Razor blades with aluminum magnesium boride (AlMgB14)-based coatings

A razor-blade technology for new coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

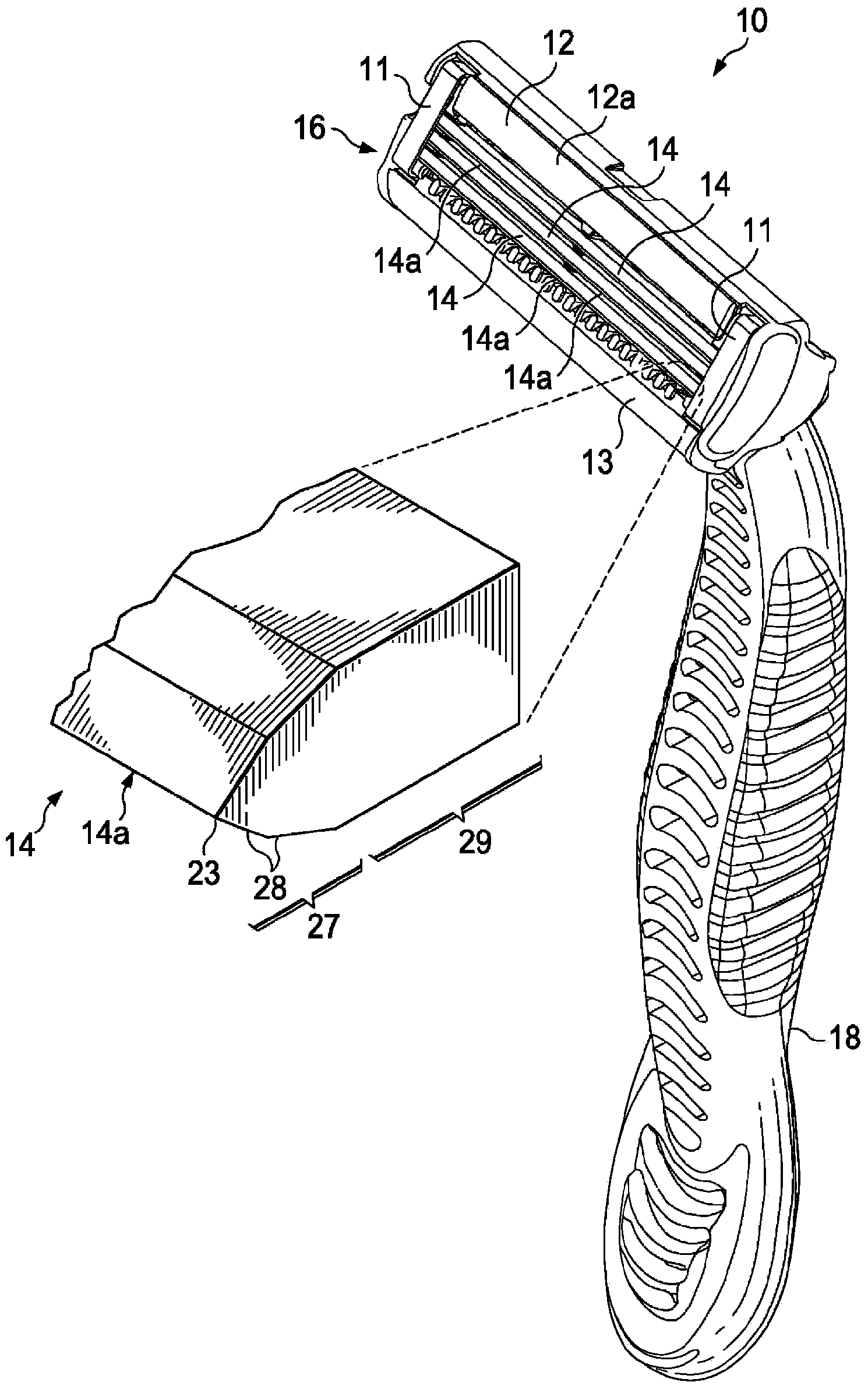

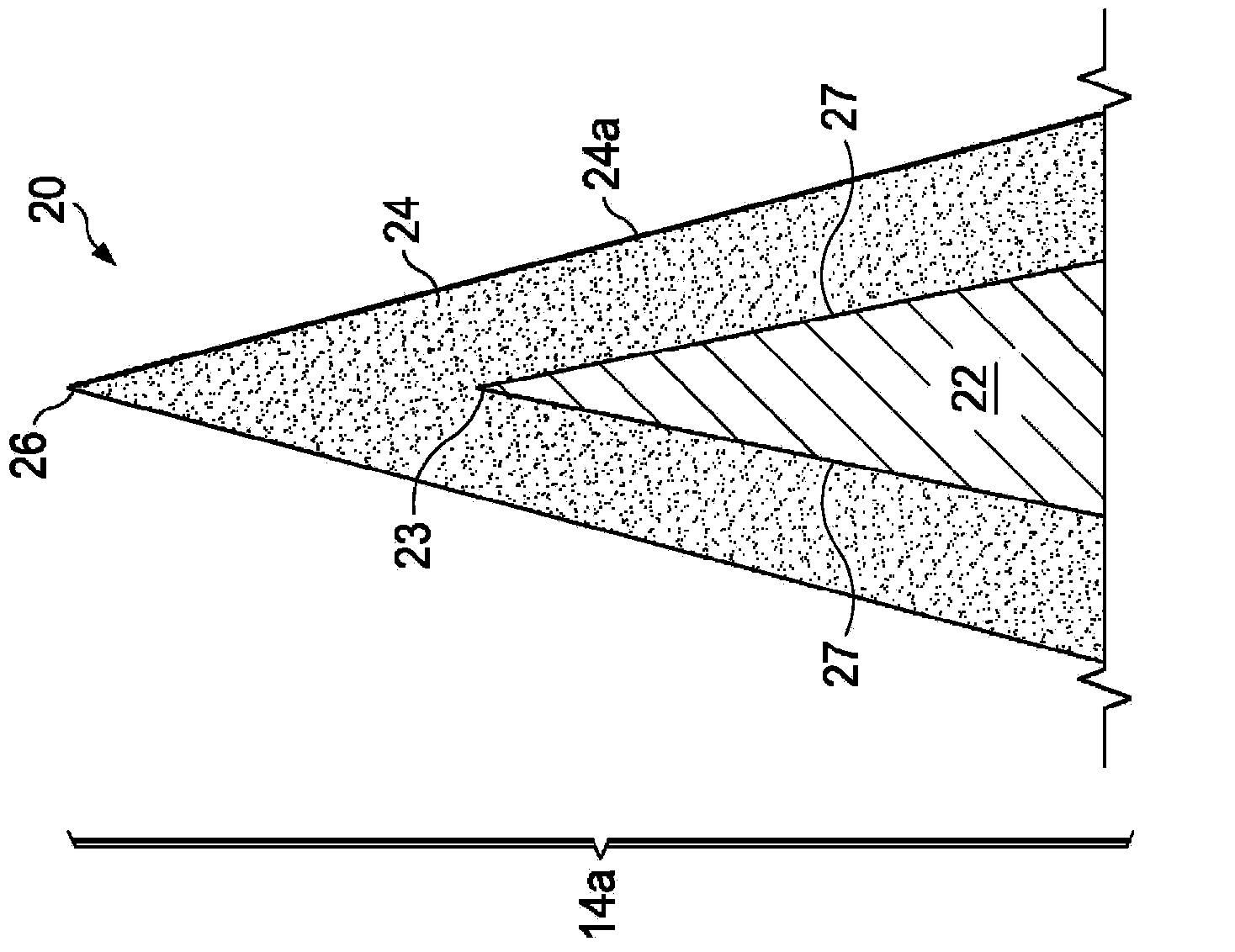

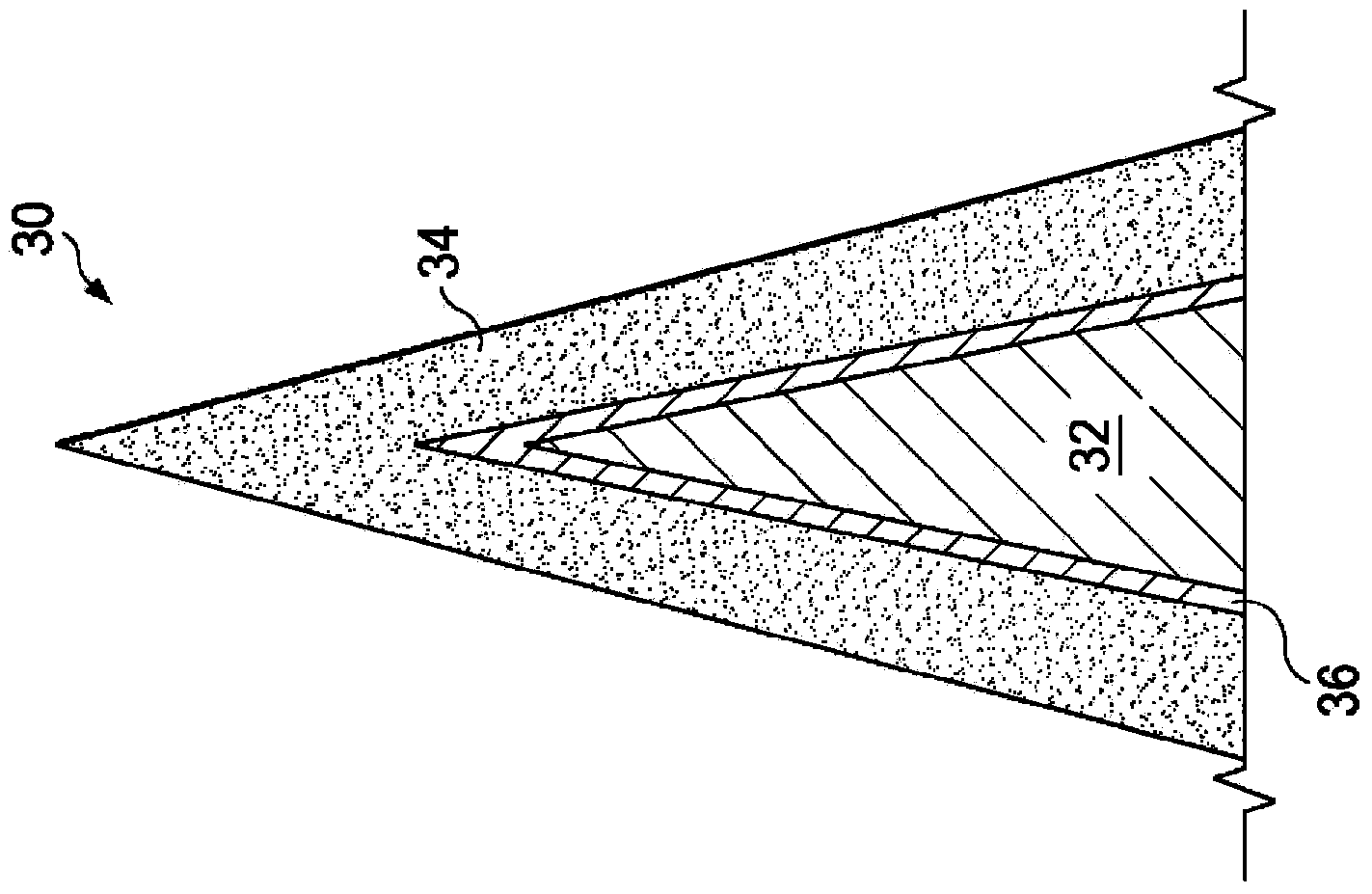

[0022] The present invention relates to a novel application in which aluminum magnesium boride (AlMgB 14 , also known as BAM) based ceramic coatings are applied to the surfaces of razor components, and in particular to the cutting edges of razor blades, as described herein. Applicant is unaware that BAM materials are being used or proposed for use with razor blades. The hard and / or low-friction properties of BAM coatings can provide significant benefits on razor blades, as these coatings can improve blade performance and / or simplify the manufacturing process.

[0023] Baseline BAM materials generally contain elemental aluminum, magnesium and boron. The term "BAM" or "BAM material" or "BAM layer" or "AlMgB 14 " or "BAM-based" or "BAM alloy" or "BAM analog" will generally be used herein interchangeably and may denote the matrix material AlMgB 14 As such, derivatives of materials such as metal borides XYB 14 , where X and Y are metal atoms, or by the matrix AlMgB 14 The mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com