Nickel silicide layer forming method and semiconductor device forming method

A nickel silicide and semiconductor technology, which is applied in semiconductor/solid-state device manufacturing, coating, electrical components, etc., can solve the problem that the resistance of the nickel silicide layer cannot be effectively reduced, and achieve the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

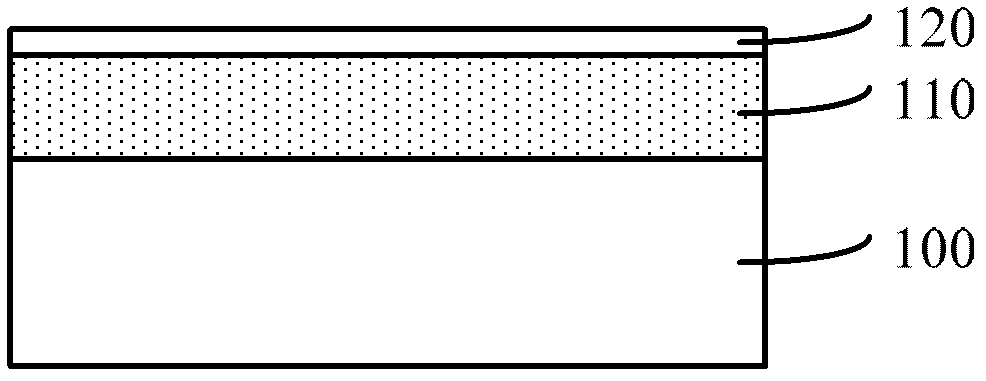

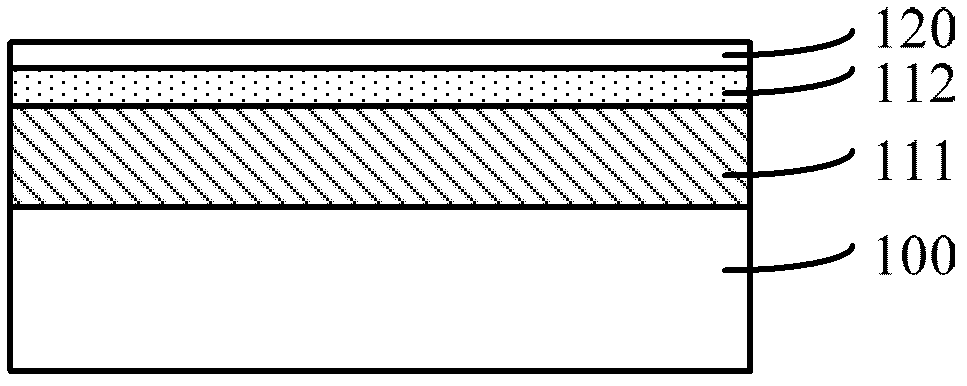

[0051]Since the prior art cannot effectively reduce the resistance of the nickel silicide layer, the RC delay of the circuit becomes larger. After research, the inventor proposes a method for forming a nickel silicide layer that can effectively reduce the resistance of the nickel silicide layer, including: providing A substrate, forming a dinickel silicide layer on the surface of the substrate; forming a silicon nitride layer containing hydrogen ions on the surface of the dinickel silicide layer; performing a second annealing treatment on the dinickel silicide layer to form a nickel silicide layer . Since the hydrogen ions in the silicon nitride layer will diffuse into the nickel silicide layer during the second annealing treatment, the sheet resistance of the nickel silicide layer containing hydrogen ions is thinner than that of the nickel silicide layer not containing hydrogen ions. The layer resistance is small, and the contact resistance between the nickel silicide layer a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com