Textile with radiation refrigeration function and preparation method thereof

A radiative refrigeration and textile technology, applied in textiles and papermaking, fiber type, fiber processing, etc., can solve the problems of restricting the development and application of radiative refrigeration materials, affecting the performance of radiative refrigeration, reducing the reflectivity of sunlight, etc., and achieving a simple cooling effect. Control, excellent refrigeration performance, cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

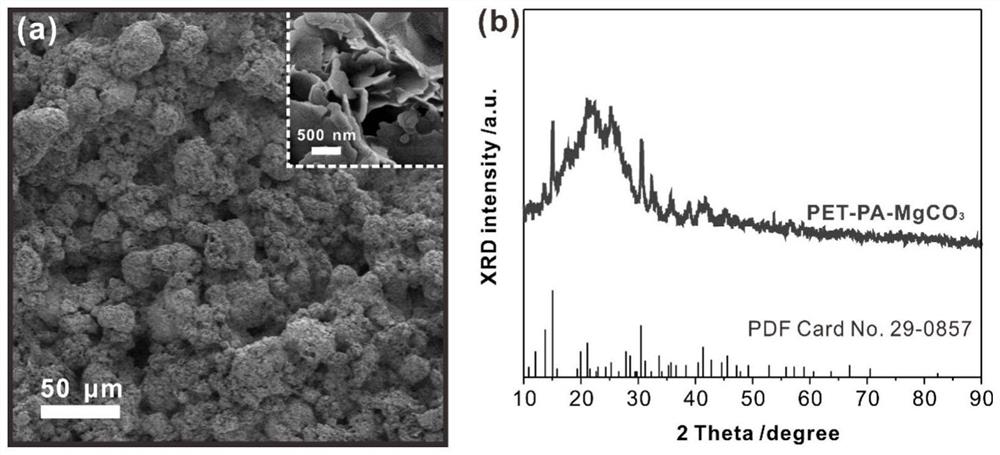

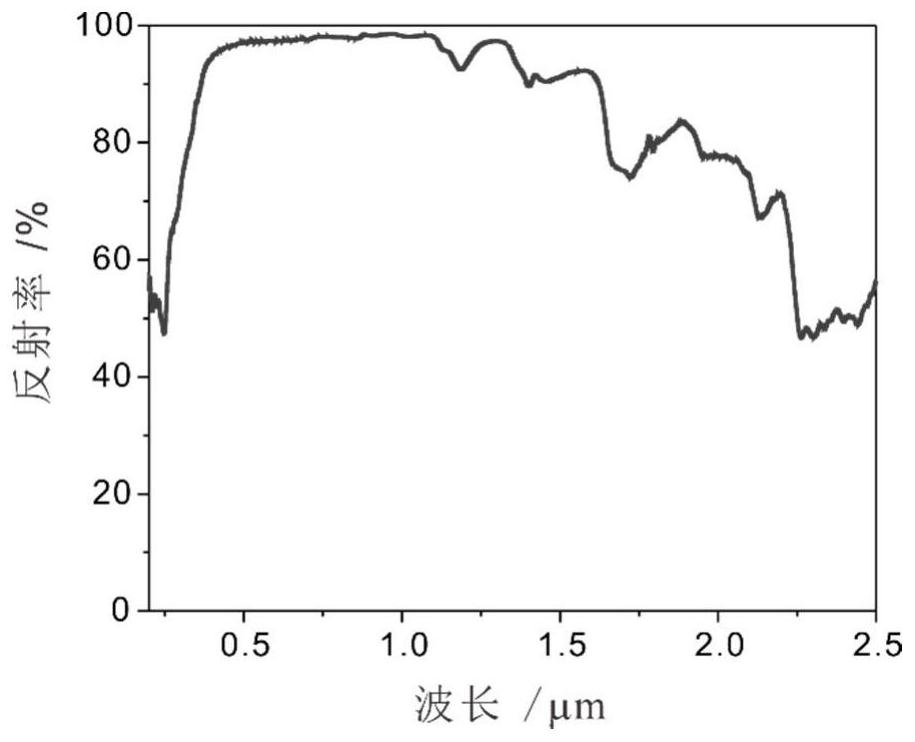

[0053] Formulated with MgCO 3 and functional material slurries for polyacrylate (PA) coating adhesives, where MgCO 3 The mass ratio to PA is 1:1, the magnesium carbonate is a nano-sheet structure, purchased from Aladdin Reagent Company, the functional material slurry is coated on the PET fiber, the coating thickness is 0.12mm, and the PET-PA- MgCO 3 Material. Example 1 with PET-PA-MgCO 3 As an example to illustrate the radiation refrigeration performance of the present invention, PET-PA-MgCO 3 The morphological and structural characterization of the figure 1 shown, figure 1 SEM of a shows that under the action of PA coating glue, MgCO 3 Nanosheets successfully adhered to the surface of PET fibers, MgCO 3 The thickness of the nanosheet is about 35nm and the diameter is about 1μm, and its mass ratio in the coating is 46wt%; figure 1 The XRD pattern of b shows the diffraction peaks of magnesium carbonate, proving that MgCO 3 The structure and composition have not been ch...

Embodiment 2

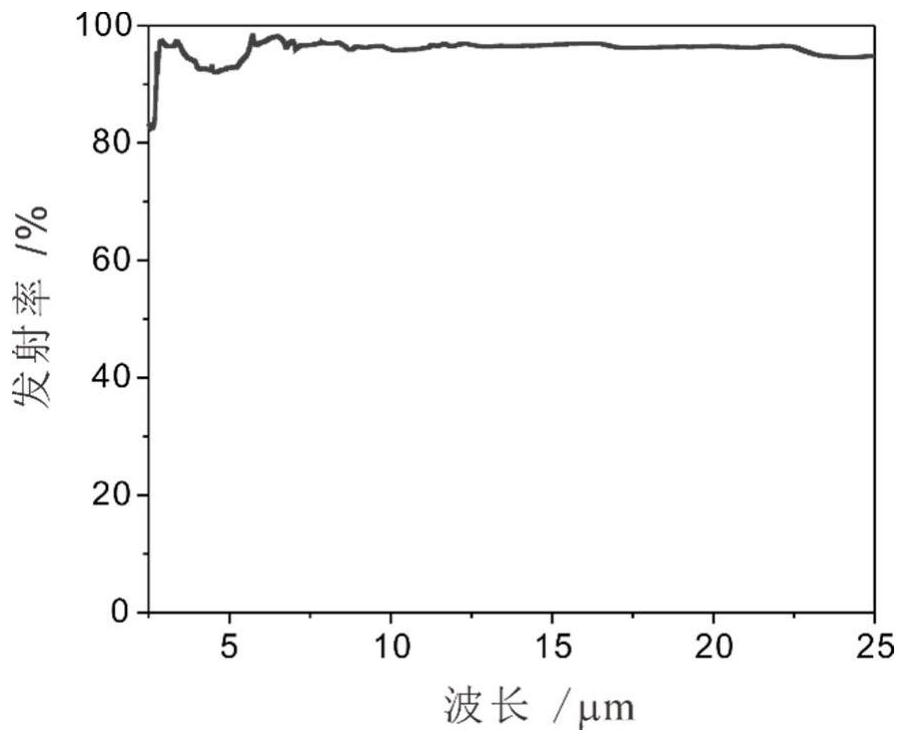

[0060] Building PA-MgCO with FDTD Soultions 3 The three-dimensional cubic structure of the model, in which the size of the model is 10 μm × 10 μm × 2 μm, the size of the sheet-like magnesium carbonate is 1 μm × 1 μm × 35 nm, the content of magnesium carbonate is 50%, the spectral reflectance and infrared spectral emissivity spectra are calculated, and its PET -PA-MgCO 3 Comparison of the actual measured solar spectral reflectance spectrum and infrared spectral emission spectrum. from Figure 4 It can be seen that in the solar spectral region, the simulated result of reflectance is slightly lower than the actual measured value, because there is no PET fiber matrix in the FDTD model, and the simulated reflectance is low. In the "atmospheric window" region of 8-13 μm, the simulation results are basically consistent with the test results, and the infrared emissivity is higher than 95%, indicating that the radiation refrigeration system proposed by the present invention has excel...

Embodiment 3

[0062] Example 1 (PET-PA-MgCO) with a size of 6×6cm was cut 3 ) sample is placed in Figure 5 The radiative cooling performance under sub-ambient temperature conditions was tested in the thermometer shown. The temperature measuring device is mainly composed of a polystyrene foam box, and the outer layers are respectively wrapped with aluminum foil paper and low-density polyethylene film material to minimize the non-radiative heat exchange between the sample and the environment. Thermocouples were placed inside and outside the device to measure the changes of sample temperature and ambient temperature, and the intensity changes of solar light power were recorded with a luminometer. Finally, the temperature-time curve and solar light intensity curve of the sample under sub-ambient temperature test conditions were obtained as follows: Figure 7 (a) and (b). from Figure 7 It can be seen from the test that the ambient temperature range during the test is 25-30 °C, the surface t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com