Preparation method and application of lithium-sulfur battery positive electrode material

A technology for lithium-sulfur batteries and cathode materials, which is applied in the field of material science and can solve the problems of low electrical conductivity, low cycle performance of lithium-sulfur batteries, and complicated charging and discharging processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Mix black phosphorus powder and magnesium boride powder in a mass ratio of 2:3, put them in a beaker and mix for 24 hours.

[0038] (2) Put it into a crucible after drying, and use a muffle furnace to perform high-temperature calcination at 620°C with a heating rate of 10°C / min and a holding time of 24h.

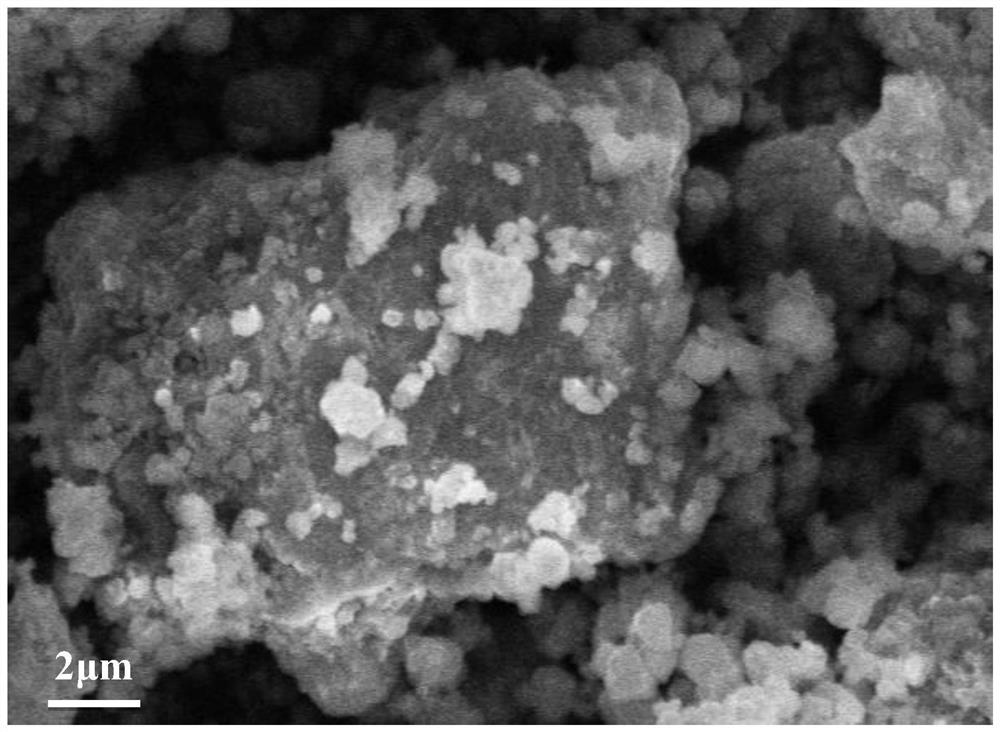

[0039] (3) Take out the calcined product, wash the product centrifugally with deionized water, and then dry it at 60° C. to obtain black phosphorus@magnesia quantum dots.

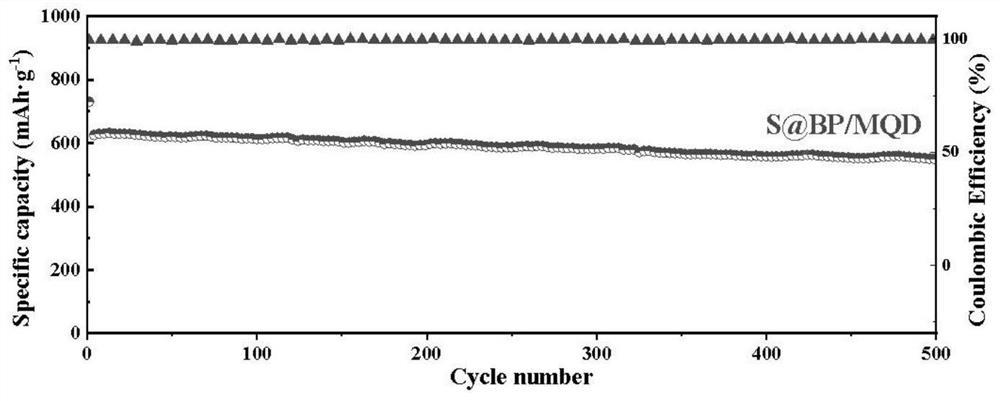

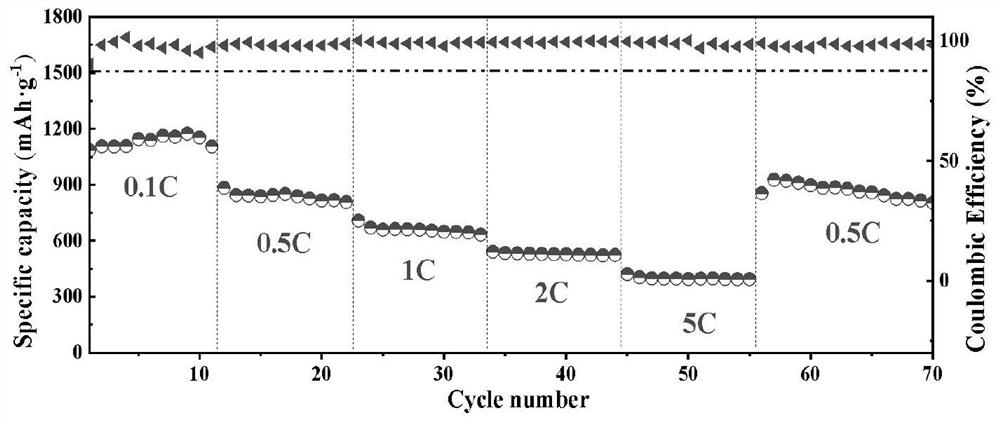

[0040] (4) Mix and grind the black phosphorus@magnesia quantum dots obtained by drying with elemental sulfur powder in a mass ratio of 1:3 for 15 minutes, and mix the obtained product with carbon disulfide in a mass ratio of 1:5, and continue grinding until The carbon disulfide is completely evaporated to obtain a uniformly mixed product, which is then collected in a sealed weighing bottle, and finally placed in an oven at 155°C for 10 hours. Finally, samples of black phosphorus@magnesia quant...

Embodiment 2

[0045] (1) Mix black phosphorus powder and magnesium boride powder at a mass ratio of 1:1, put them into a beaker, add deionized water and stir for 24 hours.

[0046] (2) Put it into a crucible after drying, and use a muffle furnace to perform high-temperature calcination at 570° C., the heating rate is 10° C. / min, and the holding time is set to 24 hours.

[0047] (4) Take out the calcined product, wash the product centrifugally with deionized water, and then dry it at 60° C. to obtain the black phosphorus / magnesia quantum dots.

[0048](5) Mix and grind the black phosphorus@magnesia quantum dots obtained by drying with the elemental sulfur powder in a mass ratio of 1:3 for 15 minutes, and mix the obtained product with carbon disulfide in a mass ratio of 1:5, and continue grinding until The carbon disulfide is completely evaporated to obtain a uniformly mixed product, which is then collected in a sealed weighing bottle, and finally placed in an oven at 150°C for 12 hours. Fin...

Embodiment 3

[0050] (1) Mix black phosphorus powder and magnesium boride powder at a mass ratio of 1:7, put them into a beaker, add deionized water and stir for 24 hours.

[0051] (2) Put it into a crucible after drying, and use a muffle furnace to perform high-temperature calcination at 720°C with a heating rate of 10°C / min and a holding time of 1h.

[0052] (4) Take out the calcined product, wash the product centrifugally with deionized water, and then dry it at 60° C. to obtain black phosphorus@magnesia quantum dots.

[0053] (5) The black phosphorus / magnesia quantum dots obtained by drying are mixed and ground for 15 minutes with the elemental sulfur powder in a ratio of 1:3 by mass, and the product obtained is mixed with carbon disulfide in a ratio of 1:5 by mass, and then continue to grind until The carbon disulfide evaporates completely to obtain a uniformly mixed product, which is then collected in a sealed weighing bottle, and finally placed in an oven at 160°C for 4 hours. Final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com