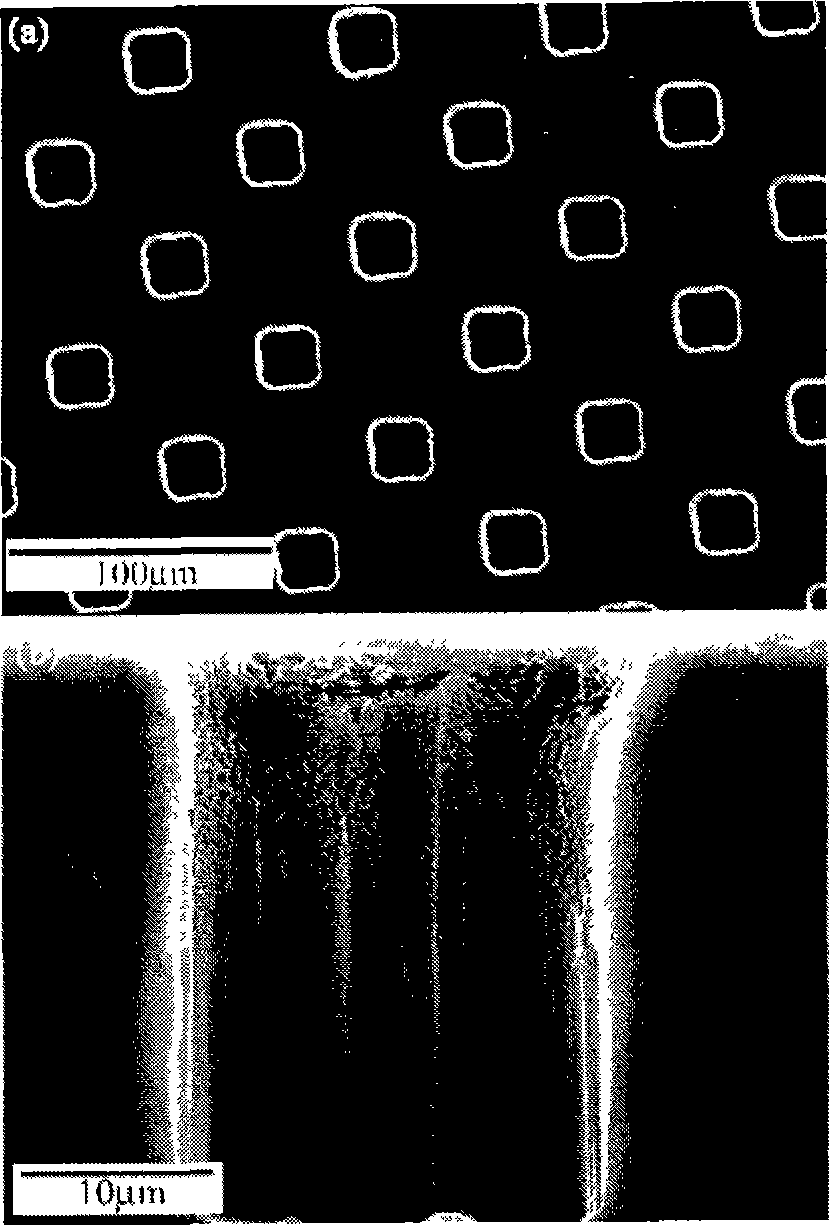

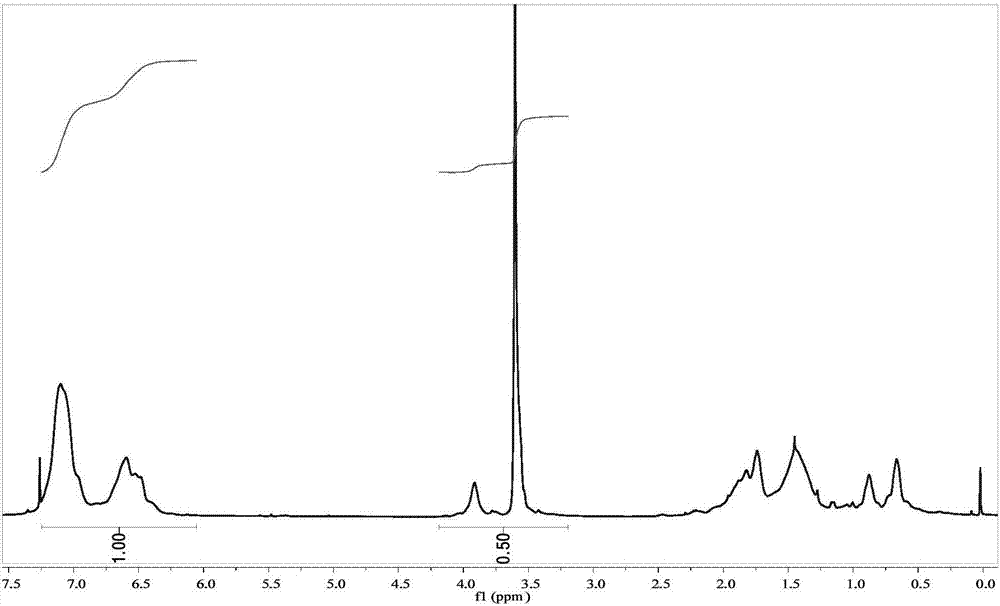

Small-size block polymer material rapidly assembled at low quenching temperature as well as preparation and application of small-size block polymer material

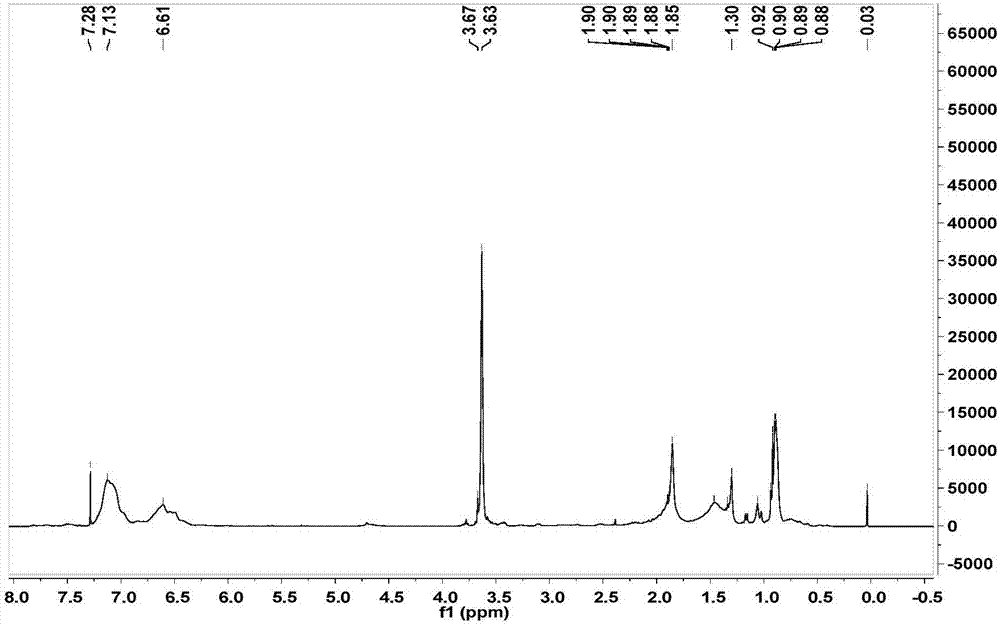

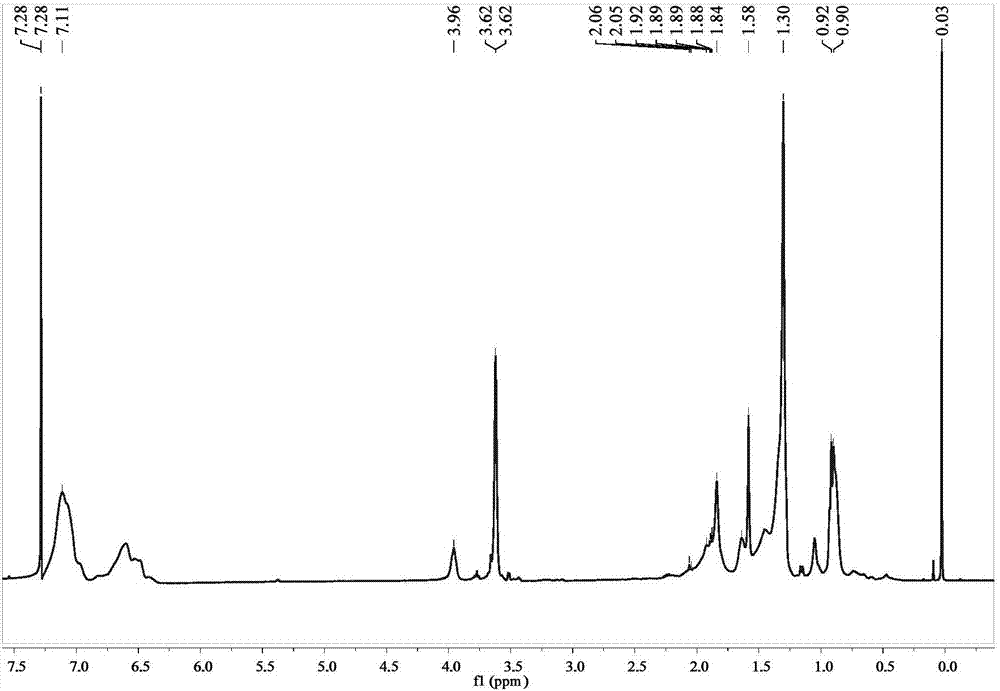

ActiveCN107245133ALow annealing temperatureShort annealing timeMaterial nanotechnologyOrganic chemistryVitrificationPolymer science

The invention relates to a small-size block polymer material assembled at a low quenching temperature as well as preparation and application of the small-size block polymer material. Particularly, the invention discloses a block copolymer which has a glass transition temperature below 120 DEG C. The invention also discloses a preparation method and the application of the block copolymer. The block copolymer can realize excellent phase separation and rapid patterning at a relatively low annealing temperature (e.g., 80 DEG C) and relatively short annealing time (e.g., 30 seconds), and is etched to obtain a photoetch pattern with extremely high resolution (e.g., 5 nm half-pitch), thereby providing a new photoetch means for the further extension of Moore's Law and photoetching semiconductors smaller than 10 nm, even 5 nm (half-pitch).

Owner:FUDAN UNIV

Magnetic recording medium and production method of magnetic recording medium

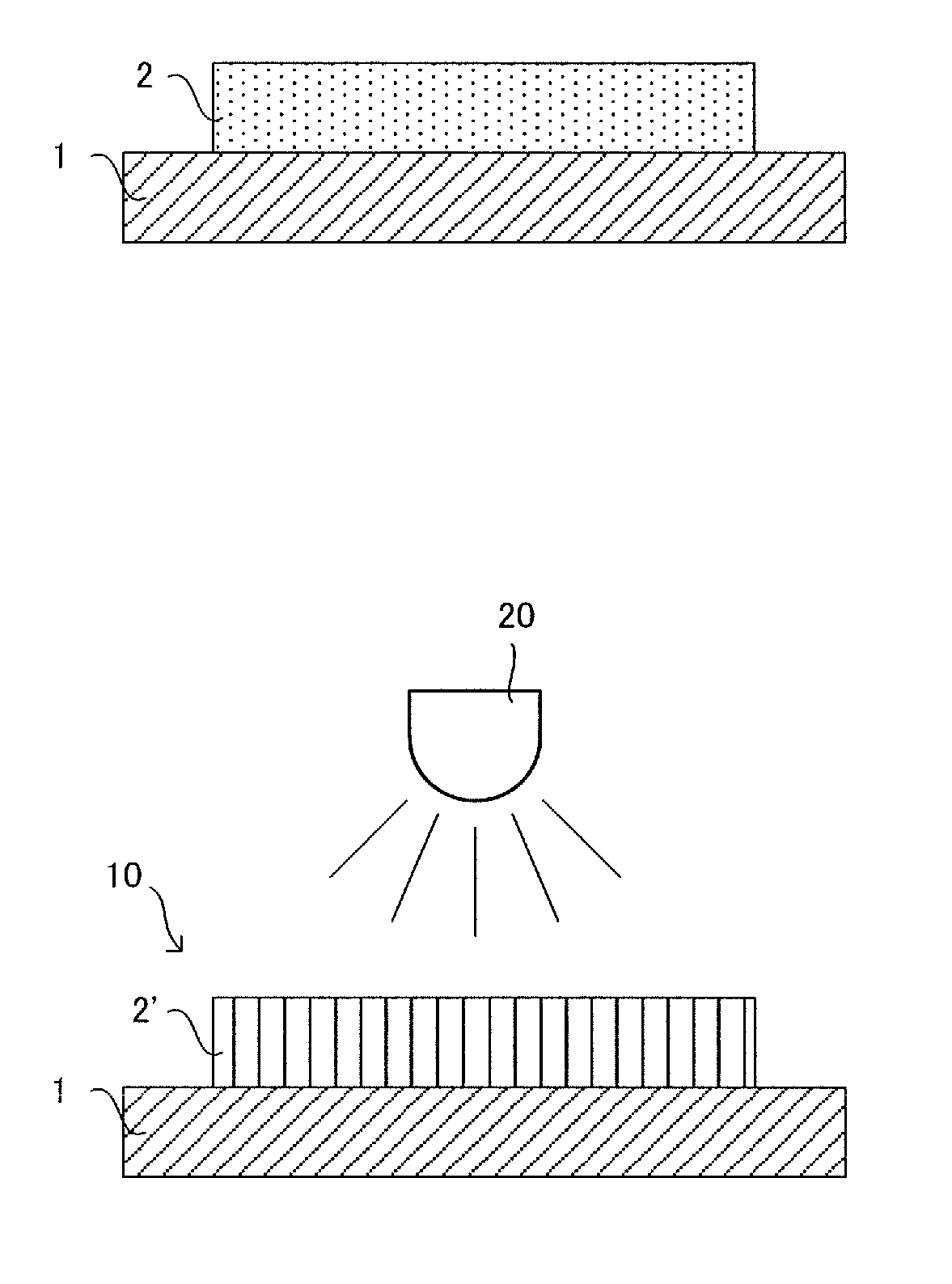

InactiveUS20130034748A1Easy to produceEasy to useMaterials with ironRecord information storageAlloyRecording layer

The present invention provides: a method of producing, at low temperature, a magnetic recording medium comprising an L10FePt thin film which is highly (001)-oriented and highly L10-ordered; and a magnetic recording medium comprising an L10FePt thin film that can be obtained by this method. In the production method of a magnetic recording medium (10), a thin film formation step S1 of forming a thin film 2 containing an FePt alloy and an oxide of metal having a melting point of 100° C. or more and 500° C. or less is carried out; an annealing step S2 of annealing the thin film 2 to a predetermined temperature is carried out; thereby a magnetic recording layer 2′ containing the FePt alloy having a L10-ordered structure and the oxide of metal is formed. The magnetic recording medium can be obtained by this production method.

Owner:AKITA UNIV

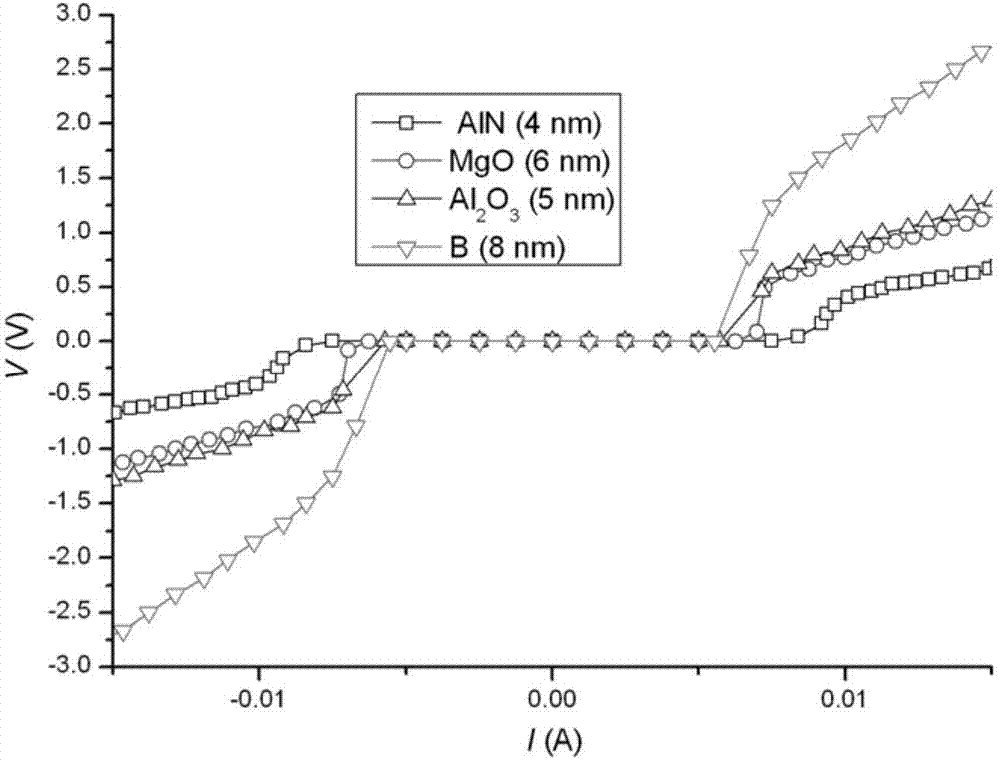

Method for preparing magnesium diboride superconductive Josephson junction through secondary mask method

ActiveCN103904210AReduce component diffusionShort annealing timeSuperconductor device manufacture/treatmentChemical reactionInsulation layer

Disclosed is a method for preparing a magnesium diboride superconductive Josephson junction through a secondary mask method. According to the method, an electron beam is adopted to carry out annealing on an interlayer type (sandwich type) magnesium diboride Josephson junction precursor film. The interlayer type magnesium diboride Josephson junction precursor film is a (Mg / B)-X-(Mg-B) structure precursor film prepared through the secondary mask method, X represents a standard conductor layer N or an insulation layer I, magnesium elementary substance and boron elementary substance in the precursor film are made to generate a chemical reaction within the annealing time of a second magnitude order, finally the SNS type or SIS type magnesium diboride superconductive Josephson junction of a MgB2-X-MgB2 structure is generated, and S represents a superconductive layer.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

La-Mg-Ni hydrogen storage alloy and preparation method thereof

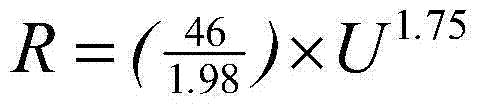

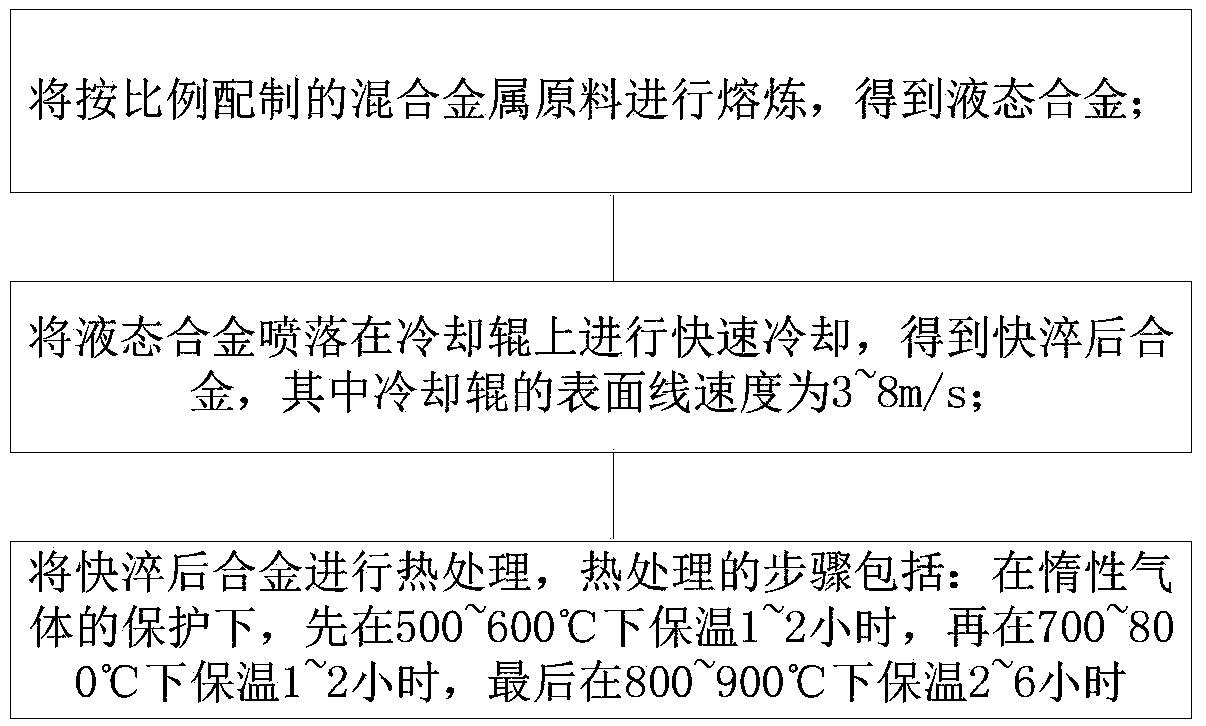

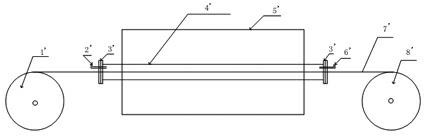

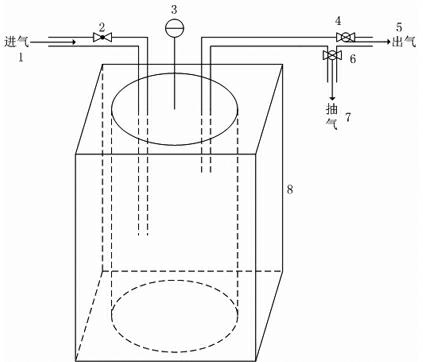

The invention provides a La-Mg-Ni hydrogen storage alloy and a preparation method thereof. The preparation method includes the following steps that a mixed metal raw material prepared in proportion is smelted to obtain a liquid alloy; the liquid alloy is sprayed to a cooling roller to be quickly cooled, so that a rapidly-quenched alloy is obtained, and the surface linear speed of the cooling roller is 3-8 m / s; and the rapidly-quenched alloy is subjected to thermal treatment which includes the steps of preserving heat for 1-2 hours at the temperature of 500-600 DEG C under the protection of inert gas, then preserving heat for 1-2 hours at the temperature of 700-800 DEG C, and finally preserving heat for 2-6 hours at the temperature of 800-900 DEG C. By means of the preparation method, the La-Mg-Ni hydrogen storage alloy with the single A2B7 phase can be obtained; meanwhile, grains of the rapidly-quenched alloy are fine, transformation kinetics is rapid, and therefore the La-Mg-Ni hydrogen storage alloy with the single A2B7 phase can be obtained through short annealing time. In addition, the method is easy to master and suitable for large-scale production.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Method for annealing simplified, efficient, low-cost and high-temperature superconductive long band

ActiveCN102682919AIncrease productivityShorten the annealing timeCable/conductor manufactureTemperature controlWinding machine

The invention provides a method for annealing a simplified, efficient, low-cost and high-temperature superconductive long band. The method comprises the following steps of: placing the superconductive long band to be annealed into a manual band winding machine, manually winding the band on an annealing plate, placing the annealing plate into a vacuum box type annealing oven, and annealing under an oxygen atmosphere according to annealing processes. The method has characteristics of low cost, short annealing time, high production efficiency, high temperature controlling precision, and capability of uniformly annealing each part of the superconductive long band. Furthermore, compared with the traditional non-vacuum annealing oven, the purity of the oxygen atmosphere in the annealing oven isgreatly increased through a vacuumizing method, so that adverse effects of N2, NO, NO2, CO, CO2 and other non-oxygen impurity gas in the residual air in an annealing furnace on the performance of thesuperconductive long band under the high temperature in the annealing process are avoided. By the method, the rare earth oxide second generation high-temperature superconductive band subjected to annealing treatment under the oxygen atmosphere has excellent superconductive performance.

Owner:SHANGHAI SUPERCONDUCTOR TECH CO LTD

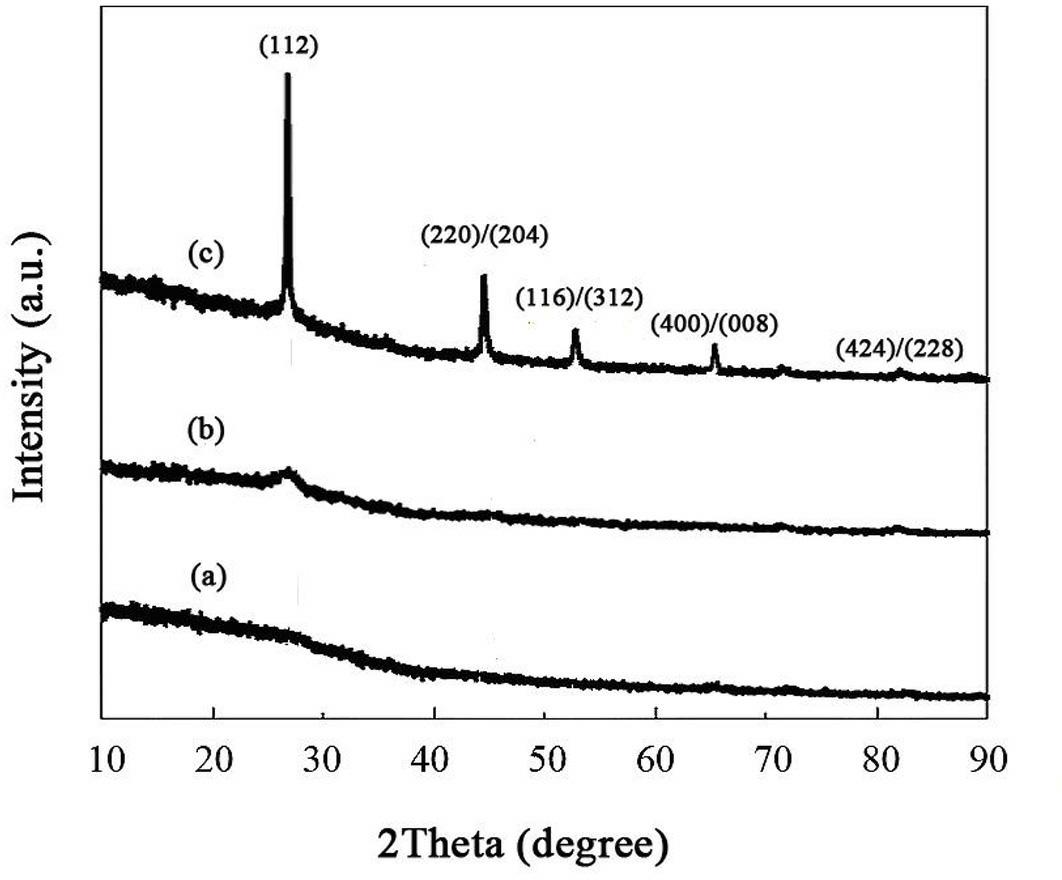

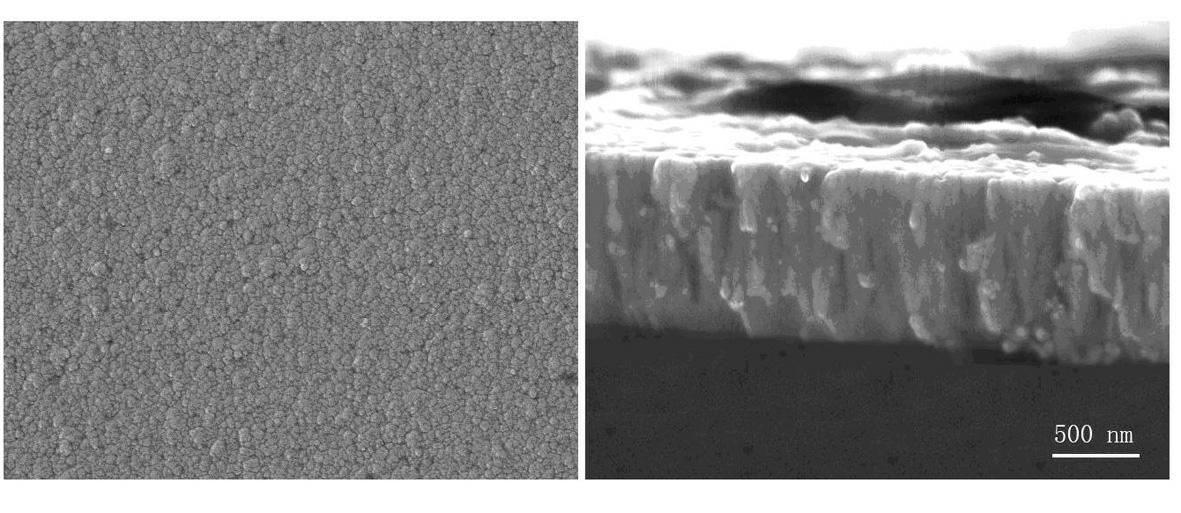

Preparation method of compound thin film for solar battery

ActiveCN102214737ARapid heat treatmentRapid coolingFinal product manufactureSemiconductor devicesLow temperature depositionIndium

The invention discloses a preparation method of a compound thin film for a solar battery. The method comprises the following steps of: firstly, sputtering a copper-indium-gallium-selenium (CIGS) quaternary compound target by using a direct-current pulse power supply, and depositing an amorphous or nano crystalline thin film material with uniform thickness, uniform components and ideal element proportions on a glass substrate at a low temperature; secondly, quickly and thermally treating the thin film in a heat field formed by a resistance heat source and a halogen tungsten lamp tube heat source to restrain the loss of an element Se so as to obtain a CIGS thin film with high crystallinity, large crystallite dimension, high compactness and good chalcopyrite structural phases, and feeding a proper amount of H2Se+Ar or H2S+Ar mixed gas into the heat field for compensation; thirdly, quickly transferring the thin film to an H2S+Ar atmosphere and suddenly cooling the thin film; and finally, performing low-temperature annealing on the CIGS thin film under the atmosphere of H2 and Ar mixed gas so as to eliminate the stress and an inner defect of the thin film and passivate a current carrier compound center.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

Cu-Cr-Ag alloy wire rod and preparation and processing method thereof

The invention relates to a Cu-Cr-Ag alloy wire rod and a preparation and processing method thereof, and belongs to the field of non-ferrous metal material preparation and processing. The alloy wire comprises the following components of, by mass, 0.31-0.45% of Cr, 0.22-0.44% of Ag and the balance Cu, wherein the content of Cr+Ag is 0.53-0.75%. The alloy is subjected to up-drawing continuous casting, large deformation cold processing, double-stage solid solution heat treatment, large deformation cold processing, double-stage aging heat treatment, large cold deformation cold processing and on-line continuous annealing processes to be prepared the ultrafine alloy wire rod. The obtained wire rod has excellent comprehensive performance, the problem of non-vacuum continuous casting of a copper-chromium-zirconium alloy is solved, the wire rod can be used for replacing the copper-chromium-zirconium alloy and serves as a high-performance electric wire and cable conductor in the environment withthe long-term working temperature lower than 200 DEG C, and a good application prospect is achieved.

Owner:GRIMAT ENG INST CO LTD

Quartz glass annealing furnace

The invention discloses a quartz glass annealing furnace. The annealing furnace comprises a furnace body, wherein a furnace chamber is arranged inside the furnace body; a furnace door used for sealing the furnace chamber is arranged on the furnace body; a furnace chamber inner layer, an insulating cotton layer, an insulating brick layer and a pearl stone layer are arranged in sequence from the internal to the external on both sides of the furnace chamber inside the furnace body; a furnace chamber bottom layer, an insulating brick layer and a pearl stone layer are arranged in sequence on the undersurface of the furnace chamber inside the furnace body; a furnace chamber top layer, an insulating cotton layer, an insulating brick layer and a pearl stone layer are arranged in sequence on the upper surface of the furnace chamber inside the furnace body; a plurality of grooves are formed in the opposite surfaces of the inner layer of the furnace chamber; a resistance wire is arranged in each groove respectively; two ends of the resistance wires stretch out from both sides of the furnace body to form terminals. The annealing furnace has the benefits of being convenient to use, high in heating speed, short in annealing time, high in processing efficiency, wide in application range and suitable for the annealing treatment on various quartz glass pieces, such as various quartz glass rods and quartz glass plates, and can reach the temperature required by annealing within 3 hours.

Owner:SHANGHAI USTRON QUARTZ GLASS CO LTD

Magnetic recording medium, and method for producing the same

InactiveUS20050217760A1Shorten the annealing timeShort annealing timeChemical vapor deposition applicationLiquid applicationFerromagnetic orderAlloy

A magnetic recording medium including: a support; and a magnetic layer provided on the support, the magnetic layer containing a magnetic particle of a CuAu type or Cu3Au type ferromagnetic ordered alloy phase, wherein a content of boron in the magnetic particle is 0 to 0.9 at %, and a content of fluorine in the magnetic particle is 0.09 to 0.3 at %. Also provided is a method for producing a magnetic recording medium including: forming an alloy particle capable of forming a CuAu type or Cu3Au type ferromagnetic ordered alloy phase by a reduction method in which a reducing agent containing a boron atom is used; forming a layer including the alloy particle on a support; heat-treating the alloy particle at a temperature below a transformation temperature of the alloy particle; and annealing the alloy particle at a temperature which is not lower than the transformation temperature of the alloy particle.

Owner:FUJIFILM CORP +1

Isothermal spheroidizing annealing furnace for automobile bearing ring machining

ActiveCN108300847AImprove the annealing effectQuality improvementFurnace typesHeat treatment furnacesMachiningCoupling

The invention discloses an isothermal spheroidizing annealing furnace for automobile bearing ring machining. The isothermal spheroidizing annealing furnace for automobile bearing ring machining comprises an annealing furnace body, wherein a fixing plate is fixedly connected between the two sides of the inner wall of the annealing furnace body, and slide blocks are slidably connected to the two sides of the bottom of the fixing plate; a spray head is fixedly connected to the bottom of each slide block; a first motor is fixedly connected to the top of the annealing furnace body through a supportframe; a thread rod is fixedly connected to the output shaft of the first motor through a shaft coupling; the bottom end of the thread rod penetrates through the annealing furnace body and extends into the annealing furnace body; and one end extending into the annealing furnace body, of the thread rod, is rotationally connected with the top of the fixing plate through a bearing. The invention relates to the technical field of automobile bearing ring machining equipment. The isothermal spheroidizing annealing furnace for automobile bearing ring machining is capable of greatly annealing a bearing ring, and short in annealing time, thereby greatly increasing the annealing efficiency and improving the quality of the bearing ring.

Owner:襄阳润欣圆锻造有限公司

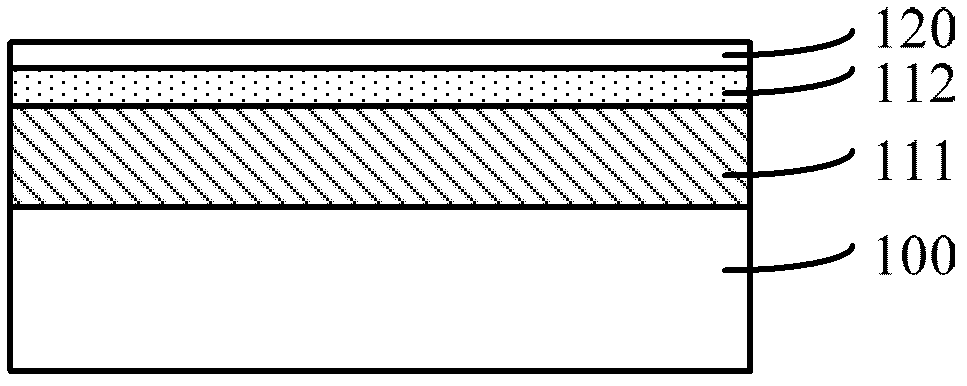

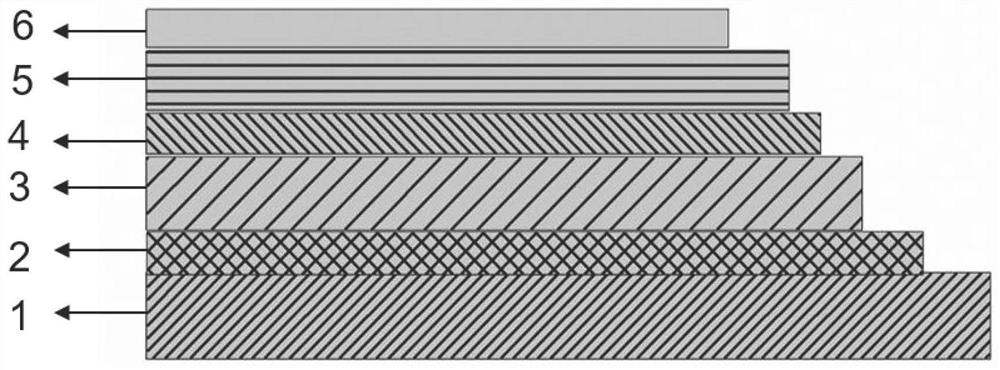

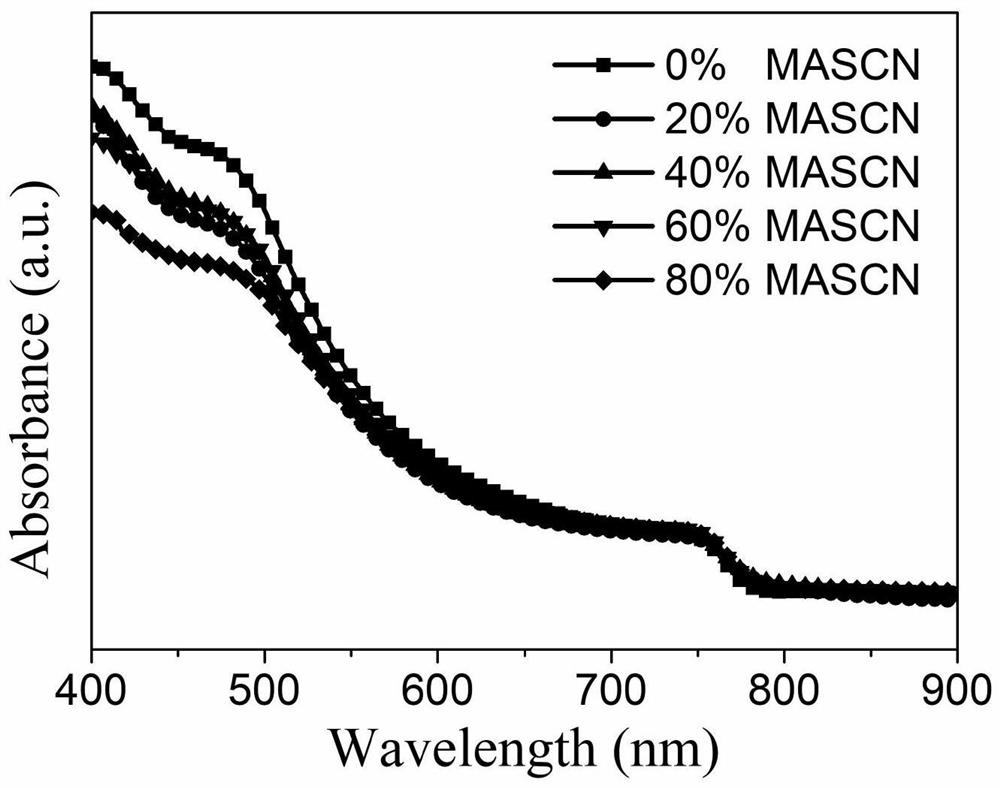

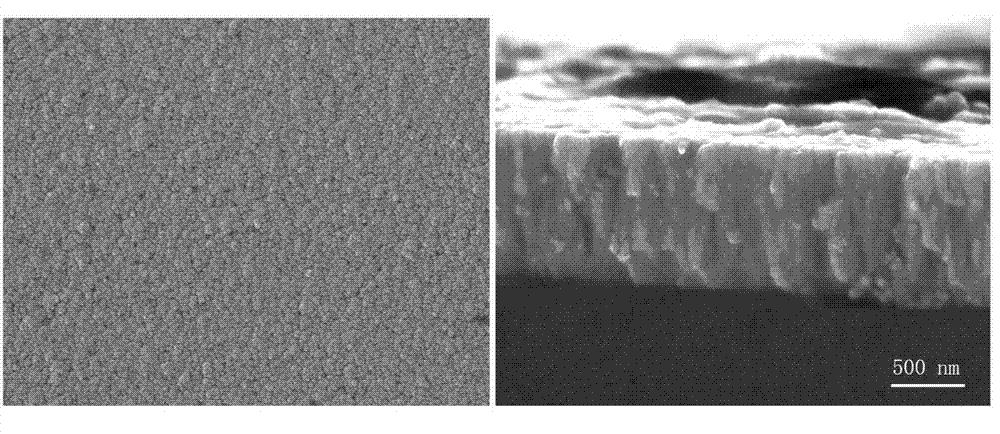

Perovskite solar cell capable of being rapidly annealed in air and preparation method of perovskite solar cell

PendingCN113903861AReduce defect densityLarge grain sizeSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsThin membrane

The invention discloses a perovskite solar cell capable of being rapidly annealed in air and a preparation method of the perovskite solar cell. The structure of the perovskite solar cell sequentially comprises transparent conductive glass, an electron transport layer, a perovskite light absorption layer, a passivation layer, a hole transport layer and a metal electrode layer from bottom to top. The preparation process of the perovskite light absorption layer in the air does not need to control the environment humidity, and the cost of large-scale industrialization of the perovskite solar cell is greatly reduced. Particularly, when the doping proportion of MASCN serving as a doping agent in the perovskite light absorption layer reaches the optimal, the crystallinity of the perovskite thin film is remarkably enhanced, the perovskite thin film has the characteristics of large grain size and single orientation of the (110) crystal face direction, and the efficient and stable perovskite solar cell can be prepared only by extremely short annealing time.

Owner:WUHAN UNIV

Preparation method of compound thin film for solar battery

ActiveCN102214737BRapid heat treatmentRapid coolingFinal product manufactureSemiconductor devicesIndiumStructural phase

The invention discloses a preparation method of a compound thin film for a solar battery. The method comprises the following steps of: firstly, sputtering a copper-indium-gallium-selenium (CIGS) quaternary compound target by using a direct-current pulse power supply, and depositing an amorphous or nano crystalline thin film material with uniform thickness, uniform components and ideal element proportions on a glass substrate at a low temperature; secondly, quickly and thermally treating the thin film in a heat field formed by a resistance heat source and a halogen tungsten lamp tube heat source to restrain the loss of an element Se so as to obtain a CIGS thin film with high crystallinity, large crystallite dimension, high compactness and good chalcopyrite structural phases, and feeding a proper amount of H2Se+Ar or H2S+Ar mixed gas into the heat field for compensation; thirdly, quickly transferring the thin film to an H2S+Ar atmosphere and suddenly cooling the thin film; and finally, performing low-temperature annealing on the CIGS thin film under the atmosphere of H2 and Ar mixed gas so as to eliminate the stress and an inner defect of the thin film and passivate a current carrier compound center.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

Short-flow rolling preparation process of high-strength and high-plasticity AlN/AZ91D magnesium base composite material plate

ActiveCN107747071AQuality improvementHigh quality and high performanceMagnesium matrix compositeIngot

The invention relates to a short-flow rolling preparation process of a high-strength and high-plasticity AlN / AZ91D magnesium base composite material plate; solid solution and water quenching processesof a cast ingot before rolling are formulated; subsequent rolling and annealing processes are optimized; and a set of cold rolling process for preparing a high-strength and high-plasticity magnesiumbase composite material rolled plate is provided. The cold rolling process is high in reduction in pass, few in annealing times among passes and short in annealing time, and can realize industrial short-flow preparation. In particular, through the patent technology, namely the optimal ratio of solid solution process parameters to water quenching process parameters to rolling process parameters toannealing process parameters, the edge cracking problem in the cold rolling process is solved when the high-strength and high-plasticity cold-rolled plate is obtained, and finally, the high-quality and high-performance magnesium alloy composite material cold-rolled plate can be obtained with high efficiency.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Microwave annealing method for improving electrochemistry property of hydrogen storage alloy M1(NiCoMnAlCu)5.05

The invention provides a microwave annealing method for improving electrochemical properties of a hydrogen storage alloy Ml(NiCoMnAlCu)5.05, which belongs to the technical field of hydrogen storage materials. The technical process of the method is as follows: 300-400 meshes of hydrogen storage alloy Ml(NiCoMnAlCu)5.05 powder is pressed into an alloy sheet by a sheeter at the pressure of 10-20MPa, then the alloy sheet is put into a microwave oven and is surrounded by a plurality of pieces of auxiliary heating materials, is annealed at the temperature of 300-500 DEG C; and then is cooled to the room temperature with the oven under the protection of argon gas or under vacuum condition for 6-14 minutes. The microwave annealing method is characterized by low annealing temperature, short time, low energy consumption and greatly decreasing the product cost. The hydrogen storage alloy treated by the method has smaller particle size, and the comprehensive electrochemical properties of the alloy are improved, more particularly, the activation times are greatly reduced, and the charge and discharge cycle life is significantly prolonged.

Owner:SHANGHAI UNIV

Image sensor and method of forming same

InactiveCN110400815AImprove performanceIncrease full well capacitanceSolid-state devicesDiodeSemiconductorHeat treated

The present invention provides an image sensor and a method of forming the same. The method comprises the steps of: providing a semiconductor substrate; forming an initial photo-doped region in the semiconductor substrate; forming mutually separated initial isolation regions in the initial photo-doped region, the initial isolation regions being doped with first ions and second ions, the conductivity type of the first ions being opposite to the conductivity type of the initial photo-doped region, the conductivity type of the second ions being the same as the conductivity type of the initial photo-doped region, and the diffusion rate of the second ions being larger than that of the first ions; performing heat treatment to diffuse the first ions and the second ions in the initial isolation region, and forming a main photo-doped region, mutually separated isolation regions and mutually separated additional photo-doped regions in the initial photo-doped region, wherein the conductivity typeof the additional photo-doped regions is the same as that of the main photo-doped region, and the conductivity type of the isolation regions is opposite to that of the main photo-doped region. The image sensor formed by adopting the method is good in performance.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com