Preparation method of compound thin film for solar battery

A technology for preparing solar cells and thin films, which is applied in the manufacture of circuits, electrical components, and final products. It can solve the problems of unsuitable continuity, high-capacity and low-cost industrial production, photovoltaic cells that are difficult to form a competitive advantage, production technology and cost. and other problems, to achieve the effect of short annealing time, large grain size and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

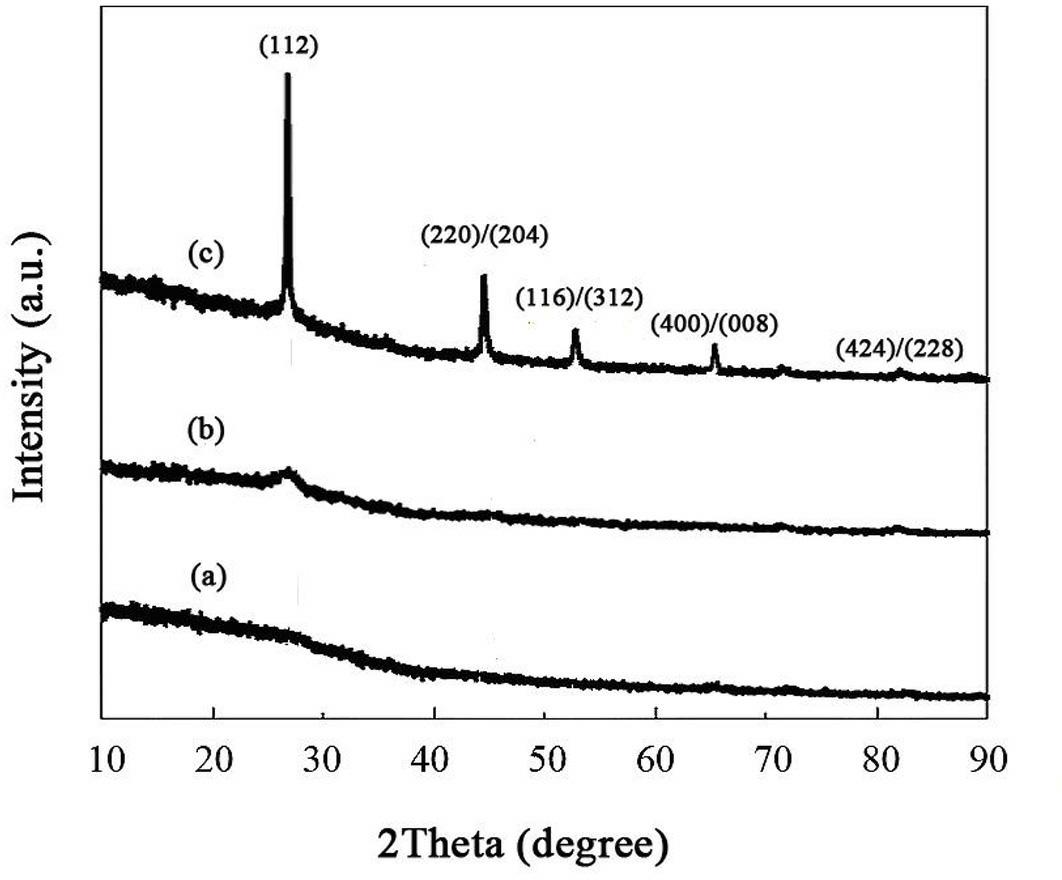

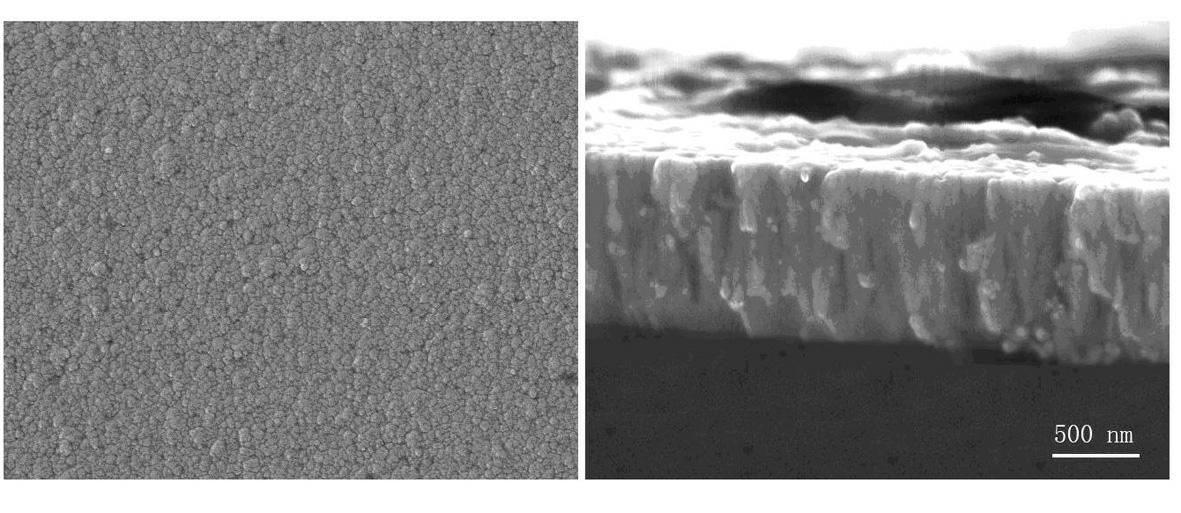

[0022] Fabrication of CuIn with a brass structure phase with a thickness of 1000 nm at a sputtering power of 3 kW 1-x Ga x Se 2-y S y film. Such as figure 1 Shown, the present invention is preparing CuIn 1-x Ga x Se 2-y S y For the thin film, a continuous multi-chamber equipment and automatic control system are used to realize the deposition preparation, rapid heat treatment, cooling and passivation annealing of the thin film in a closed state. The specific steps are as follows:

[0023] 1. Put the cleaned and dried glass substrate or the Mo-coated glass substrate on the substrate holder, and pass the equilibrium gas Ar into the transition chamber 9 to an atmospheric pressure of 1.0×10 5 Pa, open the gate valve 1, the substrate holder enters the transition chamber 9 under the action of the transmission system, close the gate valve 1, pump the transition chamber 9 to 1.0×10 -5 After Pa, the balance gas Ar is introduced to 0.8Pa,

[0024] 2. Open the gate valve 2, wai...

Embodiment 2

[0032] Preparation of CuIn with chalcopyrite structure phase with a thickness of 1500 nm at a sputtering power of 6 kW 1-x Ga x Se 2-y S y film.

[0033] Using the same steps as in Example 1, the advancing speed of the substrate in the deposition chamber was 15 mm / min, and a little H was introduced during sputtering. 2 S. Different sputtering power on CuIn 1-x Ga x Se 2-y S y The microstructure of the film has a significant impact, and the surface morphology and crystallographic properties also change accordingly, such as Figure 4 shown.

Embodiment 3

[0035] Preparation of CuIn with chalcopyrite structure phase with a thickness of 1000 nm at a sputtering power of 6 kW 1-x Ga x Se 2-y S y film.

[0036] Using the same steps as in Example 1, the advancing speed of the substrate in the deposition chamber was 20 mm / min, and a little H was introduced during sputtering. 2 S. CuIn 1-x Ga x Se 2-y S y The thickness of the film has a significant effect, as Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com