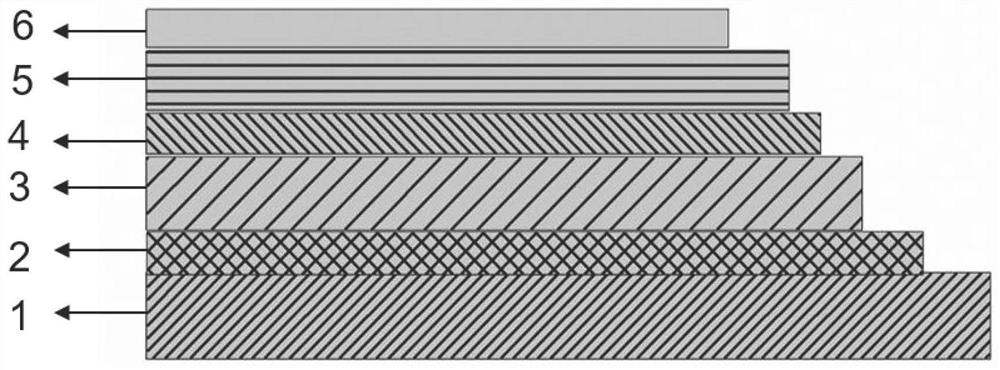

Perovskite solar cell capable of being rapidly annealed in air and preparation method of perovskite solar cell

A solar cell and rapid annealing technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of unfavorable perovskite film formation and easy decomposition, achieve enhanced crystallinity, large grain size, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In this embodiment, a method for preparing a perovskite solar cell rapidly annealed in air comprises the following steps:

[0042] S1: Substrate cleaning: Cut a large piece of conductive glass FTO into a size of 1.5×2cm with a glass knife, wipe the surface of the conductive substrate with acetone, and then place it in deionized water, acetone, isopropanol and ethanol in sequence. Ultrasonic cleaning for 20 minutes, drying with a nitrogen gun, and then UV and ozone treatment for 15 minutes.

[0043] S2: Electron transport layer preparation: Commercial 15% SnO 2 The colloidal aqueous solution and deionized water were prepared at a mass ratio of 1:5 to make 2.5% SnO 2 Colloidal solution, stirred for half an hour and set aside. Pipette 100 μl of SnO 2 The precursor solution was evenly dropped on the treated FTO transparent conductive substrate. The spin coating conditions were low speed 500rpm for 10s, high speed 4000rpm for 30s, and annealed on a heating plate at 150°C ...

Embodiment 2

[0052] In this embodiment, a method for preparing a perovskite solar cell rapidly annealed in air, the difference between this embodiment and embodiment 1 is:

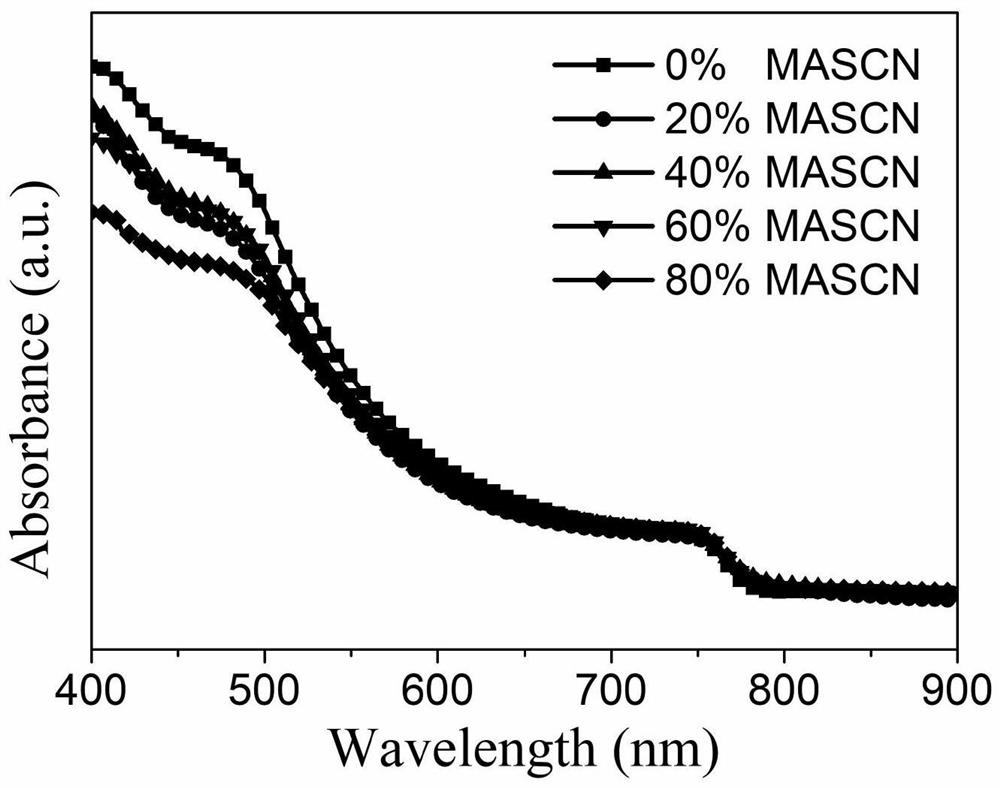

[0053] Preparation of perovskite light-absorbing layer: pure PbI 2 Dissolve MAI in a mixed solvent of dimethylformamide (DMF) and dimethyl sulfoxide (DMSO) at a molar ratio of 1:1 (V 1 :V 2 =4:1), in which MASCN was added at a molar ratio of 60%, and then stirred overnight at a temperature of 60°C to obtain five perovskite precursor solutions with a concentration of 1.3M and different doping ratios. After the stirring was completed, The solution was filtered. Use a pipette to draw 50 μl of the perovskite precursor solution and evenly spread it on the UV-ozone-treated SnO 2 On the electron transport layer substrate, spin-coat at 4000rpm for 30s, and drop EA evenly and rapidly at the 15th s of spin-coating. The perovskite mesophase film was annealed for 0min, 3min, 5min, 7min, 10min and 30min respectively to obtain t...

Embodiment 3

[0057] In this embodiment, a method for preparing a perovskite solar cell rapidly annealed in air, the difference between this embodiment and embodiment 1 is:

[0058] Preparation of perovskite light-absorbing layer: pure PbI 2 Dissolve MAI in a mixed solvent of dimethylformamide (DMF) and dimethyl sulfoxide (DMSO) at a molar ratio of 1:1 (V 1 :V 2 =9:1), wherein MASCN was added in a molar ratio of 60%, and then stirred overnight at 60°C to obtain five perovskite precursor solutions with a concentration of 1.25M in different doping ratios. After the stirring was completed, the solution was filter. Use a pipette to draw 50 μl of the perovskite precursor solution and evenly spread it on the UV-ozone-treated SnO 2 Spin-coat on the electron transport layer at a speed of 5000rpm for 30s, and drop EA evenly and rapidly at the 17th s from the start of spin-coating. The perovskite mesophase film was annealed for 0min, 3min, 5min, 7min, 10min and 30min respectively to obtain the pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com